Abstract

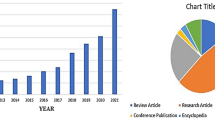

Wire arc additive manufacturing (WAAM) is an emerging technology for metal processing that offers many advantages for aerospace-grade production. It provides significant design complexity and freedom offering very fast material deposition rates and relatively good material properties. It is also based on simple hardware and materials and is easy to apply in the field, making it an ideal tool for the aerospace industry. This article reviewed the major application sectors in the aerospace industry where WAAM has been successfully used with some examples, some of the aerospace-relevant modeling and simulation work for WAAM that has been done, and the current status of the significantly used WAAM materials of interest to the aerospace industry (particularly, aluminum, titanium, and nickel alloys). It was found that the most important benefits offered by WAAM to the aerospace industry were its very fast material deposition rate, its flexibility and simplicity, and its ability to process aluminum alloys much more effectively than most other AM processes. There are still areas to be explored before WAAM could be fully integrated into the aerospace design and manufacturing system, but it is well on its way and promises to be an essential technology in the future.

Similar content being viewed by others

Availability of data and materials

The raw data is available upon reasonable request from the corresponding author.

References

Williams SW, Martina F, Addison AC, Ding J, Pardal G, Colegrove P (2016) Wire + arc additive manufacturing. Mater Sci Mater Med 32(7):641–647

Li JZ, Alkahari MR, Rosli NAB, Hasan R, Sudin MN, Ramli FR (2019) Review of wire arc additive manufacturing for 3d metal printing. Int J Autom Technol 13(3):346–353

Baier D, Bachmann A, Zaeh MF (2020) Towards wire and arc additive manufacturing of high-quality parts. Procedia CIRP 95:54–59

Ding D, Pan Z, van Duin S, Li H, Shen C (2016) Fabricating superior NiAl bronze components through wire arc additive manufacturing. Materials 9(8):652

Ding DH, Pan ZX, Dominic C, Li HJ (2015) Process planning strategy for wire and arc additive manufacturing. In: Advances in Intelligent Systems and Computing. Springer International Publishing, pp 437–450

Ding D, Pan Z, Cuiuri D, Li H, van Duin S, Larkin N (2016) Bead modelling and implementation of adaptive MAT path in wire and arc additive manufacturing. Robot Comput-Integr Manuf 39:32–42

Ding D, Pan Z, Cuiuri D, Li H (2014) A tool-path generation strategy for wire and arc additive manufacturing. Int J Adv Manuf Technol 73(1–4):173–183

Chen J (2012) Hybrid design based on wire and arc additive manufacturing in the aircraft industry. Master’s thesis, Cranfield University, UK

Dhinakaran V, Stalin B, Ravichandran M, Balasubramanian M, Chairman CA, Pritima D (2020) Wire arc additive manufacturing perspectives and recent developments. IOP Conf Ser Mater Sci Eng 988(1):012102

Alonso U, Veiga F, Suárez A, Artaza T (2019) Experimental investigation of the influence of wire arc additive manufacturing on the machinability of titanium parts. Metals 10(1):24

Veiga F, Val AGD, Suárez A, Alonso U (2020) Analysis of the machining process of titanium ti6al-4v parts manufactured by wire arc additive manufacturing (WAAM). Materials 13(3):766

Xu F, Dhokia V, Colegrove P, McAndrew A, Williams S, Henstridge A, Newman ST (2018) Realisation of a multi-sensor framework for process monitoring of the wire arc additive manufacturing in producing ti-6al-4v parts. Int J Comput Integr Manuf 31(8):785–798

Vimal K, Srinivas MN, Rajak S (2021) Wire arc additive manufacturing of aluminium alloys: a review. Mater Today Proc 41:1139–1145

Rodrigues TA, Duarte V, Miranda R, Santos TG, Oliveira J (2019) Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 12(7):1121

Ding D, Pan Z, Cuiuri D, Li H (2015) Wire-feed additive manufacturing of metal components: technologies, developments and future interests. The Int J Adv Manuf Technol 81(1–4):465-481

