Abstract

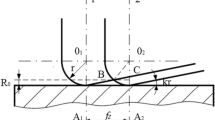

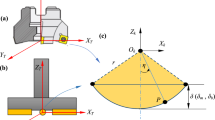

Surface roughness has a significant influence on the mechanical properties and service life of a component. During face milling, surface roughness greatly varies in the tool step direction and can be controlled by using a surface roughness prediction model. However, the issues of accuracy and efficiency of surface roughness prediction models have not been adequately addressed. This study aims to address these research constraints. An improved surface roughness prediction model is proposed, taking into consideration the influences of insert back cutting and stepover ratio. First, the profile-forming mechanism is analyzed based on geometry and kinematics. Subsequently, an improved surface roughness prediction model is established. Thereafter, the influence of feed per tooth, stepover ratio, corner radius, and minor cutting edge angle on surface roughness are analyzed through numerical simulation. Finally, the experiment of face milling aerospace aluminum alloy 7075 is suggested to verify the improved model, and the Z-Map model is introduced for comparison. Results show that the surface roughness is nonlinear with a feed per tooth and stepover ratio, a monotonic variation with corner radius, and a minor cutting edge angle. The predicted values of the improved model and the Z-Map model for the Rsm are equal to the experimental values. However, the improved model reduces the prediction error of Ra from 11.2 to 4.2% in the non-overlapping compared with the Z-Map model and from 62.58 to 13.34% in the overlapping. In addition, the improved model performs better than the Z-Map model in predicting the shape parameters. This work serves as a significant reference for selecting and optimizing the milling parameters to enable machining quality control.

Similar content being viewed by others

Data availability

Data sharing is not applicable to this article.

Code availability

Code availability is not applicable to this article.

Abbreviations

- R :

-

Tool of radius (mm)

- r :

-

Corner radius (mm)

- t :

-

Number of teeth

- N z :

-

Maximum number of teeth

- Z tn ,c, Ztn, c +1 :

-

Profile height of the insert in the insert coordinate system (mm)

- \({K}_{\mathrm{r}}^{^{\prime}}\) :

-

Minor cutting edge angle (°)

- θ :

-

Insert contact angle (°)

- f z :

-

Feed per tooth (mm/t)

- i :

-

Forward cutting insert number

- k :

-

Back cutting insert number

- a p :

-

Depth of cut (mm)

- K :

-

Stepover ratio

- Y tg :

-

Position in tool coordinate system

- Z W :

-

Profile height in the workpiece coordinate system (mm)

- a e :

-

Stepping width (mm)

- D :

-

Tool diameter (mm)

- B :

-

Initial cutting width (mm)

- S :

-

Number of stepping

- R a :

-

Profile average height deviation (μm)

- S a :

-

Surface arithmetic mean deviation (μm)

- L x :

-

Length of the workpiece (mm)

- L y :

-

Width of the workpiece (mm)

- l :

-

Insert length (mm)

- d :

-

Insert width (mm)

- t m :

-

Insert thickness (mm)

- n :

-

Rotational speed (rpm)

- V :

-

Feed rate (mm/min)

- W :

-

Width of overlapping (mm)

References

Cao Y, Zhu YJ, Ding WF, Qiu YT, Wang LF, Xu JH (2022) Vibration coupling effects and machining behavior of ultrasonic vibration plate device for creep-feed grinding of Inconel 718 nickel-based superalloy. Chin J Aeronaut 35:332–345. https://doi.org/10.1016/j.cja.2020.12.039

Kuang WJ, Miao Q, Ding WF, Zhao YJ, Zhao B, Wen XB, Li SP (2022) Fretting wear behaviour of machined layer of nickel-based superalloy produced by creep-feed profile grinding. Chin J Aeronaut 35:401–411. https://doi.org/10.1016/j.cja.2021.10.007

Bennett JM (1992) Recent developments in surface roughness characterization. Meas Sci Technol 3:1119

Myers N (1962) Characterization of surface roughness. Wear 5:182–189. https://doi.org/10.1016/0043-1648(62)90002-9

