Abstract

The migration from Industry 4.0 to Industry 5.0 is becoming more relevant nowadays, with a consequent increase in interest in the operators’ wellness in their working environment. In modern industry, there are different activities that require the flexibility of human operators in performing different tasks, while some others can be performed by collaborative robots (cobots), which promote a fair division of the tasks among the resources in industrial applications. Initially, these robots were used to increase productivity, in particular in assembly systems; currently, new goals have been introduced, such as reducing operator’s fatigue, so that he/she can be more effective in the tasks that require his/her flexibility. For this purpose, a model that aims to realize a multi-objective optimization for task allocation is here proposed. It includes makespan minimization, but also the operator’s energy expenditure and average mental workload reduction. The first objective is to reach the required high productivity standards, while the latter is to realize a human-centered workplace, as required by the Industry 5.0 paradigms. A method for average mental workload evaluation in the entire assembly process and a new constraint, related to resources’ idleness, are here suggested, together with the evaluation of the methodology in a real case study. The results show that it is possible to combine all these elements finding a procedure to define the optimal task allocation that improves the performance of the systems, both for efficiency and for workers’ well-being.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Collaborative robots (cobots) are one of the technologies introduced in the last decade. They are having an interesting diffusion [1] due to the unique advantages they can provide. Among the benefits, this new type of robot can offer a combination between productivity, typical of automatic machines, and flexibility, typical of manual systems [2], that is very useful in assembly systems. Collaborative assembly systems may be helpful in improving production, thanks to their ability to adjust to a new design or to new volume of products [3]. In fact, they are not specialized for a single product variant, like traditional robots, but they can be easily adapted to different product characteristics. Moreover, cobots can work directly with human operators, without fences, sharing space and time with the workers, thus avoiding the introduction of additional safety measures, typical of industrial robots.

More recently, a further goal has been introduced, which is related to the wellness of the operators. This is in line with the current migration, from Industry 4.0 to Industry 5.0, which aims to propose a human-centered design of the workspace [4]. Industry 5.0 builds upon Industry 4.0 and emphasizes the importance of research and innovation in driving a transition to a sustainable, human-centered, and resilient industry. Rather than focusing solely on creating value for shareholders, Industry 5.0 aims to create benefits for all stakeholders involved. This approach recognizes the potential of new technologies to bring prosperity beyond just job creation and economic growth, prioritizing the well-being of workers in the production process [5]. For this purpose, different human factors, such as ergonomic level, mental workload, skills, and capabilities, should be considered in the design of a work cell, with the evaluation of their influence, as well as of the cobot one, on the system productivity [6].

The integration, in the same workspace, of these two different resources can influence the performance of the human operator, due to the fact that his/her perception of the cobot is reflected in his/her work [7]. In fact, the perception the operator has of the cobot can have a high impact, as stated by [8], in which more than half of the implementation made failed, from the point of view of integration and flexibility, due to the lack of consideration of the human factors [9].

In order to link together the aforementioned fields, i.e., productivity, flexibility, and human factors, a correct task allocation could be developed, with the aim to achieve all the results simultaneously. It is important to properly assign the tasks to the resources, i.e., a human operator and a cobot, in order to improve the collaboration, thereby reducing the idle times but also making the operator as comfortable as possible [10].

To achieve this result, a multi-objective task allocation for collaborative assembly systems is here proposed. The objective functions consider makespan (i.e., the total time required to complete all the tasks), for productivity, and the operator’s energy expenditure and average mental workload, as human factors, both included in the perspective of creating a human-centered workplace.

The here proposed task allocation offers a new approach to evaluate the average mental workload of the entire assembly process. In fact, it is typically evaluated on the individual task, and it is not considered how the level achieved affects the subsequent tasks.

Moreover, the task allocation provides a balance between the three objectives above mentioned, although it is more likely it limits the operator’s fatigue, both physical and mental. Since this may be too restrictive for makespan minimization, a constraint on the idle times of the resource, i.e., waiting times, is also introduced. Thereby, it promotes the saturation of the resources resulting in an improvement in productivity. In particular, it is possible to find which level of resources saturation is the optimal one to have an increment of productivity keeping the variation of the operator’s effort small. Of course, it is possible to choose the solution that best fits the needs.

Since cobot systems are still evolving, also safety has been taken into account, considering, for this reason, robots that have already integrated the safety requirements imposed by [11]. This allows not reduce the flexibility of the systems, avoiding the introduction of any additional device. The resolution of this task assignment problem can have a high practical implication on industrial systems.

The novelty of the proposed method is the integration of the traditional aspects of productivity with the aspects concerning the well-being of the operator, proposing also a practical method, through the definition of new objectives and constraints, to reach the required result.

The paper is organized as follows: Section 2 describes the state of the art for multi-objective task allocation for collaborative assembly systems; Section 3 is for the description of the objectives and for the problem statement; Section 4 presents a real case study with the proposed solution obtained through the application of the Pareto Frontier. From this, the analysis of the values of the objective functions is carried out with the introduction of the saturation constraint to enhance the solution, and, finally, Section 5 draws the conclusion of this work.

2 Literature review

Multi-objective optimization has huge importance in a lot of applications, especially due to the always-increasing necessity of reaching different goals at the same time [12]. In his work, the author underlined the difference between single and multi-objective analysis with a discussion of the main principles of the second one. Initially, the proposed solutions for multi-objective problems were the result of the transformation of the multiple objectives into a single one, because of the absence of proper solving techniques. On the other side, the introduction of getting Pareto optimal solutions allows for finding a set of optimums. Often some trade-offs are shown in order to make a better choice of the analyzed variables based on the results that have to be obtained.

Starting from this, different multi-objective algorithms have been developed to evaluate various problems, for example, task allocation in assembly lines. The state of the art on this topic is summarized in Table 1, which has been ordered according to the relevance of the studies, i.e., the number of citations per year (citations from Scopus, 28 December 2022).

One solution to minimize cycle time and operation alternations was proposed by [21], where a multi-objective algorithm was presented to support the collaboration between the operators with the aim of sharing their knowledge. In their work, the authors showed that, by placing less experienced operators alongside more experienced counterparts, resources were allocated more efficiently, resulting in an overall improvement in productivity.

