Abstract

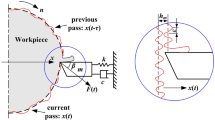

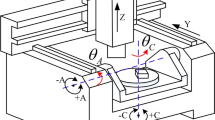

A chatter occurring in metal cutting causes a poor surface quality of product, an excessive tool wear, and a waste of workpiece materials and energy; limits the material removal rate, etc.; and leads to various negative effects. In recent years, for suppression of chatter, spindle speed variation (SSV) that changes the cutting speed continuously during processing in machine tools has interested the researchers. Mainly, studies have been done on assessment of the effectiveness of SSV technique using already given simple signal types such as triangular, rectangular or sinusoidal. However, among the previous works, studies to determine more efficient types of signals for suppression of chatter are very little. The present study proposes a method that composes the spindle speed variation in multi-harmonic series before optimally determines the number, the amplitudes, and the modulating frequencies of harmonic series, using firefly algorithm (FA) for suppressing more efficiently a chatter that occurs in turning. Firstly, after the number of harmonics, the amplitude and the fundamental frequency of multi-harmonic modulating signal of spindle are taken as optimum design variables and we set up an optimization problem such that the dynamic cutting force becomes minimal. We solve it using FA where the global search performance of FA is improved by changing the walk of fireflies nonlinearly with iteration number. We also present a convergence index that makes it possible to evaluate the performance of extremum search quantitatively. It is shown that it is reasonable to compose the spindle speed variation signal in multiple harmonic series if the fundamental frequency of SSV signal is low, in a single harmonic term if it is higher.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann Manuf Technol 53(2):619–642

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tool Manu 51:363–376

Takemura T, Kitamura T, Hoshi T, Okushimo K (1974) Active suppression of chatter by programmed variation of spindle speed. CIRP Ann 23(1):121–122

Inamura T, Sata T (1974) Stability analysis of cutting under varying spindle speed. CIRP Ann 23(1):119–120

Sexton JS, Stone BJ (1980) An investigation of variable of the transient effects during variable speed cutting. J Mech Eng Sci 22:107–118

De Canniere J et al (1981) A contribution to the mathematical analysis of variable spindle speed machining. Appl Math Model 5(3):158–164

Lin SC et al (1990) The effects of variable speed cutting on vibration control in face milling. Trans ASME J Eng Ind 112:1–11

Jayaram S, Kapoor SG, DeVor RE (2000) Analytical stability analysis of variable spindle speed machining. Trans ASME J Manuf Sci Eng 122:391–397

Yang F, Zhang B, Yu J (2003) Chatter suppression with multiple time-varying parameters in turning. J Mater Proc Technol 141(3):431–438

Al Regib E, Ni J, Lee SH (2003) Programming spindle speed variation for machine tool chatter suppression. Int J Mach Tool Manu 43(12):1229–1240

Insperger T, Stepan G (2004) Stability analysis with periodic spindle speed modulation via semi-discretization. J Vib Control 10:1835–1855

Namachchivaya NS, Beddini R (2003) Spindle speed variation for the suppression of regenerative chatter. J Nonlienear Sci 13:265–288

Demir A, Hasanov A, Namachchivaya NS (2006) Delay equations with fluctuating delay related to the regenerative chatter. Int J Nonlienear Mech 41:464–474

Jayaram S, Kapoor S, DeVor R (2000) Analytical stability analysis of variable spindle speed machining. J Manuf Sci Eng Trans ASME 122(3):391–397

Chiou YS et al (1995) Analysis of tool wear effect on chatter stability in turning. Int J Mech Sci 37(4):391–404

Hajikolaei KH et al (2010) Spindle speed variation and adaptive force regulation to suppress regenerative chatter in the turning process. J Manuf Process 12(2):106–115

Fansen K (2011) Simulation and experimental research on chatter suppression using chaotic spindle speed variation. J Manuf Sci E T ASME 133(2):1–4

Albertelli P et al (2012) Spindle speed variation in turning: technological effectiveness and applicability to real industrial cases. Int J Adv Manuf Technol 62:59–67

Falta J et al (2018) Chatter suppression in finish turning of thin- walled cylinder: model of tool workpiece interaction and effect of spindle speed variation. Procedia CIRP 77:175–176

Kvasov DE et al (2018) Metaheuristic vs. deterministic global optimization algorithms: The univariate case. Appl Math Comput 318:245–259

Yang XS (2010) Nature-inspired metaheuristic algorithms, 2nd edn, Luniver Press, pp. 81~89, 105-116

Kazemzadeh Azad S et al (2011) Optimum design of structures using an improved firefly algorithm. Int J Optim Civ Eng 2:327–340

Gholizadeh S, Barati H (2012) A comparative study of three metaheurstics for optimum design of trusses. Int J Optim Civ Eng 3:423–441

Dong X, Shen X, Fu Z (2021) Stability analysis in turning with variable spindle speed based on the reconstructed semi-discretization method. Int J Adv Manuf Technol 117(11):3393–3403

Wang C, Zhang X, Yan R, Chen X, Cao H (2019) Multi harmonic spindle speed variation for milling chatter suppression and parameters optimisation. Precis Eng 55:268–274

Wang C, Zhang X, Liu J, Cao H, Chen X (2019) Adaptive vibration reshaping based milling chatter suppression. Int J Mach Tools Manuf 41:30. https://doi.org/10.1016/j.ijmachtools.2019.04.001

Dang X, Wan M, Zhang W, Yang Y (2021) Chatter analysis and mitigation of milling of the pocket-shaped thin-walled workpieces with viscous fluid. Int J Mech Sci 194:106214. https://doi.org/10.1016/j.ijmecsci.2020.106214

Zhu L, Liu C (2020) Recent progress of chatter prediction, detection and suppression in milling. Mech Syst Signal Process 146:1–37. https://doi.org/10.1016/j.ymssp.2020.106840

Alzghoul M et al (2022) Analytical and experimental techniques for chatter prediction, suppression and avoidance in turning; literature survey. Des Mach Struct 12(2):33–43. https://doi.org/10.32972/dms.2022.011

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Paek, R., Ha, SH. & Ri, SC. Optimal determination of spindle speed variation type for the suppression of chatter in turning. Int J Adv Manuf Technol 126, 2481–2496 (2023). https://doi.org/10.1007/s00170-023-11192-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11192-9