Cui X, Li CH, Zhang YB, Ding WF, An Q L, Liu B, Li HN, Said Z, Sharma S, Li RZ, Debnath S (2022), Comparative assessment of force, temperature, and wheel wear in sustainable grinding aerospace alloy using biolubricant. Front Mech Eng-prc 18.https://doi.org/10.1007/s11465-022-0719-x

Zhao B, Wang X, Ding WF, Wang Y, Fu YC, Zhao YJ, Zhu JH (2022) Grain erosion wear properties and grinding performance of porous aggregated cubic boron nitride abrasive wheels. Chin J Aeronaut. https://doi.org/10.1016/j.cja.2022.08.005.DOI:10.1016/j.cja.2022.08.005

Miao Q, Ding WF, Xu JH, Cao LJ, Wang HC, Yin Z, Dai CW, Kuang WJ (2021) Creep feed grinding induced gradient microstructures in the superficial layer of turbine blade root of single crystal nickel-based superalloy. Int J Extreme Manuf 3.https://doi.org/10.1088/2631-7990/ac1e05

Bajić D, Lela B, Živković D (2008) Modeling of machined surface roughness and optimization of cutting parameters in face milling. Metalurgija 47:331–334

Razfar MR, Asadnia M, Haghshenas M, Farahnakian M (2010) Optimum surface roughness prediction in face milling X20Cr13 using particle swarm optimization algorithm. Proc Inst Mech Eng Part B 224:1645–1653. https://doi.org/10.1243/09544054jem1809

Zhang ZC, Sui MH, Li CH, Zhou ZM, Liu B, Chen Y, Said Z, Debnath S, Sharma S (2022) Residual stress of grinding cemented carbide using MoS2 nano-lubricant. Int J Adv Manuf Technol 119:5671–5685. https://doi.org/10.1007/s00170-022-08660-z

Wang XM, Li CH, Zhang YB, Said Z, Debnath S, Sharma S, Yang M, Gao T (2021) Influence of texture shape and arrangement on nanofluid minimum quantity lubrication turning. Int J Adv Manuf Technol 119:631–646. https://doi.org/10.1007/s00170-021-08235-4

Liu MZ, Li CH, Zhang YB, Yang M, Gao T, Cui X, Wang XM, Xu WH, Zhou ZM, Liu B, Said Z, Li RZ, Sharma S (2022) Analysis of grinding mechanics and improved grinding force model based on randomized grain geometric characteristics. Chin J Aeronaut. https://doi.org/10.1016/j.cja.2022.11.005.DOI:10.1016/j.cja.2022.11.005

Fu H-J, DeVor R, Kapoor SG (1984) A mechanistic model for the prediction of the force system in face milling operations.https://doi.org/10.1115/1.3185915

Felhő C, Karpuschewski B, Kundrák J (2015) Surface roughness modelling in face milling. Procedia CIRP 31:136–141. https://doi.org/10.1016/j.procir.2015.03.075

Li HZ, Liu K, Li XP (2001) A new method for determining the undeformed chip thickness in milling. J Mater Process Tech 113:378–384. https://doi.org/10.1016/S0924-0136(01)00586-6

Duan Z, Li C, Zhang Y, Yang M, Gao T, Liu X, Li R, Said Z, Debnath S, Sharma S (2022) Mechanical behavior and Semiempirical force model of aerospace aluminum alloy milling using nano biological lubricant. Front Mech Eng. https://doi.org/10.1007/s11465-022-0720-4

Zhang T, Li G H, Han L, Theoretical surface roughness model in high speed face milling, Advanced Materials Research, Trans Tech Publ, 2014, pp. 3331–3334.https://doi.org/10.4028/www.scientific.net/AMR.989-994.3331.