Accordingly, Battini et al. [16] provided a multi-objective model based on energy expenditure in assembly line balancing problem (ALBP). With four different objective functions, which were time and energy smoothness and time and energy mini-max station quantity, they defined the optimal Pareto Frontier for both ergonomics and energy requirements.

In order to achieve a similar result, i.e., the minimization of cycle time, in [27] an assembly line balancing problem type 2 (ALBP-2) with the introduction of the minimization of the work-loading smoothness index as the second objective was proposed. The solution was obtained through a particle swam optimization algorithm (PSO) based on a back algorithm (BA) for the task allocation, considering tasks precedence and tasks placement as constraints.

A multi-objective optimization was presented also by [26], where, with a genetic algorithm (GA), Zaidi et al. proposed a multi-robot work cell. Working robots are of great use in assembly tasks in flexible manufacturing systems (FMSs); through the proposed solution, these smart systems were able to decide their trajectory individually.

Similarly, Suemitsu et al. [22] proposed a multi-objective layout design for multi-robot cellular manufacturing systems. In their optimization, the authors considered both the components position and the tasks scheduling, with the use of a genetic algorithm.

Moreover, multi-robot systems integrated into assembly stations were studied by [23], in which the robotic balancing assembly problem (R-ALBP) was investigated. They considered the optimal tasks assignment to related workstations and the allocation of robots in them, including also the cost of the capital to be invested.

Assignment problem and pick &place sequence were analyzed by [25] in order to optimize printed-circuit board assembly. The authors proposed a hierarchical multi-objective heuristic algorithm that allowed to obtain the complete and optimal solution in real-time.

Since this paper aims to propose a multi-objective task allocation for a collaborative robot work cell, it is useful to evaluate which solutions have been proposed so far for the integration of cobots. Starting from the robotic assembly line balancing problem (R-ALBP), different solutions that integrated collaborative robots can be found [33]. However, just a few of the solutions for the collaborative assembly line balancing problem (C-ALBP) are reported, since this paper focuses on the definition of a multi-objective task allocation method, more than on the resolution of the classical line balancing problem.

A new approach for collaborative task allocation can be found in [24]. The authors proposed a solution for the C-ALBP with the aim of minimizing the makespan. They focused on the definition of different indexes, i.e., collaboration, makespan, and parallelism parameters, in order to establish the importance of the process and product designs in collaborative systems.

Another solution for the collaborative assembly line problem was proposed by [18], where the authors used cobots in ALBP to determine a cost-efficient solution in assigning the resources (operators and cobots) to the stations, considering also ergonomics aspects. Their main result was the definition of a mathematical model for the problem that also demonstrated that collaborative robots are an inexpensive option for manual manufacturing.

Focusing on cycle times, a solution to optimize the balancing was offered by [32], in which the authors, through the definition of two algorithms, evaluated how to correctly assign the resources in a U-shaped line. They compared different types of cobots and they showed that, with the correct choice of them, it is possible both to reduce cycle times but also costs.

A multi-objective approach for the optimization of the efficiency and the cost of a collaborative cell was proposed by [19], where the authors proposed a bird optimization algorithm to obtain the Pareto Frontier. Their optimization included the evaluation of different cobots, based on the purchase costs, and the optimal solution was chosen through the definition of a new population selection that was updated on the basis of the fast non-dominated sorting approach, with a restart algorithm to find the solution in the Pareto Frontier.

A trade-off between productivity, physical workload, and the mental workload was studied by [31] in order to integrate a cobot in a manual workplace. A theoretical framework using the O*NET content model was realized to evaluate which tasks could be substituted by the robot. The authors found that the cobot introduction might not be always useful unless the correct trade-off was considered.

Galin et al. [29] primarily focused on enhancing efficiency in human-robot collaboration (HRC) by utilizing group control methods and algorithms to create a diverse team consisting of both cobots and human operators. The study established guiding principles for effectively assigning tasks in a collective setting, aimed at optimizing the performance of the team.

A balance between safety requirements, ergonomics, and productivity in collaborative systems was suggested by Cunha et al. [28], which presented a realization of human-robot task allocation to enhance work conditions and, at the same time, to maximize the collaboration between the resources. The authors came to the definition of a collaborative workstation based on ergonomic criteria that allowed to improve production thanks to the reduction of ergonomic risks.

A list of requirements to create a collaborative workstation was suggested by [20], in which also the division of tasks for each resource was specified. This separation was done considering ergonomic criteria, and in particular Musculoskeletal disorders (MSDs), an acknowledged occupation problem. Their framework suggested the use of questionnaires and observations to identify the characteristics of the workstation while through a multi-method approach, they pointed out the most critical risk factors.

Musculoskeletal disorders are discussed also by [30], where the authors proposed to switch from a manual assembly aystem to a collaborative one with the introduction of two robots. First of all, an analysis of the characteristics of the tasks was carried out to understand which resource best suited each task; secondly, a genetic algorithm was applied to minimize the assembly time, the use of a less capable resource, and also the ergonomic hazard.

The reported literature analysis shows that different approaches have been studied so far for task allocation in collaborative robot assembly systems. However, very few of them proposed multi-objective optimization including productivity and human factors. Then this paper aims to propose a multi-objective optimization model that includes productivity but also physical fatigue and mental workload. This would represent the first attempt of focusing more on the operator’s wellness in collaborative systems, going towards the realization of a human-centered design.

3 Multi-objective task allocation

In this section, the three objectives of the proposed task allocation method are explained: the makespan in Section 3.1, the energy expenditure in Section 3.2, and the mental workload in Section 3.3. Furthermore, Section 3.4 is for the formulation of the collaborative task allocation problem due to the presence of the two resources: a human operator and a collaborative robot.

3.1 Makespan

In a production system, the makespan is the total time required to complete all the tasks that have to be performed [34]. The makespan has a direct impact on the system productivity; its reduction implies an increment of pieces produced or assembled. Makespan is the basis of all scheduling problems [35]; in fact, its minimization allows companies to be more competitive in the market, requiring less time to provide their products.

The makespan is included as an objective function in this work through the variable ms, to guarantee the system throughput.

