Abstract

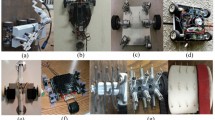

As a kind of structurally complex workpiece, open impellers made by welding are widely used in mining and light industries. The traditional robot programming method for open impeller welding path planning still requires a long cycle time, and the positioning of the open impeller after clamping is relatively complex and time-consuming. This paper proposes an open impeller welding path planning method for the purpose of improving the automation of open impeller welding by robots and shortening the open impeller welding cycle. From the analysis of the open impeller geometry, the path planning of open impeller welding is realized by extracting the welding seam curve and the blade edge curve. To enhance the open impeller posture detection after clamping on the positioner, a new structural light sensor is used to achieve open impeller alignment positioning by applying an improved iterative closest point (ICP) algorithm. Combined with the detection of the clamping posture, the robot welding path planning procedure of the open impeller is automatically generated. The final simulation and practical experiments verify the effectiveness of the proposed method.

Similar content being viewed by others

References

Chen C, Pan Y, Li D, Zhang S, Zhao Z, Hong J (2020) A virtual-physical collision detection interface for ar-based interactive teaching of robot. Robot Comput Integr Manufact 64:101,948. https://doi.org/10.1016/j.rcim.2020.101948

Chong J, Ong S, Nee A, Youcef-Youmi K (2009) Robot programming using augmented reality: an interactive method for planning collision-free paths. Robot Comput Integr Manuf 25(3):689–701. https://doi.org/10.1016/j.rcim.2008.05.002

Fogli D, Gargioni L, Guida G, Tampalini F (2022) A hybrid approach to user-oriented programming of collaborative robots. Robot Comput Integr Manufact 73:102,234. https://doi.org/10.1016/j.rcim.2021.102234

Geng Y, Zhang Y, Tian X, Shi X, Wang X, Cui Y (2022) A novel welding path planning method based on point cloud for robotic welding of impeller blades. The International Journal of Advanced Manufacturing Technology

Hu L, Zhang W (2020) Nsga-ii approach for proper choice of nodes and knots in b-spline curve interpolation. Comput Aided Des 127:102,885. https://doi.org/10.1016/j.cad.2020.102885

Jian B, Vemuri BC (2011) Robust point set registration using gaussian mixture models. IEEE Trans Pattern Anal Mach Intell 33(8):1633–1645. https://doi.org/10.1109/TPAMI.2010.223https://doi.org/10.1109/TPAMI.2010.223

Lotsaris K, Gkournelos C, Fousekis N, Kousi N, Makris S (2021) Ar based robot programming using teaching by demonstration techniques. Procedia CIRP 97:459–463. https://doi.org/10.1016/j.procir.2020.09.186

Min Z, Wang J, Pan J, Meng MQH (2021) Generalized 3-d point set registration with hybrid mixture models for computer-assisted orthopedic surgery: from isotropic to anisotropic positional error. IEEE Trans Autom Sci Eng 18(4):1679–1691. https://doi.org/10.1109/TASE.2020.3014420

Myronenko A, Song X (2010) Point set registration: coherent point drift. IEEE Trans Pattern Anal Mach Intell 32(12):2262–2275. https://doi.org/10.1109/TPAMI.2010.46

Neto P, Mendes N (2013) Direct off-line robot programming via a common cad package. Robot Auton Syst 61(8):896–910. https://doi.org/10.1016/j.robot.2013.02.005

Neto P, Pires JN, Moreira AP (2010) Cad-based off-line robot programming. In: 2010 IEEE conference on robotics, automation and mechatronics, pp 516–521. https://doi.org/10.1109/RAMECH.2010.5513141https://doi.org/10.1109/RAMECH.2010.5513141

Pavlov AL, Ovchinnikov GW, Derbyshev DY, Tsetserukou D, Oseledets IV (2018) Aa-icp: iterative closest point with anderson acceleration. In: 2018 IEEE international conference on robotics and automation (ICRA), pp 3407–3412. https://doi.org/10.1109/ICRA.2018.8461063https://doi.org/10.1109/ICRA.2018.8461063