Karayel D (2009) Prediction and control of surface roughness in CNC lathe using artificial neural network. J Mater Process Tech 209:3125–3137. https://doi.org/10.1016/j.jmatprotec.2008.07.023

Lazkano X, Aristimuño P X, Aizpuru O, Arrazola P J (2022) Roughness maps to determine the optimum process window parameters in face milling. Int J Mech Sci 221.https://doi.org/10.1016/j.ijmecsci.2022.107191

Duan ZJ, Li CH, Zhang YB, Dong L, Bai XF, Yang M, Jia DZ, Li RZ, Cao HJ, Xu XF (2021) Milling surface roughness for 7050 aluminum alloy cavity influenced by nozzle position of nanofluid minimum quantity lubrication. Chin J Aeronaut 34:33–53. https://doi.org/10.1016/j.cja.2020.04.029

Xu W H, Li C H, Zhang Y B, Ali H M, Sharma S, Li R Z, Yang M, Gao T, Liu M Z, Wang X M, Said Z, Liu X, Zhou Z M (2022), Electrostatic atomization minimum quantity lubrication machining: from mechanism to application. Int J Extreme Manuf 4.https://doi.org/10.1088/2631-7990/ac9652

Wu XF, Li CH, Zhou ZM, Nie XL, Chen Y, Zhang YB, Cao HJ, Liu B, Zhang NQ, Said Z, Debnath S, Jamil M, Ali HM, Sharma S (2021) Circulating purification of cutting fluid: an overview. Int J Adv Manuf Technol 117:2565–2600. https://doi.org/10.1007/s00170-021-07854-1

Yang M, Li CH, Said Z, Zhang YB, Li RZ, Debnath S, Ali HM, Gao T, Long YZ (2021) Semiempirical heat flux model of hard-brittle bone material in ductile microgrinding. J Manuf Process 71:501–514. https://doi.org/10.1016/j.jmapro.2021.09.053

Zhang YB, Li HN, Li CH, Huang CZ, Ali HM, Xu XF, Mao C, Ding WF, Cui X, Yang M, Yu T, Jamil M, Gupta MK, Jia DZ, Said Z (2022) Erratum to: Nano-enhanced biolubricant in sustainable manufacturing: From processability to mechanisms. Friction. https://doi.org/10.1007/s40544-022-0674-x

Jia D Z, Zhang Y B, Li C H, Yang M, Gao T, Said Z, Sharma S (2022), Lubrication-enhanced mechanisms of titanium alloy grinding using lecithin biolubricant. Tribol Int 169.https://doi.org/10.1016/j.triboint.2022.107461

Costes JP, Moreau V (2011) Surface roughness prediction in milling based on tool displacements. J Manuf Process 13:133–140. https://doi.org/10.1016/j.jmapro.2011.02.003

Cui Z P, Zhang H J, Zong W J, Li G, Du K (2022), Origin of the lateral return error in a five-axis ultraprecision machine tool and its influence on ball-end milling surface roughness. Int J Mach Tool Manu 178.https://doi.org/10.1016/j.ijmachtools.2022.103907

Song WG, Liu ZQ, Yao GH, Khan AM, Cai YK (2022) Effect of workpiece work hardening on machined surface topography generated in two-step milling process. J Manuf Process 77:348–360. https://doi.org/10.1016/j.jmapro.2022.03.039

Muñoz-Escalona P, Maropoulos PG (2015) A geometrical model for surface roughness prediction when face milling Al 7075–T7351 with square insert tools. J Manuf Syst 36:216–223. https://doi.org/10.1016/j.jmsy.2014.06.011

Miko E, Nowakowski Ł (2012) Analysis and verification of surface roughness constitution model after machining process. Procedia Eng 39:395–404. https://doi.org/10.1016/j.proeng.2012.07.043

Zhang L, Zheng GL, Shi YN, Yang RR (2017) Improved tooth trajectory model for prediction of milled surface geometry. Mach Sci Technol 21:175–201. https://doi.org/10.1080/10910344.2017.1283959

Raza MH, Hafeez F, Zhong RY, Imran A (2020) Investigation of surface roughness in face milling processes. Int J Adv Manuf Technol 111:2589–2599. https://doi.org/10.1007/s00170-020-06188-8

Ali MH, Khidhir BA, Ansari MNM, Mohamed B (2019) FEM to predict the effect of feed rate on surface roughness with cutting force during face milling of titanium alloy. HBRC Journal 9:263–269. https://doi.org/10.1016/j.hbrcj.2013.05.003

