Abstract

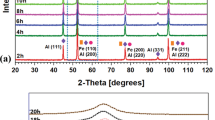

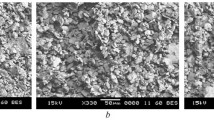

This study aims to elaborate on the production of a nanostructured Fe-Si alloy with varying silicon concentrations and how it can enhance the magnetic properties of the alloy. In order to achieve this, the mechanical alloying technique was employed to create the nanostructured alloy. After the mechanical ball milling process, the morphological, structural, and magnetic properties of the alloy were thoroughly analyzed using advanced techniques such as scanning electron microscopy (SEM) coupled with energy-dispersive spectroscopy (EDS), X-ray diffraction (XRD), and vibrating sample magnetometer (VSM). The results from these techniques revealed significant changes in the properties of the alloy. One of the major findings of this study was the appearance of Fe3Si phase, commonly known as Suessite, after the mechanical milling process. This indicates that the milling process caused a transformation in the crystal structure of the alloy. Additionally, an increase in silicon concentration led to a reduction in crystallite sizes, which was observed through the XRD analysis. Furthermore, the lattice strain and lattice parameters of the alloy were observed to increase with increasing silicon concentration until it reached 3%. After this point, the value of the lattice parameter remained constant, indicating that further increases in silicon concentration did not significantly impact the lattice structure of the alloy. The FTIR analysis revealed the presence of a distinct band at 1070 cm−1, indicating the occurrence of stretching vibrations associated with Fe-Si bonds. The milled samples exhibit improved magnetic properties, with increased saturation magnetization values observed as the silicon concentration increased.

Similar content being viewed by others

References

Suryanarayana C (2002) Nanostructured intermetallics. In: Intermetallic Compounds-Principles and Practice: Progress, vol 3, pp 749–764. https://doi.org/10.1002/0470845856

Mazaleyrat F, Varga LK (2001) Thermo-magnetic transitions in two-phase nanostructured materials. IEEE Trans Magn 37(4):2232–2235. https://doi.org/10.1109/20.951133

Rempel A (2007) Nanotechnologies. Properties and applications of nanostructured materials. Russ Chem Rev 76(5):435. https://doi.org/10.1070/RC2007v076n05ABEH003674

Strečková M, Füzer J, Kobera L, Brus J, Fáberová M, Bureš R, Bat'Ko I (2014) A comprehensive study of soft magnetic materials based on FeSi spheres and polymeric resin modified by silica nanorods. Mater Chem Phys 147(3):649–660. https://doi.org/10.1016/j.matchemphys.2014.06.004

Gleiter H (2000) Nanostructured materials: basic concepts and microstructure. Acta Mater 48(1):1–29. https://doi.org/10.1016/S1359-6454(99)00285-2

Enayati MH, Mohamed FA (2014) Application of mechanical alloying/milling for synthesis of nanocrystalline and amorphous materials. Int Mater Rev 59(7):394–416. https://doi.org/10.1179/1743280414Y.0000000036

Chaudhary V, Mantri SA, Ramanujan RV, Banerjee R (2020) Additive manufacturing of magnetic materials. Prog Mater Sci 114:100688. https://doi.org/10.1016/j.pmatsci.2020.100688

Suryanarayana C (2001) Mechanical alloying and milling. Prog Mater Sci 46(1-2):1–184. https://doi.org/10.1016/S0079-6425(99)00010-9

Hajalilou A, Kianvash A, Lavvafi H, Shameli K (2018) Nanostructured soft magnetic materials synthesized via mechanical alloying: a review. J Mater Sci Mater Electron 29:1690–1717. https://doi.org/10.1007/s10854-017-8082-0

Koch C (1997) Synthesis of nanostructured materials by mechanical milling: problems and opportunities. Nanostructured Mater 9(1-8):13–22. https://doi.org/10.1016/S0965-9773(97)00014-7

Bi X, Lan W, Ou S, Gong S, Xu H (2003) Magnetic and electrical properties of FeSi/FeSi–ZrO2 multilayers prepared by EB-PVD. J Magn Magn Mater 261(1-2):166–171. https://doi.org/10.1016/S0304-8853(02)01469-5