3.2 Energy expenditure

Since the current trend is to place the operator’s wellness at the center of the design of the workplace, also referring to the proposal of Industry 5.0 concepts, the second objective function considered is the operator’s energy expenditure.

Energy expenditure was first studied by Garg et al. [36], who proposed a new approach to evaluate the metabolic rate for manual jobs and walking movements. Their approach considered different human aspects, such as age, body weight, gender, height, and weight of the loads. Moreover, it is based on the decomposition of the total energy requirement into two parts: the energy required to maintain the posture and the energy required to perform the job. An application of this study for picking activities was made by [37].

The importance of the estimation of energy expenditure is based on the fact that it can be used as a parameter to evaluate the ergonomic risks [38,39,40] since it includes duration, level, and repetitiveness of body works that are all metrics to rate the stress caused by physical jobs [41]. Moreover, it is linked to heart rate, heart-rate variability, skin temperature, electromyographic activity, and jerk metrics.

Energy consumption is also linked to the discomfort that can lead to musculoskeletal disorders (MSDs) [42], which are still an occupation problem; indeed, for this reason, fatigue is also included in the NIOSH index [43].

The energy expenditure estimation is here considered as done by [38], where it was measured for each task that had to be performed: \(e_{jk}\) is the energy needed by the resource k to complete the task j, while E is the variable of the objective function.

3.3 Mental workload

The mental workload (MW) is another human factor that should be considered in the realization of a human-centered workplace [6]. Mental workload is defined as the combination of all the aspects (both cognitive and emotional) that are related to the complexity of the tasks, limited resources, and feelings during work. Mental dimension can be influenced by different factors, such as stressors, preconditions, perceptions, and affective state [44]. As for the ergonomic risk, also a high mental workload can influence both the productivity and the quality of work, affecting operators’ mood [45].

The current increase in the demand and the complexity of the mix of products has led to the development of an index, called CLAM (cognitive load assessment for manufacturing) [46], in order to help the designer in the assignment of the tasks to operators, keeping a reasonable level of mental stress.

This index considers different aspects:

-

saturation, that is for the balance of the tasks, i.e., it indicates how much of the time is occupied by performing tasks;

-

variant flora, that is defined starting from a product or process variation from the standard;

-

level of difficulty, that is an estimation of the effort required to complete a task;

-

production awareness, that is an indication of how much attention is required;

-

difficulty of tool use, including both the actual use complexity and the accessibility to the tools;

-

number of tools;

-

mapping, referring to the disposition of tools and items in the workstation;

-

parts identification, that is based on the approach used to identify the parts to pick;

-

information cost, that means how much burdensome is the use of the given information;

-

quality of instruction, that is based on the visibility of the instructions;

-

poke-a-yoke, that considers how many degrees of freedom are included that can cause errors.

Through the combination of these different factors, the CLAM index can be evaluated allowing an estimation of the mental workload for each task: \(mw_{jk}\) is the level of mental workload reached by the resource k to perform each task j, while MW is the variable of the objective function.

In Table 2 the ranges of the CLAM index with their respective meanings are shown.

3.4 Problem statement

3.4.1 Assumptions

The definition of the model starts from the resolution of a task allocation problem, leading to the assignment of tasks to different resources. The following assumptions are made:

-

the system realizes a product by performing J operations of the given product process, in a single-model station. This model could be a VAM (virtual average model);

-

each task is performed by only one resource at a time;

-

the assembly station includes two resources: one human operator and one cobot, i.e., \(K = 2\) (\(k=1\) for the operator, \(k=2\) for the cobot);

-

the collaborative resources share workplace and work time;

-

no particular background is required to the operator, nor social or technical background, level of education, etc.;

-

there are no technological constraints since the cobot is equipped to perform all the tasks.

The proposed method aims to offer a solution of a multi-objective task allocation through the use of the Pareto Frontier, which offers a set of non-dominated points [47]. Moreover, considering the Utopia Point, in which all the objectives have minimum values [48], the solution that will be proposed will be the one that has the minimum Euclidean distance from it. This means that the chosen solution minimizes Eq. 1, where the values of the objective functions are normalized through the difference between the maximum and the minimum values, where the latter are the values obtained with their correspondent single-objective optimization (\(ms^*\), \(E^*\), \(MW^*\) are the anchor points [49]).

All the objectives have equal importance, since these are all goals of Industry 5.0, as already described.

3.4.2 Model description

The output of the model consists of the assignment of the tasks to the operator and to the cobot, minimizing the three introduced objective functions. Then, the optimization variable \(x_{jk}\) is defined as follows:

Makespan, Eq. 3, is evaluated with the traditional formulation, [50]:

where \(G_{jk}\) represents the time in which task j performed by the resource k starts, and \(P_{jk}\) is the time required to complete task j (always performed by resource k).

The operator’s energy expenditure, Eq. 4, is evaluated as the sum of \(e_{jk}\), that is the energy required to perform each task j assigned to the human operator [36].

The energy requirement of each task is evaluated as described in Section 3.2.

It is possible to evaluate the average mental workload MW as in Eq. 5 that is the weighted average of the mental workload of each task, \(mw_{jk}\), on the time of execution of it, \(P_{jk}\), for all the tasks assigned to the operator. This choice has been made starting from the definition of the average mental workload, defined by [51], in order to consider the effect that time has on it. This approach can be useful since tasks that have the same \(mw_{jk}\) but are performed for different time durations can have a different effect on the mental workload.

The mental workload of each task is evaluated as described in Section 3.3 considering the ineffective workload as level zero.

3.4.3 Constraints

The three objective functions are subjected to:

Eq. 6 is for the occurrence constraint that along with the integrality constraint, Eq. 7, guarantees that, for each temporal instant, each task is performed by only one resource, and one resource can execute only one task.

Equations 8-9, derived from Patterson and Albracht model [52], are for precedence constraints, meaning that no task can be assigned, to one resource or to the other, before its predecessors.

The level of imposed precedence can be evaluated through the parallelism index [24], here recalled, that evaluates the number of tasks that can not be executed in parallel with the task j, for all tasks:

where \(n_j\) is the sum of the predecessors and successors of the task j.

