Abstract

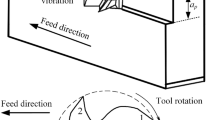

This paper reports the numerical analysis results of ultrasonic elliptical vibration cutting (UEVC) combined with the electrical discharge assistance (EDA), called UEVC + EDA. UEVC delivers decreasing cutting forces, repressing side-burrs, and lowering tool wear. EDA is a cutting technique using a pulsed spark to remove material using thermal energy. Difficult-to-cut materials, such as Ti-6Al-4 V, can be cut effectively by combining these two techniques. A numerical study was performed using ABAQUS finite element analysis (FEA) software by investigating the von Mises stress, cutting forces, and temperature. Numerical analysis was carried out by modifying the ultrasonic vibration frequency, distance of the discharge pulse, discharge voltage, and discharge pulse radius. UEVC + EDA was compared numerically and experimentally with regular cutting (NC) and UEVC in terms of cutting force and tool temperature. The results showed that the UEVC + EDA method could improve the cutting condition by reducing the cutting force and von Mises stress and increasing the tool temperature.

Similar content being viewed by others

Availability of data and material

The availability of data and material are available as requested to the authors.

Code availability

The code is available as requested to the authors.

References

Kurniawan R, Kumaran ST, Ali S et al (2018) Experimental and analytical study of ultrasonic elliptical vibration cutting on AISI 1045 for sustainable machining of round-shaped microgroove pattern. Int J Adv Manuf Technol 98:2031–2055. https://doi.org/10.1007/s00170-018-2359-1

Tan R, Zhao X, Guo S et al (2020) Sustainable production of dry-ultra-precision machining of Ti–6Al–4V alloy using PCD tool under ultrasonic elliptical vibration-assisted cutting. J Clean Prod 248:119254. https://doi.org/10.1016/j.jclepro.2019.119254

Haidong Z, Shuguang L, Ping Z, Di K (2017) Process modeling study of the ultrasonic elliptical vibration cutting of Inconel 718. Int J Adv Manuf Technol 92:2055–2068. https://doi.org/10.1007/s00170-017-0266-5

Huang W, Yu D, Zhang X et al (2018) Ductile-regime machining model for ultrasonic elliptical vibration cutting of brittle materials. J Manuf Process 36:68–76. https://doi.org/10.1016/j.jmapro.2018.09.029

Zhu W, Le Y He KF Ehmann et al (2016) Theoretical and experimental investigation on inclined ultrasonic elliptical vibration cutting of alumina ceramics. J Manuf Sci Eng Trans ASME 138. https://doi.org/10.1115/1.4033605

Lotfi M, Amini S (2018) FE simulation of linear and elliptical ultrasonic vibrations in turning of Inconel 718. Proc Inst Mech Eng Part E J Process Mech Eng 232:438–448. https://doi.org/10.1177/0954408917715533

Ma C, Shamoto E, Moriwaki T et al (2005) Suppression of burrs in turning with ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 45:1295–1300. https://doi.org/10.1016/j.ijmachtools.2005.01.011

Nath C, Rahman M, Neo KS (2009) Machinability study of tungsten carbide using PCD tools under ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 49:1089–1095. https://doi.org/10.1016/j.ijmachtools.2009.07.006

Kurniawan R, Kiswanto G, Ko TJ (2017) Surface roughness of two-frequency elliptical vibration texturing (TFEVT) method for micro-dimple pattern process. Int J Mach Tools Manuf 116:77–95. https://doi.org/10.1016/j.ijmachtools.2016.12.011

Yang Z, Zhu L, Zhang G et al (2020) Review of ultrasonic vibration-assisted machining in advanced materials. Int J Mach Tools Manuf 156:103594. https://doi.org/10.1016/j.ijmachtools.2020.103594

Kurniawan R, Ko TJ, Ping LC et al (2017) Development of a two-frequency, elliptical-vibration texturing device for surface texturing. J Mech Sci Technol 31:3465–3473. https://doi.org/10.1007/s12206-017-0635-x

Brehl D, Dow T (2008) Review of vibration-assisted machining. Precis Eng 32:153–172. https://doi.org/10.1016/j.precisioneng.2007.08.003

Kiswanto G, Libyawati W (2019) Fundamental aspects in designing vibration assisted machining: a review. IOP Conf Ser Mater Sci Eng 494. https://doi.org/10.1088/1757-899X/494/1/012095

Zheng L, Chen W, Huo D (2020) Review of vibration devices for vibration-assisted machining. Int J Adv Manuf Technol 108:1631–1651. https://doi.org/10.1007/s00170-020-05483-8