Liu N, Wang SB, Zhang YF, Lu WF (2016) A novel approach to predicting surface roughness based on specific cutting energy consumption when slot milling Al-7075. Int J Mech Sci 118:13–20. https://doi.org/10.1016/j.ijmecsci.2016.09.002

Shivanna DM, Kiran MB, Venkatesh GS, Kavitha SD (2021) Analyzing the effects of machining parameters on surface roughness of machined surfaces using vision system. Mater Today: Proc 47:4885–4890. https://doi.org/10.1016/j.matpr.2021.06.254

Kiswanto G, Zariatin DL, Ko TJ (2014) The effect of spindle speed, feed-rate and machining time to the surface roughness and burr formation of aluminum alloy 1100 in micro-milling operation. J Manuf Process 16:435–450. https://doi.org/10.1016/j.jmapro.2014.05.003

Marakini V, Pai SP, Bhat UK, Thakur DS, Achar BP (2022) High-speed face milling of AZ91 Mg alloy: Surface integrity investigations. Int J Lightweight Mater Manuf 5:528–542. https://doi.org/10.1016/j.ijlmm.2022.06.006

Zhuang KJ, Gao JQ, Ye T, Dai X (2022) Effect of cutting edge radius on cutting force and surface roughness in machining of Ti-6Al-4V. Procedia CIRP 108:571–576. https://doi.org/10.1016/j.procir.2022.03.090

Khidhir B A, Mohamed B (2011), Analyzing the effect of cutting parameters on surface roughness and tool wear when machining nickel based hastelloy – 276. IOP Conf Ser: Mater Sci Eng 17.https://doi.org/10.1088/1757-899x/17/1/012043

Wang M-Y, Chang H-Y (2004) Experimental study of surface roughness in slot end milling AL2014-T6. Int J Mach Tool Manu 44:51–57. https://doi.org/10.1016/j.ijmachtools.2003.08.011

Daniyan I, Tlhabadira I, Mpofu K, Adeodu A (2021) Investigating the geometrical effects of cutting tool on the surface roughness of titanium alloy (Ti6Al4V) during milling operation. Procedia CIRP 99:157–164. https://doi.org/10.1016/j.procir.2021.03.097

Xiong YF, Wang WH, Shi YY, Jiang RS, Shan CW, Liu XF, Lin KY (2021) Investigation on surface roughness, residual stress and fatigue property of milling in-situ TiB2/7050Al metal matrix composites. Chin J Aeronaut 34:451–464. https://doi.org/10.1016/j.cja.2020.08.046

Ozcelik B, Bayramoglu M (2006) The statistical modeling of surface roughness in high-speed flat end milling. Int J Mach Tool Manu 46:1395–1402. https://doi.org/10.1016/j.ijmachtools.2005.10.005

Tlhabadira I, Daniyan IA, Masu L, VanStaden LR (2019) Process design and optimization of surface roughness during M200 TS milling process using the Taguchi method. Procedia Cirp 84:868–873. https://doi.org/10.1016/j.procir.2019.03.200

Yadav DK, Dixit NK, Agarwal D, Khare SK (2022) Optimization of surface roughness by design of experiment techniques during CNC milling machining. Mater Today: Proc 52:1919–1923. https://doi.org/10.1016/j.matpr.2021.11.565

Kadirgama K, Noor MM, Rahman MM (2012) Optimization of surface roughness in end milling using potential support vector machine. Arab J Sci Eng 37:2269–2275. https://doi.org/10.1007/s13369-012-0314-2

B R K, Ramesh V, C M S, R T T, L M A K (2022) Analyse the surface quality in the milling process by soft computing approaches. Mater Today: Proc https://doi.org/10.1016/j.matpr.2022.09.598

Rifai AP, Aoyama H, Tho NH, Md Dawal SZ, Masruroh NA (2020) Evaluation of turned and milled surfaces roughness using convolutional neural network. Measurement 161.https://doi.org/10.1016/j.measurement.2020.107860

Oktem H, Erzurumlu T, Erzincanli F (2006) Prediction of minimum surface roughness in end milling mold parts using neural network and genetic algorithm. Mater Design 27:735–744. https://doi.org/10.1016/j.matdes.2005.01.010