Equation 10 is necessary to guarantee that the assumptions made in Section 3.4.1 are respected, i.e., both the operator and the cobot need to have at least one task assigned in order to consider the assembly station composed by more than one resource. Otherwise, the solutions will include also the cases in which all the tasks are assigned only to one resource.

In this model, another constraint about idle times is introduced, for considering the time in which one resource waits for the completion of a task performed by the other resource before it can start to execute the next task assigned to it. Equation 11, that can be called saturation constraint, imposes that the ratio between the total idle times for each resource, \(I_k\), and the makespan ms has to be less than a fixed value, \(I_{\max }\). This is introduced to promote in the solution the parallelization of tasks and the collaboration, or, even better, the cooperation [53], among the two resources.

3.4.4 Indexes

In order to better evaluate the results of the proposed method, different indexes, related to the process characteristics, are evaluated. These indexes are important, both from the perspective of the human-center design [2, 6] and from the perspective of system efficiency [7, 12].

-

makespan index \(m_\%\):

$$\begin{aligned} m_\% = \frac{ms}{\min \{ms\}_{d_{ut,\min }}} \end{aligned}$$(13)that is the ratio between the makespan of each other points of the Pareto set and the makespan of the one that has minimum distance from the Utopia Point.

-

energy index \(e_\%\):

$$\begin{aligned} e_\% = \frac{E}{\min \{E\}_{d_{ut,\min }}} \end{aligned}$$(14)that is the ratio between the energy expenditure of each other points of the Pareto set and the energy of the one that has minimum distance from the Utopia Point.

-

mental workload index \(mw_\%\):

$$\begin{aligned} mw_\% = \frac{MW}{\min \{MW\}_{d_{ut,\min }}} \end{aligned}$$(15)that is the ratio between the mental workload of each other points of the Pareto set and the mental workload of the one that has the minimum distance from the Utopia Point.

-

collaboration index \(c_\%\):

$$\begin{aligned} c_\%=\frac{T_{coll}}{ms} \end{aligned}$$(16)that is the ratio between the shared time \(T_{coll}\), i.e., the time in which both the resources are both performing a task, and the makespan [54].

4 Case study

In this section, the proposed multi-objective task allocation model is applied to the assembly process of a self-priming pump. This is made of a preassembly phase, a painting task, and a finishing phase, including cover refinement, quality, and packaging. The analysis is here focused on the preassembly in which most of the entire assembly is realized.

The assembly process is composed of \(\textit{J}= 27\) tasks, whose precedence diagram is shown in Fig. 1.

For this application, the parallelism index, Eq. 12, is \(p_\% = 25.6\%\). Moreover, the operator’s task times and task energy expenditures are derived from [38]. In particular, the times are derived with the chronometric method developed by Bedaux [55], which is based on the principle of breaking down a task into smaller, more manageable task components and assigning a predetermined score to each component, based on its level of difficulty. These scores are then added up to determine the score required to complete the task. The cobot is a KUKA LBR iiwa 14 R820, which task times are derived from [2], in which experimental tests showed that typically, a cobot takes twice as long to complete compared to tasks performed by human operators. Its energy expenditure and mental workload are obviously imposed equal to zero.

Table 3 contains, for each task, the operator’s execution times \(P_{op}\), the cobot execution times \(P_c\), the operator’s energy expenditures \(e_{j1}\), and the operator’s mental workloads \(mw_{j1}\).

4.1 Single human resource

The first analysis carried out is the evaluation of the values of the objective functions for a system that has only the human operator as resource, whit all the tasks assigned to him/her. These are reported in Table 4, where it is possible to see that the makespan ms is equal to \(10.77\ min\), while the energy expenditure E assumes the value of \(33.97\ kcal\), and the average mental workload is equal to \(MW=1.70\).

Starting from this result, in the following, we investigate how the introduction of a collaborative robot in the work area can improve the working sustainability of the operator, in line with the principles of Industry 5.0.

4.2 Optimal solutions through Pareto Frontier

The first analysis concerned the single objective optimization of the three objective functions, without the saturation constraint, in order to have the whole solutions set; i.e., \(I_{\max }=100\%\). The results are shown in Table 5, reporting the value of the single objective optimization (single O.F.), i.e., \(ms^*\), \(E^*\), and \(MW^*\), with the correspondent task allocation. Each row reports the value of the optimized objective (bold values), with also the values of the other two objective functions calculated with that specific task sequence and the saturation level of the resources.

As can be seen, there is no balancing in the assignment of the tasks to the resources and the minimization of a single objective function leads to a deep worsening of the other two objectives. Moreover, these scenarios are not realistic, and they can not be applied in an industrial application. Then a multi-objective optimization is preferable.

The application of the proposed multi-objective optimization approach has led to the Pareto Frontier shown in Fig. 2. In the figure, makespan is on x-axis, energy expenditure is on y-axis, and average mental workload is on z-axis.

The computer used to solve the model is a DELL-ALIENWARE R11, with Intel Core i7–10700KF CPU 3.80GHz and 32 GB of RAM; the algorithm used to solve the optimization is “gamultiobj” in MATLAB (Mathworks) environment. This is a genetic algorithm based on the evolutionary multi-objective optimization (EMO), [56] and it has required about 19.3 h for the result.

The total set of points consists of 251 points: the configuration that offers the minimum distance from the Utopia point is circled in red in Fig. 2, and reported in Table 6, together with the corresponding task allocation.

Figure 3 shows the overall timeshare, with the tasks and their execution times. The orange bar is for the operator (OP), the green bar is for the cobot (C) tasks with the green bar, and the blue bar (collab) shows the amount of established collaboration.

Comparing the results reported in the two Tables 5 and 6, it is possible to see that with the multi-objective optimization the makespan increases by 39% with respect to the single makespan optimization, while the energy expenditure and the average mental workload decrease, respectively, by 54% and 40%, still considering ms optimization. Compared to the energy expenditure single minimization, the multi-objective optimization allows a decrease in the makespan by 35%, while the energy expenditure increases by 6600%, and the average mental workload increases by 22600%. As far as the comparison with the mental workload single minimization is concerned, the multi-objective optimization leads to a decrease of the makespan by about 55%, while energy grows by 1212% and mental workload increases by 32600%. As it can be seen in the tasks assignment of Table 6, these heavy increases in energy expenditure and mental workload are due to the fact that the multi-objective solution assigns more tasks to the operator, anyhow proposing a more balanced solution.

