Abstract

A quartic flow velocity field is proposed to establish an online rolling force predicting model for the rolling process of aluminum alloy thick plates. The solving process relies on the energy method. Through comparing the calculated rolling force data and the actual rolling force, it is found that this model can be applied for online rolling force predicting. The assumption of the metal flow velocity in this paper is a beneficial attempt at the plastic mechanics.

Similar content being viewed by others

Code availability

Not applicable.

Abbreviations

- α :

-

Neutral angle

- H :

-

Initial thickness

- h :

-

Exit thickness

- h(x):

-

Thickness at the coordinate of x

- v 0 :

-

Initial flow velocity

- v 1 :

-

Exit flow velocity

- v(x,z):

-

Horizontal flow velocity

- u(x,z):

-

Flow velocity in the thickness direction

- A 1, A 2 :

-

Undetermined coefficient

- R :

-

Radius of work roller

- l :

-

Length of deformation zone in rolling direction

- x n :

-

Coordinate in x axial of neutral point

- m :

-

Friction coefficient

References

Li S, Wang ZG, Guo YF (2019) A novel analytical model for prediction of rolling force in hot strip rolling based on tangent velocity field and MY criterion. J Manuf Process 47:202–210. https://doi.org/10.1016/j.jmapro.2019.09.037

Hao PJ, He AR, Sun WQ (2018) Formation mechanism and control methods of inhomogeneous deformation during hot rough rolling of aluminum alloy plate. Arch Civ Mech Eng 18:245–255. https://doi.org/10.1016/j.acme.2017.07.004

Hao PJ, Liu JN (2020) Influence of snake rolling on metal flow in hot rolling of aluminum alloy thick plate. Mech Ind 21:525. https://doi.org/10.1051/meca/2020071

Ma GS, Liu YM, Peng W, Yin FC, Ding JG, Zhao DW, Di HS, Zhang DH (2017) A new model for thermos-mechanical coupled analysis of hot rolling. J Braz Soc Mech Sci 39:523–530. https://doi.org/10.1007/s40430-015-0390-9

Peng W, Zhang DH, Zhao DW (2017) Application of parabolic velocity field for the deformation analysis in hot tandem rolling. Int J Adv Manuf Technol 91:2233–2243. https://doi.org/10.1007/s00170-016-9936-y

Peng W, Ding JG, Zhang DH, Zhao DW (2017) A novel approach for the rolling force calculation of cold rolled sheet. J Braz Soc Mech Sci Eng 39:5057–5067. https://doi.org/10.1007/s40430-017-0774-0

You GH, Li S, Wang ZG, Yuan R, Wang ML (2020) A novel analytical model based on arc tangent velocity field for prediction of rolling force in strip rolling. Meccanica 55:1453–1462. https://doi.org/10.1007/s11012-020-01178-2

Liu YM, Sun J, Wang QL, Zhang DH, Zhao DW (2017) Mathematical model for cold rolling based on energy method. Meccanica 52:2069–2080. https://doi.org/10.1007/s11012-016-0569-x

Wang L, Zhu XY, Zhao DW, Zhang DH (2017) An analytical model of plate rolling force with a simple available velocity field and equal perimeter yield criterion. Adv Mech Eng 9:1–8. https://doi.org/10.1177/1687814017728837

Zhang SH, Deng L, Zhang QY, Li QH, Hou JX (2019) Modeling of rolling force of ultra-heavy plate considering the influence of deformation penetration coefficient. Int J Mech Sci 159:373–381. https://doi.org/10.1016/j.ijmecsci.2019.05.048

Liu YM, Ma GS, Zhang DH, Zhao DW (2015) Upper bound analysis of rolling force and dog-bone shape via sine function model in vertical rolling. J Mater Process Technol 223:91–97. https://doi.org/10.1016/j.jmatprotec.2015.03.051

Hao PJ, Liu JN, Yao CH (2022) A novel 2D metal flow model for hot rolling of aluminum alloy thick plate. Adv Mater Sci Eng 2022:9742633. https://doi.org/10.1155/2022/9742633

Yao CH, He AR, Shao J, Zhao JW (2019) A real-time quasi-3D metal flow model for hot strip rolling. Int J Mech Sci 159:91–102. https://doi.org/10.1016/j.ijmecsci.2019.05.045

