Abstract

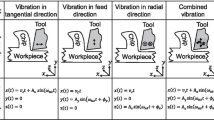

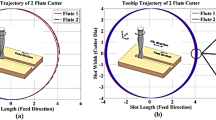

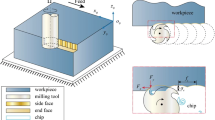

Ultrasonic vibration-assisted (UVA) cutting is an advanced technique to improve the machinability and productivity of difficult-to-machine materials. This paper aims to assess the cutting performance of ultrasonic vibration-assisted milling (UVAM) technique and conventional milling (CM) in side milling of Ti–6Al–4 V. Tool trajectory and instantaneous chip thickness are calculated considering tool runout, vibration, and deflection. The geometric-kinematic-dynamic surface topography matrix and its corresponding material elastic recovery height matrix are reconstructed based on tool trajectory and cutting thickness, which are then summed to obtain the geometric-kinematic-dynamic-physical surface topography matrix. Finally, roughness parameters Ra and Rz are predicted based on the final reconstructed physical surface topography matrix. Experimental results show that Ra and Rz of UVAM are on average 26 and 39% greater, respectively, compared to CM due to the presence of high-frequency ultrasonic vibration-induced texture patterns in the feed grooves. The average prediction error for Ra and Rz is 23%, proving the validity of the prediction model. UVAM reduces the radial and tangential cutting force coefficients and ploughing force coefficients compared to CM due to the separation and impact effect of ultrasonic vibration. However, UVAM leads to an increase in the axial ploughing force coefficient because ultrasonic vibration introduces relative motion and friction between the tool and the workpiece in the axial direction.

Similar content being viewed by others

References

Yang Z, Zhu L, Zhang G, Ni C, Lin B (2020) Review of ultrasonic vibration-assisted machining in advanced materials. Int J Mach Tools Manuf 156:103594. https://doi.org/10.1016/j.ijmachtools.2020.103594

Cao Y, Zhu Y, Ding W, Qiu Y, Wang L, Xu J (2022) Vibration coupling effects and machining behavior of ultrasonic vibration plate device for creep-feed grinding of Inconel 718 nickel-based superalloy. Chin J Aeronaut 35(2):332–345. https://doi.org/10.1016/j.cja.2020.12.039

Patil S, Joshi S, Tewari A, Joshi SS (2014) Modelling and simulation of effect of ultrasonic vibrations on machining of Ti6Al4V. Ultrasonics 54(2):694–705. https://doi.org/10.1016/j.ultras.2013.09.010

Li C, Zhang F, Meng B, Liu L, Rao X (2017) Material removal mechanism and grinding force modelling of ultrasonic vibration assisted grinding for SiC ceramics. Ceram Int 43(3):2981–2993. https://doi.org/10.1016/j.ceramint.2016.11.066

Xu W, Zhang LC, Wu Y (2014) Elliptic vibration-assisted cutting of fibre-reinforced polymer composites: understanding the material removal mechanisms. Compos Sci Technol 92:103–111. https://doi.org/10.1016/j.compscitech.2013.12.011

Wang H, Pei ZJ, Cong W (2020) A feeding-directional cutting force model for end surface grinding of CFRP composites using rotary ultrasonic machining with elliptical ultrasonic vibration. Int J Mach Tools Manuf 152:103540. https://doi.org/10.1016/j.ijmachtools.2020.103540

Xu J, Feng P, Feng F, Zha H, Liang G (2021) Subsurface damage and burr improvements of aramid fiber reinforced plastics by using longitudinal–torsional ultrasonic vibration milling. J Mater Process Technol 297:117265. https://doi.org/10.1016/j.jmatprotec.2021.117265

Xu W, Zhang LC (2014) On the mechanics and material removal mechanisms of vibration-assisted cutting of unidirectional fibre-reinforced polymer composites. Int J Mach Tools Manuf 80–81:1–10. https://doi.org/10.1016/j.ijmachtools.2014.02.004