Tripathi U, Saini N, Mulik RS, Mahapatra MM (2022) Effect of build direction on the microstructure evolution and their mechanical properties using GTAW based wire arc additive manufacturing. CIRP J Manuf Sci Technol 37:103–109

Rosli NA, Alkahari MR, bin Abdollah MF, Maidin S, Ramli FR, Herawan SG (2021) Review on effect of heat input for wire arc additive manufacturing process. J Mater Res Technol 11:2127–2145

Ding D, Pan Z, Cuiuri D, Li H (2015a) Process planning for robotic wire and arc additive manufacturing. In: 2015 IEEE 10th Conference on Industrial Electronics and Applications (ICIEA). IEEE

Ding D, Pan Z, Cuiuri D, Li H (2015) A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot Comput-Integr Manuf 31:101–110

Lockett H, Ding J, Williams S, Martina F (2017) Design for wire + arc additive manufacture: design rules and build orientation selection. J Eng Des 28(7–9):568–598

Reisch R, Hauser T, Kamps T, Knoll A (2020) Robot based wire arc additive manufacturing system with context-sensitive multivariate monitoring framework. Procedia Manufacturing 51:732–739

Wu B, Pan Z, van Duin S, Li H (2019) Thermal behavior in wire arc additive manufacturing: characteristics, effects and control. In: Transactions on Intelligent Welding Manufacturing. Springer Singapore, pp 3–18

Jin W, Zhang C, Jin S, Tian Y, Wellmann D, Liu W (2020) Wire arc additive manufacturing of stainless steels: a review. Appl Sci 10(5):1563

Bermingham M, Nicastro L, Kent D, Chen Y, Dargusch M (2018) Optimising the mechanical properties of ti-6al-4v components produced by wire + arc additive manufacturing with post-process heat treatments. J Alloys Compd 753:247–255

Martina F, Roy MJ, Szost BA, Terzi S, Colegrove PA, Williams SW, Withers PJ, Meyer J, Hofmann M (2016) Residual stress of as-deposited and rolled wire + arc additive manufacturing ti-6al-4v components. Mater Sci Technol 32(14):1439–1448

Henckell P, Günther K, Ali Y, Bergmann JP, Scholz J, Forêt P (2017) The influence of gas cooling in context of wire arc additive manufacturing—a novel strategy of affecting grain structure and size. In: The Minerals, Metals & Materials Series. Springer International Publishing, pp 147–156

Lin Z, Goulas C, Ya W, Hermans MJ (2019) Microstructure and mechanical properties of medium carbon steel deposits obtained via wire and arc additive manufacturing using metal-cored wire. Metals 9(6):673

Veiga F, Suárez A, Artaza T, Aldalur E (2022) Effect of the heat input on wire-arc additive manufacturing of invar 36 alloy: microstructure and mechanical properties. Weld World 66(6):1081–1091

Li F, Chen S, Shi J, Tian H, Zhao Y (2017) Evaluation and optimization of a hybrid manufacturing process combining wire arc additive manufacturing with milling for the fabrication of stiffened panels. Appl Sci 7(12):1233

Cunningham C, Wikshåland S, Xu F, Kemakolam N, Shokrani A, Dhokia V, Newman S (2017) Cost modelling and sensitivity analysis of wire and arc additive manufacturing. Procedia Manuf 11:650–657

Mishurova T, Sydow B, Thiede T, Sizova I, Ulbricht A, Bambach M, Bruno G (2020) Residual stress and microstructure of a ti-6al-4v wire arc additive manufacturing hybrid demonstrator. Metals 10(6):701

Knezović N, Topić A (2018) Wire and arc additive manufacturing (WAAM) – a new advance in manufacturing. In: Lecture Notes in Networks and Systems. Springer International Publishing, pp 65–71

Ding D, He F, Yuan L, Pan Z, Wang L, Ros M (2021) The first step towards intelligent wire arc additive manufacturing: an automatic bead modelling system using machine learning through industrial information integration. J Ind Inf Integr 23:100218

Chen X, Kong F, Fu Y, Zhao X, Li R, Wang G, Zhang H (2021) A review on wire-arc additive manufacturing: typical defects, detection approaches, and multisensor data fusion-based model. Int J Adv Manuf Technol 117(3–4):707–727