Li X, Wang HY, Liu YM, Zhang DH, Zhao DW (2017) Analysis of edge rolling based on continuous symmetric parabola curves. J Braz Soc Mech Sci Eng 39:1259–1268. https://doi.org/10.1007/s40430-016-0587-6

Ding JG, Wang HY, Zhang DH, Zhao DW (2017) Slab analysis based on stream function method in chamfer edge rolling of ultra-heavy plate. Proc Inst Mech Eng, Part C: J Mech Eng Sci 231:1237–1251. https://doi.org/10.1177/0954406216646400

Liu YM, Hao PJ, Wang T, Ren ZK, Sun J, Zhang DH, Zhang SH (2020) Mathematical model for vertical rolling deformation based on energy method. Int J Adv Manuf Technol 107:875–883. https://doi.org/10.1007/s00170-020-05094-3

Ren ZK, Xiao H, Liu X, Yan ZC (2018) An analysis of the metal transverse flow in the roll gap for ultra-thin strip rolling using the energy method. ISIJ Int 58:309–315. https://doi.org/10.2355/isijinternational.ISIJINT-2017-519

Zhang YF, Zhao MY, Xu L, Di HS, Zhou XJ, Wen P, Zhao DW (2022) Optimization solution of vertical rolling force using unified yield criterion. Int J Adv Manuf Technol 119:1035–1045. https://doi.org/10.1007/s00170-021-08333-3

Hamidpour SP, Parvizi A, Nosrati AS (2019) Upper bound analysis of wire flat rolling with experimental and FEM verifications. Meccanica 54:2247–2261. https://doi.org/10.1007/s11012-019-01066-4

Zhang QD, Zhang BY, Li B, Zhang XF (2015) Element free Galerkin method coupled flow function for plane strain strip rolling process. J Mech Eng 51:48–54. https://doi.org/10.3901/JME.2015.10.048

Liu HM, Jin D, Wang YR (2004) Strip layer method for simulation of the three-dimensional deformations of plate and strip rolling. Commun Numer Meth Eng 20:183–191. https://doi.org/10.1002/cnm.659

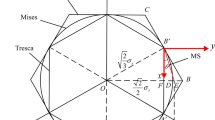

Zhao DW, Xie YJ, Liu XH, Wang GD (2006) Three-dimensional analysis of rolling by twin shear stress yield criterion. J Iron Steel Res Int 13:21–26. https://doi.org/10.1016/S1006-706X(06)60104-0

Gao JZ, Zhao DW, Zhang SH, Peng W, Chen SZ, Zhang DH (2014) Analysis of hot tandem rolling force with logarithmic velocity field and EA yield criterion. J Iron Steel Res Int 21:295–299. https://doi.org/10.1016/S1006-706X(14)60045-5

Jiang XR, Zhang SH, Wang CJ, Li YX, Tian WH (2020) Analysis of elliptical velocity field in heavy plate rolling by integral mean value yield criterion. J Harb I Tech 52:41–48. https://doi.org/10.11918/201910203

Zhang SH, Tian WH, Deng L (2021) A novel yield criterion and its application to calculate the rolling force of a thick plate during hot rolling. J Braz Soc Mech Sci 43:12. https://doi.org/10.1007/s40430-020-02761-0

Funding

This study was supported by the Fundamental Research Funds for the Central Universities of China (Grant No. FRF-GF-20-24B and FRF-MP-19-014) and Innovation Group Project of Southern Marine Science and Engineering Guangdong Laboratory (Zhuhai) (No. 311021013).

Author information

Authors and Affiliations

Contributions

Xiuliang Wang established and solved the model and completed this manuscript; Weidong Zhang offered part of literature and the device for solving the model and then organized the industrial experiment; Yibo Ai collected data in the industrial experiment.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

All the authors listed agree to participate in this work and have approved this manuscript.

Consent for publication

All the authors listed agree to publish this paper.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Zhang, W. & Ai, Y. A novel model based on quartic velocity field for hot rolling force of aluminum alloy thick plate. Int J Adv Manuf Technol 127, 5119–5125 (2023). https://doi.org/10.1007/s00170-023-11885-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11885-1