Zhao B, Wu B, Yue Y, Ding W, Xu J, Guo G (2023) Developing a novel radial ultrasonic vibration-assisted grinding device and evaluating its performance in machining PTMCs. Chin J Aeronaut. https://doi.org/10.1016/j.cja.2023.01.008

Bai W, Roy A, Sun R, Silberschmidt VV (2019) Enhanced machinability of SiC-reinforced metal-matrix composite with hybrid turning. J Mater Process Technol 268:149–161. https://doi.org/10.1016/j.jmatprotec.2019.01.017

Dong Z, Zhang H, Kang R, Ran Y, Bao Y (2022) Mechanical modeling of ultrasonic vibration helical grinding of SiCf/SiC composites. Int J Mech Sci 234:107701. https://doi.org/10.1016/j.ijmecsci.2022.107701

Gao J, Altintas Y (2020) Chatter stability of synchronized elliptical vibration assisted milling. CIRP J Manuf Sci Technol 28:76–86. https://doi.org/10.1016/j.cirpj.2019.11.006

Ulutan D, Ozel T (2011) Machining induced surface integrity in titanium and nickel alloys: a review. Int J Mach Tools Manuf 51(3):250–280. https://doi.org/10.1016/j.ijmachtools.2010.11.003

An Q, Cai C, Zou F, Liang X, Chen M (2020) Tool wear and machined surface characteristics in side milling Ti6Al4V under dry and supercritical CO2 with MQL conditions. Tribol Int 151:106511. https://doi.org/10.1016/j.triboint.2020.106511

Cai C, Liang X, An Q, Tao Z, Ming W, Chen M (2021) Cooling/lubrication performance of dry and supercritical CO2-based minimum quantity lubrication in peripheral milling Ti-6Al-4V. Int J Pr Eng Man-GT 8(2):405–421. https://doi.org/10.1007/s40684-020-00194-7

Liu D, Li C, Dong L, Qin A, Zhang Y, Yang M, Gao T, Wang X, Liu M, Cui X, Ali HM, Sharma S (2022) Kinematics and improved surface roughness model in milling. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-022-10729-8

Wu P, Dai H, Li Y, He Y, Zhong R, He J (2022) A physics-informed machine learning model for surface roughness prediction in milling operations. Int J Adv Manuf Technol 123(11):4065–4076. https://doi.org/10.1007/s00170-022-10470-2

Verma GC, Pandey PM (2019) Machining forces in ultrasonic-vibration assisted end milling. Ultrasonics 94:350–363. https://doi.org/10.1016/j.ultras.2018.07.004

Cao Y, Ding W, Zhao B, Wen X, Li S, Wang J (2022) Effect of intermittent cutting behavior on the ultrasonic vibration-assisted grinding performance of Inconel 718 nickel-based superalloy. Precis Eng 78:248–260. https://doi.org/10.1016/j.precisioneng.2022.08.006

Gao G, Xia Z, Yuan Z, Xiang D, Zhao B (2020) Influence of longitudinal-torsional ultrasonic-assisted vibration on micro-hole drilling Ti-6Al-4V. Chin J Aeronaut. https://doi.org/10.1016/j.cja.2020.06.012

Liu X, Wang W, Jiang R, Xiong Y, Lin K, Li J, Shan C (2020) Analytical model of cutting force in axial ultrasonic vibration-assisted milling in-situ TiB2/7050Al PRMMCs. Chin J Aeronaut. https://doi.org/10.1016/j.cja.2020.08.009

Feng Y, Hsu F-C, Lu Y-T, Lin Y-F, Lin C-T, Lin C-F, Lu Y-C, Liang SY (2020) Temperature prediction of ultrasonic vibration-assisted milling. Ultrasonics 108:106212. https://doi.org/10.1016/j.ultras.2020.106212

