Abstract

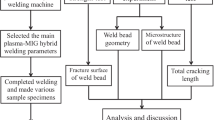

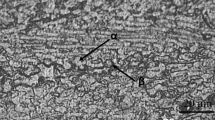

An advanced plasma-MIG hybrid welding was employed for the butt-joint of titanium (Ti) alloy and aluminum (Al) alloy sheets in this study. First, the weld bead appearance and geometry of 3 mm thick Ti/Al butt-joint specimens under different hybrid welding parameters were investigated. Then, the effects of hybrid welding parameters on the mechanical properties, fracture surface, and weld bead microstructure of the specimen were researched. In addition, the fracture mechanism between weld bead geometry and failure load of specimen was further discussed. This study selected the plasma arc current, MIG welding current, and the central gas flow rate of plasma arc as the hybrid welding parameters. The results demonstrate that Ti/Al butt-joints produced at a higher MIG welding current of 110 A or a higher central gas flow rate of 0.3 L/min increase both the height of reinforcement and porosity of fusion zone. When the MIG welding current is set to 100 A and the central gas flow rate is set to 0.2 L/min, increasing the plasma arc current to 60 A improves both weld bead geometry and tensile strength.

Similar content being viewed by others

Data availability

All data are presented in this published article.

References

Baqer YM, Ramesh S, Yusof F, Manladan SM (2018) Challenges and advances in laser welding of dissimilar light alloys: Al/Mg, Al/Ti, and Mg/Ti alloys. Int J Adv Manuf Technol 95:4353–4369

Ma Z, Sun X, Ji S, Wang Y, Yue Y (2021) Influences of ultrasonic on friction stir welding of Al/Ti dissimilar alloys under different welding conditions. Int J Adv Manuf Technol 112:2573–2582

Ma Z, Jin Y, Ji S, Meng X, Ma L, Li Q (2019) A general strategy for the reliable joining of Al/Ti dissimilar alloys via ultrasonic assisted friction stir welding. J Mater Sci Technol 35:94–99

Chen WB (2016) Microstructure and mechanical properties of tungsten inert gas welded–brazed Al/Ti joints. Sci Technol Weld Joining 21(7):547–554

Miao Y, Ma Z, Yang X, Liu J, Han D (2018) Experimental study on microstructure and mechanical properties of AA6061/Ti-6Al-4V joints made by bypass-current MIG welding-brazing. J Mater Process Technol 260:104–111

Zhang Y, Huang J, Ye Z, Cheng Z, Yang J, Chen S (2018) Influence of welding parameters on the IMCs and the mechanical properties of Ti/Al butt joints welded by MIG/TIG double-sided arc welding-brazing. J Alloy Compd 747:764–771

Chen Y, Chen S, Li L (2009) Effects of heat input on microstructure and mechanical property of Al/Ti joints by rectangular spot laser welding-brazing method. Int J Adv Manuf Technol 44:265–272

Li P, Lei Z, Zhang X, Liu J, Chen Y (2020) Effects of laser power on the interfacial intermetallic compounds and mechanical properties of dual-spot laser welded–brazed Ti/Al butt joint. Opt Laser Technol 124:105987

Shaker MA, Jain MK, Chen JZ (2020) Deformation behavior of steel-to-aluminum tailor blanks made by laser/MIG hybrid and cold metal transfer brazing methods. Int J Adv Manuf Technol 110:3061–3076

Thomy C, Vollertsen F (2012) Laser-MIG hybrid welding of aluminium to steel – effect of process parameters on joint properties. Weld World 56:124–132

Hong H, Han Y, Du M, Tong J (2016) Investigation on droplet momentum in VPPA-GMAW hybrid welding of aluminum alloys. Int J Adv Manuf Technol 86:2301–2308

Guo Y, Pan H, Ren L, Quan G (2018) An investigation on plasma-MIG hybrid welding of 5083 aluminum alloy. Int J Adv Manuf Technol 98:1433–1440

Lin HL, Chen GC, Cheng CM (2022) Effects of plasma-MIG hybrid welding parameters on performance and hot cracking susceptibility of 5083 Al alloy butt-joint welds. Int J Adv Manuf Technol 122:4055–4064

Wei S, Li Y, Wang J, Liu K (2014) Influence of welding heat input on microstructure of Ti/Al joint during pulsed gas metal arc welding. Mater Manuf Processes 29:954–960

Wei S, Li Y, Wang J, Liu K (2014) Use of welding–brazing technology on microstructural development of titanium/aluminum dissimilar joints. Mater Manuf Processes 29:961–968

Zhang J, Zhao J, Hu K, Gao Q, Zhan X (2022) Improving intermetallic compounds inhomogeneity of Ti/Al butt joints by dual laser-beam bilateral synchronous welding-brazing. Opt Laser Technol 146:107533

Wei S, Li Y, Wang J, Liu K, Zhang P (2014) Microstructure and joining mechanism of Ti/Al dissimilar joint by pulsed gas metal arc welding. Int J Adv Manuf Technol 70:1137–1142

Tian R, Chen S, Yang B, Wu J, Li P, Chen N, Li H, Wang Q, Xia H, Ma N (2023) Elemental diffusion, atomic substitution mechanisms and interfacial fracture behavior in laser welded–brazed Al/Ti. Mater Charact 202:112998

Chen X, Lei Z, Chen Y, Jiang M, Jiang N, Bi J, Lin S (2021) Enhanced wetting behavior using femtosecond laser-textured surface in laser welding–brazing of Ti/Al butt joint. Opt Laser Technol 142:107212

Funding

This published article was financially supported by the Ministry of Science and Technology (MOST) of Taiwan under the project no. MOST 110–2221-E-017–006.

Author information

Authors and Affiliations

Contributions

Hsuan-Liang Lin planned the MOST project, including the main conceptual ideas of this study and conducted experimental discussions. Po-An Chen performed all welding experiments and verified the experimental results using tensile testing, hardness testing, OM, and SEM. All authors discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable. This published article involves no studies on human or animal subjects.

Consent to participate

Not applicable. This published article involves no studies on human subjects.

Consent for publication

Not applicable. This published article involves no studies on human subjects.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, HL., Chen, PA. Effects of parameters on welding performance of the Ti/Al butt-joint in advanced plasma-MIG hybrid welding. Int J Adv Manuf Technol 130, 2661–2673 (2024). https://doi.org/10.1007/s00170-023-12849-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12849-1