Subsequently, the indexes presented in Section 3.4.4 are here analyzed. The trend of the makespan index \(m_\%\), based on the distance from Utopia point, is reported in Fig. 4a.

Since the point that has minimum distance from the Utopia one is quite in the middle of the Pareto Frontier, as it is possible to see from Fig. 2, this index has a double trend as the distance increases. However, its slope of growth (blue line in Fig. 4a), moving away from utopia, is greater than the one of decrease (orange line in Fig. 4a).

This is also confirmed by the double trend of the energy expenditure index, \(e_\%\), and by the mental workload index, \(mw_\%\), represented in Fig. 4b and c respectively. As for \(m_\%\), their slope is higher in case of increase (orange lines) than in case of decrease (blue lines). It is important to underline that in correspondence with an increase in the makespan there is a decrease in energy expenditure and mental workload and vice versa. Then, the trends of the three indexes are related, i.e., the rate of growth of ms is related to the rate of decrease of E and of MW and conversely.

The collaboration index \(c_\%\) is shown in Fig. 4d. It presents the same trend of the energy expenditure and mental workload indexes since it is related to the makespan. In fact, it increases with the decrement of ms since, in order to have a smaller makespan, it is necessary to increase the tasks parallelization, resulting in an increment of the collaboration time.

4.3 Sensitivity analysis

This section is for the analysis of the objective functions by varying the maximum percentage of idle times, i.e., changing \(I_{\max }\) (Eq. 11). This is strictly linked to the resources’ saturation, as follows:

Here, it is advisable to introduce the saturation constraint, Eq. 11, since the multi-objective solution, obtained as the one that has minimum distance from the Utopia point, tends to assign more tasks to the cobot, as it is possible to see from Fig. 3, in order to reduce the energy and the mental workload values. This solution assigned 18 tasks to the cobot and only 9 to the operator, with a low amount of collaboration equal to the 23.27% of ms. The solution promotes the operator’s idleness, despite the makespan: the operator’s saturation \(S_{OP}\), in fact, is 31.92%, while cobot saturation \(S_C\) is 91.35%. By fixing a stricter idle time limit, it is possible to better saturate both resources, obviously keeping the heaviest tasks assigned to the cobot.

Table 7 reports how the objective functions change by increasing the saturation of both resources. In particular, it shows the level of \(I_{\max }\) imposed, the makespan ms, and its difference \(\Delta _{ms}\) with respect to the value obtained with \(I_{\max }=100\%\). Similarly, E and \(\Delta _E\) are for the operator’s energy expenditure, while MW and \(\Delta _{MW}\) are for his/her average mental workload. The values reported are until \(I_{\max } = 36 \%\) since for smaller values there are no solutions in the Pareto set, because of the level of precedence imposed.

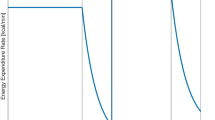

The decrement of \(I_{\max }\) has an opposite influence on ms with respect to E and to MW, as shown in Figs. 5a, 6a, 7a: the first objective decreases of about 20% from \(I_{\max }=100\%\) to \(I_{\max } = 36\%\), while the second one increases of 69% and the third one of 140%. These trends are reported, respectively, in Figs. 5b, 6b, 7b.

Figure 8a and b show the level of saturation of the operator and of the cobot. For the operator, there is a maximum increment of 32.82%, while for the cobot a maximum decrement of 26.61%.

From this analysis, it is possible to conclude that both the energy and the mental workload are widely affected by the increase of the saturation of the resources, while the makespan presents a smaller variation, although opposed.

4.3.1 Choice of the saturation level

Since the energy expenditure and the mental workload present opposed trends with respect to the makespan, it is interesting to evaluate until which value of \(I_{\max }\) it is actually convenient to increasingly saturate the resources. Here, convenience is meant as finding the range in which there is a high makespan decrease while keeping the energy and the mental workload increments small. In order to find this interval, the following procedure can be followed: after the evaluation of the solutions obtained with different levels of the imposed saturation constraint, the values that the objective functions assume are analyzed, always considering the best solution as the one that has the minimum distance from the Utopia point. Later, the difference between the values obtained with \(I_{\max }=100\%\) and the ones just obtained is analyzed, getting the \(\Delta \)(s) shown in Table 7. These differences represent how significant the changes are in the corresponding objective functions. In order to achieve the best task allocation, it is required to increase a lot \(\Delta _{ms}\) while keeping small (in absolute values) the others: in this way in correspondence with a remarkable decrease of the makespan, there are low increments of the energy expenditure and of the average mental workload. For this purpose, the ratios between the before explained \(\Delta \)(s) are evaluated. In particular, the ratios analyzed are reported in (18) and (19), where the absolute values of \(\Delta _E\) and of \(\Delta _{MW}\) are taken for better understanding, while Figs. 9 and 10 show their trends as a function of the maximum idle times percentage (excluding the ratios equal to zero).

From the data, it is possible to notice that the optimal range in which the makespan decreases remarkably with a small increment of energy is with \(I_{\max }\) between 45% and 50%, while before and after this interval a big variation of the makespan is associated to a big variation of the energy. For the mental workload, the range is exactly the same.

Thanks to the interpolations (with an \(R^2\simeq 90\%\)), it is possible to find two curves that have a maximum in correspondence of \(I_{\max }^*\simeq 46\%\) (Fig. 9) and of \(I_{\max }^*\simeq 47\%\) (Fig. 10), with which the ratios obtained are:

It is important to underline that in these points, we have the maximum makespan decrease with the minimum energy and mental workload increments.

The value of the Pareto Frontier that is the nearest to these maxima corresponds to \(\Delta _{ms} =1.84\ min \), to \(\Delta _E = -6.04\ kcal\), and to \(\Delta _{MW}=-0.65\) that means that the makespan obtained is \(ms=12.04\ min\) and the energy expenditure is \(E=18.11\ kcal\), with also an average mental workload limited and equal to \(MW=1.59\) that is in the “very low” range of Table 2. The corresponding task allocation is shown in Fig. 11, where the saturation of the operator is \(S_{OP}=53.57\%\) and the cobot one is \(S_C=71.76\%\). Therefore, this solution also promotes collaboration, which increases by about 2%, leading, as demonstrated before, to a decrease in the time required to complete the process.