Najmon JC, Raeisi S, Tovar A (2019) Review of additive manufacturing technologies and applications in the aerospace industry. In: Additive Manufacturing for the Aerospace Industry. Elsevier, pp 7–31

Botila L (2019) Considerations regarding aluminum alloys used in the aeronautic/aerospace industry and use of wire arc additive manufacturing waam for applications. Weld Mater Test 4:9–24

www.stelia-aerospace.com/en/p14-aerostructures/, (2023a). Accessed 15 Mar 2023

www.3dprint.com/79389/3d-printed-fuselage/, (2023b). Accessed 15 Mar 2023

www.waammat.com/about/demo-parts, (2023c). Accessed 15 Mar 2023

www.waam3d.com/parts#print-with-us, (2023d). Accessed 15 Mar 2023

Li Y, Polden J, Pan Z, Cui J, Xia C, He F, Mu H, Li H, Wang L (2022) A defect detection system for wire arc additive manufacturing using incremental learning. J Ind Inf Integr 27:100291

Raguvarun K, Balasubramaniam K, Rajagopal P, Palanisamy S, Nagarajah R, Hoye N, Curiri D, Kapoor A (2015) A study of internal structure in components made by additive manufacturing process using 3 d x-ray tomography. In: AIP Conference Proceedings. AIP Publishing LLC

Val AGD, Cearsolo X, Suarez A, Veiga F, Altuna I, Ortiz M (2023) Machinability characterization in end milling of invar 36 fabricated by wire arc additive manufacturing. J Mater Res Technol 23:300–315

Patterson AE, Lee YH, Allison JT (2021) Generation and enforcement of process-driven manufacturability constraints: a survey of methods and perspectives for product design. J Mech Des 143(11):110801

Hauser T, Reisch RT, Breese PP, Lutz BS, Pantano M, Nalam Y, Bela K, Kamps T, Volpp J, Kaplan AF (2021) Porosity in wire arc additive manufacturing of aluminium alloys. Additive Manuf 41:101993

Dharmawan AG, Xiong Y, Foong S, Soh GS (2020) A model-based reinforcement learning and correction framework for process control of robotic wire arc additive manufacturing. In: 2020 IEEE International Conference on Robotics and Automation (ICRA). IEEE

Xia C, Pan Z, Zhang S, Polden J, Wang L, Li H, Xu Y, Chen S (2020) Model predictive control of layer width in wire arc additive manufacturing. J Manuf Process 58:179–186

Rodrigues TA, Escobar J, Shen J, Duarte VR, Ribamar G, Avila JA, Maawad E, Schell N, Santos TG, Oliveira J (2021) Effect of heat treatments on 316 stainless steel parts fabricated by wire and arc additive manufacturing : microstructure and synchrotron x-ray diffraction analysis. Additive Manuf 48:102428

Rodrigues TA, Farias FWC, Avila JA, Maawad E, Schell N, Santos TG, Oliveira JP (2023) Effect of heat treatments on inconel 625 fabricated by wire and arc additive manufacturing: an in situ synchrotron x-ray diffraction analysis. Sci Technol Weld Join 1–6

Shen C, Pan Z, Ma Y, Cuiuri D, Li H (2015) Fabrication of iron-rich fe-al intermetallics using the wire-arc additive manufacturing process. Additive Manuf 7:20–26

Morais PJ, Gomes B, Santos P, Gomes M, Gradinger R, Schnall M, Bozorgi S, Klein T, Fleischhacker D, Warczok P, Falahati A, Kozeschnik E (2020) Characterisation of a high-performance al-zn-mg-cu alloy designed for wire arc additive manufacturing. Materials 13(7):1610

Hoye N, Cuiuri D, Rashid RAR, Palanisamy S (2018) Machining of GTAW additively manufactured ti-6al-4v structures. Int J Adv Manuf Technol 99(1–4):313–326

Ceritbinmez F, Günen A, Gürol U, Çam G (2023) A comparative study on drillability of inconel 625 alloy fabricated by wire arc additive manufacturing. J Manuf Process 89:150–169