Kant G, Sangwan KS (2015) Predictive modelling and optimization of machining parameters to minimize surface roughness using artificial neural network coupled with genetic algorithm. Procedia CIRP 31:453–458. https://doi.org/10.1016/j.procir.2015.03.043

Bharathi Raja S, Baskar N (2012) Application of Particle Swarm Optimization technique for achieving desired milled surface roughness in minimum machining time. Expert Syst Appl 39:5982–5989. https://doi.org/10.1016/j.eswa.2011.11.110

Motta MP, Pelaingre C, Delamézière A, Ayed LB, Barlier C (2022) Machine learning models for surface roughness monitoring in machining operations. Procedia CIRP 108:710–715. https://doi.org/10.1016/j.procir.2022.03.110

Zhang XP, Li CH, Zhang YB, Jia DZ, Li BK, Wang YG, Yang M, Hou YL, Zhang XW (2016) Performances of Al2O3/SiC hybrid nanofluids in minimum-quantity lubrication grinding. Int J Adv Manuf Technol 86:3427–3441. https://doi.org/10.1007/s00170-016-8453-3

Shi Z, Liu LN, Liu ZQ (2015) Influence of dynamic effects on surface roughness for face milling process. Int J Adv Manuf Technol 80:1823–1831. https://doi.org/10.1007/s00170-015-7127-x

Denkena B, Dittrich M-A, Huuk J (2021) Simulation-based surface roughness modelling in end milling. Procedia CIRP 99:151–156. https://doi.org/10.1016/j.procir.2021.03.096

Zheng FY, Zhang MD, Zhang WQ, Tan RL, Guo XD (2019) The fundamental roughness model for face-milling spiral bevel gears considering run-outs. Int J Mech Sci 156:272–282. https://doi.org/10.1016/j.ijmecsci.2019.03.017

Franco P, Estrems M, Faura F (2004) Influence of radial and axial runouts on surface roughness in face milling with round insert cutting tools. Int J Mach Tool Manu 44:1555–1565. https://doi.org/10.1016/j.ijmachtools.2004.06.007

Gao GF, Fu ZX, Zhao JZ, Wang Y (2014) Study on surface roughness of milling based on the elastic-plastic deformation. Appl Mech Mater 551:55–60. https://doi.org/10.4028/www.scientific.net/AMM.551.55

Melkote S, Sutherland J, King C (1999), The effect of tool flexibility on back-cutting in end milled surfaces. J Manuf Sci E-t Asme 121.https://doi.org/10.1115/1.2832713

Ryu SH, Choi DK, Chu CN (2006) Roughness and texture generation on end milled surfaces. Int J Mach Tool Manu 46:404–412. https://doi.org/10.1016/j.ijmachtools.2005.05.010

Hadad M, Ramezani M (2016) Modeling and analysis of a novel approach in machining and structuring of flat surfaces using face milling process. Int J Mach Tool Manu 105:32–44. https://doi.org/10.1016/j.ijmachtools.2016.03.005

Urbikain Pelayo G, Olvera-Trejo D, Luo M, López de Lacalle LN, Elías-Zuñiga A (2021) Surface roughness prediction with new barrel-shape mills considering runout: modelling and validation. Measurement 173. https://doi.org/10.1016/j.measurement.2020.108670

Arizmendi M, Jiménez A (2019) Modelling and analysis of surface topography generated in face milling operations. Int J Mech Sci 163.https://doi.org/10.1016/j.ijmecsci.2019.105061

Dong YH, Li SJ, Li Y, Li PY, Yang ZZ (2017), Simulation and experimental study of ball-end milling surface topography based on an improved Z-MAP algorithm. J Mech Eng 53.https://doi.org/10.3901/jme.2017.23.197

Layegh KSE, Lazoglu I (2017) 3D surface topography analysis in 5-axis ball-end milling. Cirp Ann-manuf Techn 66:133–136. https://doi.org/10.1016/j.cirp.2017.04.021