Peng Z, Zhang X, Zhang D (2021) Effect of radial high-speed ultrasonic vibration cutting on machining performance during finish turning of hardened steel. Ultrasonics 111:106340. https://doi.org/10.1016/j.ultras.2020.106340

Ni C, Zhu L, Liu C, Yang Z (2018) Analytical modeling of tool-workpiece contact rate and experimental study in ultrasonic vibration-assisted milling of Ti–6Al–4V. Int J Mech Sci 142–143:97–111. https://doi.org/10.1016/j.ijmecsci.2018.04.037

Jung H, Hayasaka T, Shamoto E, Xu L (2020) Suppression of forced vibration due to chip segmentation in ultrasonic elliptical vibration cutting of titanium alloy Ti–6Al–4V. Precis Eng 64:98–107. https://doi.org/10.1016/j.precisioneng.2020.03.017

Lotfi M, Charkhian A, Akbari J (2022) Surface analysis in rotary ultrasonic-assisted milling of CFRP and titanium. J Manuf Process 84:174–182. https://doi.org/10.1016/j.jmapro.2022.10.006

Greco S, Klauer K, Kirsch B, Aurich JC (2021) Vibration-assisted micro milling of AISI 316L produced by laser-based powder bed fusion. J Manuf Process 71:298–305. https://doi.org/10.1016/j.jmapro.2021.09.020

Cao Y, Yin J, Ding W, Xu J (2021) Alumina abrasive wheel wear in ultrasonic vibration-assisted creep-feed grinding of Inconel 718 nickel-based superalloy. J Mater Process Technol 297:117241. https://doi.org/10.1016/j.jmatprotec.2021.117241

Sorgato M, Bertolini R, Ghiotti A, Bruschi S (2021) Tool wear analysis in high-frequency vibration-assisted drilling of additive manufactured Ti6Al4V alloy. Wear 477:203814. https://doi.org/10.1016/j.wear.2021.203814

Ni C, Zhu L (2020) Investigation on machining characteristics of TC4 alloy by simultaneous application of ultrasonic vibration assisted milling (UVAM) and economical-environmental MQL technology. J Mater Process Technol 278:116518. https://doi.org/10.1016/j.jmatprotec.2019.116518

Namlu RH, Yılmaz OD, Lotfisadigh B, Kılıç SE (2022) An experimental study on surface quality of Al6061-T6 in ultrasonic vibration-assisted milling with minimum quantity lubrication. Procedia CIRP 108:311–316. https://doi.org/10.1016/j.procir.2022.04.071

Gao T, Zhang X, Li C, Zhang Y, Yang M, Jia D, Ji H, Zhao Y, Li R, Yao P, Zhu L (2020) Surface morphology evaluation of multi-angle 2D ultrasonic vibration integrated with nanofluid minimum quantity lubrication grinding. J Manuf Process 51:44–61. https://doi.org/10.1016/j.jmapro.2020.01.024

Sajjady SA, Nouri Hossein Abadi H, Amini S, Nosouhi R (2016) Analytical and experimental study of topography of surface texture in ultrasonic vibration assisted turning. Mater Des 93:311–323. https://doi.org/10.1016/j.matdes.2015.12.119

Amini S, Hosseinabadi HN, Sajjady SA (2016) Experimental study on effect of micro textured surfaces generated by ultrasonic vibration assisted face turning on friction and wear performance. Appl Surf Sci 390:633–648. https://doi.org/10.1016/j.apsusc.2016.07.064

Bertolini R, Ghiotti A, Bruschi S (2021) Wear behavior of Ti6Al4V surfaces functionalized through ultrasonic vibration turning. J Mater Eng Perform 30(10):7597–7608. https://doi.org/10.1007/s11665-021-05952-5

