Abstract

This research aims to examine the relationship between roughness, film thickness, and friction coefficient in relation to pitting wear resistance during the rolling-sliding contact fatigue of forged and plasma-nitrided gears. In the present work, forged gears in continuous cooling bainitic steel were manufactured and plasma nitrided with three sets of N2-H2 gas mixtures, containing 5 vol%, 24 vol%, and 76 vol% N2. The present investigation evaluated the contact analysis between gears from the macroscopic point of view and the microscopic. At the same time, the evolution of roughness and pitting damage area after each test stage was monitored. The study determined the stress field after each loading cycle and correlated the regions of higher stresses with surface and sub-surface fatigue. Weibull’s statistical approach showed that nitrided gears with 24 vol% N2 exhibit the most reduced pitting wear rates among the gears tested. This outcome is attributed to the optimal balance of surface hardness, fracture toughness, compound layer depth, and surface phases. The most pitting damage occurred in the dedendum and pitch line regions, being the regions that reported the greatest Hertz contact pressure. This is due to the rolling direction being opposed to the friction force in the dedendum region. This paper shows that pitting wear intensifies with increasing roughness, but this same behavior was not observed between the wear evolution and the maximum shear stress field in the sub-surface. Another interesting fact is that nitrided gears with 24 vol% N2 (best condition) have a greater film thickness at the end of the rolling-sliding contact fatigue, which gives it greater protection, less friction, and pitting wear. In general, the cracks were observed in areas very close to the surface and, with the course of the propagation stage, reached the surface, causing the formation of damage by pitting or spalling.

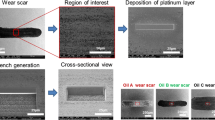

Adapted from Palma Calabokis et al. [32]. (b) Selected points for measuring roughness in the radial direction: 1–3, addendum; 4–6, pitch line; and 7–9, dedendum

Adapted from Dalcin et al. [3]

Similar content being viewed by others

References

Hatwig RA, Dong J, Epp J, Rocha ADS (2021) Effect of compressive deformations on the final microstructure of a low carbon high silicon bainitic steel thermomechanically processed. Mat Res 24:e20200346. https://doi.org/10.1590/1980-5373-mr-2020-0346

Bhadeshia HKDH (2015) Bainite in steels: theory and practice, 3rd edn. Maney Publishing, Leeds

Dalcin RL, Marques de Menezes V, Fonseca Oliveira L et al (2022) Improvement on pitting wear resistance of gears by controlled forging and plasma nitriding. J Mater Res Technol 18:4698–4713. https://doi.org/10.1016/j.jmrt.2022.04.122

Sugimoto K, Hojo T, Srivastava A (2019) Low and medium carbon advanced high-strength forging steels for automotive applications. Metals 9:1263. https://doi.org/10.3390/met9121263

Silveira ACDF, Bevilaqua WL, Dias VW et al (2020) Influence of hot forging parameters on a low carbon continuous cooling bainitic steel microstructure. Metals 601:11. https://doi.org/10.3390/met10050601

Ivaniski TM, de Castro PJ, Rodrigues D et al (2022) Numerical and experimental study of an industrial case for grain size evolution in bainitic steel in controlled hot forging and its influence on mechanical performance. Mat Res 25:e20210598. https://doi.org/10.1590/1980-5373-mr-2021-0598

Ivaniski TM, de Souza TF, Épp J, Rocha ADS (2020) Constitutive modelling of high temperature flow behaviour for a low carbon high silicon bainitic steel. Mat Res 23:e20200264. https://doi.org/10.1590/1980-5373-mr-2020-0264

de Castro PJ, SilveiraIvaniski ACDFTM et al (2021) Two-step continuous cooling heat treatment applied in a low carbon bainitic steel. Mat Res 24:e20200334. https://doi.org/10.1590/1980-5373-mr-2020-0334

Podgornik B, Vižintin J (2001) Sliding and pitting wear resistance of plasma and pulse plasma nitrided steel. Surf Eng 17:6. https://doi.org/10.1179/026708401101517917

