Abstract

The advent of smart manufacturing and the exposure to a new generation of technological enablers have revolutionized the way manufacturing process is carried out. Cyber-Physical Production Systems (CPPS) are introduced as main actors of this manufacturing shift. They are characterized for having high levels of communication, integration and computational capabilities that led them to a certain level of autonomy. Despite the high expectations and vision of CPPS, it still remains an exploratory topic. Multi-Agent Systems (MAS) have been widely used by software engineers to solve traditional computing problems, e.g., banking transactions. Because of their high levels of distribution and autonomous capabilities, MAS have been considered by the research community as a good solution to design and implement CPPS. This work first introduces a collection of requirements and characteristics of smart manufacturing. A comprehensive review of various research applications is presented to understand the current state of the art and the application of agent technology in manufacturing. Considering the smart manufacturing requirements and current research application, a SWOT analysis was formulated which identifies pros and cons of the implementation of agents in industry. The SWOT analysis was further validated by an industrial expert evaluation and the main findings and discussion of the results are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In Manufacturing, two major shifts are taking place. On one hand, the market need for highly customized products has pushed manufacturers into the development of a more modular, reconfigurable and distributed shop-floor [1]. On the other hand, the advancements in digital technology and its adoption in manufacturing have aided in more responsive, autonomous and efficient shop-floor. Manufacturing industry is witnessing a new revolution due to this combination of market push and technology pull [2]. This new revolution could be defined as “smart manufacturing”.

Emerging technologies in smart manufacturing

The advances in information, computation and communication technologies have helped shape the new manufacturing evolution. Mittal et al. [3] have classified these enabling technologies into various technological clusters. A similar technological clustering is listed below,

-

Visual technologies (Virtual and Augmented Reality, Hologram)

-

Data Analytics (Big Data, Machine learning, Modeling and Simulation)

-

Cyber-Physical System and digital twin

-

Cloud manufacturing (cloud, Edge and Fog computing)

-

Advance manufacturing (Plug and Produce, Additive manufacturing, Flexible and Reconfigurable Manufacturing System)

-

Internet of Things/Services

-

Cyber security (Federated learning)

-

Smart products/parts (reusable and resilient parts, smart sensors, RFID)

These technologies combined with the legacy systems in place have led to a smarter and more efficient manufacturing system.

Multi-Agent System (MAS) in smart manufacturing

An emerging technology, which has not been widely used by manufacturers but has a high potential to develop a more autonomous and efficient system especially in complex manufacturing process is agent-based computation. Agent-based technologies have attracted considerable interest in the research community due to their ability to tackle highly distributed and reconfigurable control systems [4]. These can help in developing a much dynamic and flexible manufacturing solution.

Agents, in simple terms, are “cognitive entities with autonomous and social abilities”. There is very little consensus in properly defining an agent. A commonly accepted definition for an agent is that it is “an encapsulated computational system that is situated in some environment and that is capable of flexible, autonomous action in that environment in order to meet its design objectives [5]”. Despite the lack of consensus in a proper definition of an agent, it is widely accepted that certain properties of agents are desirable. Some of these are described below (also see Fig. 1). A more complete description of these characteristics can be found in Leitao [6] and Wooldridge [7].

-

Autonomy — ability to have control on its own behaviors [8].

-

Reactivity — ability to receive inputs and react to environment to achieve its objective.

-

Pro-Activeness — ability to initiate and adapt to achieve its objective.

-

Social Ability — ability to collaborate with other agents in achieving interdependent tasks.

These Agents could be inhabited in a physical environment (ex. thermostat) or software/virtual environment (ex. software daemons). An agent by itself is limited to its information, computing ability and environmental perspectives and is able to solve a complex problem. In order to tackle these large and unpredictable problems, the agents collaborate with each other to solve the problem. Such systems are called as Multi-Agent System where each agent solves its particular problems using its abilities but also collaborates with other agents to solve interdependent problems [9].

Need and aim of this work

Some researchers have presented extensive review on certain research areas and applications of agent-based manufacturing (Table 1), but to the best of our knowledge, there has not been an extensive review on the mapping of the various smart manufacturing requirements with the existing research on agent technologies in all areas of manufacturing shop-floor and validated with industrial experts evaluation. Need for such a work is vital in understanding the current requirement and provides future direction for an agent-based manufacturing. The current work aims to provide this understanding and guide future researchers in agent technologies for smart manufacturing applications.

Current work

This paper is divided into 4 sections. The paper initially identifies the requirements need in achieving a smart manufacturing environment. It lists 12 core requirements based on previous literature. This list complements previous similar works [3, 18, 19]. The paper then presents a comprehensive review on the use of agent technologies in various manufacturing shop-floor applications like process control, planning and scheduling, quality control and diagnosis, simulation and execution, shop-floor reconfiguration [20] and application of emerging technologies like service and cloud based. Considering the smart manufacturing requirements and the comprehensive review, the pros and cons of integrating the agent technologies are explained using a SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis. SWOT is a strategic planning framework that provides details about a system’s organization capabilities [21]. It is also applied to evaluate plans, projects, persons or business activities [21]. In various research works (Table 2), SWOT has been also used to evaluate the influence for strategic management and enablement of new technologies. This is imperative nowadays considering emergent digitalization and high level of computational power. Hajizadeh [22] apply a SWOT analysis to evaluate the effects of Machine Learning in oil and gas industries. Helms et al. [23] apply the analysis to understand the application of Information Technology (IT) in the health care industry. Ahmadi et al. [24] aim to understand benefits and limitations of big data using a SWOT analysis.

By doing an analogy with the strategic planning framework that SWOT utilizes for organizations, previous evidence suggests the suitability of such methodology for new technologies by providing:

-

Strengths: Advantages of a technology over other technologies and description of the unique features that it has.

-

Weaknesses: Limitations or drawbacks the technologies have, also what barriers exist towards its adoption.

-

Opportunities: What type of needs the technology is addressing in relation to the market. What is the competitive advantage the technology has.

-

Threats: What are the potential risks associated with the technology. Also the description of potential substitutes for the technology?

With previous context we believe that the utilization of a SWOT analysis for agent-based technologies in manufacturing applications is important to understand its implementation benefits, opportunities and challenges.

The last section of this work contemplates an industrial assessment made to several companies to understand the need of the implementation of agent technologies. Questions of the assessment are based on the SWOT analysis implemented.

2 Requirements in smart manufacturing

The shift in the market needs has always impacted the manufacturers and has defined new requirements to be satisfied by the manufacturing industry. Increased competition from emerging markets and mass customization demands has pushed manufacturers to better utilize the new digital technologies. This has laid the foundation for smart manufacturing. These market needs have posed new requirements in smart manufacturing. Table 3 list these new requirements with their definition and a brief overview of these new requirements in the shop-floor is mentioned below,

-

R1 Interoperability: The challenge of interoperability appears in the shop-floor because of the need for integration and cooperation in the production processes due to the different actors involved (e.g., people, machines), and their role in the shop floor. Interoperability should be anchored with high level of standardization [18]. Different categories, approaches and perspectives of interoperability have been explained in previous years, e.g., device, semantic, syntactic and technical interoperability [28]. They describe data formats, ontological reasoning, technologies and even computation needed to achieve such level of communication exchange. Several technological enablers like multi-agent systems, cloud-based technologies and service-oriented architectures have been highly applied for providing necessary infrastructure and autonomy for achieving such level of interoperability [6].

