Abstract

Conventional means of producing material via metal casting have long been used for centuries. In spite of its advantages in producing durable parts with lower cost implications and the accommodation of large part production, this conventional approach is still characterized by the challenges of high lead time in patterns production, poor surface finish, and the need for secondary manufacturing operations, which always leads to material loss. Hence, the introduction of additive manufacturing (AM) to metal casting process has been immensely recognized because of its huge advantages in negating some of the challenges encountered in the conventional route. However, the inconsistency in the material properties (such as density, strength, elastic modulus, dimensional accuracies, surface finish), produced by one of the AM techniques (rapid sand casting), has not been yielding optimum results to be applied in high-tech application like aerospace and automotive industries. Furthermore, this technique lacks efficient qualification and certification, which contributes to their disadvantages. This review focuses on the challenges and recent progress in producing parts from rapid sand moulds and cores via binder jetting (BJ), as well as the need to incorporate efficient qualification and certification in the future production of parts from rapid sand casting.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Additive manufacturing (AM), which is also regarded as 3D printing, direct digital manufacturing, or rapid prototyping, has been developed and studied for more than 20 years [1, 2]. AM develops 3D components through the introduction of layer-by-layer materials directly from computer-aided design (CAD) models. This minimizes material wastage and provides higher benefits for part building with material and geometric difficulties that cannot be fabricated by subtractive manufacturing methods [3,4,5]. This technique is a modern and quickly developing technology that is evolving in its uses worldwide and is engaged in building physical items from scratch via the addition of geometrical representation. These print techniques are maximally applied in mass modification and develop various parts of the open-source design in health, aviation, agriculture, locomotives, and automotive [6,7,8]. In proffering solutions for many challenges in material development, 3D printing has stood at the leading edge. This technology has created a platform for developing a whole gadget fabrication system. [9,10,11,12,13].

American Society for Testing and Materials (ASTM) formally categorized fabrication via 3D technique as a group of seven diverse techniques, each with distinctive features to perform some specific development. These techniques include binder jetting, powder bed fusion, stereolithography, vat polymerization, directed energy deposition, material extrusion, selective laser sintering, and sheet lamination. They differ across many parameters from the components being applied to the procedure and mode of object printing [14,15,16]. Some of these techniques apply materials in powder form, while others apply them in another mode, like thin wires. The individual technique has certain uses with their disadvantages. Various common AM techniques use a heat source to combine raw materials to develop the components. Some use light to produce a liquid crosslink constructively. Comparatively, the particles are glued layer by layer when binder jetting is applied to create the geometry; hence, during this fabrication, no heat is needed. Also, temporarily, the unbound powder maintains the material fragments to be unconnected, which permits interior volumes to be made; hence, materials’ waste is noticeably minimized. Materials being applied in 3D production are spread across a huge spectrum, extending from metals to polymers to different materials like ceramics, thermoplastics, and graphene-based materials. The component being applied should be judiciously selected and applied as it directly influences the performance, quality, and properties of the fabricated components [15, 17,18,19].

3D printing technique manufactures very precise objects with less effort and time, hence making the technique to be resourceful for application in most sectors and industries. AM printing can enhance production techniques and transform industries. This implementation increases production speed while minimizing expenses. The utilization of 3D printing development in the assembly industry has various challenges. For instance, the use of 3D manufacturing techniques decreases the physical labour or work input into the fabrication method, and this consequently has a negative effect on some nation’s economies that rely on a large quantity of low-ability jobs [20, 21]. This technique permits users the liability to manufacture a huge different object; also, it gives high prospects for the new industry to minimize material fabrication time and enhance their affordability worldwide. AM is an economical technique for complex–shapes or smaller collections of parts, which are difficult to be fabricated via subtractive methods. AM is developing very fast in applications; various fields have used AM in rapid tool development [22, 23], biomedical engineering [24], mechanical engineering [25,26,27,28], etc. With the innovation of AM technique, its uses have changed from manufacturing prototypes for design verification to manufacturing the final functional material. Presently, direct manufacturing of multi-faceted consumer components has emerged as the major development of AM technology [29, 30]. One of the techniques under AM, which has evolved in recent times, is rapid sand casting (RSC).

RSC applies AM procedure to hasten the production of sand cores and moulds in contrast to the conventional techniques. The use of binder jetting in RSC supports the deposition of sand and binders, layer by layer on the build platform with the aid of recoater and the inkjet head, respectively, aimed at developing the inputted design model. The binder glues the sand together, after some curing or sintering at certain parameter. Despite the importance of RSC, their inconsistency or variability in properties, as well as the absence of efficient qualification and certification for these products, has limited their cognizance in high-tech application. The inconsistency or variability in the properties for RSC product has been observed in the sand cores and moulds production after two or three batches. The properties of the successive products diminish with respect to the designed model.

This review focuses on the challenges and recent progress in the production of rapid sand moulds and cores via BJ, with more emphasis on property consistency, dimensional accuracy, surface finish, and other important features, as well as the need to incorporate efficient qualification and certification in the future production of parts from rapid sand casting.

1.1 RSC

This is also regarded as three-dimensional sand printing (3DSP), which is a typical AM techniques that directly manufactures sand cores and moulds. This manufacturing technique allows quick fabrication of castings using sand. RSC can manufacture small to large volumes and fabricate sand parts for particular metal casting [31,32,33].

There are diverse AM techniques that are available to manufacture sand cores and moulds, one of them being binder jetting. This sand part fabrication technique has received a high industrial application. RSC comprises an advanced binder jetting system, which involves a liquid binder that is successively deposited on the sand, layer by layer, and pre-coated with a liquid catalyst. The recognized 3D model techniques for producing sand cores and moulds are ExOne and Voxeljet machines [31, 34,35,36].

The RSC is a self-hardening technique established on organic binders and inorganic resins, such as alkaline phenolic and furan resin-bonded sand systems [37,38,39,40]. Chemically bonded sand is generally applied in casting because its casting products have superior dimensional accuracy and mechanical properties. However, alkaline phenolic and furan resin mechanisms are appropriate for RSC, and the furan mechanism has been hugely applied compared to alkaline phenolic mechanism. The furan mechanism comprises furfuryl alcohol (FA) and acidic activator (sulphonic acid), which provide 3D polymer chains via acid solidifying reactions, polymerization, and establishment. The polymer chain system (H-C bonds) is discovered in furan-bonded sand, which is the cause behind the cohesive strength of the sand particles [39, 41, 42]. This mechanism now develops solid 3D objects such as cores and moulds. For the sand particles to sustain their reliability when in contact with the molten metal, cohesive strength is needed. The reaction between the sulphonic acid and the furan produces a build-up reaction that delivers water. Contrastingly, dehydration happens, which is more inclined to hinder the pace-setting and thus impact the moulds and cores’ mechanical features [35, 43,44,45].