Ochoa EA, Wisnivesky D, Minea T et al (2009) Microstructure and properties of the compound layer obtained by pulsed plasma nitriding in steel gears. Surf Coat Technol 203:1457–1461. https://doi.org/10.1016/j.surfcoat.2008.11.025

Dalcin RL, RochaCastro ADSVVD et al (2022) Microstructure and wear properties of a low carbon bainitic steel on plasma nitriding at different N2–H2 gas mixtures. Mater Res 25:e20210447. https://doi.org/10.1590/1980-5373-MR-2021-0447

Dalcin RL, RochaCastro ADSVVD et al (2021) Influence of plasma nitriding with a nitrogen rich gas composition on the reciprocating sliding wear of a DIN 18MnCrSiMo6-4 steel. Mater Res 24:e20200592. https://doi.org/10.1590/1980-5373-MR-2020-0592

Dalcin RL, Oliveira LF, Diehl IL et al (2020) Response of a DIN 18MnCrSiMo6-4 continuous cooling bainitic steel to plasma nitriding with a nitrogen rich gas composition. Mat Res 23:e20200036. https://doi.org/10.1590/1980-5373-mr-2020-0036

Dalcin RL, Oliveira LF, Diehl CATS, da Silva RA (2020) Response of a DIN 18MnCrSiMo6-4 continuous cooling bainitic steel to different plasma nitriding gas mixtures. Mat Res 23:e20200269. https://doi.org/10.1590/1980-5373-mr-2020-0269

Ongtrakulkij G, Kajornchaiyakul J, Kondoh K, Khantachawana A (2022) Investigation of microstructure, residual stress, and hardness of Ti-6Al-4V after plasma nitriding process with different times and temperatures. Coatings 12:1932. https://doi.org/10.3390/coatings12121932

Martins R, Seabra J, Magalhães L (2008) Austempered ductile iron (ADI) gears: power loss, pitting and micropitting. Wear 264:838–849. https://doi.org/10.1016/j.wear.2007.05.007

Mallipeddi D, Norell M, Sosa M, Nyborg L (2019) The effect of manufacturing method and running-in load on the surface integrity of efficiency tested ground, honed and superfinished gears. Tribol Int 131:277–287. https://doi.org/10.1016/j.triboint.2018.10.051

Beheshti A, Aghdam AB, Khonsari MM (2013) Deterministic surface tractions in rough contact under stick–slip condition: application to fretting fatigue crack initiation. Int J Fatigue 56:75–85. https://doi.org/10.1016/j.ijfatigue.2013.08.007

Seabra J, Berthe D (1987) Influence of surface waviness and roughness on the normal pressure distribution in the Hertzian contact. J Tribol 109:462–469. https://doi.org/10.1115/1.3261472

Liu H, Liu H, Zhu C et al (2019) Tribological behavior of coated spur gear pairs with tooth surface roughness. Friction 7:117–128. https://doi.org/10.1007/s40544-017-0193-3

Bergstedt E, Lin J, Andersson M et al (2021) Gear micropitting initiation of ground and superfinished gears: wrought versus pressed and sintered steel. Tribol Int 160:107062. https://doi.org/10.1016/j.triboint.2021.107062

Zafosnik B, Glodez S, Ulbin M, Flasker J (2007) A fracture mechanics model for the analysis of micro-pitting in regard to lubricated rolling–sliding contact problems. Int J Fatigue 29:1950–1958. https://doi.org/10.1016/j.ijfatigue.2006.12.015

Brandão JA, Martins R, Seabra JHO, Castro MJD (2014) Calculation of gear tooth flank surface wear during an FZG micropitting test. Wear 311:31–39. https://doi.org/10.1016/j.wear.2013.12.025

Brandão JA, Martins R, Seabra J, Castro MJD (2015) An approach to the simulation of concurrent gear micropitting and mild wear. Wear 324–325:64–73. https://doi.org/10.1016/j.wear.2014.12.001

