Abstract

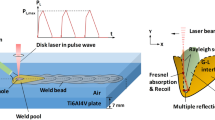

For numerical investigation of the quasi-continuous laser beam welding (Q-CLBW) process, the existing research usually considered a constant welding heat input, which to some degree loses accuracy in representing the welding dynamics. This paper developed a validated CFD model for the simulation of Q-CLBW of Ti6Al4V alloy based on a near-reality heat source model. The coupled transient temperature, velocity, and phase fields were solved under a high-frequency pulsed laser power (HF-PLP) at 5000 Hz as well as a constant laser power (CLP) which has been conventionally employed. Comparative analysis was carried out with respect to keyhole stability, melt flow pattern, and weld pool dimensions resulting from different heat sources and different heat input values with laser peak power of 2800 ~ 3800 W and welding velocity of 0.02 ~ 0.04 m/s. Results indicate that the time-dependent laser input yields less stabilized dynamics featured with middle-depth keyhole collapse, chaotic melt flow, and periodic vapor eruption, and such characteristics are difficult to be observed with CLP. The maximum temperature, pressure, and velocity magnitude of molten metal present remarkable oscillations in relation to welding time. With decreasing heat input in HF-PLP welding cases, the keyhole geometry tends to collapse in the tip segment while the melt flow becomes regular. Furthermore, the employment of the HF-PLP condition also enhances the accuracy in predicting the cross-sectional seam profile in terms of width and depth. Pulsed laser input should be taken into full consideration in the numerical simulation of the Q-CLBW process.

Similar content being viewed by others

References

Chang B, Allen C, Blackburn J, Hilton P, Du D (2015) Fluid flow characteristics and porosity behavior in full penetration laser welding of a titanium alloy. Metall Mater Trans B 46:906–918

Chen Z, Wang BF, Duan BH (2020) Mechanical properties and microstructure of a high-power laser-welded Ti6Al4V titanium alloy. J Mater Eng Perform 29:2296–2304

Seto N, Katayama S, Matsunawa A (2000) High-speed simultaneous observation of plasma and keyhole behavior during high power CO2 laser welding: effect of shielding gas on porosity formation. J Laser Appl 12:245–250

Tao W, Yang Z, Chen Y, Li L (2013) Double-sided fiber laser beam welding process of T-joints for aluminum aircraft fuselage panels: filler wire melting behavior, process stability, and their effects on porosity defects. Opt Laser Technol 52:1–9

Wolff SJ, Gould B, Parab N, Zhao C, Sun T (2021) Preliminary study on the influence of an external magnetic field on melt pool behavior in laser melting of 4140 steel using in-situ X-ray imaging. J Micro Nano-Manuf 8:041016

Yi Z, Chen G, Wei H, Zhang J (2008) A novel “sandwich” method for observation of the keyhole in deep penetration laser welding. Opt Laser Eng 46:133–139

Üstündağ Ö, Bakir N, Gumenyuk A, Rethmeier M (2021) Influence of oscillating magnetic field on the keyhole stability in deep penetration laser beam welding. Opt Laser Technol 135:106715

Ki H, Mazumder J, Mohanty PS (2002) Modeling of laser keyhole welding: part I. Mathematical modeling, numerical methodology, role of recoil pressure, multiple reflections, and free surface evolution. Metall Mater Trans A 33:1817–1830

Ki H, Mazumder J, Mohanty PS (2002) Modeling of laser keyhole welding: part II. simulation of keyhole evolution, velocity, temperature profile, and experimental verification. Metall Mater Trans A 33:1831–1842

Cho WI, Na SJ, Thomy C, Vollertsen F (2012) Numerical simulation of molten pool dynamics in high power disk laser welding. J Mater Process Tech 212:262–275

Cho WI, Na SJ, Cho MH (2010) Numerical study of alloying element distribution in CO2 laser-GMA hybrid welding. Comp Mater Sci 49:790–800

Pang S, Chen L, Zhou J, Yin Y, Chen T (2011) A three-dimensional sharp interface model for self-consistent keyhole and weld pool dynamics in deep penetration laser welding. J Phys D Appl Phys 44:025301

Pang S, Chen X, Zhou J, Shao X, Wang C (2015) 3D transient multiphase model for keyhole, vapor plume, and weld pool dynamics in laser welding including the ambient pressure effect. Opt Laser Eng 74:47–58

Luo M, Hu R, Li Q, Huang A, Pang S (2019) Physical understanding of keyhole and weld pool dynamics in laser welding under different water pressures. Int J Heat Mass Tran 137:328–336

Li Z, Rostam K, Panjehpour A, Akbari M, Rostami S (2020) Experimental and numerical study of temperature field and molten pool dimensions in dissimilar thickness laser welding of Ti6Al4V alloy. J Manuf Process 49:438–446

Yang Z, Zhao X, Tao W, Jin C (2019) Effects of keyhole status on melt flow and flow-induced porosity formation during double-sided laser welding of AA6056/AA6156 aluminium alloy T-joint. Opt Laser Technol 109:39–48