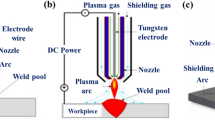

A typical binder jetting (Fig. 1) applied in 3DP technique is a Voxeljet furan-based printer fortified with a recoater that spreads a slice or fine layer of acid-mixed sand on the printing board. Subsequently, the other machine component which deposits a resin binder on a specific cross-sectional area is the print head. For a fresh material layer, the build platform for the design printing will then be lowered. Then, one layer at a time, these approaches are interruptedly repeated until a solid 3D component is developed from multiple bonded material layers. The chemical reaction between the catalyst and the binder starts to occur within the area where the sand layer is wet by the binder. The additional process of oven curing at a certain temperature is accompanied to attain the sand particle cohesion [43, 46]. The stages involved in producing RSC moulds and cores are depicted in Fig. 2.

A typical diagram of a 3D sand core and mould printing [47]

1.2 Importance of RSC

The introduction of a rapid manufacturing system has initiated foundries to apply this technique because it offers substantial benefits. Casting models, for example, were fabricated by AM and used to manufacture castings. Casting models were similarly produced via the high-speed milling method [31, 48]. A vital improvement in AM was the automatic development of the core and mould in a single period. For instance, investment casting has been advanced because of AM, wholly to patterns production made of wax, which is further immersed in plaster or refractory slurry to manufacture a solidified cylindrical part encompassing a mould chamber. Recently, materials can be quickly produced without using plaster or shell mould [49,50,51]. Also, RSC, a category of rapid manufacturing system, has begun to be used to produce sand cores and moulds (Fig. 3) instead of the conventional method of making patterns. This system of rapid manufacturing always minimizes lead time for part production.

RSC subdues the common challenges experienced in the conventional fabricating method. The comparison between the conventional technique and RSC technique is shown in Fig. 4, depicting the comparative advantage of RSC in the production of cores and moulds [52,53,54,55].

RSC produces the following advantages:

-

Adaptable development, low-volume, and cost-effective

-

Minimized fabrication time and expenses

-

It has the capability to immensely enhance the properties of components

-

It has the ability to make designs that have complex geometries that are suited for a specific application

-

It minimizes environmental influence

-

It minimizes the need for expensive tools

1.3 Qualification and certification of rapid sand casting

Qualification and certification are important phases for fabrication popularization, verification, inspection, and product evaluation. Qualification is a procedure of examining a design template, a component, and the product during production. Things to be evaluated or qualified can be materials, machines, techniques, and parts of the suppliers [56,57,58,59]. Certification is mainly introduced for product approval by a certification organization or authority. Things to be certified can be components, parts, equipment, systems, or the evaluating techniques for a material or component or product during or at the concluding establishment/production stages. In most circumstances, certification and qualification can be interchanged because the two evaluation strategy aims to satisfy specific necessities [60,61,62,63,64]. Qualification concentrates on whether the component is designed or produced in respect to industrial requirements, while certification focuses largely on the contentment of deliverables (products) by the required authority. Certification and qualification have three pillars, and they are standards, rules, and regulations. Standards are intended to fulfil diverse necessities from consumer groups, industries, and trading system globally. Some organizations are establishing metal AM standards that encompass parts, techniques, post-techniques, and inspections. These organizations comprise the ASTM International, Aerospace Materials Society (AMS), Society of Automotive Engineers (SAE), International Organization for Standardization (ISO), American Society of Mechanical Engineers (ASME), and American Welding Society (AWS). The establishment of AM standards gives industries some guidelines for strong communication, robust manufacturing, easy trade, accurate measurement, and mutual understanding [65,66,67,68].

Rules can be defined as industrial practices or guidelines, while regulations denote the statutes or directives imposed by the law. Both are governed by international organization standards, and they are established to fulfil technical, regulatory, and safety necessities in specific areas. For instance, aviation license like the European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) established their rules and regulations in the aerospace industry for metal AM. Owing to the aerospace products’ complexity and specificity, their certification and qualification systems may not be used by other industries. Hence, some commercial administrations that include Bureau Veritas (BV), Det Norske Veritas (DNV), Underwriters Laboratories (UL), American Bureau of Shipping (ABS), Technischer Überwachungsverein (TÜV SÜD), and Lloyd’s Register (LR) have been operating on developing particular standards, rules, and regulations for establishing metal AM [63, 69,70,71,72,73].

There are some voids in qualification and certification for rapid sand casting, like ‘standards’ which can sustain the certifying and qualifying criteria for a different mechanism. In contrast to conventional manufacturing techniques, the generally accepted procedures for examining defects in products from RSC (for instance, non-destructive testing for porosity and cracks) have not been produced. Specifically, some complexity in metallurgical techniques in RSC has made it hard to develop standards in a universal and systematic form. Thus, limiting this route (RSC) to be employed in producing some sophisticated parts in vital industries.

2 Challenges of rapid sand casting

For high-tech applications such as aerospace, biomedical, and automotive, the application of RSC in these fields has been limited because of the quality and property inconsistency or variability of the parts produced from this technique. The inconsistency or variability in this technique has been observed in the sand core and mould production after two or three batches, where the properties of the successive products diminish with respect to the designed model. Also, the lack of efficient qualification and certification as well as the lack of in-depth procedures for which RSC must undergo for it to be prominently used has created some devoid of reliability and trust in the parts produced.

The inconsistency in the parts’ quality and properties are density, bearing capacity, strength, elastic modulus, dimensional accuracies, and surface finish (roughness). These challenges are a consequence of certain parameters (such as curing temperature and time, binders, shell mould thickness, and shapes). The lack of in-depth processes of these parameters has brought some limitations to this technique.

2.1 The influence of some process parameters on the properties of rapid sand casting moulds and cores as well as on the cast material

The repetitive use of RSC materials (cores and moulds) for a long time often results in the decline of the dimensional accuracy, density, surface finish, strength, hardness, etc., of the parts fabricated from them. The parameters responsible for the inconsistency or variability in properties are the type of binder, sand, curing temperature and time, the type of materials for the casting, etc., [40, 74, 75]. The following sections will highlight and elaborate on how the parameters mentioned above influence the properties of RSC.

2.1.1 The influence of binder on the printed moulds and cores as well as on the cast material

Various activators, binders, and sand mechanisms are applied to fabricate 3D-printed sand cores and moulds needed for many types of alloy casting [76,77,78]. The organic binder often applied for 3D printing can initiate harmful gases in casting, which are not ecologically friendly, although they help the industry better in respect to the casting. Likewise, it has been discovered that furan initiates a health danger to machinists because of its carcinogen. Hence, it is important to search for alternative binders. The available binder in the market for 3D sand core and mould printing is a silicate binder with low gas emission, but this binder requires further study. The features of sand cores and moulds fabricated via the 3D printers can be influenced by diverse conditions during the printing/curing cycle. These features can be affected by the sand properties, the type of binder, concentration of binder, type of printing speed and activator, building orientation of sample printed and job-box co-ordinate, and locker thickness [79,80,81,82]. It has been discovered that reducing the layer thickness and improving saturation enhances the tensile strength and decreases the surface quality of moulds or cores [83,84,85,86,87].