Veiga F, Suárez A, Aldalur E, Goenaga I, Amondarain J (2023) Wire arc additive manufacturing process for topologically optimized aeronautical fixtures. 3D Print Additive Manuf 10(1):23-33

Feier A, Buta I, Florica C, Blaga L (2022) Optimization of wire arc additive manufacturing (WAAM) process for the production of mechanical components using a CNC machine. Materials 16(1):17

Gou J, Wang Z, Hu S, Shen J, Liu Z, Yang C, Bai Y, Lu WF (2022) Effect of cold metal transfer mode on the microstructure and machinability of ti-6al-4v alloy fabricated by wire and arc additive manufacturing in ultra-precision machining. J Mater Res Technol 21:1581–1594

Wu Q, Lu J, Liu C, Fan H, Shi X, Fu J, Ma S (2017) Effect of molten pool size on microstructure and tensile properties of wire arc additive manufacturing of ti-6al-4v alloy. Materials 10(7):749

Aldalur E, Suárez A, Veiga F (2022) Thermal expansion behaviour of invar 36 alloy parts fabricated by wire-arc additive manufacturing. J Mater Res Technol 19:3634–3645

Ogino Y, Asai S, Hirata Y (2018) Numerical simulation of WAAM process by a GMAW weld pool model. Weld World 62(2):393–401

Ji F, Qin X, Hu Z, Xiong X, Ni M, Wu M (2022) Influence of ultrasonic vibration on molten pool behavior and deposition layer forming morphology for wire and arc additive manufacturing. Int Commun Heat Mass Transf 130:105789

Ke W, Oliveira J, Cong B, Ao S, Qi Z, Peng B, Zeng Z (2022) Multi-layer deposition mechanism in ultra high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Additive Manuf 50:102513

Nomoto S, Kusano M, Kitano H, Watanabe M (2022) Multi-phase field method for solidification microstructure evolution for a ni-based alloy in wire arc additive manufacturing. Metals 12(10):1720

Sridar S, Klecka MA, Xiong W (2022) Interfacial characteristics of p91 steel - inconel 740h bimetallic structure fabricated using wire-arc additive manufacturing. J Mater Process Technol 300:117396

Zhang D, Qiu D, Gibson MA, Zheng Y, Fraser HL, StJohn DH, Easton MA (2019) Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 576(7785):91–95

Alipour S, Moridi A, Liou F, Emdadi A (2022) The trajectory of additively manufactured titanium alloys with superior mechanical properties and engineered microstructures. Additive Manuf 60:103245

Ho A, Zhao H, Fellowes JW, Martina F, Davis AE, Prangnell PB (2019) On the origin of microstructural banding in ti-6al4v wire-arc based high deposition rate additive manufacturing. Acta Mater 166:306–323

Donoghue J, Davis A, Daniel C, Garner A, Martina F, da Fonseca JQ, Prangnell P (2020) On the observation of annealing twins during simulating \(\beta\)-grain refinement in ti-6al-4v high deposition rate AM with in-process deformation. Acta Mater 186:229-241

Klein T, Schnall M, Gomes B, Warczok P, Fleischhacker D, Morais PJ (2021) Wire-arc additive manufacturing of a novel high-performance al-zn-mg-cu alloy: processing, characterization and feasibility demonstration. Additive Manuf 37:101663

Welk BA, Taylor N, Kloenne Z, Chaput KJ, Fox S, Fraser HL (2021) Use of alloying to effect an equiaxed microstructure in additive manufacturing and subsequent heat treatment of high-strength titanium alloys. Metall and Mater Trans A 52(12):5367–5380

Langelandsvik G, Akselsen OM, Furu T, Roven HJ (2021) Review of aluminum alloy development for wire arc additive manufacturing. Materials 14(18):5370

Treutler K, Wesling V (2021) The current state of research of wire arc additive manufacturing (WAAM): a review. Appl Sci 11(18):8619

Raut LP, Taiwade RV (2021) Wire arc additive manufacturing: a comprehensive review and research directions. J Mater Eng Perform 30(7):4768–4791

Priarone PC, Pagone E, Martina F, Catalano AR, Settineri L (2020) Multi-criteria environmental and economic impact assessment of wire arc additive manufacturing. CIRP Annals 69(1):37–40