-

R2 Virtualization: Virtualization is enabled by the development of a cyber system through the integration of multiple sensors [29]. These real-time sensory data are used to update the existing cyber system. Apart from monitoring and control, virtualization could also be used to design prototypes of a new system and simulate its behaviors before purchasing. This virtual model could be then tested and modified saving investment loses. Other applications include tracking, training, diagnosis and prognosis [30]. Recent enablers of virtualization are virtual and augmented reality (VR and AR) which provide a faster learning curve and an immersive experience.

-

R3 Service orientation: The concept stems from the view that manufacturing would be more focused on providing services along with products to the customers. Traditional manufacturing focused profit mainly from its product and outsource its services but the new requirements would push manufacturer to focus on providing both product and services as a combined solution with profit mainly derived from its services [31, 32]. Cloud manufacturing is a new paradigm that is based on this concept where the infrastructure is designed to receive and provide services through cloud. In a CPS, the skills provided by each entity could be accessed by other entities (as a service) to execute complex tasks. An enabler for service-oriented architecture is the manufacturing app marketplaces.

-

R4 Reconfigurability: In smart manufacturing the role of such reconfigurability results in high levels of re-usability of components, an increasing agility which is reflected in less time to system adaptation and the reduction of re-engineering effort. This level of reconfiguration is achieved by creating knowledge-based systems, e.g., ontologies or data models which provide the necessary expertise to support system changes and reconfiguration. Reconfigurable systems can be related to machine tools, fixturing systems, assembly systems, material handling systems and finally higher levels of reconfigurability which are on the top of the shop floor [33]. Key characteristics for considering a system to be reconfigurable are: Modularity, Integration capability, Customization, Convertibility and Diagnosability [34]. In addition, the control of such reconfigurable systems should fulfill specific requirements, i.e., autonomous, distributed, open and scalable.

-

R5 Cyber security: Cyber security related to offensive or defensive security practices relying on information and/or operational technology. manufacturing systems can be vulnerable at intersections of cyber, physical, cyber-physical and human entities. The entire business model can be affected due to these vulnerabilities. Cyber security accidents happen in different scales and areas, even from the lower levels of manufacturing management to cross-site attacks on different targets and types [35]. Although cybersecurity is perceived as a priority, the majority of companies have not been well prepared yet, which is further evidenced by the report in 2017 by McKinsey and Company [36] indicating that only 16 percent of companies agree that they are well prepared. One of the reasons that limit the ability to deal with the cybersecurity threads is that those threads associated with the scales and objectives have evolved and adapted in different ways. The workers are more concerned on safety and environmental risks in work space in which the cyber attacker may take over the control on manufacturing process or emission treatment and perform endangering modifications on the user interface to cause human safety risks.

-

R6 Modularity: In Manufacturing, the concept of modularity is related to the ability to rapidly change to customer needs (i.e., product change) by having a system which can be flexibly adapted (by replacing or expanding individual modules). Its characteristics are not restricted to changes in the layout of the shop floor but also include the ability to change the production capacity [37] or integrate new functionalities. Certain requirements of smart manufacturing are similar to Modularity for example, Composability (ability to be developed from subsystems) or Convertibility (ability to extend the system functionality). A key requirement to enable modularity is the plug and produce nature of the system/machines [38]. Modularity can enable the ability to self-adapt, make the system scalable and composable, rapid integration and relocate the production line on time.

-

R7 Decentralization: Decentralization in manufacturing is achieved when system elements (workstations, machine tools, AGVs, products etc.) make autonomous decision in real time with focus on an overall organizational goal without a common control unit. The systems should perform the tasks autonomous (even during external interferences, specific exception and/or conflicting goals) and be designed to achieve global goals with local operating information. The Shift from a central to de-central control could be attributed to the effect of self-capabilities of Cyber-Physical System. This may be achieved with the help of embedded computers interacting with sensors and actuators. Emerging technologies like Internet of Things make new data available at real time and aid in decentralized decision-making [39]. A common synonym of decentralization used in manufacturing is Distribution (network of computers exchanging information for a specific goal).

-

R8 Real-time capability: Real-time capability could be achieved by analyzing the data generated from raw materials, equipments and finished goods. The systems and subsystems (including product tracking) need to be monitored and controlled in real time to achieve this requirement. The system control could be using either diagnostic or reactive decision-making enabling the ability to recover from disturbances also in real time. The system should also be able to include humans and communicate with them in real time. Virtualization, real-time visibility and Digital twinning could be considered as complementary characteristics to real-time capability as they tried to create a digital replica and visualize the real system [40]. In order to respond in real time, the system has to either reconfigure with the help of existing resources or request services (mostly cloud based). Proper communication infrastructure ensures data acquisition and information feedback in real time. Real-time capability could be applied to prevent breakdown [41], detect quality defects and ensure safety [42]. An extension to this ability would be the ability to provide intelligence/smartness to the system with the collected historical data and current real-time information [43].

-

R9 Cooperation: Even though Cooperation and collaboration have similar features, the concept of collaboration has a higher importance due to its ability to share resources and combine individual goals in achieve a common goal [44]. In CPSs there is actually a shift from a cooperative environment towards a collaborative one. In achieving this requirement, the CPSs could react to changes in the system and also achieve specific goals in an optimized manner. This collaborative environment in an autonomous system will enable smart factories with self-x characteristics like self-maintain and self-organized. Another aspect of collaboration involves the use of human in the loop. This would enable a combination of accuracy and computational capability provided by the robots/machines with the intelligence and flexibility provided by the human [45]. This human-machine collaboration could be achieved through voice or hand gestures interactions. It should be noted that some researches use the term “symbiosis” instead of collaboration to stress the fact that the abilities of the humans are not replaced in achieving the goals. Another role of collaboration is in the area of information sharing from lower level to higher level across involved parties.

-

R10 Data Management: In data management, the information should be accurate, consistent, and secure [46]. The management of large and complex amount of data becomes more troubling while using traditional data process application. The encountered challenges are included gathering, curation, analysis and storage of large amount of dataset. The dataset sheet causes complexity of analysis along with commercial optimization which led to new tools for tackling down the obstacles like enhancement of technological tools and further management of data [47, 48]. Other challenges are heterogeneity (un-structured data), incompleteness, scale (Moore’s law meet the requirement of increasing volume of data as well as advance graphics processing unit system), timeliness of data (processing big volume of data in real time) and data privacy and confidential right applied to keep the information safe [49].

-

R11 Context awareness: Contextual information includes data which is relevant for a given entity, e.g., machines, people software or hardware. This contextual information may fall into different categories and variables, e.g., location, temperature, role, activities, tasks, and processes. Context awareness methods are widely used in computing systems to enable automatic and to some extent intelligent processes, giving actionable experiences to users. In manufacturing, the contextual information comes from sensors that are afterwards handled by a set of rules, event-driven algorithms or computational intelligence methods. They provide the adaptation logic to change parameters, control variables and overall the behavior of the system.