Huge differences in the physical features of 3DP sand moulds bonded with resin have been encountered by foundries. The features such as permeability and three-point bending (3 PB) strength of 3DP resin-bonded sand moulds rely on specific parameters like binder and moisture content. Generally, higher binder compositions in the sand moulds often produce enhanced mechanical strength, although it consequently evolves more gas during the metal casting. Likewise, a huge quantity of binder allows the 3DP sand mould highly rigid hence inhibiting efficient expansion and prompting hot tearing defects and elevated residual stresses. In comparison, lesser binder quantity minimizes the off-gassing, although it negatively affects the mechanical strength, which causes molten metal penetration into the interstices of the large inter-sand; thus, bloated rough surfaces are developed on the casting. Contrastingly, the mould filling techniques need some measures in air evacuation from the mould cavity because there is often gas compression induced the melting. The melt can capture gases and air in the mould cavity, aided by turbulent filling. Therefore, it is important to remove the gas effectively to achieve a complete casting component with minimal defects [84, 88,89,90]. Owing to these facts, the achievement of this modern technique is highly accustomed via the establishment of enough permeable sand moulds with suitable mechanical strength for their operation. As a result of the immense demand for high mechanical strength and dimensional precision of the cast components, 3DP furan bonded resin sand is hugely applied in casting. The furan binder (FB) is comprised of furfuryl alcohol and acid catalyst (toluene sulfonic acid) that establishes a 3-D polymer chain system (furan resin bridges) via polymerization, acid-hardening reaction, and condensation. It has been discovered that the polymer bridges in furan-bonded resin sand mould give additional strength and cohesion to the silica sand particles, which is important to maintain the 3D-printed sand-shaped moulds when in connection with the melt. The reaction from the condensation of furan binder gives water (dehydration); this inclines to lower the curing rate and thus influences the permeability and strength of the moulds [34, 79, 91].

Snelling et al. [92] differentiated the binder burnout features and the strength of the ExOne™ furan resin with a sulphonic acid catalyst system (3D printed) with selected available binder and sand as well as their strength. In assessing the binder burnout, the materials were set to curing cycles of 105–900 °C. It was discovered that the ExOne™ printed materials possessed an optimum strength of 1.3 MPa because they were well-distributed binder and sand. The printed samples also sustained their shape to greater temperature burnout of 450 °C. It was discovered that the 3D printed mechanism performed more excellently than the conventionally arranged sand mould using phenolic acid and furan resin system. The research revealed that the printed moulds are higher in quality than traditional fabricated moulds and possess lesser and exact well-regulated binder constituents, which brings about gas build-up minimization and thus enhanced casting.

Mita et al. [93] researched the impacts of binder composition on the mechanical strength and permeability of 3DP sand moulds at varying parameters. With regard to distinguishing between the pores, the sand particles, and the furan resin bridges, the SEM images of the samples (Fig. 5) depict the furan resin bridge’s formation within the 3D-printed sample cross-section. In determining the impacts of the inertia pressure, the local permeability of 3DP samples was assessed as a dependency on the injection flow rate. The printed moulds’ mechanical strengths were discovered to be highly reliant on the curing system and the amount of binder. For all the binder compositions, the three-point bending (3 PB) strength was detected to improve when cured at 100 °C and declined at 200 °C (Fig. 6). Hence, the optimum strength of 3 PB was achieved when cured at 100 °C for all the binder compositions. However, the amount of binder within the functional binder range mass fraction (1.02–1.98%) was observed not to significantly influence the samples’ initial permeability before curing. Optimum permeability was achieved at similar parameters as the 3 PB strength. Thus, indicating that the samples’ mechanical strength can be improved within the examined binder range constituents without producing any decline in permeability.

SEM image of the 3DP sample — zoom (a and b) depicting the resin bridges [93]

The curing time effect on 3 PB strength [93]

Kafara et al. [94] examined the effect of binder quality on resilience and dimensional accuracy in 3D printing. Five different categories of samples were printed with binder contents equivalent to 40%, 55%, 70%, 85%, and 100%, respectively. Depending on the binder content, the printed samples’ bending strength is depicted in Fig. 7a. It was discovered that the printed samples’ bending strength improves almost linearly in a researched area with increasing binder quantities. The amount of binder effect on the compressive strength is revealed in Fig. 7b. The samples’ compressive strength rises almost linearly with an increasing amount of binder (40%, 55%, and 70%). In contrast, a lower compressive strength was achieved for the samples with 85% and 100% amount of binders. Similarly, the results of examined samples with the two amounts of binders show a huge deviation among the samples with a similar quantity of binder. This is because with the increasing amount of binder, the samples’ surface loaded during the experiment decreases (Fig. 8). Thus, this revealed that with an increasing amount of binders in a sample, there is declination in the dimensional accuracy [85, 95]. It is consequently projected that with the evaluated outcomes for the binder saturation, there is no reflection of 85% and 100% of the binder. Most likely, binder saturation has the same effect on the compressive strength as similarly detected on the bending strength.

The samples’ a bending strength and b compressive strength — depending on their binder quantity [94]

The test of a sample’s compressive strength with 100% amount of binder [94]

Khandelwal and Ravi [96] investigated the impact of binder quantities on the features and shrinkage of moulds and cores fabricated via a three-part binder system (resin, catalyst, and crosslinking agent). It was found that the rise in the quantity of resin (of approximately 2.4% of the sand weight) produces an increased core shrinkage of about 0.15% in length. A rise in the quantity of catalyst (with the quantity of resin unchanged) depicted a similar total shrinkage degree; however, the initial shrinkage rate increased (during the first 3 h after curing). Additional assessment via hardness test, weight measurement, and SEM provides details on the shrinkage system. The bridges which were developed during the resin polymerization reaction occur between compacted sand particles in the mould (Fig. 9). The bridge’s shortening, which consequently led to core shrinkage, was prompted by the gradual evaporation of the solvent existing in the resin bridges. This was vindicated via weight reduction measurements (Fig. 10) comprising only a chemical mixture (deficient of sand). Another important assessment is that the catalyst with a higher percentage yields rapid curing and thus a greater core shrinkage rate. This observation was buttressed by hardness measurement (Fig. 11) and weight reduction tests.

SEM depicting resin bridges between the sand grains [96]

Weight reduction with different quantities of catalyst (resin percentage) [96]

Core hardness (with different content of catalyst and resin) after 3 h [96]

Ramakrishnan et al. [97] examined the mechanism of an organic binder for sand mould printing by Voxeljet 3D printer, which was first established for developing polymer powders. The binder-dehydrate sodium silicate powder was mixed with quartz sand, and the fluid for printing contained thickened water, which is capable of liquefying the sodium silicate (deposited via the printing head). Changing two factors, such as heat input and the concentration of binder ratio to fluid printing, can all be used to examine the effect of strength and fluid migration of the printed samples. Hence, by heating the sample while printing or by decreasing the input fluid to the sand binder mechanism, the fluid migration can be decreased. The average peak strength of 5.65 N/mm2 was attained when the fluid migration was increased. However, it declined to 4.14 N/mm2 during printing when the heat was used. It is being observed that the printed components that can resist higher mechanical weight can produce smaller dimensional tolerances between thin walls because of sand adhesion.

