Abstract

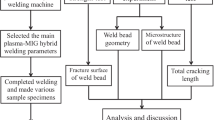

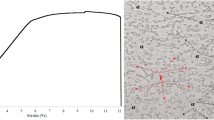

The complexity of joining Ti6Al4V alloy enhances with reduction in sheet thickness. The present work puts emphasis on microplasma arc welding (MPAW) of 500-μm-thick Ti6Al4V alloy in butt joint configuration. Using controlled and regulated arc current, the MPAW process is specifically designed to use in joining of thin sheet components over a wide range of process parameters. The weld quality is assessed by carefully controlling the process parameters and by reducing the formation of oxides. The combined effect of welding speed and current on the weld joint properties is evaluated for joining of Ti6Al4V alloy. The macro- and microstructural characterizations of the weldment by optical microscopy as well as the analysis of mechanical properties by microtensile and microhardness test have been performed. The weld joint quality is affected by specifically designed fixture that controls the oxidation of the joint and introduces high cooling rate. Hence, the solidified microstructure of welded specimen influences the mechanical properties of the joint. The butt joint of titanium alloy by MPAW at optimal process parameters is of very high quality, without any internal defects and with minimum residual distortion.

Similar content being viewed by others

References

M.J. Donachie, Titanium: A Technical Guide, 2nd ed., ASM International, Metals Park, OH, 2000

A. Beranoagirre, D. Olvera, and L.N. López de Lacalle, Milling of Gamma Titanium–Aluminum Alloys, Int. J. Adv. Manuf. Technol., 2012, 62, p 83–88

W. Lucas, TIG and Plasma Welding, Woodhead Publishing, Cambridge, 1990

C.S. Wu, L. Wang, W.J. Ren, and X.Y. Zhang, Plasma arc Welding: Process, Sensing, Control and Modelling, J. Manuf. Process, 2014, 16(1), p 74–85

T. S. Baker, Fatigue Crack Propagation and Fracture Toughness of Plasma Arc Welded Ti-6Al-4 V Alloy, Royal Aircraft Establishment 1985, Technical Report No: 85066 1985

F. Karimzadeh, M. Salehi, A. Saatchi, and M. Meratian, Effect of Microplasma arc Welding Process Parameters on Grain Growth and Porosity Distribution of Thin Sheet Ti6Al4 V Alloy Weldment, Mater. Manuf. Process., 2005, 20(2), p 205–219

F. Karimzadeh, A. Ebnonnasir, and A. Foroughi, Artificial Neural Network Modeling for Evaluating of Epitaxial Growth of Ti6Al4 V Weldment, Mater. Sci. Eng., A, 2006, 432, p 184–190

J. Chen and C. Pan, Welding of Ti-6Al-4 V Alloy Using Dynamically Controlled Plasma arc Welding Process, Trans. Non Ferrous Soc. China, 2011, 21, p 1506–1512

M. Baruah and S. Bag, Influence of Heat Input in Microwelding of Titanium Alloy by Microplasma Arc, J. Mater. Processing Technol., 2016, 231, p 100–112

Y. Fan, Z. Yang, P. Cheng, K. Egland, and Y.L. Yao, Effects of Phase Transformations on Laser Forming of Ti-6Al-4 V Alloy, J. Appl. Phys, 2005, 98(1), p 013518

H.K. Rafi, N.V. Karthik, H. Gong, T.L. Starr, and B.E. Stucker, Microstructures and Mechanical Properties of Ti6Al4 V Parts Fabricated by Selective Laser Melting and Electron Beam Melting, J. Mater. Eng. Perf., 2013, 22, p 3872–3883

T. Ahmed and H.J. Rack, Phase Transformations During Cooling in +β Titanium Alloys, Mater. Sci. Eng. A, 1998, 243, p 206–211

C. Churiaque, M.R. Amaya-Vazquez, F.J. Botana, J.M. Sa´nchez-Amaya (2016) FEM Simulation and Experimental Validation of LBW Under Conduction Regime of Ti6Al4 V Alloy J. Mater. Eng. Perf.

J.W. Elmer, T.A. Palmer, S.S. Babu, W. Zhang, and T. DebRoy, Direct Observations of Phase Transitions in Ti-6Al-4 V Alloy Transient Welds Using Time Resolved x-ray Diffraction, J. Appl. Phys, 2003, 95(12), p 8327–8339

A.S.H. Kabir, X. Cao, J. Gholipour, P. Wanjara, J. Cuddy, A. Birur, and M. Medraj, Effect of Post Heat Treatment on Microstructure, Hardness, and Tensile Properties of Laser Welded Ti6Al4 V, Metallurgical Mater. Trans. A, 2012, 43A, p 4171–4184

N. Kashaev, M. Horstmann, V. Ventzke, S. Riekehr, and N. Huber, Comparative Study of Mechanical Properties Using Standard and Micro-Specimens of Base Materials Inconel 625, Inconel 718 and Ti-6Al-4 V, J. Mater. Res. Technol., 2013, 2(1), p 43–47

X.L. Gao, L.J. Zhang, J. Liu, and J.X. Zhang, Comparison of Tensile Damage Evolution in Ti6A14 V Joints Between Laser Beam Welding and Gas Tungsten Arc Welding, J. Mater. Eng. Perf., 2014, 23, p 4316–4327

S. Wang and X. Wu, Investigation on the Microstructure and Mechanical Properties of Ti–6Al–4V Alloy Joints with Electron Beam Welding, Mater. Design, 2012, 36, p 663–670

V.A. Kumar, R.K. Gupta, and G. Sudarsana Rao, Solution Treatment and Aging (STA) Study of Ti Alloy Ti5Al3Mo1.5V, J. Mater. Eng. Perf., 2015, 24, p 24–31

X. Gao, L. Zhang, J. Liu, and J. Zhang, A Comparative Study of Pulsed Nd:YAG Laser Welding and TIG Welding of Thin Ti6Al4 V Titanium Alloy Plate, Mater. Sci. Eng., A, 2013, 559, p 14–21

M. Watanabe and K. Satoh, On the Type of Distortion in Various Welded Joints: Shrinkage Distortion in Welded Joint, J. Jpn. Weld. Soc., 1957, 26(6), p 399–405

Acknowledgment

The authors gratefully acknowledge the financial support provided by SERB (Science & Engineering Research Board), India (Grant No. SERB/F/0797/2013-2014 dated 20.05.2013), to carry out this research work. The suggestions provided by Prof. P. S. Robi, Department of Mechanical Engineering, IIT Guwahati, India, to revise this manuscript are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baruah, M., Bag, S. Microstructural Influence on Mechanical Properties in Plasma Microwelding of Ti6Al4V Alloy. J. of Materi Eng and Perform 25, 4718–4728 (2016). https://doi.org/10.1007/s11665-016-2333-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2333-8