Muraro MA, Koda F, Reisdorfer U Jr, da Silva CH (2012) The influence of contact stress distribution and specific film thickness on the wear of spur gears during pitting tests. J Braz Soc Mech Sci Eng 34:135–144. https://doi.org/10.1590/S1678-58782012000200005

Gans LHA, Guesser WL, Luersen MA, da Silva CH (2015) Numerical analysis of the influence of graphite nodule size on the pitting resistance of austepered ductile iron gears. Adv Mater Res 1120–1121:763–772. https://doi.org/10.4028/www.scientific.net/AMR.1120-1121.763

Rego R (2016) Residual stress interaction in-between processes of the gear manufacturing chain. Doctorate Thesis, Aeronautic Institute of Technology

Li W, Liu B (2018) Experimental investigation on the effect of shot peening on contact fatigue strength for carburized and quenched gears. Int J Fatigue 106:103–113. https://doi.org/10.1016/j.ijfatigue.2017.09.015

Rego R, Löpenhaus F, Gomes J, Klocke F (2018) Residual stress interaction on gear manufacturing. J Mater Process Technol 252:249–258. https://doi.org/10.1016/j.jmatprotec.2017.09.017

Cardoso NFR, Martins RC, Seabra JHO et al (2009) Micropitting performance of nitrided steel gears lubricated with mineral and ester oils. Tribol Int 42:77–87. https://doi.org/10.1016/j.triboint.2008.05.010

Ding Y, Rieger NF (2003) Spalling formation mechanism for gears. Wear 254:1307–1317. https://doi.org/10.1016/S0043-1648(03)00126-1

Palma Calabokis O, Núñez de la Rosa YE, de Moraes SP et al (2022) Experimental and numerical study of contact fatigue for 18CrNiMo7-6 and 20MnCr5 carburized gear tooth. Surf Topogr: Metrol Prop 10:034007. https://doi.org/10.1088/2051-672X/ac939f

Liu H, Liu H, Zhu C, Parker RG (2020) Effects of lubrication on gear performance: a review. Mech Mach Theory 145:103701. https://doi.org/10.1016/j.mechmachtheory.2019.103701

Zhao J, Sheng W, Li Z et al (2022) Effect of lubricant selection on the wear characteristics of spur gear under oil-air mixed lubrication. Tribol Int 167:107382. https://doi.org/10.1016/j.triboint.2021.107382

Chang X, Renqing D, Liao L et al (2023) Study on hydrodynamic lubrication and friction reduction performance of spur gear with groove texture. Tribol Int 177:107978. https://doi.org/10.1016/j.triboint.2022.107978

Karmiris-Obratański P, Karkalos NE, Kudelski R, Markopoulos AP (2022) Experimental study on the effect of the cooling method on surface topography and workpiece integrity during trochoidal end milling of Incoloy 800. Tribol Int 176:107899. https://doi.org/10.1016/j.triboint.2022.107899

Molnár V (2021) Minimization method for 3D surface roughness evaluation area. Machines 9:192. https://doi.org/10.3390/machines9090192

Brandão JA, Seabra JHO, Castro MJD (2016) Surface fitting of an involute spur gear tooth flank roughness measurement to its nominal shape. Measurement 91:479–487. https://doi.org/10.1016/j.measurement.2016.05.076

Magalhães L (2003) Caracterização tribológica de um ferro nodular austemperado em ensaios disco-disco e de engrenagens FZG. Universidade do Porto, Tese de Doutorado

Matsumoto S, Morikawa K (2014) The new estimation formula of coefficient of friction in rolling-sliding contact surface under mixed lubrication condition for the power loss reduction of power transmission gears. In: International Gear Conference 2014: 26th–28th August 2014, Lyon. Elsevier, pp 1078–1088

Nolan D, Leskovsek V, Jenko M (2006) Estimation of fracture toughness of nitride compound layers on tool steel by application of the Vickers indentation method. Surf Coat Technol 201:182–188. https://doi.org/10.1016/j.surfcoat.2005.11.077