2.1.2 The influence of curing parameters (temperature and time) on the printed moulds and cores as well as on the cast material

Curing is a chemical reaction technique (such as polymerization) or physical action (like evaporation), producing a tougher, harder, or more firm substance (like concrete) or linkage (like an adhesive bond). In some curing techniques, there may be the need to sustain the procedure for specific humidity and temperature level; others may be specific time and pressure [99,100,101]. Cure monitoring techniques provide an important understanding of the chemical system and describe procedural actions to attain a certain quality of the cured component. Curing may entail any technique where heat application is engaged to initiate or catalyse molecular-level and chemical structural modification in a polymeric substance like silicones, epoxies, polyesters, and phenolics. These substances are used in various routes to many products for insulation, sealing, protective coating, bonding, and other applications. Also, curing with efficient parameters provides enhanced mechanical properties, ensures material durability, inhibits cracking in material, and minimizes permeability [96, 102, 103].

McKenna et al. [104] examined the impacts of curing time and temperature on the mechanical features, especially the sand moulds’ permeability and strength. These were fabricated using Zb56 resin binder mechanism with ZCast 501 powder. The temperature and curing time were altered between 150 and 250 °C and 4–8 h, respectively. These were applied to characterize the combined and individual influence of these conditions on the printed mould’s permeability and compressive strength. A linear regression model with a 99% confidence level was attained when the statistical design of the experiment was utilized. It was established that as a result of the volatile escape of components, the permeability rises with the curing time. Prolonged heating could have initiated embrittlement of gypsum plaster and low melting temperature fusion phases, causing decreased compressive strength and permeability, respectively. The research excluded the other features of the produced cores and moulds like cohesiveness, refractoriness, and collapsibility; the study ignited the curiosity to further establish the understanding for the correct uses of the technique to produce quality castings from the moulds and cores. Primkulov et al. [98] examined the impacts of curing temperature on strength samples of sand-based rock and furfuryl alcohol resin. It was discovered that the composite material’s compressive strength (equivalent to 19.0 MPa) got enhanced at the optimum temperature of 80 °C, and beyond this temperature, there was a depreciation in furfuryl alcohol resin and consequently reducing the 3D printed sand-stones strength.

Another research tried to optimize the temperature and time for optimum compressive strength with cylindrical ZCast samples [105]. In contrast to McKenna et al. [104], the temperature ranges from 423 to 523 K, and the compressive strength changed from 6.2 to 2.4 MPa. It was stated that the curing time was insignificant on the optimized temperature and strength. These conflicting outcomes necessitate more investigation in this area. Others have considered the casting flaws because of volatile off-gassing of the binder materials; this was attempted by optimizing the curing cycle. Owing to the high surface area to volume ratio of ZCast powder, it needs 8–9% higher quantity of binder in contrast to foundry sand (1.4%). Diverse curing cycles were done to adequately remove the binder and the casted component from the moulds, and a curing temperature of 316 °C for 1 h was discovered to be efficient with adequate mould strength and with no visible defects.

The 3DP powders, which are ZCast and ViriCastTM and no-bake foundry sand, were juxtaposed by Snelling et al. [49], depending on their properties and handleability of the fabricated cast metal. From A356 alloy, cylindrical samples of length 101.6 mm and 25.4 mm diameter were cast out. The samples were examined for hardness, surface roughness, density, microstructure, and porosity. It was detected that the casted parts’ strength and hardness from the 3D moulds were similar to conventional cast alloy (A356). Although from the microstructural evaluation (Fig. 12), ZCast and ViriCast mould reveal dendritic arm spacing. The prepared samples with no-bake moulds had considerably lesser spacing in the dendrite arm than the prepared 3DP samples. This indicated the 3DP and the no-bake’s heat treatment parameters differ, and thus, their strength and hardness are incomparable. The no-bake sand had a marginal higher density and hardenability in the casted parts, with much lower porosity. Contrastingly, ZCast moulds exhibited higher surface roughness. It was established that in producing cast parts with the same feature of no-bake sands, the powders applied for the 3D printing were appropriate.

A356-T6 alloy — dendritic microstructure cast in a no-bake moulds, b ViriCast moulds, and c ZCast moulds [49]

2.1.3 The influence of other parameters (such as shell mould thickness, shapes, and heat transfer) on the printed moulds and cores as well as on the cast material

The influence of shell mould wall thickness, casting volume, and pouring temperature on the surface roughness of fabricated castings was carried out by Chhabra and Singh [106]. Mould of varying shell thickness and volumes were produced and applied to cast brass, aluminium, and copper. The shell wall thickness and pouring temperature were discovered to have a respective 2% and 97.55% contribution to the surface roughness. This outcome is ascribed to the volatile substance decomposition at the metal-mould interface, and thus, the produced gas might influence the cast part’s property which is above the sand particle size effect.

Gill and Kaplas [107] made a comparison analysis on the parts produced from split pattern shells via 3D printing and the components designed from investment mould casting. In assessing the thickness effect on the casting, the moulds whose shell thickness decreases were produced; hence, 3 mm and 6 mm were the highest values discovered for A356 aluminium alloy and ZA12 zinc alloy respectively. The microstructural evaluation revealed the impact of shell wall thickness on the ZCast technique. Non-uniform dispersal of dendritic structures were observed on the A356 aluminium alloy microstructures whose shell wall thickness are 12 mm (Fig. 13a) and 6 mm (Fig. 13b). The ‘white’ areas in the Fig. 13, which are defined by the eutectic silicon elements edges, are the dendritic cells. The ‘darker black’ areas are the silicon elements in the A356 aluminium alloy microstructures, in which they can collate with other silicon elements to develop bands. The 3D printed components have poor properties in hardness and surface roughness in contrast to investment casting. This is because the solidification process affects the microstructure and consequently relies on the mould capability to convey the heat [108]. Other factors which could contribute to these are uneven distribution and/or higher amount of the binder about the sand substances inside the 3D printed mould. As for the binder, the binder distribution relies on the binder viscosity and chemical reaction speed, and thus, if these parameters are low, the sprayed binder via the print head possibly will not wet the entire surface of the individual sand particles. The moulds’ thermal and mechanical features manufactured with ZCast mixture via ZPrinter 310 plus have been analysed in [109]. The features were applied to enhance the mould wall thickness and to pattern the casting procedure. By changing their thickness and calcination period, the parts’ tensile strength was measured. After calcination, a 7-mm thickness was discovered to be tougher than the 15-mm indicated manufacturer thickness, thus promoting efficiency in mould printing. The thermal transfer properties such as heat capacity, heat diffusivity, and thermal conductivity were assessed and applied to plot the AK81 cooling curves. The results depicted better convergence with experimental cooling curves. The research has connected the knowledge space concerning mould characteristics and their importance for procedural modeling. More mould characteristics, especially density, permeability, and their relationship with thermal properties, are needed to be studied.