Basically, it can be concluded that, aiming at reducing makespan and contemporary ensuring that the effort required by the operator is not too demanding, this range can be considered as the optimal one. Moreover, between these values of \(I_{\max }\), the levels of both the energy expenditure and the average mental workload are acceptable.

5 Conclusions

The principles introduced by Industry 5.0 are nowadays leading to the current trends in the design of workplaces, putting the attention on operators’ needs, but also including the need for standards of flexibility and productivity highlighted by Industry 4.0. In this direction, the proposed work fits in the very current trend related to the human-centered design of workplaces, which is one of the principles of Industry 5.0. In particular, Industry 5.0 builds upon Industry 4.0 and emphasizes the importance of research and innovation in driving a transition to a sustainable, human-centered, and resilient industry. This approach recognizes the potential of new technologies, such as collaborative robots, to bring prosperity beyond just job creation and economic growth, prioritizing the well-being of workers in the production process [5].

However, up to now, the contributions related to the solution of task allocation problems mainly focus on the consideration of only one human factor or on the balancing of more human factors, but not in collaborative cells, resulting that multi-objective approaches, to realize a human-centered design including cobot systems, do not exist.

As a result of this gap, a new method for multi-objective task allocation problems for collaborative assembly systems is here presented, with the aim to minimize three objective functions, i.e., makespan for productivity, operator’s energy expenditure, and average mental workload for wellness. Unlike makespan and energy expenditure, for which how to evaluate them in an entire assembly process is well established [34, 37], for the mental workload such an assessment is still under development. Therefore, the first novelty of this work is the proposal to evaluate it overall and not task by task.

The second novelty deals with the introduction of a constraint that promotes the saturation of the resources, called saturation constraint. This is needed since the proposed formulation has the tendency to assign more tasks to the cobot, in order to minimize the operator’s effort, but with a worsening of the makespan. By varying the maximum level of the idle times of the resources, it is possible to obtain a better balance of tasks division, naturally continuing to assign the burdensome ones for energy and mental workload to the cobot.

The application of the model to a real case study, through the evaluation of the Pareto Frontier and the proposal of the best solution as the one that has minimum distance from the Utopia Point, has led to the analysis of the above-mentioned saturation of the resources and of its impact on the outcome of the model. The third novelty here presented is related to the actual level of idleness that has to be imposed; it is here suggested to consider the one that offers the maximum decrease of the makespan, keeping the lowest increase of energy expenditure and mental workload, with respect to the solution without the saturation constraint. In this way, it is possible to have the best trade-off between the objective functions, while also promoting a reduction of idle times.

Considered as a whole, the proposed methodology represents an interesting contribution to the field of study and design of human-centered collaborative systems. By prioritizing the well-being of workers and creating a positive work environment that supports employee satisfaction and retention, companies can enjoy a range of benefits that go beyond simple efficiency improvement.

Among the others, there are two important questions that we want to propose as possible future developments. These are related to the introduction of stochastic values for the objective functions which have been for now considered

deterministic, and the application of this model with a dynamic perspective. For the first point, this variability can be introduced to better reflect the fact that the amounts of time, energy expenditures, and mental workload are not always the same, even in the same activities. Moreover, this extension would be useful also to consider the differences among workers and how these can impact the productivity of the system [57]. For the second one, this model can be the starting point to define the assignment of tasks also in real-time, considering the operators’ needs, and their changes over time, during the execution of the tasks and/or at different moments of the day. Real collaboration is an evolving relationship, and thus a task allocation decision, that will be developed online and dynamically, is the next step that will be pursued.

Moreover, more case studies could be analyzed in order to consolidate the method, derive guidelines and insights from their results, and better compare the provided advantages in the field, including the definition of which are the best potential application settings.

6 Nomenclature

- \(\text {j}\):

-

Task index \(j = 1,...,J\)

- \(\text {J}\):

-

Number of tasks

- \(\text {k}\):

-

Resource index \(k=1,...,K\)

- \(\text {K}\):

-

Number of resources

- ms:

-

Makespan [min]

- \(e_{jk}\):

-

Energy expenditure of task j for resource k [kcal]

- E:

-

Operator’s energy expenditure [kcal]

- \(mw_{jk}\):

-

Mental workload of task j for resource k

- MW:

-

Operator’s average mental workload

- \(ms^*\):

-

Single objective makespan [min]

- \(E^*\):

-

Single objective energy expenditure [kcal]

- \(MW^*\):

-

Single objective average mental workload

- \(ms_{max}\):

-

Maximum makespan [min]

- \(E_{max}\):

-

Maximum energy expenditure [kcal]

- \(MW_{max}\):

-

Maximum average mental workload

- \(d_{ut}\):

-

Distance from Utopia Point

- \(x_{jk}\):

-

Task allocation decision variable [binary]

- \(G_{jk}\):

-

Start time of task j for resource k [min]

- \(P_{jk}\):

-

Time of task j for resource k [min]

- t:

-

Temporal instant [s]

- T:

-

Temporal horizon [s]

- \(E_p\):

-

Set of predecessors of task p

- \(L_p\):

-

Set of successors of task p

- \(I_{k}\):

-

Idle times of the resource k [min]

- \(p_\%\):

-

Parallelism index

- \(n_j\):

-

Sum of the predecessors and successors of the task j

- \(I_{max}\):

-

Maximum percentage of idle times [%]

- \(m_\%\):

-

Makespan index

- \(e_\%\):

-

Energy index

- \(mw_\%\):

-

Mental workload index

- \(c_\%\):

-

Collaboration index

- \(T_{coll}\):

-

Collaboration time [s]

- \(S_k\):

-

Saturation of resource k [%]

- \(ms_{I_{max}=100\%}\):

-

Makespan with \(I_{max}=100\%\) [min]

- \(E_{I_{max}=100\%}\):