Klein T, Arnoldt A, Lahnsteiner R, Schnall M (2022) Microstructure and mechanical properties of a structurally refined al-mg-si alloy for wire-arc additive manufacturing. Mater Sci Eng A 830:142318

Zhang H, Wang Y, Vecchis RRD, Xiong W (2022) Evolution of carbide precipitates in haynes® 282 superalloy processed by wire arc additive manufacturing. J Mater Process Technol 305:117597

Sargent N, Jones M, Otis R, Shapiro AA, Delplanque JP, Xiong W (2021) Integration of processing and microstructure models for non-equilibrium solidification in additive manufacturing. Metals 11(4):570

Martina F, Roy M, Colegrove P, Williams SW (2014) Residual stress reduction in high pressure interpass rolled wire + arc additive manufacturing ti-6al-4v components. In: 2014 International Solid Freeform Fabrication Symposium. University of Texas at Austin

Shi X, Ma S, Liu C, Wu Q, Lu J, Liu Y, Shi W (2017) Selective laser melting-wire arc additive manufacturing hybrid fabrication of ti-6al-4v alloy: microstructure and mechanical properties. Mater Sci Eng A 684:196–204

Liu J, Xu Y, Ge Y, Hou Z, Chen S (2020) Wire and arc additive manufacturing of metal components: a review of recent research developments. Int J Adv Manuf Technol 111(1–2):149–198

Bermingham M, Thomson-Larkins J, John DS, Dargusch M (2018) Sensitivity of ti-6al-4v components to oxidation during out of chamber wire + arc additive manufacturing. J Mater Process Technol 258:29–37

Bambach M, Sizova I, Sydow B, Hemes S, Meiners F (2020) Hybrid manufacturing of components from ti-6al-4v by metal forming and wire-arc additive manufacturing. J Mater Process Technol 282:116689

Sizova I, Hirtler M, Günther M, Bambach M (2019) Wire-arc additive manufacturing of pre-forms for forging of a ti–6al–4v turbine blade. In: AIP Conference Proceedings. AIP Publishing

Lin Z, Song K, Yu X (2021) A review on wire and arc additive manufacturing of titanium alloy. J Manuf Process 70:24–45

Weiss I, Semiatin S (1999) Thermomechanical processing of alpha titanium alloys–an overview. Mater Sci Eng A 263(2):243–256

Yamada M (1996) An overview on the development of titanium alloys for non-aerospace application in japan. Mater Sci Eng A 213(1–2):8–15

Boyer R, Briggs R (2005) The use of \(\beta\) titanium alloys in the aerospace industry. J Mater Eng Perform 14(6):681–685

Wu B, Ding D, Pan Z, Cuiuri D, Li H, Han J, Fei Z (2017) Effects of heat accumulation on the arc characteristics and metal transfer behavior in wire arc additive manufacturing of ti6al4v. J Mater Process Technol 250:304–312

Halisch C, Milcke B, Radel T, Rentsch R, Seefeld T (2022) Influence of oxygen content in the shielding gas chamber on mechanical properties and macroscopic structure of ti-6al-4v during wire arc additive manufacturing. Int J Adv Manuf Technol 124(3–4):1065–1076

Kennedy J, Davis A, Caballero A, Byres N, Williams S, Pickering E, Prangnell P (2022) \(\beta\) grain refinement by yttrium addition in ti-6al-4v wire-arc additive manufacturing. J Alloys Compd 895:162735

Meiners F, Ihne J, Jürgens P, Hemes S, Mathes M, Sizova I, Bambach M, Hama-Saleh R, Weisheit A (2020) New hybrid manufacturing routes combining forging and additive manufacturing to efficiently produce high performance components from ti-6al-4v. Procedia Manuf 47:261–267

Gierth M, Henckell P, Ali Y, Scholl J, Bergmann JP (2020) Wire arc additive manufacturing (WAAM) of aluminum alloy AlMg5mn with energy-reduced gas metal arc welding (GMAW). Materials 13(12):2671