Chen W, Huo D, Shi Y, Hale JM (2018) State-of-the-art review on vibration-assisted milling: principle, system design, and application. Int J Adv Manuf Technol 97:2033–2049. https://doi.org/10.1007/s00170-018-2073-z

Hafiz MSA, Kawaz MHA, Mohamad WNF et al (2017) A review on feasibility study of ultrasonic assisted machining on aircraft component manufacturing. IOP Conf Ser Mater Sci Eng 270. https://doi.org/10.1088/1757-899X/270/1/012034

Xu S, Kuriyagawa T, Shimada K, Mizutani M (2017) Recent advances in ultrasonic-assisted machining for the fabrication of micro/nano-textured surfaces. Front Mech Eng 12:33–45. https://doi.org/10.1007/s11465-017-0422-5

Kang D, Zou P, Wu H et al (2019) Study on ultrasonic vibration–assisted cutting of Nomex honeycomb cores. Int J Adv Manuf Technol 104:979–992. https://doi.org/10.1007/s00170-019-03883-z

Chen W, Zheng L, Teng X et al (2019) Finite element simulation and experimental investigation on cutting mechanism in vibration-assisted micro-milling. Int J Adv Manuf Technol 105:4539–4549. https://doi.org/10.1007/s00170-019-03402-0

Jamshidi H, Nategh MJ (2013) Theoretical and experimental investigation of the frictional behavior of the tool-chip interface in ultrasonic-vibration assisted turning. Int J Mach Tools Manuf 65:1–7. https://doi.org/10.1016/j.ijmachtools.2012.09.004

Liu X, Wu D, Zhang J et al (2019) Analysis of surface texturing in radial ultrasonic vibration-assisted turning. J Mater Process Technol 267:186–195. https://doi.org/10.1016/j.jmatprotec.2018.12.021

Liu X, Wu D, Zhang J (2018) Fabrication of micro-textured surface using feed-direction ultrasonic vibration-assisted turning. Int J Adv Manuf Technol 97:3849–3857. https://doi.org/10.1007/s00170-018-2082-y

Liu X, Zhang J, Hu X, Wu D (2019) Influence of tool material and geometry on micro-textured surface in radial ultrasonic vibration-assisted turning. Int J Mech Sci 152:545–557. https://doi.org/10.1016/j.ijmecsci.2019.01.027

Li G, Wang B, Xue J et al (2019) Development of vibration-assisted micro-milling device and effect of vibration parameters on surface quality and exit-burr. Proc Inst Mech Eng Part B J Eng Manuf 233:1723–1729. https://doi.org/10.1177/0954405418774592

Fl LC, Gonz A (2020) Estimation of specific cutting energy in an s235 alloy for multi-directional ultrasonic vibration-assisted machining using the finite element method. Materials (Basel) 13(3)

He Y, Zou P, Le ZhuW, Ehmann KF (2017) Ultrasonic elliptical vibration cutting of hard materials: simulation and experimental study. Int J Adv Manuf Technol 91:363–374. https://doi.org/10.1007/s00170-016-9716-8

Kong C, Wang D (2018) Numerical investigation of the performance of elliptical vibration cutting in machining of AISI 1045 steel. Int J Adv Manuf Technol 98:715–727. https://doi.org/10.1007/s00170-018-2277-2

Kurniawan R, Kiswanto G, Ko TJ (2016) Micro-dimple pattern process and orthogonal cutting force analysis of elliptical vibration texturing. Int J Mach Tools Manuf 106:127–140. https://doi.org/10.1016/j.ijmachtools.2016.03.007

Jieqiong L, Jinguo H, Xiaoqin Z et al (2016) Study on predictive model of cutting force and geometry parameters for oblique elliptical vibration cutting. Int J Mech Sci 117:43–52. https://doi.org/10.1016/j.ijmecsci.2016.08.004

Shu L, Sugita N (2020) Analysis of fracture, force, and temperature in orthogonal elliptical vibration-assisted bone cutting. J Mech Behav Biomed Mater 103:103599. https://doi.org/10.1016/j.jmbbm.2019.103599

Zhao L, Zhang J, Zhang J, Hartmaier A (2021) Atomistic investigation of machinability of monocrystalline 3C–SiC in elliptical vibration-assisted diamond cutting. Ceram Int 47:2358–2366. https://doi.org/10.1016/j.ceramint.2020.09.078