-

Energy expenditure with \(_{max}=100\%\) [kcal]

- \(MW_{I_{max}=100\%}\):

-

Average mental workload with \(I_{max}=100\%\)

- \(\Delta _{ms}\):

-

Difference between \(ms_{I_{max}=100\%}\) and ms [min]

- \(\Delta _{E}\):

-

Difference between \(E_{I_{max}=100\%}\) and E [kcal]

- \(\Delta _{MW}\):

-

Difference between \(MW_{I_{max}=100\%}\) and MW

- \(I_{max}^*\):

-

Optimal maximum percentage of idle times [%]

References

of Robotics IF (2020) Ifr press conference. https://ifr.org/downloads/press2018/Presentation_WR_2020.pdf

Faccio M, Bottin M, Rosati G (2019) Collaborative and traditional robotic assembly: a comparison model. Int J Adv Manuf Technol 102(5):1355–1372

Takata S, Hirano T (2011) Human and robot allocation method for hybrid assembly systems. CIRP Ann 60(1):9–12

Romero D, Stahre J (2021) Towards the resilient operator 5.0: The future of work in smart resilient manufacturing systems. Procedia CIRP 104:1089–1094

Commission E, for Research DG, Innovation, Breque M, De Nul L, Petridis A (2021) Industry 5.0 : towards a sustainable, human-centric and resilient european industry. Publications Office https://doi.org/10.2777/308407

Faccio M, Granata I, Menini A, Milanese M, Rossato C, Bottin M, Minto R, Pluchino P, Gamberini L, Boschetti G, Rosati G (2022) Human factors in cobot era: a review of modern production systems features. J Intell Manuf. https://doi.org/10.1007/s10845-022-01953-w

Fletcher SR, Johnson T, Adlon T, Larreina J, Casla P, Parigot L, Alfaro PJ, del Mar Otero M (2020) Adaptive automation assembly: Identifying system requirements for technical efficiency and worker satisfaction. Comput Ind Eng 139:105772

Chung CA (1996) Human issues influencing the successful implementation of advanced manufacturing technology. J Eng Technol Manag 13(3–4):283–299

Ghani KA, Jayabalan V (2000) Advanced manufacturing technology and planned organizational change. J High Technol Manag Res 11(1):1–18

Kulic D, Croft E (2005) Anxiety detection during human-robot interaction. IEEE, pp 616–621

ISO/TS 15066:2016, Robots and Robotic Devices - “Collaborative Robots”. International Organization for Standardization (2016)

Deb K (2014) Multi-objective optimization. In: Search Methodologies: Introductory Tutorials in Optimization and Decision Support Techniques, Springer US, Boston, MA, pp 403–449, https://doi.org/10.1007/978-1-4614-6940-7_15

Liu H, Wang L (2018) Gesture recognition for human-robot collaboration: A review. Int J Ind Ergon 68:355–367

Ranz F, Hummel V, Sihn W (2017) Capability-based task allocation in human-robot collaboration. Procedia Manuf 9:182–189

Pearce M, Mutlu B, Shah J, Radwin R (2018) Optimizing makespan and ergonomics in integrating collaborative robots into manufacturing processes. IEEE Trans Autom Sci Eng 15(4):1772–1784

Battini D, Delorme X, Dolgui A, Persona A, Sgarbossa F (2016) Ergonomics in assembly line balancing based on energy expenditure: a multi-objective model. Int J Prod Res 54(3):824–845

Tsarouchi P, Matthaiakis AS, Makris S, Chryssolouris G (2017) On a human-robot collaboration in an assembly cell. Int J Comput Integr Manuf 30(6):580–589

Weckenborg C, Spengler TS (2019) Assembly line balancing with collaborative robots under consideration of ergonomics: a cost-oriented approach. IFAC-PapersOnLine 52(13):1860–1865

Li Z, Janardhanan MN, Tang Q (2021) Multi-objective migrating bird optimization algorithm for cost-oriented assembly line balancing problem with collaborative robots. Neural Comput Appl 33(14):8575–8596

Colim A, Faria C, Braga AC, Sousa N, Rocha L, Carneiro P, Costa N, Arezes P (2020) Towards an ergonomic assessment framework for industrial assembly workstations–a case study. Appl Sci 10(9):3048

Tang Q, Meng K, Cheng L, Zhang Z (2022) An improved multi-objective multifactorial evolutionary algorithm for assembly line balancing problem considering regular production and preventive maintenance scenarios. Swarm Evol Comput 68:101021

Suemitsu I, Izui K, Yamada T, Nishiwaki S, Noda A, Nagatani T (2016) Simultaneous optimization of layout and task schedule for robotic cellular manufacturing systems. Comput Ind Eng 102:396–407

Çil ZA, Mete S, Ağpak K (2016) A goal programming approach for robotic assembly line balancing problem. IFAC-PapersOnLine 49(12):938–942

Boschetti G, Faccio M, Milanese M, Minto R (2021) C-alb (collaborative assembly line balancing): a new approach in cobot solutions. Int J Adv Manuf Technol 116(9):3027–3042

Gao H, Li Z, Yu X, Qiu J (2021) Hierarchical multiobjective heuristic for pcb assembly optimization in a beam-head surface mounter. IEEE Trans Cyberne 52(7):6911–6924

Zaidi L, Bettayeb B, Sahnoun M (2021) Optimisation and simulation of transportation tasks in flexible job shop with muti-robot systems. In: 2021 1st International Conference On Cyber Management And Engineering (CyMaEn). IEEE, pp 1–6

Xu L, Cai B, Qu B, LI A (2016) Assembly line balancing problem-2 with task zoning constraints and workstation related constraints. J Tongji Univ (Nat Sci) 44(2):269–275

Cunha JG, Faria C, Colim A, Oliveira J, Rocha LA, Silva M, Monteiro S, Bicho E (2021) From handcrafting to a certified and ergonomic collaborative workstation: the digital transformation process. In: 2021 IEEE International Conference on Intelligence and Safety for Robotics (ISR). IEEE, pp 363–366

Galin R, Mamchenko M, Meshcheryakov R (2022) Analysis of the allocation and implementation of tasks in the heterogeneous team of the collaborative robotic system. In: Ronzhin A, Shishlakov V (eds) Electromechanics and Robotics. Springer Singapore, Singapore, pp 109–119