-

R12 Autonomy: Autonomy may be generalized as the aptitude of individual components to take independent decisions. The individual entities in an autonomous system should have the capability to collaborate, implement and move towards such a goal. These individual entities in themselves may have their own rules and control mechanisms but collectively compliment to a specific goal. An intelligent machine is considered to be autonomous if it is able to execute complex tasks and show dynamic adaptable behavior without inherently relying on detailed sequential programming and human-control [50]. The level of autonomy can be related by the number of decision taken by the system, criteria-based approach used and level of uncertainty in the system [51, 52]). The aptitude with which it could plan, control and execute such actions without assistance gives an idea of autonomy level of the system.

3 Agent technology in manufacturing

Research on agent technologies in manufacturing started in the mid-1990s with earlier publications showing promising results for its implementation. Goujon et al. [55] highlighted the use of a multi-agent model to specify the decisional subsystem of a manufacturing system and validated the methodology on a system that produces coils. Maturana et al. [56] developed a Mediator architecture for distributed task planning and coordination using multi-agent paradigms. The system dynamically adapts to evolving manufacturing tasks and can be used for other distributed organizational systems beyond manufacturing. Sikora et al. [57] discuss the need for a new paradigm for managing distributed manufacturing systems and present a multi-agent framework for achieving system integration and coordination mechanisms among components. The framework is applied to a printed circuit board manufacturing system, and performance results are described. Sluga et al. [58] present a multi-agent approach to developing a distributed manufacturing architecture, introducing the virtual work system (VWS) as an essential building block and demonstrating its role in a case study of a machining work system. Lee et al. [59] present a multi-agent model equipped with computational intelligence technologies for monitoring the information flow and task allocation among companies in a dispersed manufacturing network, using intelligent agents and a genetic algorithm scheme to optimize task sequences and minimize overhead.

Currently, MAS technology is being applied to several industrial applications in the context of smart manufacturing. The applications include process control, production planning, scheduling, monitoring, quality control, diagnosis, process reconfiguration and manufacturing simulation and executions. This chapter surveys and discusses some existing industrial applications which have been developed in the last decade. Results of this survey will be utilized to evaluate the current status of its industrial adoption, main advantages and current challenges.

3.1 Process control

Li et al. [60] developed a MAS architecture for collaborative control in process industry. The MAS uses an hierarchical distributed cooperation architecture. A Deep Deterministic policy gradient algorithm is presented by the authors for collaborative control. The same authors in a different article presented an optimization model for process control and also validated the model in a cement production process [61]. The model uses MAS with Multi-Objective Particle Swarm Optimization (PSO) algorithm and is divided into two layers: control and execution. In order to reduce the time consumption, separate agents are used for algorithm storage, data and communication between agents. Raileanu et al. [62] presented a semi-heterarchical control architecture with a Multi-agent solution for robotized holonic manufacturing. The solution provides an automated component supply with agents operating physical components. The MAS control solution includes different types of agents: resource, order, supply and supply station agents. Vatankhan et al. [63] provided a solution to improve manufacturing control system with focus on improving self-organization and reducing the processing time using ant agents. The solution utilized an indirect coordination (stigmergy) mechanism based on ant colony intelligence. The developed system is based on indirect communication of the agents. Roque Rolo et al. [64] expanded the MAS distributed system by introducing two more layers: Integration and Simulation, to achieve a digital twin for manufacturing control. Implementation of the framework helped in predicting and understanding the execution of systems in run time. The results also showed that for effective control there is a need for not only to mimic the agent interactions but also other information like network connections, modules, computational devices. In a presentation on Industry 4.0, Li et al. [65] presented a proposal which involves the smart goods, cloud computing, and shop floor systems (machines, conveyers, etc.) that are able to communicate and collaborate interactively via networks. The shop floor entities are regarded as agents. To decrease the load-unbalance help of big data feedback [66], smart assessment and control techniques are suggested. In Hussain and Ali [67], industrial control system was developed using multi-agent-based control architecture. The distributed control system offers an effective method for optimizing system performance in a reactive and dynamic manner. Bulatov and Kryukov [68] suggests that the event model based multi-agent control system of dispersed generating facilities should include a design, description, and Joiner-network. The distributed system’s central control is hindered by the excessive quantity of data needed to transmit to the control center. Use of peripheral systems based on the agent approach increases control efficiency. The agents describe the primary functions of the interactive network. The flexibility of the system in regard to changes in circumstances and the MAS’ usefulness for building dynamic adaptive power networks is shown. Mezgebe et al. [69] proposes a consensus algorithm for a multi-agent-based manufacturing system to control rush orders and minimize makespan. The algorithm uses a leader-follower communication approach and decision-making is based on the behavior of each agent’s state. The algorithm is validated with simulation experiments on a full-sized application platform, showing significant reduction in the impact of rush orders on makespan.

MAS technology clearly shows the advantage of its implementation in a distributed and collaborative control of manufacturing systems. MAS can be used as the extension of the existing control architecture. These can be further expanded by introducing some modularity and self-organization characteristics. In spite of the wide range of applications of MAS the Technology Readiness Level (TRL) of the adaptation is very low. Most of the works cited here are below TRL 6. This is due to the unpredictability and uncertainty associated with the distributed approaches. The lack of an industrial standard for agent technologies also contributes to the low adaptation of agents control systems in manufacturing.

3.2 Planning and scheduling

Production Scheduling is considered a difficult problem as it involves multiple resources and multiple operations. Integration of process planning and scheduling becomes even more complex. Without use of enumerative algorithms, it is hard to find optimal solutions, and computation time increases exponentially with problem size. Intelligent manufacturing can benefit from cutting-edge technologies like MAS which have been applied also in manufacturing scheduling [70, 71]. An agent-based framework is a suitable solution for problems related to production planning and scheduling by defining work-flows and following manufacturing logic facilitating decision-making [72].

The work done by He et al. [73] presents a methodology of using hierarchical agent bidding system to enhance operational performance, robustness and flexibility by dealing with dynamic changes in real-time business environment. Advantage offered by this technology utilization is realization of the capability in manufacturing setup, reorganizing within system constraints for orders with minimum disturbance. Other works [74] utilize production smoothing by agent technology to balance out the production load across workstations decreasing work in process, effective material flow and shorter lead times. The work proposed by Zhong et al. [75] shows an application that utilizes event-driven RFID for planning and scheduling (collective intelligence). Data from RFID along with standard operation times allow the reasoning about planning and scheduling activities. The approach breaks the traditional architecture between planing and scheduling into a continuous and automated feedback operation, enhancing the decision-making. Collective intelligence and RFID are based on agent-based technologies. Cadavid et al. [76] presented a detailed review on application of machine learning in production planning, control and scheduling aspect of manufacturing systems. Tools, techniques, data sources and activities realized by and through machine learning can aid in better production system performance and consistency while incrementally increasing efficiency along the time period.