Dai H, Du H, Chen J, Chen G (2019) Influence of elliptical vibration on the behavior of silicon during nanocutting. Int J Adv Manuf Technol 102:3597–3612. https://doi.org/10.1007/s00170-019-03361-6

Zhang J, Zhang J, Cui T et al (2017) Sculpturing of single crystal silicon microstructures by elliptical vibration cutting. J Manuf Process 29:389–398. https://doi.org/10.1016/j.jmapro.2017.09.003

Zhang J, Han L, Zhang J et al (2019) Brittle-to-ductile transition in elliptical vibration-assisted diamond cutting of reaction-bonded silicon carbide. J Manuf Process 45:670–681. https://doi.org/10.1016/j.jmapro.2019.08.005

Yang Y, Pan Y, Guo P (2017) Structural coloration of metallic surfaces with micro/nano-structures induced by elliptical vibration texturing. Appl Surf Sci 402:400–409. https://doi.org/10.1016/j.apsusc.2017.01.026

Zhang J, Zhang J, Rosenkranz A et al (2019) Frictional properties of surface textures fabricated on hardened steel by elliptical vibration diamond cutting. Precis Eng 59:66–72. https://doi.org/10.1016/j.precisioneng.2019.06.001

Shamoto E, Suzuki N, Hino R (2008) Analysis of 3D elliptical vibration cutting with thin shear plane model. CIRP Ann - Manuf Technol 57:57–60. https://doi.org/10.1016/j.cirp.2008.03.073

Kurniawan R, Ali S, Park KM et al (2019) Development of a three-dimensional ultrasonic elliptical vibration transducer (3D-UEVT) based on sandwiched piezoelectric actuator for micro-grooving. Int J Precis Eng Manuf. https://doi.org/10.1007/s12541-019-00126-9

Kurniawan R, Ko TJ, Kumaran ST, Ahmed F (2021) 3-DOF ultrasonic elliptical vibration tool holder based on coupled resonance modes for manufacturing micro-groove. Precis Eng 67. https://doi.org/10.1016/j.precisioneng.2020.10.002

Kurniawan R, Ko TJ (2019) Surface topography analysis in three-dimensional elliptical vibration texturing ( 3D-EVT ). Int J Adv Manuf Technol 1–21

Wang H, Hu Y, Cong W et al (2020) A novel investigation on horizontal and 3D elliptical ultrasonic vibrations in rotary ultrasonic surface machining of carbon fiber reinforced plastic composites. J Manuf Process 52:12–25. https://doi.org/10.1016/j.jmapro.2020.01.027

Lotfi M, Amini S, Akbari J (2020) Surface integrity and microstructure changes in 3D elliptical ultrasonic assisted turning of Ti–6Al–4V: FEM and experimental examination. Tribol Int 106492. https://doi.org/10.1016/j.triboint.2020.106492

Kurniawan R, Ali S, Ko TJ (2020) Measurement of wettability on rhombohedral pattern fabricated by using 3D-UEVT. Meas J Int Meas Confed 160:107784. https://doi.org/10.1016/j.measurement.2020.107784

Ali S, Kurniawan R, Ko TJ (2021) Development of 3D resonant elliptical vibration transducer for dual-frequency micro-dimple surface texturing. Int J Precis Eng Manuf. https://doi.org/10.1007/s12541-021-00551-9

Jeon Y, Park HW, Lee CM (2013) Current research trends in external energy assisted machining. Int J Precis Eng Manuf 14:337–342. https://doi.org/10.1007/s12541-013-0047-5

Lei S, Pfefferkorn F (2007) A review of thermally assisted machining. Proc ASME Int Manuf Sci Eng Conf 2007(MSEC2007):325–336. https://doi.org/10.1115/MSEC2007-31096

Venkatesan K, Ramanujam R, Kuppan P (2014) Laser assisted machining of difficult to cut materials: research opportunities and future directions — a comprehensive review. Procedia Eng 97:1626–1636. https://doi.org/10.1016/j.proeng.2014.12.313

Jeon Y, Lee CM (2012) Current research trend on laser assisted machining. Int J Precis Eng Manuf 13:311–317. https://doi.org/10.1007/s12541-012-0040-4

Tian Y, Shin YC (2006) Thermal modeling for laser-assisted machining of silicon nitride ceramics with complex features. J Manuf Sci Eng Trans ASME 128:425–434. https://doi.org/10.1115/1.2162906

Leshock CE, Kim JN, Shin YC (2001) Plasma enhanced machining of Inconel 718: modeling of workpiece temperature with plasma heating and experimental results. Int J Mach Tools Manuf 41:877–897. https://doi.org/10.1016/S0890-6955(00)00106-1