Geng H, Li J, Xiong J, Lin X, Zhang F (2017) Optimization of wire feed for GTAW based additive manufacturing. J Mater Process Technol 243:40–47

Zuo W, Ma L, Lu Y, yong Li S, Ji Z, Ding M (2018) Effects of solution treatment temperatures on microstructure and mechanical properties of TIG-MIG hybrid arc additive manufactured 5356 aluminum alloy. Metals Mater Int 24(6):1346–1358

Derekar K, Lawrence J, Melton G, Addison A, Zhang X, Xu L (2019) Influence of interpass temperature on wire arc additive manufacturing (WAAM) of aluminium alloy components. MATEC Web Conf 269:05001

Guo X, Li H, Pan Z, Zhou S (2022) Microstructure and mechanical properties of ultra-high strength al-zn-mg-cu-sc aluminum alloy fabricated by wire + arc additive manufacturing. J Manuf Process 79:576–586

Yang J, Ni Y, Li H, Fang X, Lu B (2023) Heat treatment optimization of 2219 aluminum alloy fabricated by wire-arc additive manufacturing. Coatings 13(3):610

Fu R, Guo Y, Cui Y, Wang J, Lei H, Liu C (2023) Large-size ultra-high strength-plasticity aluminum alloys fabricated by wire arc additive manufacturing via added nanoparticles. Mater Sci Eng A 864:144582

Thapliyal S (2019) Challenges associated with the wire arc additive manufacturing (WAAM) of aluminum alloys. Mater Res Express 6(11):112006

Geng H, Li J, Xiong J, Lin X, Huang D, Zhang F (2018) Formation and improvement of surface waviness for additive manufacturing 5a06 aluminium alloy component with GTAW system. Rapid Prototyp J 24(2):342–350

Geng H, Li J, Xiong J, Lin X, Zhang F (2016) Geometric limitation and tensile properties of wire and arc additive manufacturing 5a06 aluminum alloy parts. J Mater Eng Perform 26(2):621–629

Bai JY, Yang CL, Lin SB, Dong BL, Fan CL (2015) Mechanical properties of 2219-al components produced by additive manufacturing with TIG. Int J Adv Manuf Technol 86(1–4):479–485

Silva CMA, Bragança IMF, Cabrita A, Quintino L, Martins PAF (2017) Formability of a wire arc deposited aluminium alloy. J Braz Soc Mech Sci Eng 39(10):4059–4068

Alonso U, Veiga F, Suárez A, Val AGD (2021) Characterization of inconel 718® superalloy fabricated by wire arc additive manufacturing: effect on mechanical properties and machinability. J Mater Res Technol 14:2665–2676

Xu F, Lv Y, Xu B, Liu Y, Shu F, He P (2013) Effect of deposition strategy on the microstructure and mechanical properties of inconel 625 superalloy fabricated by pulsed plasma arc deposition. Mater Des 45:446–455

Baufeld B (2011) Mechanical properties of INCONEL 718 parts manufactured by shaped metal deposition (SMD). J Mater Eng Perform 21(7):1416–1421

Bauccio M (1993) ASM metals reference book. ASM International

Xu F, Lv Y, Liu Y, Shu F, He P, Xu B (2013) Microstructural evolution and mechanical properties of inconel 625 alloy during pulsed plasma arc deposition process. J Mater Sci Technol 29(5):480–488

Wang J, Sun Q, Wang H, Liu J, Feng J (2016) Effect of location on microstructure and mechanical properties of additive layer manufactured inconel 625 using gas tungsten arc welding. Mater Sci Eng A 676:395–405

Dhinakaran V, Ajith J, Fahmidha AFY, Jagadeesha T, Sathish T, Stalin B (2020) Wire arc additive manufacturing (WAAM) process of nickel based superalloys - a review. Mater Today Proc 21:920–925

Benakis M, Costanzo D, Patran A (2020) Current mode effects on weld bead geometry and heat affected zone in pulsed wire arc additive manufacturing of ti-6-4 and inconel 718. J Manuf Process 60:61–74

Wu B, Pan Z, Ding D, Cuiuri D, Li H, Xu J, Norrish J (2018) A review of the wire arc additive manufacturing of metals: properties, defects and quality improvement. J Manuf Process 35:127–139