DIN 50 190 (1979) Härtetiefe wärmebehandelter Tiele: Ermittlung der Nitrierhärtetiefe. Teil 3. Berlin: DIN Deutsches Institut für Normung

Koda F (2009) Estudo da fadiga de contato em engrenagens cilíndricas de dentes retos. Universidade Tecnológica Federal do Paraná (UTFPR), Dissertação de Mestrado

DIN 14635–1 (2006) Gears – FZG test procedures – part 1: FZG test method A/8.3/90 for relative scuffing load-carrying capacity of oils. Teil 3. Berlin: Deutsches Institut für Normung

Guesser WL, Koda F, Martinez JAB, Silva CH da (2012) Austempered ductile iron for gears. SAE Technical Paper Series 2012–36–0305

ASTM D341 (2003) Standard test method for viscosity-temperature charts for liquid petroleum products. ASTM Internacional. https://www.astm.org/d0341-03.html

ISO 4287 (2002) Geometrical product specifications (GPS) – surface texture: profile method – terms, definitions and surface texture parameters. International Organization for Standardization. Genebra: ISO. https://idoc.pub/documents/nbr-iso-4287-2002-especificacoes-geometric-as-do-produto-gps-rugosidademetodo-do-perfil-1-pon29dommml0

ISO 4288 (2008) Geometrical product specifications (GPS) – surface texture: profile method – rules and procedures for the assessment of surface texture. International Organization for Standardization. Genebra: ISO

Muraro MA, Reisdorfer Junior U (2010) Análise das variáveis envolvidas no contato de engrenagens cilíndricas de dentes retos. Universidade Tecnológica Federal do Paraná (UTFPR), Trabalho de Conclusão de Curso

Stachowiak GW, Batchelor AW (2005) Engineering tribology, 3rd edn. Elsevier Butterworth-Heinemann, Amsterdam, Boston

Broszeit E, Preussler Th, Wagner M, Zwirlein O (1986) Stress hypotheses and material stresses in Hertzian contacts. Mat-wiss u Werkstofftech 17:238–246. https://doi.org/10.1002/mawe.19860170706

Turnbull R, Rahmani R, Rahnejat H (2020) The effect of outer ring elastodynamics on vibration and power loss of radial ball bearings. P I MECH ENG K-J PRO 234:707–722. https://doi.org/10.1177/1464419320951398

Tiryakioğlu M, Hudak D (2011) Guidelines for two-parameter Weibull analysis for flaw-containing materials. Metall Mater Trans B 42:1130–1135. https://doi.org/10.1007/s11663-011-9556-8

Abernethy R (2006) The new Weibull handbook, 5th ed. North Palm Beach: Dr. Robert. B. Abernethy. https://dl.icdst.org/pdfs/files3/c64437fb3adfa5efafd1cb89063cb323.pdf

Wollmann D, Soares GPPP, Grabarski MI et al (2017) Rolling contact fatigue failure mechanisms of plasma-nitrided ductile cast iron. J of Materi Eng and Perform 26:2859–2868. https://doi.org/10.1007/s11665-017-2717-4

Reliasoft (2015) Life data analysis reference. Tucson: ReliaSoft Corporation. https://www.reliawiki.com/index.php/Life_Data_Analysis_Reference_Book

Höhn B-R (2010) Influence of lubricant on the pitting capacity of case carburized gears in load-spectra and single-stage-investigations. Frankfurt: FVA (Technical Report FVA-Research Project 2/IV)

Mauch H, Zenner H (1999) Statistische methoden zur beurteilung von bauteillebensdauer und zuverlässigkeit und ihre beispielhafte anwendung auf zahnräder

Rakhit AK (2000) Heat treatment of gears: a practical guide for engineers. ASM International, Materials Park, OH

Terrin A, Dengo C, Meneghetti G (2017) Experimental analysis of contact fatigue damage in case hardened gears for off-highway axles. Eng Fail Anal 76:10–26. https://doi.org/10.1016/j.engfailanal.2017.01.019