Negotiation mechanism in agent-based technologies have been used in manufacturing production to improve system efficiency [77]. The mechanism could be anchored by having agent negotiations map managerial structure of the manufacturing enterprise. The insight could then be decentralized to product formulation at each step of production process where each aspect could be monitored and controlled at every period of production [78]. This gives leverage to controlling accumulating production costs over time [79]. Recent works have shown a shift of incorporation of control, machine learning and agent technology for getting higher efficiency. Cooperative multi-agent behavior by means of reinforcement learning (RL) can factor in key performance indicators to develop effective production control [78, 80] and planning phase for problems considering complex tasks performed by manipulators for task-agent assignment [81]. Much larger scheduling problem have been addressed in research where transport in production facility was controlled by multi-agent interaction by self-controlling and self-organizing agents [82]. Elaboration on these works need to be done for targeting or mapping all the characteristics of supply chain process [83]. A greater need for integration of learning and testing models remains evident for production planning and scheduling.

3.3 Quality control and diagnosis

Peres et al. [84] presented a pluggable framework for real-time monitoring with three components: Cyber-Physical Production System (CPPS) component, Real-time Data Analysis Component and Knowledge Management Component. In implementing the CPPS component — to extract data from the shop floor — a MAS was implemented using Java Agent DEvelopment Framework (JADE) based on work carried out in FP7 PRIME project [85]. The same framework was also implemented in a different work for multistage quality control in earlier prediction of defects [86]. This was implemented in assembly of tailgate for automotive industry. The MAS abstracts both components and subsystems. The system includes three types of agents: Component Monitoring Agent, Subsystem Monitoring Agent and Deployment Agents. Baer et al. [87] developed an initial concept for handling un-foreseen machine failures using Deep Reinforcement Learning agents. Each product is controlled by its own agents and handles reconfigurations of the plant topology by considering local and global optimization goals. Rokhforoz et al. [88] integrated central coordination system and distributed agents for developing a multi-agent decision support framework for maintenance in power grid. The decision support system works in two levels. The framework uses distributed algorithm for maintenance decisions and to communicate with central coordinator and a negotiation algorithm for coordination problems. Cui et al. [89] provided a multi-agent-based solution for a two-level multi-component system addressing its maintenance resource scheduling problem. The user can choose between two selection criteria — Fixed-pair and nearest distance — according to the failure situation. Mantravadi et al. [90] developed a Machine Learning based anomaly detection algorithm and an architecture for multi-agent Manufacturing Execution System (MES). The authors demonstrated that the MES executes the “turning off” command of a machine without human intervention.

MAS is these applications is largely used for the abstraction of resources or the subsystems in the shop-floor. These abstractions provide information in monitoring, predicting failures and decision support. The use of Machine Learning especially deep learning techniques provides skills to predict un-foreseen machine failures. The applications of MAS in shop-floor for monitoring and maintenance activities show that it adapts to the changes in the shop-floor quickly and provides additional flexibility and robustness. A summary of publications considered in this work, main technologies used, and approaches is presented in Table 4.

3.4 Simulation and execution

Multi-agent modeling is a versatile method for conducting and generating models that are adaptable enough to meet various research goals. Simulation of complex systems using many autonomous agents is known as Agent-based modeling and simulation (ABMS). When discussing the model of the production system, there may be instances when a batch of model production system agents is produced apart from other kinds of production system agents like machine tools, conveyors, or replacement stands.

According to Gwiazda et al. [91], simulation that includes many agents is a technique that may analyze complicated systems. As part of his proposal, Blesing et al. [92] presented a new idea for a flexible decentralized production system that integrates a precedence graph-based planning approach with a multi-agent control system. In addition, the initial findings of a pilot demonstration and simulation tests are given. Büth et al. [93] is interested in creating a complex manufacturing system simulation model from scratch in an industrial-grade discrete-event simulation tool. An example application is based on a matrix-structural manufacturing system that offers a flexible and scalable method without a set cycle time, due to the structure and to the entities operating as separate and independent agents. Huang et al. [110] discusses the need for efficient technologies to manage networked resources in distributed manufacturing systems, and critiques the complexity and cost of existing systems such as manufacturing automation protocol (MAP). They propose the use of the simple network management protocol (SNMP) and mobile agent (MA) technology for managing networked manufacturing devices. They also develop an integrated network management framework based on MA technology to investigate aligning network management with strategic management decisions.

Production firms have to adjust to increased competition and rising market dynamics to allow for more flexibility in their manufacturing processes. Therefore, more innovative methods that go beyond the conventional production system’s capabilities are required. The simulation modeling of such systems must be revisited as well. The tools industry uses for simulation, often known as industrial-grade simulation tools, are not adequate for this purpose. Agent-based manufacturing simulation can aid in tackling this problem.

3.5 Reconfiguration

Agent solutions for reconfigurable manufacturing systems have been developed for more than two decades [14]. They are based on negotiation protocols, where agentified manufacturing entities collaborate and negotiate to fulfill a specific order or requirement. They either follow a specific paradigm, e.g., PROSA [111], COBASA [112], ADACOR [113] or are simply a variation of them with the main focus of showing adaptability in the event of changes.

Barbosa et al. [94], present a dynamic self-organizing holonic manufacturing system. The work shows a 2D model based on a behavioral (low level) and structural (macro-level) reconfiguration. In this reference architecture there is an entity that is in charge of the global control. It consists of a discovery, reasoning and learning mechanism. Also it presents a nervousness stabilizer block in case of chaotic behaviors. The process is based on a rule base engine in a flexible manufacturing system where the objective is the assembly of various parts. Zhang et al. [95] show a reconfiguration process assisted by the use of a cloud infrastructure. This work is based on negotiation between products, machines and conveyors. It also includes big data that supports the process negotiation and considers a deadlock prevention. Wang et al. proposed a similar approach [96, 102]. In the context of industry 4.0 they introduce big data analysis of sensorial information of resources that is processed in the cloud. In Rodrigues et al. [97], a different application uses the multi-agent reconfiguration approach as a way to dynamic reconfigure services (they act as resource functionalities: e.g., quality control, welding, transportation). By continuous monitoring, this approach constantly finds opportunities to reconfigure, considering also optimization indicators. The decision of the service reconfiguration is based on the evaluation of various alternatives considering costs, stability mechanisms and collaboration, i.e., deadlock, non-beneficial solutions, etc. A slightly different work is presented in CASOA (An Architecture for Agent-Based Manufacturing System in the Context of Industry 4.0, Tang et al. [103]. There is an ontological representation to provide a basis for decision-making. This work introduces cloud-assisted mechanisms to coordinates agents globally. One of the few works that does not considered a negotiation mechanism is BIOSOARM [114]. It applies an attraction mechanism (bio-inspired implementation/firefly algorithm) as a way to select an adequate path for the self-organization process and to find also the most adequate resources. In this work, there is no need to define a self-organizing mechanism. In fact, “entities do not need to be fully awarded of sequences”, e.g., If a part or resource is missing, the system will automatically attract another part to take place of the removed one.