Börner R, Winkler S, Junge T, Titsch C, Schubert A, Drossel W-G (2018) Generation of functional surfaces by using a simulation tool for surface prediction and micro structuring of cold-working steel with ultrasonic vibration assisted face milling. J Mater Process Technol 255:749–759. https://doi.org/10.1016/j.jmatprotec.2018.01.027

Chen W, Zheng L, Xie W, Yang K, Huo D (2019) Modelling and experimental investigation on textured surface generation in vibration-assisted micro-milling. J Mater Process Technol 266:339–350. https://doi.org/10.1016/j.jmatprotec.2018.11.011

Chen P, Tong J, Zhao J, Zhang Z, Zhao B (2020) A study ofthe surface microstructure and tool wear of titanium alloys after ultrasonic longitudinal-torsional milling. J Manuf Process 53:1–11. https://doi.org/10.1016/j.jmapro.2020.01.040

Zhao B, Li P, Zhao C, Wang X (2020) Fractal characterization of surface microtexture of Ti6Al4V subjected to ultrasonic vibration assisted milling. Ultrasonics 102:106052. https://doi.org/10.1016/j.ultras.2019.106052

Xie W, Wang X, Zhao B, Li G, Xie Z (2022) Surface and subsurface analysis of TC18 titanium alloy subject to longitudinal-torsional ultrasonic vibration-assisted end milling. J Alloys Compd 929:167259. https://doi.org/10.1016/j.jallcom.2022.167259

Zhang M, Zhang D, Geng D, Liu J, Shao Z, Jiang X (2020) Surface and sub-surface analysis of rotary ultrasonic elliptical end milling of Ti-6Al-4V. Mater Des 191:108658. https://doi.org/10.1016/j.matdes.2020.108658

Maurotto A, Wickramarachchi CT (2016) Experimental investigations on effects of frequency in ultrasonically-assisted end-milling of AISI 316L: a feasibility study. Ultrasonics 65:113–120. https://doi.org/10.1016/j.ultras.2015.10.012

Krüger M, Denkena B (2013) Model-based identification of tool runout in end milling and estimation of surface roughness from measured cutting forces. Int J Adv Manuf Technol 65(5):1067–1080. https://doi.org/10.1007/s00170-012-4240-y

Buj-Corral I, Vivancos-Calvet J, González-Rojas H (2011) Influence of feed, eccentricity and helix angle on topography obtained in side milling processes. Int J Mach Tools Manuf 51(12):889–897. https://doi.org/10.1016/j.ijmachtools.2011.08.001

Zhang X, Zhang W, Zhang J, Pang B, Zhao W (2017) Systematic study of the prediction methods for machined surface topography and form error during milling process with flat-end cutter. P I Mech Eng B-J Eng 233:095440541774092. https://doi.org/10.1177/0954405417740924

Lee KY, Kang MC, Jeong YH, Lee DW, Kim JS (2001) Simulation of surface roughness and profile in high-speed end milling. J Mater Process Technol 113(1):410–415. https://doi.org/10.1016/S0924-0136(01)00697-5

Wojciechowski S, Twardowski P, Pelic M, Maruda RW, Barrans S, Krolczyk GM (2016) Precision surface characterization for finish cylindrical milling with dynamic tool displacements model. Precis Eng 46:158–165. https://doi.org/10.1016/j.precisioneng.2016.04.010

Denkena B, Krüger M, Bachrathy D, Stepan G (2012) Model based reconstruction of milled surface topography from measured cutting forces. Int J Mach Tools Manuf 54–55:25–33. https://doi.org/10.1016/j.ijmachtools.2011.12.007

Elbestawi MA, Ismail F, Yuen KM (1994) Surface topography characterization in finish milling. Int J Mach Tools Manuf 34(2):245–255. https://doi.org/10.1016/0890-6955(94)90104-X

Yang D, Liu Z (2015) Surface plastic deformation and surface topography prediction in peripheral milling with variable pitch end mill. Int J Mach Tools Manuf 91:43–53. https://doi.org/10.1016/j.ijmachtools.2014.11.009