Micrograph image of A356 aluminium alloy with shell wall thickness of a 12 mm and b 6 mm [107]

Shangguan et al. [110] examine the cooling efficiency of a casted stress frame Al alloy (A356) sample by comparing the influence of a conventional dense mould with a 3D printed rib-enforced shell. The outcomes indicated that the casting cooling efficiency significantly improved when rib-enforced shell mould was applied, and hence, in natural conditions, about 40% of cooling time is preserved, and in air blowing conditions, 35% is further preserved for the stress frame samples prior to shakeout. It was discovered that this mould technique compared to traditional mould can feasibly allow the associated cooling condition area to be easily modified and also ensures uniform and rapid casting cooling. This consequently enhances manufacturing efficiency and minimizes the casting residual stresses and deformation. Likewise, the fabricated casting has the excellent surface finish and dimensional accuracy. Furthermore, the 3D printing rib-enforced moulds preserved per mould about nine-tenths of the sand. Some samples’ analysis based on the variation of temperature with time at various stages on the dense sand mould and the rib-enforced sand mould is depicted in Fig. 14. Figure 14 shows that the rib-enforced sand mould approached the optimum temperature after pouring at 800 s. Also, during solidification, the shell approached a temperature of 596 K. Throughout the overall cooling procedure, the temperature range for the shell is from 620 to 380 K, therefore indicating that the new sand mould has an excellent heat discharging capacity to the surrounding.

The plot of temperature variation with time for the dense sand mould and the rib-enforced sand mould. a Rib-enforced sand mould and casting; b dense and rib-enforced sand mould [110]

Another vital parameter affecting the value of the cast metal components is the thermal gradient present in the mould and the heat trapped at the mould metal interface. The heat features and binder depreciation properties of 3D printed (phenolic and furan mechanisms) spherical cores were studied by Fourier thermal [111]. The conditions that were assessed are the overall and fraction heat absorbed, as well as the heat rate absorption under casting factors of aluminium and iron. The disparity of the amount of water in the phenolic mechanism and the thermal degradation behaviour causes the furan absorbed 30% higher heat of 283 kJ/kg as against 221 kJ/kg and possessed a greater heat absorption rate. The furan process was discovered to behave better since it has a moderate and smoother degradation and better cooling capacity. This fact will be necessary to establish numerical simulations of the heat distribution and binder degradation. The research examination varies in the route that it regard the core properties that will assist in achieving better core design and their influence on the internal cast part properties. Excluding the mould properties, it is pertinent to research the mould influence on the fabricated castings. As mentioned earlier, this can be a result of the heat transfer features at the metal-mould boundary and because of the off-gassing in the course of the binder depletion. The thermal transfer features influence the solidification rate, and as a result, the density and strength of the cast component are affected. The release of volatile substances produces unwanted surface abnormalities.

3 Futuristic approaches or progress needed in RSC technique for part production

Various researches have shown that there are numerous parameters influencing the 3DP sand mould quality, comprising curing temperature and time, furan resin binder content, heat transfer properties, types of sand grain size, and base sand. The lack of in-depth processes for all these parameters has contributed to the inconsistencies and variability of 3DP sand moulds and cores as well as the parts produced from them. These challenges have limited this technique from being used in high-tech applications. Recent or futuristic approaches to curtail all these challenges are to establish an efficient qualification such as design specification, specification review, materials and feedstock evaluation, manufacturing follow-up procedure, and product testing and inspection, and certification procedure such as test specimen observation, test and inspection, verification of compliance to requirement, and verification of traceability, which are all needed to certify the products for the intended application. The establishment of this qualification and certification in any production of parts from RSC will ensure that deficiency in any path can easily be traced and corrected before the final production stages for the part usage in service. These approaches have been carried out in metal AM, where fine metal powders are applied to form strong, intricate parts which are developed by employing a scan 3D object or by CAD program. The software computer divides the design into various layers which behave as the structure or outline which AM process will follow. Then, a sophisticated approach in qualifying and certifying the various procedures to produce the components is employed in the manufacturing routes. This mechanism has been carried out to produce different AM components especially for marine, energy, and offshore industries [112]. American Petroleum Institute uses the qualification routes to develop an outline for the metallic parts production in gas and oil sectors [113]. Burea veritas [114] established a qualification and certification routes for AM components for ship and offshore units. The overall outcomes from the application of these mechanisms indicated an outstanding performance without failure of the products during service.

Therefore, this approach is envisaged to also bring an excellent productivity when newly introduced in RSC technique. Consequently, making the faultless production of parts possible for high-tech industries such as in aerospace, automotive, medical industries, etc.

4 Conclusion

In the production of parts for high-tech application like aerospace, automotive, and biomedical industries, different sophisticated approaches in AM have been used, because of their high performance in producing different intricate parts. However, RSC, one of the approaches in rapid prototyping of AM, has been limited in application. This is due to the absence of in-depth processes that control the parameters for RSC, and this has consequently produced inconsistency or variability in components’ properties. Also, the lack of qualification and certification for RSC compared to other AM techniques have all stood as challenges for RSC. This review conspicuously highlights the various parameters (such as type of binder and sand, curing temperature and time, the materials type for casting, shell mould thickness, shapes, and heat transfer) required to be considered so that future production of parts from RSC will nullify the aforesaid challenges. Furthermore, the establishment of efficient qualification and certification as stated in the section ‘Futuristic approaches or progresses needed in RSC technique for part production’ is needed to be incorporated in any fabrication of components from RSC. This approach has similarly been done in metal AM, and profound results have been reported from it. Hence, applying the same approach in the RSC technique will make it feasible to produce components for high-tech application.

Data availability

N/A.

Code availability

N/A.

References

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos B Eng 143:172–196

Singh S, Ramakrishna S, Singh R (2017) Material issues in additive manufacturing: a review. J Manuf Process 25:185–200

Dizon JRC, Espera AH Jr, Chen Q, Advincula RC (2018) Mechanical characterization of 3D-printed polymers. Addit Manuf 20:44–67

Jiménez M, Romero L, Domínguez IA (2019) Espinosa MdM, Domínguez M (2019) Additive manufacturing technologies: an overview about 3D printing methods and future prospects. Complexity 2019(9656938):30. https://doi.org/10.1155/2019/9656938

Oguntuyi SD, Malatji N, Shongwe MB, Johnson OT, Khoathane C, Tshabalala L (2022) The influence of Si3N4 on the microstructure, mechanical properties and the wear performance of TiB2–SiC synthesized via spark plasma sintering. Int J Light Mater Manuf 5(3):326–338

Sabahi N, Chen W, Wang C-H, Kruzic JJ, Li X (2020) A review on additive manufacturing of shape-memory materials for biomedical applications. Jom 72(3):1229–1253

Nath SD, Nilufar S (2020) An overview of additive manufacturing of polymers and associated composites. Polymers 12(11):2719

Shongwe MB (2020) Spark plasma sintering of ceramic matrix composite of TiC: microstructure, densification, and mechanical properties: a review. Adv Mater Sci Eng: Selected Articles from ICMMPE 2020, 93

Le-Bail A, Maniglia BC, Le-Bail P (2020) Recent advances and future perspective in additive manufacturing of foods based on 3D printing. Curr Opin Food Sci 35:54–64

Jasiuk I, Abueidda DW, Kozuch C, Pang S, Su FY, McKittrick J (2018) An overview on additive manufacturing of polymers. Jom 70(3):275–283