Wang J, Song S, Sun H, Xue Z (2021) Improvement of magnetic properties for FeSi/FeSiAl compound soft magnetic composites by introducing impact of powder size matching. J Mater Sci Mater Electron 32:8545–8556. https://doi.org/10.1007/s10854-021-05488-3

Balakrishna AR, James RD (2021) A tool to predict coercivity in magnetic materials. Acta Mater 208:116697. https://doi.org/10.1016/j.actamat.2021.116697

Dascalu M, Cesura F, Lev G, Diéguez O, Kohn A, Goldfarb I (2019) Controlling the supermagnetic response of tetragonal α-FeSi2 nanoislands. Appl Surf Sci 476:189–197. https://doi.org/10.1016/j.apsusc.2019.01.079

Du VA, Sidorenko A, Bethge O, Paschen S, Bertagnolli E, Schubert U (2011) Iron silicide nanoparticles in a SiC/C matrix from organometallic polymers: characterization and magnetic properties. J Mater Chem 21(33):12232–12238 https://doi.org/10.1039/C1JM11099C

Zhou T, Zhang J, Xu J, Yu Z, Gu G, Wang D, Huang H, Du Y, Wang J, Jiang Y (1996) Preparation of nanocrystalline Fe-Si alloys and their magnetic properties. J Magn Mater 164:219. https://doi.org/10.1016/S0304-8853(96)00384-8

Parzych G, Jankowska-Kisielinska J, Dobrzyński L (2010) Magnetic properties of DO_3-type alloys based on Fe_3Si and Fe_3Al. Acta Physica Polonica A 117(4):578–581. https://doi.org/10.12693/APhysPolA.117.578H

Atmani H, Grognet S, Teillet J (2001) Crystallization-nitriding process of FeSiB and FeSiBCuNb ribbons: influence of additive (Cu,Nb) pair and nitrogen on structure, magnetic and magnetostrictive parameters. J Non Cryst Solids 290(2-3):194–207. https://doi.org/10.1016/S0022-3093(01)00737-2

Akinwamide SO, Lemika SM, Abiodun B (2019) Study of microstructural and mechanical properties of stir cast Al (SiC-Mg-TiFe) composite. Fluid Dyn Mater Process 15(1):15–26. https://doi.org/10.32604/fdmp.2019.04761

Akinwamide SO, Akinribide OJ, Olubambi PA (2021) Microstructural evolution, mechanical and nanoindentation studies of stir cast binary and ternary aluminium based composites. J Alloys Compd 850:156586. https://doi.org/10.1016/j.jallcom.2020.156586

Gao ZQ, Fultz B (1994) Thermal stability of Fe3Si-based nanocrystals. Hyperfine Interact 94:2213–2218. https://doi.org/10.1007/BF02063764

Grognet S, Le Breton JM, Atmani H, Teillet J (2000) Microstructural study of nanocrystalline Fe–(Cu–Nb)–Si–B ribbons obtained by a nitriding thermochemical treatment. J Magn Mater 210:167–180. https://doi.org/10.1016/S0304-8853(99)00763-5

Dilmi N, Bacha NE, Younes A (2020) Structural and magnetic properties of Fe 60–x Ni x (ZnO) 40 nanocomposites produced by mechanical milling and coated by thermal spraying on a steel substrate. Powder Metallurgy and Metal Ceramics 59:35–45. https://doi.org/10.1007/s11106-020-00136-7

Younes A, Khorchef M, Bouamer A, Amar H (2019) Magnetic and structural behavior of Fe-CoO nanocomposites mechanically milled. IOP Conf Ser: Mater Sci Eng 557:012064. https://doi.org/10.1088/1757-899X/557/1/012064

Soni PR (2000) Mechanical alloying: fundamentals and applications. Cambridge Int Science Publishing

Suryanarayana C (2008) Recent developments in mechanical alloying. Rev Adv Mater Sci 18(3):203–211

Herr U (1995) Mechanical alloying and milling. In: Key engineering materials, vol 103. Trans Tech Publications Ltd., pp 113–124