Cai CY, Dang JQ, An QL, Ming WW, Chen M (2022) Surface morphology characterization of unidirectional carbon fibre reinforced plastic machined by peripheral milling. Chin J Aeronaut 35:361–375. https://doi.org/10.1016/j.cja.2021.04.024

Cao Y, Zhu YJ, Li HN, Wang CX, Su HH, Yin Z, Ding WF (2020) Development and performance of a novel ultrasonic vibration plate sonotrode for grinding. J Manuf Process 57:174–186. https://doi.org/10.1016/j.jmapro.2020.06.030

Cao Y, Yin JF, Ding WF, Xu JH (2021) Alumina abrasive wheel wear in ultrasonic vibration-assisted creep-feed grinding of Inconel 718 nickel-based superalloy. J Mater Process Tech 297.https://doi.org/10.1016/j.jmatprotec.2021.117241

Gao T, Li CH, Wang YQ, Liu XS, An QL, Li HN, Zhang YB, Cao HJ, Liu B, Wang DZ, Said Z, Debnath S, Jamil M, Ali HM, Sharma S (2022), Carbon fiber reinforced polymer in drilling: from damage mechanisms to suppression. Compos Struct 286.https://doi.org/10.1016/j.compstruct.2022.115232

Zhao XF, Li CH, Yu TB (2022) Effect of B4C on CBN/CuSnTi laser cladding grinding tool. Int J Adv Manuf Technol 119:6307–6319. https://doi.org/10.1007/s00170-021-08460-x

Magsipoc E, Zhao Q, Grasselli G (2019) 2D and 3D roughness characterization. Rock Mech Rock Eng 53:1495–1519. https://doi.org/10.1007/s00603-019-01977-4

Deltombe R, Kubiak KJ, Bigerelle M (2014) How to select the most relevant 3D roughness parameters of a surface. Scanning 36:150–160. https://doi.org/10.1002/sca.21113

M P, N S P (2020), Effect of cutting edge form factor (K-factor) on the performance of a face milling tool. Cirp J Manuf Sci Tec 31 305-313. https://doi.org/10.1016/j.cirpj.2020.06.004

Funding

This study was financially supported by the National Natural Science Foundation of China (Grant Nos. 51975305 and 51905289), the Major Science and Technology Innovation Engineering Projects of Shandong Province (Grant No. 2019JZZY020111), the Natural Science Foundation of Shandong Province (Grant No. ZR2020KE027), the National Key Research and Development Plan (Grant No.2020YFB2010500), and the Science and Technology SMEs Innovation Capacity Improvement Project of Shandong Province (Grant No. 2022TSGC1115).

Author information

Authors and Affiliations

Contributions

Dewei Liu: investigation, writing (original draft), and writing (review and editing).

Changhe Li: technical and material support; instructional support, and writing (review).

Lan Dong: collect and organize data and writing (review and editing).

Aiguo Qin: formal analysis and validation.

Yanbin Zhang: formal analysis and validation.

Min Yang: modify paper and formal analysis.

Teng Gao: collect and organize data.

Xiaoming Wang: modify paper and validation.

Mingzheng Liu: modify paper and validation.

Xin Cui: formal analysis and validation.

Hafiz Muhammad Ali: conceptualization and validation.

Shubham Sharma: formal analysis and validation.

Corresponding author

Ethics declarations

Ethics approval

We declare that the papers we submitted are my research work under the guidance of the instructor and research results we have obtained. We confirm that this article has not been published previously and is not being submitted for publication elsewhere. We have not considered elsewhere except The International Journal of Advanced Manufacturing Technology. We confirm that this article has had the full consent of all authors. If this article was accepted, we confirm that it will not be published elsewhere in the same form, in English or in any other language, without the written consent of the publisher.

Consent to participate

Consent to participate is not applicable to this article.

Consent for publication

The authors declare that they participated in this paper willingly, and the authors declare to consent to the publication of this paper.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, D., Li, C., Dong, L. et al. Kinematics and improved surface roughness model in milling. Int J Adv Manuf Technol 131, 2087–2108 (2024). https://doi.org/10.1007/s00170-022-10729-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10729-8