Razavykia A, Brusa E, Delprete C, Yavari R (2020) An overview of additive manufacturing technologies—a review to technical synthesis in numerical study of selective laser melting. Materials 13(17):3895

Oguntuyi SD, Johnson OT, Shongwe MB (2021) Spark plasma sintering of ceramic matrix composite of TiC: microstructure, densification, and mechanical properties: a review. Int J Adv Manuf Technol 116(1):69–82

Ke WC, Oliveira JP, Cong BQ, Ao SS, Qi ZW, Peng B, Zeng Z (2022) Multi-layer deposition mechanism in ultra high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Addit Manuf 50:102513

Horn TJ, Harrysson OLA (2012) Overview of current additive manufacturing technologies and selected applications. Sci Prog 95(3):255–282

Prakash KS, Nancharaih T, Rao VVS (2018) Additive manufacturing techniques in manufacturing-an overview. Mater Today Proc 5(2):3873–3882

Silva JVL, Rezende RA (2013) Additive manufacturing and its future impact in logistics. IFAC Proc Vol 46(24):277–282

Blakey-Milner B, Gradl P, Snedden G, Brooks M, Pitot J, Lopez E, du Plessis A (2021) Metal additive manufacturing in aerospace: a review. Mater Des 209:110008

Hällgren S, Pejryd L, Ekengren J (2016) (Re) Design for additive manufacturing. Procedia Cirp 50:246–251

Mota C, Puppi D, Chiellini F, Chiellini E (2015) Additive manufacturing techniques for the production of tissue engineering constructs. J Tissue Eng Regen Med 9(3):174–190

Fucile P, Papallo I, Improta G, De Santis R, Gloria A, Onofrio I, Russo T (2019) Reverse engineering and additive manufacturing towards the design of 3D advanced scaffolds for hard tissue regeneration. In 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4. 0&IoT). Ieee, pp 33–37

Altıparmak SC, Xiao B (2021) A market assessment of additive manufacturing potential for the aerospace industry. J Manuf Process 68:728–738

Kruth JP, Leu M-C, Nakagawa T (1998) Progress in additive manufacturing and rapid prototyping. CIRP Ann 47(2):525–540

Kandukuri S, Ze C (2021) Progress of metal AM and certification pathway. Trans Indian Natl Acad Eng 6(4):909–915

Zadpoor AA, Malda J (2017) Additive manufacturing of biomaterials, tissues, and organs, vol 45. Springer, pp 1–11

Sarvankar SG, Yewale SN (2019) Additive manufacturing in automobile industry. Int J Res Aeronaut Mech Eng 7(4):1–10

Oguntuyi SD, Shongwe MB, Tshabalala L, Johnson OT, Malatji N (2022) Effects of SiC on the microstructure, densification, hardness and wear performance of TiB2 ceramic matrix composite consolidated via spark plasma sintering. Arab J Sci Eng 48(3):2889–903

Liu Z, Zhao D, Wang P, Yan M, Yang C, Chen Z, Lu Z (2022) Additive manufacturing of metals: microstructure evolution and multistage control. J Mater Sci Technol 100:224–236

Oguntuyi SD, Nyembwe K, Shongwe MB, Johnson OT, Adewumi JR, Malatji N, Olubambi P (2022) Improvement on the fabrication OF SiC materials: processing, reinforcing phase, fabricating route—a review. Int J Light Mater Manuf 6(2):225–237

Mohanavel V, Ali KSA, Ranganathan K, Jeffrey JA, Ravikumar MM, Rajkumar S (2021) The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater Today Proc 47:405–409

Oguntuyi SD, Johnson OT, Shongwe MB, Jeje SO, Rominiyi AL (2021) The effects of sintering additives on the ceramic matrix composite of ZrO2: microstructure, densification, and mechanical properties—a review. Adv Appl Ceram 120(5–8):319–335

Saxena P, Pagone E, Salonitis K, Jolly MR (2021) Sustainability metrics for rapid manufacturing of the sand casting moulds: a multi-criteria decision-making algorithm-based approach. J Clean Prod 311:127506

Lynch P, Hasbrouck CR, Wilck J, Kay M, Manogharan G (2020) Challenges and opportunities to integrate the oldest and newest manufacturing processes: metal casting and additive manufacturing. Rapid Prototyp J 26(6):1145–1154

Ettemeyer F, Lechner P, Hofmann T, Andrä H, Schneider M, Günther D (2020) Digital sand core physics: predicting physical properties of sand cores by simulations on digital microstructures. Int J Solids Struct 188:155–168

Le Néel TA, Mognol P, Hascoët J-Y (2018) A review on additive manufacturing of sand molds by binder jetting and selective laser sintering. Rapid Prototyp J 24(8):1355–2546

Budzik G (2007) Possibilities of utilizing 3DP technology for foundry mould making. Arch Foundry Eng 7(2):65–68

Martinez D, Bate C, Manogharan G (2020) Towards functionally graded sand molds for metal casting: engineering thermo-mechanical properties using 3D sand printing. Jom 72(3):1340–1354

Ghosh D (2013) Modern furan for modern castings. In Transactions of 61st Indian Foundry Congress 1–4

Fortini A, Merlin M, Raminella G (2022) A comparative analysis on organic and inorganic core binders for a gravity diecasting Al alloy component. Int J Metalcast 16(2):674–688

Vykoukal M, Burian A, Prerovska M (2019) Geopol®. The innovated environment friendly inorganic binder system. Arch Foundry Eng 19(1):109–116. https://doi.org/10.24425/afe.2019.127103

Prabhushankar N, Balaji N (2020) Various alternative sources for silica sand, binders and additives in sand casting and their properties—a review. In IOP Conference Series: Mater Sci Eng 993:1 012137 (IOP Publishing)

Holtzer M, Dańko R, Kmita A (2016) Influence of a reclaimed sand addition to moulding sand with furan resin on its impact on the environment. Water Air Soil Pollut 227(1):1–12

Oguntuyi SD, Johnson OT, Shongwe MB (2021) Spark plasma sintering of ceramic matrix composite of ZrB2 and TiB2: microstructure, densification, and mechanical properties—a review. Met Mater Int 27(7):2146–2159

Dańko R, Holtzer M, Dańko J (2011) Reclamation of alkaline spent moulding sands of organic and inorganic type and their mixtures. Arch Foundry Eng 11(4):25–30

Li Y, Liu J, Huang W, Zhang S (2022) Microstructure related analysis of tensile and fatigue properties for sand casting aluminum alloy cylinder head. Eng Fail Anal 136:106210

Uyan T, Jalava K, Orkas J, Otto K (2022) Sand casting implementation of two-dimensional digital code direct-part-marking using additively manufactured tags. Int J Metalcast 16(3):1140–1151

Holtzer M, Dańko R, Kmita A, Drożyński D, Kubecki M, Skrzyński M, Roczniak A (2020) Environmental impact of the reclaimed sand addition to molding sand with furan and phenol-formaldehyde resin—a comparison. Materials 13(19):4395

Upadhyay M, Sivarupan T, El Mansori M (2017) 3D printing for rapid sand casting—A review. J Manuf Process 29:211–220