Agents used for reconfiguration technology are mostly catered to introducing aspects of modularity in production settings such as in case of research done by Kim et al. [98]. The collaboration between agents in the research proved to be an anchor for rapid factory transformation when applied to discrete component assembly, machine shops and customization of products. The propagation of transformation is encapsulated by using agents for control applications driven by infrared communication along with sate management by protocol-guided update mechanism for rapid workstation deployment resulting in time-saving in reconfiguration [98]. Mueller et al. [99] presented an agent-driven reconfiguration method that identified demand and used it to generate feasible alternatives for the system. A suitable intelligence mechanism is a necessary requirement to evaluate among the alternatives and go for optimum selection. While discussing this approach for intelligence in their prototype they tried to tackle issue of time taken for reconfiguration. Significant work is needed on the approach as current intelligence design is not concrete, resulting in error-prone method compatibility, not reaching optimum for reconfiguration and high human dependency.

Plug and produce approach applied for reconfiguration gives a product-centric control to the assembly components. However, this requires protocols for the components to interact with the environment like the work done by Atmojo et al. [100] which used OPC UA to interact with IEC 61499-based environment. This kind of approach requires an accurate representation in terms of information model regarding manufacturing services present in environment. This approach is feasible for products that are present in small lot sizes requiring customization and huge environmental agility for adaptation. A number of projects have focused on deployment of agent-based solutions for automated configurations and coordination in robotic systems [115]. Ontology-based principles have seen significant acceptance for agent-based control and coordination for dynamic operations. This type of deployment couples with service-oriented architecture to reduce setup and programming time shifting by agent-based configuration through ontology-based registration of resource network settings. Lyu et al. [101] presents an approach based on this for development of controls strategies based on ontology knowledge base and factual inferences. In a similar manner the configuration of Programmable Logic Controllers (PLCs) has been exploited for control at high level whereas IEC 61499 controllers exploit low-level functionalities. The authors stressed the work for protocols that are needed to establish communication between CPS for real-time adaptation. Other works on agent implementation for reconfiguration have targeted service-oriented architecture for enabling self-organization behavior in resource networks [116], developing of production system for industrial robotics [117], self-repairing of manufacturing systems [118], and adaptive automation assembly systems [119]. Agent technology has been significant application to solve challenges of dynamic adaptation such as for reorganization, task execution, resource network variation, part and system diagnosis. Most of these applications require in some essence need for reconfiguration to be made either to cyber or physical infrastructure.

Agents for further progression in manufacturing should target, in regards to reconfiguration, continuous production operations. Feasible application demonstrations are necessary to ensure ROI to address economic concerns. Agents for modular transformations can be further enforced by proper transformable jigs and fixtures, proper tracking and tracing and in-process quality inspection [98]. Intelligence must be incorporated in agents for proper reconfiguration strategy deployment mainly targeting intelligence integration at the machine level to ensure optimization of production parameters [99]. Agent-driven protocols require proper commissioning and standardization mechanism for proper environmental interaction [100]. Agent systems can be used for fault detection, failure event prediction and real-time diagnosis [115]. A proper control mechanism however requires proper communication for handling frequent changes and constant uncertainties [101].

Significant challenges to agent implementation to reconfiguration problems are pivoted by lack of monitoring and analysis tools along with platforms to develop dynamic context-based insight [116]. These challenges are further enforced by lack of integration mechanisms between cloud/edge computing resources, Wireless sensor and Actuator Network coupled with ontology frameworks [117]. Proper learning mechanisms are necessary in the system to achieve self-diagnosis with focus on varying demand and costing needs [118].

3.6 Service, cloud and AI base applications

Wang et al. [96] in the context of a process reconfiguration based on multi-agent negotiation, a cloud infrastructure is used as an interaction management framework. It hosts a SQL server and various virtual machines. One is a Hadoop cluster that performs distributed data processing, the other one is a Flume server, and finally a MySQL server. The cloud is utilized as a multi-layer interaction to integrate consumers, management and shop-floor entities. Also, the cloud assists the interaction between robots functionalities and transport systems. This work is showcased by means of the flow control of a prototype for packaging assorted candies. A similar approach is presented in the author’s previous work also [102]. Here the cloud acts as a supervisory control entity. A cloud-based self-organizing architecture with agents is presented in Tang et al. [103]. There is an ontological representation to provide decision-making support during jobs execution. Also communication methods are proposed to meet interoperability communication demands. These methods are based on OPC UA, which is used as a network bridge for monitoring and data acquisition. The framework also supports higher integration levels, e.g., Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM). Zhang et al. [95] propose a self-organizing and self-adaptable manufacturing framework, service-oriented technologies wrapped the functionalities of machines and resources which can be invoked and deployed on demand considering various models and intelligent algorithms for task allocation. Importance is given to functionalities like proactive service discovery, conflict resolution models, and optimal configuration of resources according to a manufacturing cost evaluation. The lack of a complex case study analysis is one of the limitations of the work. Manufacturing shop floor include complex environments and therefore more intelligent service discovery, composition and orchestration should be developed. In Rodrigues et al. [97], an extensive work for dynamic service reconfiguration is presented. Services are wrapped for quality control, welding or transport operations and a dynamic orchestration looking for opportunities to reconfigure is done by a multi-agent layer. The compatibility of services and operations utilizes a semantic matching to reduce the dimensions of alternative solutions. Various alternatives of reconfiguration are evaluated based on metrics of reconfiguration, deadlock situations, collaboration, etc. The non-consideration of possible nervousness (instability) of the system because of its high dynamicty is one of the drawbacks in this research.

The combination of agents and web services with provide both autonomy and interoperability. Lower level devices provide services, creates virtual resource and has interoperability in agent-based system. Colombo et al. [120]. Lower level control is provided by existing service-based logic and higher level is provided by agent-based logic where execution is also performed [121]. The execution layer can adapt its behavior depending on different scenarios and can aid in enterprise-level integration. In various cases the utilization of service and specially cloud-based infrastructures assists the interaction of negotiation of the cyber-physical units. However, very few works utilize such infrastructures to run agent operations. Additionally, several approaches utilize cloud technologies to support the operation and data distribution at the shop floor level.

AI is used in agent-based manufacturing systems to achieve autonomy, decentralization, flexibility, reliability, efficiency, learning, and self-regeneration characteristics. AI techniques such as Multi-Agent Reinforcement Learning, Probabilistic Machine Learning, and Bayesian Neural Networks have been applied in agent-based manufacturing systems for real-time condition monitoring, optimization, and control. Scrimieri et al. [122] presents an approach to reconfiguring distributed production systems based on complex product requirements, using a multi-agent system and data-driven machine intelligence. They introduce a method for checking the feasibility of a product and adapting resources, as well as a self-adaptation technique based on a machine learning algorithm. The approach is evaluated on a distributed robotic manufacturing system and is applicable to other scenarios. Huang et al. [104] proposal of an integrated control framework for optimizing production yield by modeling the manufacturing system as a graph and using Recursive Bayesian Estimation and Graph Neural Networks to process real-time information and generate node embedding. The framework then applies Multi-Agent Reinforcement Learning to treat each machine node as a distributed agent, and uses state-of-the-art algorithms to train learnable parameters and learn the optimal multi-agent policy, with extensive numerical experiments proving its effectiveness. Yong et al. [105] proposed a multi-agent system architecture that leverages probabilistic machine learning to address uncertainty in a cyber-physical manufacturing system scenario, demonstrated through the implementation of Bayesian Neural Networks for real-time condition monitoring of a hydraulic system. Dittrich et al. [80] proposed a novel cooperative multi-agent system approach that uses reinforcement learning and considers global key performance indicators to limit the control problem in complex production systems. Malus et al. [123] proposed a multi-agent reinforcement learning approach for efficient autonomous mobile robot order dispatching in dynamic production environments. El et al. [124] propose a hybrid supervised and semi-supervised machine learning approach for real-time fault diagnosis in industrial processes. Some of the challenges in using AI in agent-based manufacturing systems include dealing with uncertainty, handling large amounts of heterogeneous data, addressing the issue of explainability and interpretability of AI-based decision-making, ensuring safety and security, designing effective learning strategies, and integrating AI with existing manufacturing systems and processes. Other challenges include the need for high computational power, addressing ethical concerns, and ensuring the interoperability and standardization of AI-based systems.