Stepan G, Toth M, Bachrathy D, Ganeriwala S (2016) Spectral properties of milling and machined surface. Mater Sci Forum 836–837:570–577. https://doi.org/10.4028/www.scientific.net/MSF.836-837.570

Seguy S, Dessein G, Arnaud L (2008) Surface roughness variation of thin wall milling, related to modal interactions. Int J Mach Tools Manuf 48(3):261–274. https://doi.org/10.1016/j.ijmachtools.2007.09.005

Grossi N, Scippa A, Sallese L, Montevecchi F, Campatelli G (2018) On the generation of chatter marks in peripheral milling: a spectral interpretation. Int J Mach Tools Manuf 133:31–46. https://doi.org/10.1016/j.ijmachtools.2018.05.008

Ismail F, Elbestawi MA, Du R, Urbasik K (1993) Generation of milled surfaces including tool dynamics and wear. J Eng Ind 115(3):245–252. https://doi.org/10.1115/1.2901656

Omar OEEK, El-Wardany T, Ng E, Elbestawi MA (2007) An improved cutting force and surface topography prediction model in end milling. Int J Mach Tools Manuf 47(7):1263–1275. https://doi.org/10.1016/j.ijmachtools.2006.08.021

Morelli L, Grossi N, Campatelli G, Scippa A (2022) Surface location error prediction in 2.5-axis peripheral milling considering tool dynamic stiffness variation. Precis Eng 76:95–109. https://doi.org/10.1016/j.precisioneng.2022.03.008

Liu X, DeVor RE, Kapoor SG (2006) Model-based analysis of the surface generation in microendmilling—part I: Model Development. J Manuf Sci E-T ASME 129(3):453–460. https://doi.org/10.1115/1.2716705

Arizmendi M, Fernández J, Gil A, Veiga F (2009) Effect of tool setting error on the topography of surfaces machined by peripheral milling. Int J Mach Tools Manuf 49(1):36–52. https://doi.org/10.1016/j.ijmachtools.2008.08.004

Arizmendi M, Fernández J, Gil A, Veiga F (2010) Identification of tool parallel axis offset through the analysis of the topography of surfaces machined by peripheral milling. Int J Mach Tools Manuf 50(12):1097–1114. https://doi.org/10.1016/j.ijmachtools.2010.07.006

Arizmendi M, Fernández J, Gil A, Veiga F (2010) Model for the prediction of heterogeneity bands in the topography of surfaces machined by peripheral milling considering tool runout. Int J Mach Tools Manuf 50(1):51–64. https://doi.org/10.1016/j.ijmachtools.2009.09.007

Niu J, Jia J, Sun Y, Guo D (2020) Generation mechanism and quality of milling surface profile for variable pitch tools considering runout. J Manuf Sci E-T ASME 142(12). https://doi.org/10.1115/1.4047622

Artetxe E, Olvera D, López de Lacalle LN, Campa FJ, Olvera D, Lamikiz A (2017) Solid subtraction model for the surface topography prediction in flank milling of thin-walled integral blade rotors (IBRs). Int J Adv Manuf Technol 90(1):741–752. https://doi.org/10.1007/s00170-016-9435-1

Urbikain G, López de Lacalle LN (2018) Modelling of surface roughness in inclined milling operations with circle-segment end mills. Simul Model Pract Theory 84:161–176. https://doi.org/10.1016/j.simpat.2018.02.003

Urbikain Pelayo G (2019) Modelling of static and dynamic milling forces in inclined operations with circle-segment end mills. Precis Eng 56:123–135. https://doi.org/10.1016/j.precisioneng.2018.11.007

UrbikainPelayo G, Olvera-Trejo D, Luo M, López de Lacalle LN, Elías-Zuñiga A (2021) Surface roughness prediction with new barrel-shape mills considering runout: Modelling and validation. Measurement 173:108670. https://doi.org/10.1016/j.measurement.2020.108670