Chen X, Wei Y, Chang Y, Kong B, Cheng J (2022) Study on keyhole characteristics and weld pool dynamics of Ti6Al4V alloy fabricated by continuous wave laser beam welding. Int J Adv Manuf Tech 119:2999–3012

Kumar KS (2015) Numerical modeling and simulation of a butt joint welding of AISI 316l stainless steels using a pulsed laser beam. Mater Today Proc 2:2256–2266

Zhou J, Tsai HL, Wang PC (2006) Transport phenomena and keyhole dynamics during pulsed laser welding. J Heat Trans-T ASME 128:680–690

Zhou J, Tsai HL (2007) Effects of electromagnetic force on melt flow and porosity prevention in pulsed laser keyhole welding. Int J Heat Mass Tran 50:2217–2235

Liang R, Luo Y (2017) Study on weld pool behaviors and ripple formation in dissimilar welding under pulsed laser. Opt Laser Technol 93:1–8

Chen J, Ouyang Z, Du X, Wei Y (2022) Weld pool dynamics and joining mechanism in pulse wave laser beam welding of Ti-6Al-4V titanium alloy sheets assembled in butt joint with an air gap. Opt Laser Technol 146:107558

Salminen A (2010) The filler wire - laser beam interaction during laser welding with low alloyed steel filler wire. Mechanika 84:67–74

Jia Z, Zhang P, Yu Z, Shi H, Tian Y (2020) Effect of pulse shaping on solidification process and crack in 5083 aluminum alloy by pulsed laser welding. Opt Laser Technol 134:106608

Gao X, Liu J, Zhang L (2018) Effect of heat input on microstructure and mechanical properties of pulsed laser welded joints in Ti6Al4V/Nb dissimilar alloys. Int J Adv Manuf Tech 94:3937–3947

Katayama S, Kawahito Y (2009) Elucidation of phenomena in high-power fiber laser welding and development of prevention procedures of welding defects. Fiber Lasers VI: Technology, Systems, and Applications 7195:71951R

Lin R, Wang HP, Lu F, Solomon J, Carlson BE (2017) Numerical study of keyhole dynamics and keyhole-induced porosity formation in remote laser welding of Al alloys. Int J Heat Mass Tran 108:244–256

Tan W, Bailey NS, Shin YC (2013) Investigation of keyhole plume and molten pool based on a three-dimensional dynamic model with sharp interface formulation. J Phys D Appl Phys 46:55501

Lee WH (1979) A pressure iteration scheme for two-phase flow modeling. Math Model C3:406–4311

Norman AF, Ducharme R, Mackwood A, Kapadia P, Prangnell PB (1998) Application of thermal modelling to laser beam welding of aluminium alloys. Sci Technol Weld Joi 3:260–266

Qian L, Wei Y, Xiao F (2018) Coupled THINC and level set method: a conservative interface capturing scheme with arbitrary-order surface representations. J Comput Phys 373:284–303

Bachmann M, Meng X, Artinov A, Rethmeier M (2022) Elucidation of the bulging effect by an improved ray‐tracing algorithm in deep penetration wire feed laser beam welding and its influence on the mixing behavior. Adv Eng Mater 2101299

Cho JH, Na SJ (2006) Implementation of real-time multiple reflection and Fresnel absorption of laser beam in keyhole. J Phys D Appl Phys 39:5372–5378

Lee JY, Ko SH, Farson DF, Yoo CD (2002) Mechanism of keyhole formation and stability in stationary laser welding. J Phys D Appl Phys 35:1570

Ahn J, Chen L, Davies CM, Dear JP (2016) Parametric optimisation and microstructural analysis on high power Yb-fibre laser welding of Ti-6Al-4V. Opt Laser Eng 86:156–171

Chen X, Pang S, Shao X, Wang C, Xiao J, Jiang P (2017) Three-dimensional transient thermoelectric currents in deep penetration laser welding of austenite stainless steel. Opt Laser Eng 91:196–205

Tan W, Shin YC (2014) Analysis of multi-phase interaction and its effects on keyhole dynamics with a multi-physics numerical model. J Phys D Appl Phys 47:345501

Panwisawas C, Perumal B, Ward RM, Turner N, Turner RP, Brooks JW, Basoalto HC (2017) Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: experimental and modelling. Acta Mater 126:251–263

Funding

The research is funded by China Postdoctoral Science Foundation No. 2020M671479 and Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Contributions

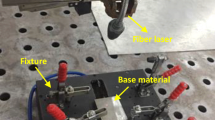

Jicheng Chen: modeling and simulation, data analysis and visualization, writing-original draft preparation and revision. Xiaomei Chen: methodology, experiment, assessment. Xuejun Liu and Yanhong Wei: conceptualization, supervision, writing-reviewing and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

The authors declare their consent to participate.

Consent for publication

The authors declare their consent for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, J., Chen, X., Liu, X. et al. Numerical investigation on keyhole stability and weld pool dynamics during quasi-continuous laser beam welding of Ti6Al4V plate using constant and modulated high-frequency pulsed heat input. Int J Adv Manuf Technol 121, 229–247 (2022). https://doi.org/10.1007/s00170-022-09323-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09323-9