Sanin VN, Ikornikov DM, Andreev DE, Sachkova NV, Yukhvid VI (2019) Mill scale recycling by SHS metallurgy for production of cast ferrosilicon and ferro-silico-aluminium. IOP Conf Ser: Mater Sci Eng 558:012041. https://doi.org/10.1088/1757-899X/558/1/012041

Piamba JF, Rodríguez R, Alcazar GP (2012) Mössbauer and XRD study of the Fe0.5Si0.5 system produced by mechanical alloying and sinterization. Revista Mexicana de Física 58(2):88–92 https://www.redalyc.org/articulo.oa?id=57030392023

Abbassi L, Mesguich D, Berthebaud D, Le Tonquesse S, Srinivasan B, Mori T, Beaudhuin M (2021) Effect of nanostructuring on the thermoelectric properties of β-FeSi2. Nanomaterials 11(11):2852. https://doi.org/10.3390/nano11112852

Yamada H, Katsumata H, Yuasa D, Uekusa S, Ishiyama M, Souma H, Azumaya I (2012) Structural and electrical properties of β-FeSi2 bulk materials for thermoelectric applications. Phys Procedia 23:13–16. https://doi.org/10.1016/j.phpro.2012.01.004

Piamba JF, Ortega C, Hernández-Bravo R, Carmona JG, Tabares JA, Alcázar GP, Alvarado-Orozco JM (2020) Theoretical and experimental study of FeSi on magnetic and phase properties. Appl Phys A 126:1–9. https://doi.org/10.1007/s00339-020-04038-8

Cherigui M, Guessasma S, Fenineche N, Hamzaoui R, El-Kedim O, Coddet C (2005) Studies of magnetic properties of iron-based coatings produced by a high-velocity oxy-fuel process. Mater Chem Phys 92(2-3):419–423. https://doi.org/10.1016/j.matchemphys.2005.01.047

Ma Y, Liu L, Ren X, Liu A (2018) The effect of target-substrate distance on surface morphology and properties of β-FeSi2 films prepared by pulsed laser deposition. IOP Conf Ser: Mater Sci Eng 452:022153. https://doi.org/10.1088/1757-899X/452/2/022153

Lefki K, Muret P, Bustarret E, Boutarek N, Madar R, Chevrier J et al (1991) Infrared and Raman characterization of beta iron silicide. Solid State Commun 80(10):791–795

Niyonshuti II, Krishnamurthi VR, Okyere D, Song L, Benamara M, Tong X, Wang Y, Chen J (2020) Polydopamine surface coating synergizes the antimicrobial activity of silver nanoparticles. ACS Appl Mater Interfaces 12:40067–40077

Wang J, Guo Z, Zeng Q, Hang G, Xue Z, Chen D et al (2020) Magnetic properties regulation and loss contribution analysis for Fe-based amorphous powder cores doped with micron-sized FeSi powders. Journal of Magnetism and Magnetic Materials 510:166931

Sun K, Feng S, Jiang Q, Li XF, Li Y, Fan RH, An Y, Wang JQ (2020) Intergranular insulating reduced iron powder-carbonyl iron powder/SiO2-Al2O3 soft magnetic composites with high saturation magnetic flux density and low core loss. J MagnMagn Mater 493:165705

Nguyen CC, Yoon T, Seo DM, Guduru P, Lucht BL (2016) Systematic investigation of binders for silicon anodes: interactions of binder with silicon particles and electrolytes and effects of binders on solid electrolyte interphase formation. ACS Appl Mater Interfaces 8(19):12211–12220

Poljansek I, Krajnc M (2005) Characterization of phenol-formaldehyde prepolymer resins by in line FT-IR spectroscopy. Acta Chimica Slovenica 52(3):238

Zhang Y, Ivey DG (1998) Fe3Si formation in Fe–Si diffusion couples. J Mater Sci 33:3131–3135. https://doi.org/10.1023/A:1004347907052