Topčić A, Dž T, Fajić A, Cerjaković E (2008) Implementation of three dimensional–3DP printing process in casting. In 5th International Symposium-Konstruisanje, oblikovanje i dizajn KOD

Snelling D, Blount H, Forman C, Ramsburg K, Wentzel A, Williams C, Druschitz A (2013) The effects on 3D printed molds on metal castings. In 2013 International Solid Freeform Fabrication Symposium. University of Texas at Austin. https://doi.org/10.26153/tsw/15611

Ziaee M, Crane NB (2019) Binder jetting: a review of process, materials, and methods. Addit Manuf 28:781–801

Wang W, Conley JG, Stoll HW (1999) Rapid tooling for sand casting using laminated object manufacturing process. Rapid Prototyp J 5(3):134–140

Sivarupan T, El Mansori M, Coniglio N, Dargusch M (2020) Effect of process parameters on flexure strength and gas permeability of 3D printed sand molds. J Manuf Process 54:420–437

Almaghariz ES, Conner BP, Lenner L, Gullapalli R, Manogharan GP, Lamoncha B, Fang M (2016) Quantifying the role of part design complexity in using 3D sand printing for molds and cores. Int J Metalcast 10(3):240–252

Almaghariz E (2015) Determining when to use 3D sand printing quantifying the role of complexity (Doctoral dissertation)

Madhav CHV, Kesav R, Narayan YS (2016) Importance and utilization of 3D printing in various applications. Int J Mod Eng Res (IJMER) 24–29

Seifi M, Gorelik M, Waller J, Hrabe N, Shamsaei N, Daniewicz S, Lewandowski JJ (2017) Progress towards metal additive manufacturing standardization to support qualification and certification. Jom 69(3):439–455

Dordlofva C, Törlind P (2018) Design for qualification: a process for developing additive manufacturing components for critical systems. DS 91: Proceedings of NordDesign 2018, Linköping, Sweden, 14th-17th August 2018

Liu J, Jalalahmadi B, Guo YB, Sealy MP, Bolander N (2018) A review of computational modeling in powder-based additive manufacturing for metallic part qualification. Rapid Prototyp J 24(8):1245–1264

Babu SS, Raghavan N, Raplee J, Foster SJ, Frederick C, Haines M, Lee Y (2018) Additive manufacturing of nickel superalloys: opportunities for innovation and challenges related to qualification. Metall Mater Trans A 49(9):3764–3780

Russell R, Wells D, Waller J, Poorganji B, Ott E, Nakagawa T, Seifi M (2019) Qualification and certification of metal additive manufactured hardware for aerospace applications. Addit Manuf Aerosp Ind 33–66. https://doi.org/10.1016/B978-0-12-814062-8.00003-0

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23(6):1917–1928

Gupta N, Weber C, Newsome S (2012) Additive manufacturing: status and opportunities. Science and Technology Policy Institute, Washington

Madhavadas V, Srivastava D, Chadha U, Raj SA, Sultan MTH, Shahar FS, Shah AUM (2022) A review on metal additive manufacturing for intricately shaped aerospace components. CIRP J Manuf Sci Technol 39:18–36

Kawalkar R, Dubey HK, Lokhande SP (2022) A review for advancements in standardization for additive manufacturing. Mater Today Proc 50:1983–1990

DebRoy T, Mukherjee T, Milewski JO, Elmer JW, Ribic B, Blecher JJ, Zhang W (2019) Scientific, technological and economic issues in metal printing and their solutions. Nat Mater 18(10):1026–1032

DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Zhang W (2018) Additive manufacturing of metallic components—process, structure and properties. Prog Mater Sci 92:112–224

Chua CK, Wong CH, Yeong WY (2017) Standards, quality control, and measurement sciences in 3D printing and additive manufacturing: Academic Press

Balaji D, Ranga J, Bhuvaneswari V, Arulmurugan B, Rajeshkumar L, Manimohan MP, Masi C (2022) Additive manufacturing for aerospace from inception to certification. J Nanomater 2022. https://doi.org/10.1155/2022/7226852

De Bernardi C, Miller D (2020) Additive manufacturing in the oil & gas industry and status update on the new API 20S standard qualification of additively manufactured metallic materials for use in the petroleum and natural gas industries. https://doi.org/10.4043/30603-MS

Dutton B, Vesga W, Waller J, James S, Seifi M (2020) Metal additive manufacturing defect formation and nondestructive evaluation detectability. Structural Integrity of Additive Manufactured Parts: ASTM International pp 1–50. https://doi.org/10.1520/STP162020180136

Serra A, Valles E (2018) Advanced electrochemical synthesis of multicomponent metallic nanorods and nanowires: fundamentals and applications. Appl Mater Today 12:207–234

Kumar LJ, Pandey PM, Wimpenny DI (2019) 3D printing and additive manufacturing technologies, vol 311. Springer

Seifi M, Salem A, Beuth J, Harrysson O, Lewandowski JJ (2016) Overview of materials qualification needs for metal additive manufacturing. Jom 68(3):747–764

Sivarupan T, Balasubramani N, Saxena P, Nagarajan D, El Mansori M, Salonitis K, Dargusch MS (2021) A review on the progress and challenges of binder jet 3D printing of sand moulds for advanced casting. Addit Manuf 40:101889

Dalquist S, Gutowski T (2004) Life cycle analysis of conventional manufacturing techniques. Sand Casting 62599:631–641. https://doi.org/10.1115/IMECE2004-62599

Sama SR, Wang J, Manogharan G (2018) Non-conventional mold design for metal casting using 3D sand-printing. J Manuf Process 34:765–775

Walker J, Harris E, Lynagh C, Beck A, Lonardo R, Vuksanovich B, MacDonald E (2018) 3D printed smart molds for sand casting. Int J Met 12(4):785–796

Mitra S, Rodríguez de Castro A, El Mansori M (2018) The effect of ageing process on three-point bending strength and permeability of 3D printed sand molds. Int J Adv Manuf Technol 97(1):1241–1251

Coniglio N, Sivarupan T, El Mansori M (2018) Investigation of process parameter effect on anisotropic properties of 3D printed sand molds. Int J Adv Manuf Technol 94(5):2175–2185

Hackney PM, Wooldridge R (2017) Characterisation of direct 3D sand printing process for the production of sand cast mould tools. Rapid Prototyp J 23(1):7–15

Dariko R (2013) Criteria for an advanced assessment of quality of moulding sands with organic binders and reclamation process products. China Foundry 10(3):181–186

Akhyar A, Ali M, Nurdin A, Ahmad F (2020) Effect of different gating systems and sand mold binder on the cast-quality of bicycle frame produced through sand casting method. In Defect and diffusion forum, vol 402. Trans Tech Publications Ltd, pp 100–107

Vaezi M, Chua CK (2011) Effects of layer thickness and binder saturation level parameters on 3D printing process. Int J Adv Manuf Technol 53(1):275–284

Snelling DA, Williams CB, Druschitz AP (2019) Mechanical and material properties of castings produced via 3D printed molds. Addit Manuf 27:199–207