Liau YY, Ryu K (2022) Genetic algorithm-based task allocation in multiple modes of human-robot collaboration systems with two cobots. Int J Adv Manuf Technol 119(1):1–19

Liu L, Schoen AJ, Henrichs C, Li J, Mutlu B, Radwin RG, Zhang Y (2022) Human robot collaboration for enhancing work activities. Human Factors 00187208221077722

Li Z, Janardhanan M, Tang Q, Zhang Z (2022) Models and algorithms for u-shaped assembly line balancing problem with collaborative robots. Soft Comput 27:9639–9659

Chutima P (2022) A comprehensive review of robotic assembly line balancing problem. J Intell Manuf 33(1):1–34

Tayali HA (2021) Manufacturing scheduling strategy for digital enterprise transformation. Emerging Challenges, Solutions, and Best Practices for Digital Enterprise Transformation. IGI Global, Hershey, Pennsylvania, USA, pp 104–119

Pinedo M, Hadavi K (1992) Scheduling: Theory, algorithms and systems development. In: Gaul W, Bachem A, Habenicht W, Runge W, Stahl WW (eds) Operations Research Proceedings 1991. Springer Berlin Heidelberg, Berlin, Heidelberg, pp 35–42

Garg A, Chaffin DB, Herrin GD (1978) Prediction of metabolic rates for manual materials handling jobs. Am Ind Hyg Assoc J 39(8):661–674

Calzavara M, Glock CH, Grosse EH, Persona A, Sgarbossa F (2017) Analysis of economic and ergonomic performance measures of different rack layouts in an order picking warehouse. Comput Ind Eng 111:527–536

Battini D, Calzavara M, Otto A, Sgarbossa F (2017) Preventing ergonomic risks with integrated planning on assembly line balancing and parts feeding. Int J Prod Res 55(24):7452–7472

Stecke KE, Mokhtarzadeh M (2022) Balancing collaborative human-robot assembly lines to optimise cycle time and ergonomic risk. Int J Prod Res 60(1):25–47

Granata I, Faccio M, Calzavara M (2023) Energy expenditure and makespan multi-objective optimization for cobots systems design. Procedia Comput Sci 217:126–135

Anwer S, Li H, Antwi-Afari MF, Umer W, Wong AYL (2021) Evaluation of physiological metrics as real-time measurement of physical fatigue in construction workers: State-of-the-art review. J Constr Eng Manag 147(5)

Gonsalves NJ, Ogunseiju OO, Akanmu AA, Nnaji CA (2021) Assessment of a passive wearable robot for reducing low back disorders during rebar work. J Inf Technol Constr 26:936–952

Waters TR, Putz-Anderson V, Garg A, Fine LJ (1993) Revised niosh equation for the design and evaluation of manual lifting tasks. Ergonomics 36(7):749–776

Rosen PH, Sommer S, Wischniwski S (2018) Evaluation of human-robot interaction quality: A toolkit for workplace design. In: Congress of the international ergonomics association. Springer, pp 1649–1662

Van Acker BB, Parmentier DD, Vlerick P, Saldien J (2018) Understanding mental workload: from a clarifying concept analysis toward an implementable framework. Cogn Technol Work 20(3):351–365

Thorvald P, Lindblom J, Andreasson R (2019) On the development of a method for cognitive load assessment in manufacturing. Robot Comput-Integr Manuf 59:252–266

Messac A, Ismail-Yahaya A, Mattson CA (2003) The normalized normal constraint method for generating the pareto frontier. Structur Multidiscip Optim 25(2):86–98

Gunantara N (2018) A review of multi-objective optimization: Methods and its applications. Cogent Eng 5(1):1502242

Kinast A, Braune R, Doerner KF, Rinderle-Ma S, Weckenborg C (2022) A hybrid metaheuristic solution approach for the cobot assignment and job shop scheduling problem. J Ind Inf Integr 28:100350

Chang HC, Chen YP, Liu TK, Chou JH (2015) Solving the flexible job shop scheduling problem with makespan optimization by using a hybrid taguchi-genetic algorithm. IEEE Access 3:1740–1754

Xie B, Salvendy G (2000) Review and reappraisal of modelling and predicting mental workload in single-and multi-task environments. Work Stress 14(1):74–99

Scholl A, Scholl A (1999) Balancing and sequencing of assembly lines

Müller R, Vette M, Geenen A (2017) Skill-based dynamic task allocation in human-robot-cooperation with the example of welding application. Procedia Manuf 11:13–21

Faccio M, Minto R, Rosati G, Bottin M (2020) The influence of the product characteristics on human-robot collaboration: a model for the performance of collaborative robotic assembly. Int J Adv Manuf Technol 106(5):2317–2331

Zandin KB (2001) Maynard’s industrial engineering handbook. McGraw-Hill Education

Deb K (2011) Multi-objective optimisation using evolutionary algorithms: An introduction. In: Multi-objective Evolutionary Optimisation for Product Design and Manufacturing. Springer London, London, pp 3–34, https://doi.org/10.1007/978-0-85729-652-8_1

Katiraee N, Calzavara M, Finco S, Battini D, Battaïa O (2021) Consideration of workers’ differences in production systems modelling and design: State of the art and directions for future research. Int J Prod Res 59(11):3237–3268

Funding

Open access funding provided by Università degli Studi di Padova within the CRUI-CARE Agreement. This study was carried out within the PNRR research activities of the consortium iNEST (Interconnected North-Est Innovation Ecosystem) funded by the European Union Next-GenerationEU (Piano Nazionale di Ripresa e Resilienza (PNRR) - Missione 4 Componente 2, Investimento 1.5 - D.D. 1058 23/06/2022, ECS_00000043). This manuscript reflects only the Authors’ views and opinions, neither the European Union nor the European Commission can be considered responsible for them.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Calzavara, M., Faccio, M. & Granata, I. Multi-objective task allocation for collaborative robot systems with an Industry 5.0 human-centered perspective. Int J Adv Manuf Technol 128, 297–314 (2023). https://doi.org/10.1007/s00170-023-11673-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11673-x