Li H, Xue CL, Yang Y, Liang JL (2023) Preparation of Fe3Si and FeSi intermetallic compounds from copper slag by electrochemical method. J Iron Steel Res Int 30(2):305–316. https://doi.org/10.1007/s42243-022-00880-7

Yakin A, Simsek T, Avar B, Simsek T, Chattopadhyay AK (2023) A review of soft magnetic properties of mechanically alloyed amorphous and nanocrystalline powders. Emergent Materials:1–29. https://doi.org/10.1007/s42247-023-00485-0

Yang YM, Loka C, Kim DP, Joo SY, Moon SW, Choi YS, Lee KS (2017) Si-FeSi2/C nanocomposite anode materials produced by two-stage high-energy mechanical milling. Met Mater Int 23:610–617. https://doi.org/10.1007/s12540-017-6510-6

Vorauer T, Kumar P, Berhaut CL, Chamasemani FF, Jouneau PH, Aradilla D, Brunner R (2020) Multi-scale quantification and modeling of aged nanostructured silicon-based composite anodes. Commun Chem 3(1):141–152. https://doi.org/10.1038/s42004-020-00386-x

Yeh CL, Chen KT (2021) Synthesis of FeSi-Al2O3 composites by autowave combustion with metallothermic reduction. Metals 11:258. https://doi.org/10.3390/met11020258

Stanciu CD, Marinca TF, Chicinaş I, Isnard O (2017) Characterization of the Fe-10 wt% Si nanocrystalline powder obtained by mechanical alloying and annealing. J Magn Magn Mater 441:455–464. https://doi.org/10.1016/j.jmmm.2017.06.010

Overman NR, Jiang X, Kukkadapu RK, Clark T, Roosendaal TJ, Coffey G, Mathaudhu SN (2018) Physical and electrical properties of melt-spun Fe-Si (3–8 wt.%) soft magnetic ribbons. Mater Charact 136:212–220. https://doi.org/10.1016/j.matchar.2017.12.019

Clark T, Mathaudhu SN (2019) Microstructure and magnetic properties of dilute nanocrystalline Fe-Si prepared by high energy ball milling. J Magn Magn Mater 484:350–355. https://doi.org/10.1016/j.jmmm.2019.03.070

Li M, Birringer R, Johnson WL, Shull RD (1993) Nanocrystalline Fe-Si phase by mechanical attrition and its soft magnetic properties. Nanostruct Mater 3:407–412. https://doi.org/10.1016/0965-9773(93)90106-L

Vinzelberg H, Schumann J, Elefant D, Arushanov E, Schmidt OG (2008) Transport and magnetic properties of Fe3Si epitaxial films. J Appl Phys 104(9):093707. https://doi.org/10.1063/1.3008010

McHenry ME, Laughlin DE (2000) Nano-scale materials development for future magnetic applications. Acta Mater 48(1):223–238. https://doi.org/10.1016/S1359-6454(99)00296-7

Cunha MA, Johnson GW (1990) Rapidly solidified Si-Fe alloys. J Mater Sci 25(5):2481–2486. https://doi.org/10.1007/BF00638046

Salaheldeen M, Garcia-Gomez A, Corte-León P, Gonzalez A, Ipatov M, Zhukova V, Zhukov A (2022) Manipulation of magnetic and structure properties of Ni2FeSi glass-coated microwires by annealing. https://doi.org/10.2139/ssrn.4174945

Hocine M, Guittoum A, Hemmous M, Martínez-Blanco D, Gorria P, Rahal B, Laggoun A (2017) The role of silicon on the microstructure and magnetic behaviour of nanostructured (Fe0.7Co0.3)100−xSix powders. J Magn Magn Mater 422:149–156. https://doi.org/10.1016/j.jmmm.2016.08.058

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical statement

The manuscript has not been submitted to more than one publication for simultaneous consideration. The submitted work is original and has not been published elsewhere in any form or language.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ouadah, M., Younes, A. Effects of silicon concentration on the magnetic and structural properties of nanostructured Fe-Si alloy synthesized by ball mill process. Int J Adv Manuf Technol 127, 3655–3663 (2023). https://doi.org/10.1007/s00170-023-11748-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11748-9