4 SWOT analysis of agent-based manufacturing

This section provides an overview of the Strengths, Weakness, Opportunities, and Threats (SWOT) of the application of agent technologies in manufacturing. The SWOT analysis as a strategic planning framework provides details about a system’s organization capabilities [21]. It is used here to identify internal and external factors that affect the application of agent technologies in manufacturing and as a baseline to evaluate their advantages and disadvantages. Also, the current section intends to harmonize and link concepts and applications of Sections 2 and 3.

4.1 Method

The SWOT analysis is the result of a reflection and evaluation of the previous literature and requirements revision. Main steps for its development are describe below:

-

Understanding of smart manufacturing requirements.

-

Review of the application of agents in smart manufacturing.

-

Brainstorming and reflection on Strengths, Weaknesses, Opportunities, and Threats of Agent technology. This reflection was based on four dimensions: current market variability, current technological status, future of autonomous systems and feasibility of new technological status. Several meetings were carried out during the brainstorming and final agreement on the SWOT analysis. Members of these meetings consisted of researchers and professors of the Nova University of Lisbon (Portugal), the University of Nottingham (UK), TQC Ltd (UK) and the Institute for the Development of New Technologies (Portugal). Members of these meetings had different backgrounds, i.e., academic, industry (manufacturing) and business intelligence, which can provide more validity to the results of the analysis.

The result of the SWOT analysis is represented in Fig. 2. The first columns show a description of each of the SWOT variables. The second columns show related requirements in the context of smart manufacturing. The last column shows some application examples.

4.2 Strengths

The integration of MAS in manufacturing potentiates the decentralization and distribution of process control [60, 64]. Less centralized systems are more adaptable and fault tolerant. Decentralization also means the development of units with local intelligence and the increase of the level of autonomy. In manufacturing, this is the result of machines that have context base decision-making, i.e., they can take autonomous decisions [107].

Likewise, social ability properties increase the cooperation of manufacturing elements. This has been exemplified with direct and indirect communication between resources, orders, logistic agents, etc. which work together to perform assembly operations (for control and diagnosis, [88]). This fosters the design and implementation of process modules, which are software and hardware abstractions developed with the purpose of increasing process customization. Modules can form different processes when re-arranged without major engineering effort. This is commonly known as plug and produce [84, 100].

Current agent technological capabilities are also compliant with emerging technologies like web services, cloud computing, machine learning, interoperability thought ontological models, etc. This technological integration add additional functionalities and features in manufacturing operations. For example agent-service integration adds software scalability for modules. Machine learning techniques can be used as an input for agent negotiation [102, 103].

In a more conceptual discussion, MAS push more creative ways of thinking when designing distributed systems. As traditional centralized approaches cannot cope with current market dynamism (mass customization), distributed solutions should be pushed forward in smart manufacturing applications.

4.3 Weaknesses

Agent technology applications are constrained in their application because of lack of integration between production and process systems. This integration issue primarily is contributed by adaptability restriction in systems usually involving protocols, standards, framework similarity, and synergy at low-level component. These restrictions lead to significant difficulty in adapting agent technology at the system level as the program needs to be molded to address each component [95, 106].

Along with these to ensure proper integration of these technologies for decentralized control a significant capital investment is incumbent. This is to assure standard is maintained across the production system, and program consistency is maintained. Production planning and scheduling activities can be homogenized if a matching framework is adopted.

The applications in some cases need to be simulated before execution, there a robust software that can align and accommodate multiple scenarios is required. Currently this is one of the major hurdles to widespread adoption as safety and security of execution needs to be validated before operation [92, 93]. In a similar case due to extensive programming requirements agent technology is less significantly used, however making standard interfaces could be helpful in monitoring and diagnosis of manufacturing applications.

Negotiation rules need to be programmed which requires high-level experts, an intuitive means of inserting negotiation rules as functional blocks may be helpful in wider adaptation. Agents framework must also be expanded to include aspects of humans as agents.

4.4 Opportunities

Opportunities refer to favorable external factors that could give an organization a competitive advantage. In this case, we refer to competitive advantages to the benefits that the implementation of MAS may bring to manufacturing industries. The first point to consider is the digitization of factories. As it is essential to the abstraction of physical resources, decision-making and processes as software units, agent-based design is paving the way towards achieving this goal, with several use cases already implemented. At the same time agent-based applications promote integration and interoperability in the manufacturing chain. [88, 97, 103] New design methods in distributed solutions are taking advantage of agent-based principles. This is specially applied for manufacturing control and diagnosis; for example when mimicking the behavior of natural processes. Various applications have been referenced in this work that use pheromones, chemical reactions, or attraction mechanisms. Those provide new sources of inspiration to overcome current engineer limitations [67, 118]. These new methodological ideas and design result in more flexibility and agility at the shop floor level. In other words, software and hardware modules that can be easily adapted for new processes, requiring few/no engineering effort and time [92]

4.5 Threats

A significant threat to application and acceptance of agents in manufacturing organizations is the bias towards centralized control. A distributed control thinking must be propagated to take full benefit from agent technology. To ensure this proper safety and security standard must be developed and validated.

There also exists a lack of practical examples of implementation of agent technologies that must be worked on. A mechanism where these technologies can be integrated will significantly build trust in industrial organizations. Pilot projects implementation which shows significant results in shop-floor would encourage more widespread adaptation of the agent technologies. Other threats include competition with other approaches which might provide advantages similar to the adaptation of agent technologies. The competing technologies might include the combination of cloud-based systems, Internet of Things and Service-oriented Architectures [25].

5 Industrial expert evaluation of the SWOT analysis

In order to evaluate main features, advantages and disadvantages of the implementation of MAS in manufacturing and to understand the industrial need of this technology, we conducted a survey to various industrial experts. The methodology, findings, results and analysis of the survey are described in the rest of this section.

5.1 Methodology

The survey considers the experience of the authors, the SWOT analysis and the review of the state-of-the-art applications made in previous sections. From these results, we try to evaluate various aspects that have influenced and will influence the implementation of MAS in manufacturing. The survey was disseminated to the experts in small- and medium-scale manufacturers. These experts are mainly technology experts or managers of a manufacturing firm. These experts were chosen to understand the ground reality in the implementation of agent-based technologies. As the panel of the survey are manufacturing experts from small- and medium-scale sectors, we take the assumption that their knowledge in agent-based systems (an emerging technology in its earlier stage of implementation in industries) would be limited. Hence, the questionnaires were prepared without asking explicitly the applications of agent technologies but rather considering the SWOT analysis results and framing the question indirectly to understand its need and implementation in manufacturing. The question was prepared using Google Forms and deployed through e-mail to the experts.