Wen S, Shen Q, Wei Q, Yan C, Zhu W, Shi Y, Shi Y (2015) Material optimization and post-processing of sand moulds manufactured by the selective laser sintering of binder-coated Al2O3 sands. J Mater Process Technol 225:93–102

Stefanescu DM (2008) The effect of mould/metal interface phenomena on the surface quality of castings. In: 10th Asian Foundry Congress (AFC10). Nagoya, Japan pp 21–24

Hodder KJ, Chalaturnyk RJ (2019) Bridging additive manufacturing and sand casting: Utilizing foundry sand. Addit Manuf 28:649–660

Dady O, Nyembwe K, Van Tonder PJM (2018) Sulfonic acid coating of refractory sand for three-dimensional printing applications. In: Rapid Product Development Association of South Africa (RAPDASA) 2018 Conference Proceedings. Braamfontein, Johannesburg

Tshabalala NV, Nyembwe KD, Van Tonder PJM (2021) Optimisation of a resin-coated chromite sand for rapid sand casting applications. S Afr J Ind Eng 32(3):290–298

Sivarupan T, El Mansori M, Daly K, Mavrogordato MN, Pierron F (2018) Characterisation of 3D printed sand moulds using micro-focus X-ray computed tomography. Rapid Prototyp J 25(2):404–416

Bryant N, Frush T, Thiel J, MacDonald E, Walker J (2021) Influence of machine parameters on the physical characteristics of 3D-printed sand molds for metal casting. Int J Metalcast 15(2):361–372

Snelling D, Williams C, Druschitz A (2014) A comparison of binder burnout and mechanical characteristics of printed and chemically bonded sand molds. https://doi.org/10.26153/tsw/15677

Mitra S, de Castro AR, El Mansori M (2019) On the rapid manufacturing process of functional 3D printed sand molds. J Manuf Process 42:202–212

Kafara M, Kemnitzer J, Westermann HH, Steinhilper R (2018) Influence of binder quantity on dimensional accuracy and resilience in 3D-printing. Procedia Manuf 21:638–646

Sahu KK, Modi YK (2021) Investigation on dimensional accuracy, compressive strength and measured porosity of additively manufactured calcium sulphate porous bone scaffolds. Mater Technol 36(8):492–503

Khandelwal H, Ravi B (2015) Effect of binder composition on the shrinkage of chemically bonded sand cores. Mater Manuf Process 30(12):1465–1470

Ramakrishnan R, Griebel B, Volk W, Günther D, Günther J (2014) 3D printing of inorganic sand moulds for casting applications. Adv Mater Res 1018:441–449 (Trans Tech Publications Ltd.)

Primkulov B, Chalaturnyk J, Chalaturnyk R, Zambrano Narvaez G (2017) 3D printed sandstone strength: curing of furfuryl alcohol resin-based sandstones. 3D Print Add Manuf 4(3):149–156

Joseph MK, Banganayi F, Oyombo D (2017) Moulding sand recycling and reuse in small foundries. Procedia Manuf 7:86–91

Zanetti MC, Fiore S (2003) Foundry processes: the recovery of green moulding sands for core operations. Resour Conserv Recycl 38(3):243–254

Casalino G, De Filippis LAC, Ludovico A (2005) A technical note on the mechanical and physical characterization of selective laser sintered sand for rapid casting. J Mater Process Technol 166(1):1–8

Svidró JT, Diószegi A, Svidró J, Ferenczi T (2017) The effect of different binder levels on the heat absorption capacity of moulding mixtures made by the phenolic urethane cold-box process. J Therm Anal Calorim 130(3):1769–1777

Khandelwal H, Ravi B (2016) Effect of molding parameters on chemically bonded sand mold properties. J Manuf Process 22:127–133

McKenna N, Singamneni S, Diegel O, Singh D, Neitzert T, St George, J, Yarlagadda P (2008) Direct metal casting through 3D printing: a critical analysis of the mould characteristics. In: Proceedings of the 9th Global Congress on Manufacturing and Management. GCMM2008, Queensland Univ Technol pp 1–5

Bassoli E, Atzeni E (2009) Direct metal rapid casting: mechanical optimization and tolerance calculation. Rapid Prototyp J 15(3):238–243

Chhabra M, Singh R (2012) Obtaining desired surface roughness of castings produced using ZCast direct metal casting process through Taguchi’s experimental approach. Rapid Prototyp J 18(6):458–471

Gill SS, Kaplas M (2011) Efficacy of powder-based three-dimensional printing (3DP) technologies for rapid casting of light alloys. Int J Adv Manuf Technol 52(1):53–64

Phanikumar G, Chattopadhyay K (2001) Solidification microstructure development. Sadhana 26(1):25–34

Drokina VV, Belov VD, Chekhonin SN (2011) Obtaining casts of aluminum alloys by foundry in loose molds fabricated on installations of three-dimensional printing. Russ J Ferrous Metals 52(1):24–28

Shangguan H, Kang J, Deng C, Yi J, Hu Y, Huang T (2018) 3D-printed rib-enforced shell sand mold for aluminum castings. Int J Adv Manuf Technol 96(5):2175–2182

Tóth J, Svidró JT, Diószegi A, Stevenson D (2016) Heat absorption capacity and binder degradation characteristics of 3D printed cores investigated by inverse Fourier thermal analysis. Int J Metalcast 10(3):306–314

DNV GL. 2017a. Class orogramme DNVGL-CP-0267. Additive nanufacturing. Accessed 9 Jan 2023. https://rules.dnv.com/docs/pdf/DNV/CP/2018-07/DNVGL-CP-0267.pdf

American Petroleum Institute (API). 2021. Standards plan. (9) Accessed Jan 2023. https://www.api.org/productsand-services/standards/standards-plan

Bureau Veritas (BV). 2018. Rule note NR 320 DT R04 E. Certification scheme of materials and equipment for the classification of marine units. Accessed 9 Jan 2023. https://erules.veristar.com/dy/data/bv/pdf/320-NR_2018-07.pdf.

Acknowledgements

The authors recognize the support from CPAM scheme, and the assistance of the Metallurgy Department of the University of Johannesburg and Tshwane University of Technology.

Funding

Open access funding provided by University of Johannesburg.

Author information

Authors and Affiliations

Contributions

This work was achieved with a collective effort by all the authors. Mr. S. D. Oguntuyi and Prof. K. Nyembwe drafted the works and collected the necessary information from all literature (related works) about the topic. Dr. M. B. Shongwe and Dr. T. Mojisola interpreted the literature and made a systematic arrangement of the review work. All authors all worked efficiently on the proof-reading and the final authorization of the manuscript submission.

Corresponding author

Ethics declarations

Ethics approval

N/A

Consent to participate

N/A

Consent for publication

I author Mr. Oguntuyi Samson give my consent for the publication of identifiable details, which can include a photograph(s) and or details within the text (‘Material’) to be published in the above journal and article.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Oguntuyi, S.D., Nyembwe, K., Shongwe, M.B. et al. Challenges and recent progress on the application of rapid sand casting for part production: a review. Int J Adv Manuf Technol 126, 891–906 (2023). https://doi.org/10.1007/s00170-023-11049-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11049-1