Wang B, Hu SJ, Sun L, Freiheit T (2020) Intelligent welding system technologies: state-of-the-art review and perspectives. J Manuf Syst 56:373–391. https://doi.org/10.1016/j.jmsy.2020.06.020

Xu F, Xu Y, Zhang H, Chen S (2022) Application of sensing technology in intelligent robotic arc welding: a review. J Manuf Process 79:854–880. https://doi.org/10.1016/j.jmapro.2022.05.029

Yin Z, Guan Y, Chen S, Wu W, Zhang H (2013) Off-line programming of robotic system based on dxf files of 3d models. In: 2013 IEEE international conference on information and automation (ICIA), pp 1296–1301

Yu J, Shi P, Lin C, Yu H (2019) Adaptive neural command filtering control for nonlinear mimo systems with saturation input and unknown control direction. IEEE Trans Cybern pp:1–10. https://doi.org/10.1109/TCYB.2019.2901250

Yu J, Shi P, Chen X, Cui G (2021) Finite-time command filtered adaptive control for nonlinear systems via immersion and invariance. Sci China Inform Sci 64:192–202. https://doi.org/10.1007/s11432-020-3144-6

Yu J, Shi P, Liu J, Lin C (2022) Neuroadaptive finite-time control for nonlinear mimo systems with input constraint. IEEE Trans Cybern 52(7):6676–6683. https://doi.org/10.1109/TCYB.2020.3032530

Zhang F, Lai CY, Simic M, Ding S (2020) Augmented reality in robot programming. Procedia Computer Science 176:1221–1230. https://doi.org/10.1016/j.procs.2020.09.119

Zhang J, Yao Y, Deng B (2022) Fast and robust iterative closest point. IEEE Trans Pattern Anal Mach Intell 44(7):3450–3466. https://doi.org/10.1109/TPAMI.2021.3054619

Zhang Z, Ge P, Zhao G (2017) Numerical studies of post weld heat treatment on residual stresses in welded impeller. Int J Press Vessel Pip 153:1–14. https://doi.org/10.1016/j.ijpvp.2017.05.005

Zhang Z, Min Z, Zhang A, Wang J, Song S, Meng MQH (2021) Reliable hybrid mixture model for generalized point set registration. IEEE Trans Instrum Meas 70:1–10. https://doi.org/10.1109/TIM.2021.3120377

Zheng C, An Y, Wang Z, Wu H, Qin X, Eynard B, Zhang Y (2022a) Hybrid offline programming method for robotic welding systems. Robot Comput Integr Manufact 73:102,238. https://doi.org/10.1016/j.rcim.2021.102238

Zheng C, Xing J, Wang Z, Qin X, Eynard B, Li J, Bai J, Zhang Y (2022b) Knowledge-based program generation approach for robotic manufacturing systems. Robot Comput Integr Manufact 73:102,242. https://doi.org/10.1016/j.rcim.2021.102242https://doi.org/10.1016/j.rcim.2021.102242

Zhou P, Peng R, Xu M, Wu V, Navarro-Alarcon D (2021) Path planning with automatic seam extraction over point cloud models for robotic arc welding. IEEE Robotics and Automation Letters 6 (3):5002–5009. https://doi.org/10.1109/LRA.2021.3070828https://doi.org/10.1109/LRA.2021.3070828

Funding

This work was supported in part by the National Natural Science Foundation of China under Grant No. U20A20201, in part by Shandong Provincial Key Research and Development Program under Grant No. 2022CXGC010101, and in part by Taishan Industry Leading Talent Project.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare no competing interests.

Additional information

Author contribution

Weihua Fang conceived of the presented idea, developed the theory, and carried out the experiments. Luguo Ding implements computer code and support algorithms. Fuquan Zheng and Xincheng Tian were involved in planning and supervised the work. The first draft of the manuscript was written by Weihua Fang and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fang, W., Ding, L., Tian, X. et al. A robot welding path planning and automatic programming method for open impeller. Int J Adv Manuf Technol 124, 1639–1650 (2023). https://doi.org/10.1007/s00170-022-10415-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10415-9