We have analyzed four categories namely:

-

Current market variability

-

Current technological status

-

Feasibility of new technological adaptation

-

Future of autonomous Systems

The market variability section responds to the analysis of the flexibility and agility of contemporary manufacturing systems, i.e., how easy can they be adapted and how quickly this adaptation process can be carried out in different contexts. It is focused on factors that appear as a consequence of the parading shift (from mass production to mass customization), i.e., setup time, deployment time, type of machines used and programming skills needed.

The current technological status section aims to evaluate which emerging technologies are being applied in industries. A lot of current research assumes that manufacturers have already adopted various emerging technologies, i.e., AI, cloud computing, collaborative robotics, etc. or at least assume that they are willing to do it.

The feasibility of new technological adaptation section, unlike previous one, tries to understand how practical it is for companies to adopt new solutions, what opportunities they have to fulfill their needs and how easy it is for them to support legacy systems and traditional standards.

Finally, the future of autonomous systems section explores some benefits and effects of these new technologies, emphasizing the role of autonomous control, digitization and the future of humans in shop floor lines. Questions were prepared and sent to various industrial experts using Google Forms. The results of the survey and the study made during this work were used to discuss, compare and evaluate the application of agents in industry as will shown in the next subsections. A summary of this process is shown in Fig. 3 and the survey questionnaire is provided in the Appendix.

5.2 Results

A survey to present the current industrial understanding of multi-agent systems was carried out. It was used to highlight the industrial perception towards multi-agent applications and approach, leading to industrial acceptance and adoption. The survey gives an insight in establishing industrial perception on technology and its application.

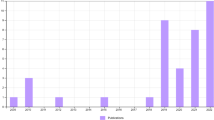

The survey primarily focused on the manufacturing companies in Europe, targeting small-, medium-, and large-scale industries. As seen in Fig. 4, 45.5% of the survey response came for individuals associated with large-scale setup. Equivalent population (27.3%) of responders were from small- and medium-scale setups. The setup size for small- and medium-scale industry ranged from 10 to 200 people, large-scale industries was around 1000 people or greater.

Survey was carried out among industries belonging to different sectors like oil and gas, metal processing, automotive, molding, medical implants, sensor manufacturing and manufacturing services. The survey targeted mid to upper level management of various industries, as they are directly involved in the decision-making process and could provide valuable insight into the applicability of this technology in a manufacturing setting. To maintain respondent privacy, some questions were optional, resulting in a total of 10 respondents who provided information on their expertise and experience. The respondents included three CEOs, a general director, a project manager, a production manager, two product development engineers, an industrial consultant, and an operator, providing a diverse range of perspectives on the topic.

The application of distributed manufacturing could be best realized where industries have higher product customization. To accumulate and factor in this information, and relating it to multi-agent system application, the question was framed. The insight basically targeted “different products produced in a month at the shop floor, especially those that involved manual changeover”. The survey yielded an increasing trend towards product variability that stresses the need for distributed manufacturing.

An increasing problem in manufacturing in the significant changeover time required to make the production line ready for manufacturing a different product. Efforts are usually carried out at the production facility to reduce this time but still a major time wastage is attributed to setup. The survey highlighted this trend with 44.4% associating 1–12 h with changeover.

A trend in distributed manufacturing is towards the “plug and produce” concept where the setup time is greatly reduced. Application of multi-agent systems in manufacturing is supposed to make it instantaneous. Current insight generated by the survey highlights the issue where the “commissioning of new equipment on shop floor” usually takes more than 4 weeks to be made functional.

Some level of programming is required to integrate the components in a production system. However, mostly industries tend to “rely on components that come with applications that assist in integration”.

In industrial settings, the prime motivator for technology adoption is to make processes economical and productive. Mass customization and variability are achieved as real-time data is interchanged. As industries move to data-oriented decision-making, more and more data interchange is required. Most of the survey responders were of the view that there is some at data interchange once an hour almost 50% of the time, while an increasing trend was towards real-time data interchange (30%).

Most of the industrial sectors adopt PLCs for their shop-floor automation, which is quite rigid in terms of flexibility required for distributed control. However, this rigidity is paramount for secure application execution. These security risks are of much larger concerns in data-oriented manufacturing. Conventional programming is still more widely accepted, followed by PLC standard application.

EtherCAT remains the most effective mode of data interchange for M2M communication, followed by TCP-IP with increased adoption of OPC UA.

IEC-61131, IEC 61499 and High-level programming remain the most used programming language/industrial standard for the production systems. This also couples up with a continuous requirement for software support.

Most of the industrial settings require some kind of software support, primarily dealing with websites, emails, and cloud infrastructure. However, these settings require scaling up and maintenance support. From the survey, we could also observe that all companies are familiar with internet/intranet-based services in shop-floor operation.

More industrial insight is observed towards automated machine adoption. Distributed manufacturing systems make systems more autonomous with less reliance on human operators. Currently, as per insight from surveys, a significant population (40%) attributes downtime to maintenance. The companies want to decrease this by increasing their adoption of smart production systems. About 50% believe that future investments will be carried out towards shop-floor automation, with 40% optimistic on having autonomous machines on shop-floor. This will result in increased performance and reduced human resource (50% believe this).

5.3 Analysis

The results of this survey are not indented to give accurate results of the questions asked but to show the trends in the current manufacturing shop floor.

Company details

The results show that the survey has been conducted with an even mix of large-, medium- and small-sized companies. This shows that the survey could be a representative of the entire manufacturing scale. This result is further validated in analyzing the number of employees in the company. The companies in the survey have employees ranging from as low as three to a large manufacturing plant of 1800 employees. These manufacturing companies also produce a wide variety of products like implants, sensors, automotive parts, and electric vehicles, but also include oil and gas plants. This shows the results are not restricted to one sector. Almost all the participants in the survey are from managerial position in the company; this is important as they have an overall picture of the company and not restricted to just the shop-floor.

Market variability

We find that both large- and medium-scale companies have high product variability, around 10 different parts in a month per shop floor line. This shows the trend of the market moving towards mass customization. The implementation of agent-based technologies will help in this trend. More than half of the companies take more than an hour to adapt to this product change with some companies taking beyond 2 days. Also we see that in installing a new machine to cope with the market variability it takes more than 1 week for most of the companies; in fact, half of these companies take more than 3 weeks (in setting up machines like cutting, injection molding, gluing). These results clearly show the lack of readiness in the current manufacturing to cope with the market need for mass customization. New technologies especially agent-based technologies could help in this process in implementing systems with faster response to product change and characteristics like plug and produce. A weakness of agent technologies is the lack of experts in the shop-floor to support its implementation and monitor the process. This statement is further validated with this survey. The results show that in most of the companies the person responsible for the deployment of the new machines and making changes to existing machines in the shop-floor has zero to low programming skills. At the current stage, implementing and maintaining the agent technologies in shop-floor require experts with high programming skills and the current manufacturing plants are not prepared for that. The main reason for less preparation includes the lack of awareness and maturity.