Magalhães L, Seabra J, Sá C (2000) Experimental observations of contact fatigue crack mechanisms for austempered ductile iron (ADI) discs. Wear 246:134–148. https://doi.org/10.1016/S0043-1648(00)00493-2

Raje N, Sadeghi F, Rateick RG (2008) A statistical damage mechanics model for subsurface initiated spalling in rolling contacts. J Tribol 130:042201. https://doi.org/10.1115/1.2959109

Glodež S, Winter H, Stüwe HP (1997) A fracture mechanics model for the wear of gear flanks by pitting. Wear 208:177–183. https://doi.org/10.1016/S0043-1648(97)00008-2

Ding Y, Gear JA (2009) Spalling depth prediction model. Wear 267:1181–1190. https://doi.org/10.1016/j.wear.2008.12.064

Kharka V, Jain NK, Gupta K (2020) Influence of MQL and hobbing parameters on microgeometry deviations and flank roughness of spur gears manufactured by MQL assisted hobbing. J Market Res 9:9646–9656. https://doi.org/10.1016/j.jmrt.2020.06.085

Xu X, Lai J, Lohmann C et al (2019) A model to predict initiation and propagation of micro-pitting on tooth flanks of spur gears. Int J Fatigue 122:106–115. https://doi.org/10.1016/j.ijfatigue.2019.01.004

Martins RC, Cardoso NFR, Bock H et al (2009) Power loss performance of high pressure nitrided steel gears. Tribol Int 42:1807–1815. https://doi.org/10.1016/j.triboint.2009.03.006

Vengudusamy B, Grafl A, Novotny-Farkas F, Schöfmann W (2013) Comparison of frictional properties of gear oils in boundary and mixed lubricated rolling–sliding and pure sliding contacts. Tribol Int 62:100–109. https://doi.org/10.1016/j.triboint.2013.02.001

Gunsel S, Korcek S, Smeeth M, Spikes HA (1999) The elastohydrodynamic friction and film forming properties of lubricant base oils. Tribol Trans 42:559–569. https://doi.org/10.1080/10402009908982255

Hutchings I, Shipway P (2017) Tribology: friction and wear of engineering materials, 2nd edn. Butterworth–Heinemann, p 412. https://www.sciencedirect.com/book/9780081009109/tribology

Brandão JA, Martins R, Seabra JH, Castro MJ (2012) Surface damage prediction during an FZG gear micropitting test. P I MECH ENG J-J PRO 226:1051–1073. https://doi.org/10.1177/1350650112461879

da Silva RA, Strohaecker T, Tomala V, Hirsch T (1999) Microstructure and residual stresses of a plasma-nitrided M2 tool steel. Surf Coat Technol 115:24–31. https://doi.org/10.1016/S0257-8972(99)00063-8

Hamilton GM, Goodman LE (1966) The stress field created by a circular sliding contact. J Appl Mech 33:371–376. https://doi.org/10.1115/1.3625051

daS Rocha A, Strohaecker T, Hirsch T (2003) Effect of different surface states before plasma nitriding on properties and machining behavior of M2 high-speed steel. Surf Coat Technol 165(176):185. https://doi.org/10.1016/S0257-8972(02)00768-5

Funding

This work was carried out with the support of CAPES–BRAGECRIM program (Process no. 88881.142485/2017–01, aid number 1844/2017) and CAPES–PROEX (Process 23038.000341/2019–71). R. L. Dalcin acknowledges CAPES (Grant 88882.345854/2019–01), V. M. Menezes acknowledges CAPES (Grant 88887.358965/2019–00), and A. da Silva Rocha acknowledges CNPq (Grant 308773/2018–7).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dalcin, R.L., de Menezes, V.M., da Silva Rocha, A. et al. Correlation between roughness, film thickness, and friction coefficient with pitting wear resistance of spur gears. Int J Adv Manuf Technol 129, 5473–5492 (2023). https://doi.org/10.1007/s00170-023-12576-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12576-7