Kline WA, DeVor RE (1983) The effect of runout on cutting geometry and forces in end milling. Int J Mach Tool Des Res 23(2):123–140. https://doi.org/10.1016/0020-7357(83)90012-4

Altintas Y (2012) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design, 2nd edn. Cambridge University Press, Cambridge

Schmitz TL, Smith KS (2019) Milling Dynamics. Machining dynamics: frequency response to improved productivity. Cham: Springer International Publishing. 129–212

Zong WJ, Huang YH, Zhang YL, Sun T (2014) Conservation law of surface roughness in single point diamond turning. Int J Mach Tools Manuf 84:58–63. https://doi.org/10.1016/j.ijmachtools.2014.04.006

Budak E (2006) Analytical models for high performance milling. Part I: cutting forces, structural deformations and tolerance integrity. Int J Mach Tools Manuf 46(12):1478–1488. https://doi.org/10.1016/j.ijmachtools.2005.09.009

Zhang X, Sui H, Zhang D, Jiang X (2018) Measurement of ultrasonic-frequency repetitive impulse cutting force signal. Measurement 129:653–663. https://doi.org/10.1016/j.measurement.2018.06.043

Grossi N, Sallese L, Scippa A, Campatelli G (2015) Speed-varying cutting force coefficient identification in milling. Precis Eng 42:321–334. https://doi.org/10.1016/j.precisioneng.2015.04.006

Kiran K, Kayacan MC (2019) Cutting force modeling and accurate measurement in milling of flexible workpieces. Mech Syst Signal Process 133:106284. https://doi.org/10.1016/j.ymssp.2019.106284

Magnevall M, Lundblad M, Ahlin K, Broman G (2012) High frequency measurements of cutting forces in milling by inverse filtering. Mach Sci Technol 16(4):487–500. https://doi.org/10.1080/10910344.2012.698970

Rubeo MA, Schmitz TL (2016) Mechanistic force model coefficients: a comparison of linear regression and nonlinear optimization. Precis Eng 45:311–321. https://doi.org/10.1016/j.precisioneng.2016.03.008

Scippa A, Sallese L, Grossi N, Campatelli G (2015) Improved dynamic compensation for accurate cutting force measurements in milling applications. Mech Syst Signal Process 54–55:314–324. https://doi.org/10.1016/j.ymssp.2014.08.019

Wan M, Yin W, Zhang W-H, Liu H (2017) Improved inverse filter for the correction of distorted measured cutting forces. Int J Mech Sci 120:276–285. https://doi.org/10.1016/j.ijmecsci.2016.11.033

Totis G, Sortino M (2022) Upgraded regularized deconvolution of complex dynamometer dynamics for an improved correction of cutting forces in milling. Mech Syst Signal Process 166:108412. https://doi.org/10.1016/j.ymssp.2021.108412

Zhao B, Bie W, Wang X, Chen F, Wang Y, Chang B (2019) The effects of thermo-mechanical load on the vibrational characteristics of ultrasonic vibration system. Ultrasonics 98:7–14. https://doi.org/10.1016/j.ultras.2019.05.005

Nieslony P, Krolczyk GM, Zak K, Maruda RW, Legutko S (2017) Comparative assessment of the mechanical and electromagnetic surfaces of explosively clad Ti–steel plates after drilling process. Precis Eng 47:104–110. https://doi.org/10.1016/j.precisioneng.2016.07.011

Funding

This work was financially supported by National Natural Science Foundation of China (Grant number: 92160206).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ming, W., Cai, C., Ma, Z. et al. Milling mechanism and surface roughness prediction model in ultrasonic vibration-assisted side milling of Ti–6Al–4 V. Int J Adv Manuf Technol 131, 2279–2293 (2024). https://doi.org/10.1007/s00170-023-11109-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11109-6