Current technological status

There is a push towards a faster information transfer within the shop-floor and information transfer from the shop-floor to other departments. This is evident from the survey results which show almost all companies transfer data from shop-floor to the production department within 1 h and some even transfer in real time. Agent technologies with their distributed nature could help in this requirement, but its development should take into consideration the high execution time during negotiations. A threat to the implementation of agent technologies is increasing need for data safety and security. Even though the results of the survey show that only one company had a data privacy breach in the last 5 years, this threat is real and the development of agent technologies should take it into consideration. The agent technologies implementation in its current stage lacks integration features with legacy systems. The results show that almost all the companies mainly use only PLCs. A robust integration of agents technologies with PLCs would help in integration of Agents in the current industrial settings. Currently most of them are restricted to only open source hardware like Arduino and Raspberry pi, which is not widely used outside research communities. The widely used platform for implementing agents is JADE. Some of the communication protocol used in industries like EtherCAT and TCP-IP have already being supported by JADE but there is still a need for other communication protocol support. The same is true for also the programming languages used, with very few companies using high-level programming languages like Java in their shop floor.

Current industrial and educational outlook

Manufacturing companies may not be adequately prepared to incorporate emerging technologies into their manufacturing processes due to a range of factors. One major obstacle is the lack of information and understanding of the technology and how it can be efficiently utilized. Additionally, concerns about the cost and potential disruptions associated with implementing and maintaining new technologies, as well as a shortage of technical expertise and resources to develop and manage these systems, can also pose significant challenges.

The industrial sector can take various steps to enhance their ability and sophistication in incorporating emerging technologies. One important measure is to invest in education and training for their workforce to ensure that they possess the necessary skills and knowledge to operate and maintain these technologies effectively. This may include technical training and support.

In addition, companies can encourage a culture of innovation and experimentation by empowering their employees to take risks and explore new technologies. Collaborating with other organizations, such as technology providers or research institutions, can also enable companies to leverage their expertise and resources when implementing these systems.

Furthermore, educational institutions can play a crucial role in this process by offering tailored training and education programs that keep pace with emerging industrial technologies. By partnering with industry stakeholders to ensure alignment with the sector’s needs and requirements, educational institutions can provide students with opportunities to gain hands-on experience through internships or apprenticeships.

Ultimately, it is essential for both the industrial sector and educational institutions to collaborate and work together to ensure that the workforce is equipped with the necessary skills and knowledge to effectively implement emerging technologies.

Feasibility for new technology adaptation

The use of agent technologies could considerably reduce the need for software updates and supports and have a higher level of autonomy. The industrial survey results show that this is not of greater advantage to the shop-floor as most of them require only very few software support/updates. In any case, the advantage would be helpful for some companies in the survey which needs more than 5 times software support and constant software updation. All companies in the list use internet-based services in the shop-floor which is a good sign as this provides an easier adaption of digital technologies in the shop-floor including agent-based which could be integrated with web-based services. Even though the survey shows none of the companies is familiar with agent-based systems, some companies being familiar with web service and cloud-based infrastructures is a positive sign. Finally, the strong interest in using standards like IEC and ISO in the manufacturing shop-floor shows the greater need for the development of standards for agent-based technologies.

Future of autonomous systems

The need for maintenance in the shop-floor line with the stoppage of the line would guide us in understanding how far we have reached in developing autonomous systems. Excluding the Oil and Gas plants which require No maintenance by stopping of the line almost all the plants require certain level of maintenance by stopping the production — some even as high as 16–20 times in a month. Agent technologies would help in this aspect. The view of most companies in investing in digital technologies and autonomous machines in the upcoming years is a positive sign and an opportunity for the development of agent technologies. The lack of similar view when it comes to the need for humans shows the increasing need for developing system with human-in-loop and better human-machine interactions.

6 Conclusion

This work gives an overview of the integration of agent’s technology in manufacturing. The requirements of smart manufacturing are discussed in detail. Manufacturers are required to fulfill smart manufacturing requirements in order to compete with expanding markets and mass customization. The requirements include computational capability, integration, virtualization, service orientation, complexity, interoperability and reconfigurability.

MAS technology and its application are introduced to meet some requirements of the manufacturing. MAS can be used in various smart manufacturing applications, such as process control, production planning, scheduling, monitoring, quality control, diagnosis, process reconfiguration and manufacturing simulation and executions.

The Strengths, Weakness, Opportunities, and Threats (SWOT) analysis method was used to evaluate the application of agent technologies in manufacturing. The integration of MAS means more decentralized and distributed process control, coordination and social ability, plug and produce ability, modularity and cloud-based integration. However, the agent technologies have also limitations, such as investment cost, legacy system integration, lack of experts and awareness. With the development of digitalization, mass customization adoption and autonomous needs, the MAS technologies can potentially be used widely in manufacturing industry.

A survey is conducted through industrial experts to evaluate the pros/cons of integration of MAS in practice. These results should be carefully taken into account by future practitioners and researchers. The more general conclusion that we may extrapolate from this work, is that despite the big plethora of research and implementation results, companies are still not prepared in terms of technological capabilities for the implementation of emerging technologies like MAS; however, the benefits are clear. The research community should push the implementation of methodologies and use cases in this direction to increase this technological awareness.

There are various techniques available to model and simulate complex systems, and Agent-based modeling and simulation (ABMS) is one such approach. Other methods include, for example, system dynamics, discrete-event simulation, and Monte Carlo simulation. The choice of method depends on the specific features of the system being studied and the research questions being asked. ABMS is particularly suitable for modeling systems with emergent behavior, such as biological and social systems, but can also be applied to other types of systems. Some examples of industries where ABMS has been used include supply chains, transportation systems, and manufacturing systems.

The suitability of ABMS for a specific manufacturing industry depends on the complexity and characteristics of the system being modeled. ABMS can be used to model systems at different levels of granularity, from a macro-level to a micro-level, but the level of detail and complexity that can be handled depends on the available computational resources and the modeling tools being used. For instance, ABMS can be employed to model a manufacturing supply chain at a macro-level to explore the effects of various inventory policies on system performance, or at a micro-level to simulate the interactions between individual production machines and workers.

To summarize, ABMS is one of several methods for modeling and simulating complex systems, and its applicability to a specific manufacturing industry depends on the particular features of the system being studied and the research questions being asked.

Abbreviations

- AGV:

-

Automated Guided Vehicle

- AI:

-

Artificial Intelligence

- AR:

-

Augmented Reality

- CPPS:

-

Cyber-Physical Production System

- CPS:

-

Cyber-Physical System

- ERP:

-

Enterprise resource planning

- GPU:

-

Graphics Processing Unit

- ICT:

-

Information and Communication Technologies

- IoT:

-

Internet of Things

- IT:

-

Information Technology

- JADE:

-

Java Agent DEvelopment framework

- MAS:

-

Multi-Agent System

- MES:

-

Manufacturing Execution System