Chadha U, Abrol A, Vora NP, Tiwari A, Shanker SK, Selvaraj SK (2022) Performance evaluation of 3d printing technologies: a review, recent advances, current challenges, and future directions. Prog Addit Manuf 7(5):853–886

Chadha U, Selvaraj SK, Lamsal AS, Maddini Y, Ravinuthala AK, Choudhary B, Mishra A, Padala D, Lahoti SMV, Adefris A, Dhanalakshmi S (2022) Directed energy deposition via artificial intelligence-enabled approaches. Complexity 2022:1–32

Uriondo A, Esperon-Miguez M, Perinpanayagam S (2015) The present and future of additive manufacturing in the aerospace sector: a review of important aspects. Proc Inst Mech Eng G J Aerosp Eng 229(11):2132–2147

Hoye N, Li HJ, Cuiuri D, Paradowska AM (2014) Measurement of residual stresses in titanium aerospace components formed via additive manufacturing. Mater Sci Forum 777:124–129

Colomo AG, Wood D, Martina F, Williams SW (2020) A comparison framework to support the selection of the best additive manufacturing process for specific aerospace applications. Int J Rapid Manuf 9(2/3):194

Cottam R, Palanisamy S, Avdeev M, Jarvis T, Henry C, Cuiuri D, Balogh L, Rashid RAR (2019) Diffraction line profile analysis of 3d wedge samples of ti-6al-4v fabricated using four different additive manufacturing processes. Metals 9(1):60

Chadha C, Crowe K, Carmen C, Patterson A (2018) Exploring an AM-enabled combination-of-functions approach for modular product design. Designs 2(4):37

Nie Z, Jung S, Kara LB, Whitefoot KS (2019) Optimization of part consolidation for minimum production costs and time using additive manufacturing. J Mech Des 142(7):1–16

Schmelzle J, Kline EV, Dickman CJ, Reutzel EW, Jones G, Simpson TW (2015) (re)designing for part consolidation: understanding the challenges of metal additive manufacturing. J Mech Des 137(11):111711

Ghimire T, Joshi A, Sen S, Kapruan C, Chadha U, Selvaraj SK (2022) Blockchain in additive manufacturing processes: recent trends & its future possibilities. Mater Today Proc 50:2170–2180

Cai X, Dong B, Yin X, Lin S, Fan C, Yang C (2020) Wire arc additive manufacturing of titanium aluminide alloys using two-wire TOP-TIG welding: processing, microstructures, and mechanical properties. Additive Manuf 35:101344

Cunningham C, Flynn J, Shokrani A, Dhokia V, Newman S (2018) Invited review article: strategies and processes for high quality wire arc additive manufacturing. Additive Manuf 22:672–686

Xu T, Tang S, Liu C, Li Z, Fan H, Ma S (2020) Obtaining large-size pyramidal lattice cell structures by pulse wire arc additive manufacturing. Mater Des 187:108401

Titanium N (2017) Norsk titanium to deliver the world’s first faa-approved, 3d-printed, structural titanium components to boeing. https://www.businesswire.com/news/home/20170410005330/en/Norsk-Titanium-to-Deliver-the-World%E2%80%99s-First-FAA-Approved-3D-Printed-Structural-Titanium-Components-to-Boeing. Accessed 15 Mar 2023

Author information

Authors and Affiliations

Contributions

HP: Study design, literature collection and analysis, first draft section writing. AA: Study design, literature collection and analysis, first draft section writing. GSG: Study design, literature collection and analysis, first draft section writing. UC: Study design, review coordination, literature collation, first draft preparation, figures. AS: Study design, supervision, literature collection and analysis, figures, final draft preparation and polishing. AEP: Supervision, study design, literature collection, figures, final draft preparation and polishing, journal submission and correspondence. All opinions and conclusions are solely those of the authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pant, H., Arora, A., Gopakumar, G.S. et al. Applications of wire arc additive manufacturing (WAAM) for aerospace component manufacturing. Int J Adv Manuf Technol 127, 4995–5011 (2023). https://doi.org/10.1007/s00170-023-11623-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11623-7