Shams OA, Pramanik A, Chandratilleke TT (2017) Thermal-assisted machining of titanium alloys. J Adv Manuf Technol pp 49–76

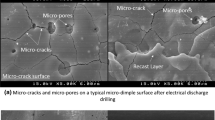

Jung ST, Kurniawan R, Kumaran ST et al (2020) Mechanism study of micro-electrical discharge drilling method during micro-dimpling. J Mech Sci Technol 34:2549–2559. https://doi.org/10.1007/s12206-020-0530-8

Kurniawan R, Thirumalai Kumaran S, Arumuga Prabu V et al (2017) Measurement of burr removal rate and analysis of machining parameters in ultrasonic assisted dry EDM (US-EDM) for deburring drilled holes in CFRP composite. Measurement 110:98–115. https://doi.org/10.1016/j.measurement.2017.06.008

Leão FN, Pashby IR (2004) A review on the use of environmentally-friendly dielectric fluids in electrical discharge machining. J Mater Process Technol 149:341–346. https://doi.org/10.1016/j.jmatprotec.2003.10.043

Shen Y, Liu Y, Zhang Y et al (2015) High-speed dry electrical discharge machining. Int J Mach Tools Manuf 93:19–25. https://doi.org/10.1016/j.ijmachtools.2015.03.004

Mohd Abbas N, Solomon DG, Fuad Bahari M (2007) A review on current research trends in electrical discharge machining (EDM). Int J Mach Tools Manuf 47:1214–1228. https://doi.org/10.1016/j.ijmachtools.2006.08.026

Kumar S, Singh R, Singh TP, Sethi BL (2009) Surface modification by electrical discharge machining: a review. J Mater Process Technol 209:3675–3687. https://doi.org/10.1016/j.jmatprotec.2008.09.032

Shrivastava PK, Dubey AK (2014) Electrical discharge machining-based hybrid machining processes: A review. Proc Inst Mech Eng Part B J Eng Manuf 228:799–825. https://doi.org/10.1177/0954405413508939

Chakraborty S, Dey V, Ghosh SK (2015) A review on the use of dielectric fluids and their effects in electrical discharge machining characteristics. Precis Eng 40:1–6. https://doi.org/10.1016/j.precisioneng.2014.11.003

Prakash V, Kumar P, Singh PK et al (2019) Micro-electrical discharge machining of difficult-to-machine materials: a review. Proc Inst Mech Eng Part B J Eng Manuf 233:339–370. https://doi.org/10.1177/0954405417718591

Kandpal BC, kumar J, Singh H (2015) Machining of aluminium metal matrix composites with electrical discharge machining — a review. Mater Today Proc 2:1665–1671. https://doi.org/10.1016/j.matpr.2015.07.094

Gangil M, Pradhan MK, Purohit R (2017) Review on modelling and optimization of electrical discharge machining process using modern Techniques. Mater Today Proc 4:2048–2057. https://doi.org/10.1016/j.matpr.2017.02.050

Macedo FTB, Wiessner M, Hollenstein C et al (2019) Anode power deposition in dry EDM. Int J Precis Eng Manuf - Green Technol 6:197–210. https://doi.org/10.1007/s40684-019-00051-2

Dhakar K, Chaudhary K, Dvivedi A, Bembalge O (2019) An environment-friendly and sustainable machining method: near-dry EDM. Mater Manuf Process 34:1307–1315. https://doi.org/10.1080/10426914.2019.1643471

Shervani-Tabar MT, Maghsoudi K, Shabgard MR (2013) Effects of simultaneous ultrasonic vibration of the tool and the workpiece in ultrasonic assisted EDM. Int J Comput Methods Eng Sci Mech 14:1–9. https://doi.org/10.1080/15502287.2012.698696

Han W, Kunieda M (2019) A novel method to switch machining mode between micro-ECM and micro-EDM using oxide film on surface of tungsten electrode. Precis Eng 56:455–465. https://doi.org/10.1016/j.precisioneng.2019.02.002

Li CP, Kim MY, Islam MM, Ko TJ (2016) Mechanism analysis of hybrid machining process comprising EDM and end milling. J Mater Process Technol 237:309–319. https://doi.org/10.1016/j.jmatprotec.2016.06.022

Baghel R, Mali HS, Biswas SK (2019) Parametric optimization and surface analysis of diamond grinding-assisted EDM of TiN-Al2O3 ceramic composite. Int J Adv Manuf Technol 100:1183–1192. https://doi.org/10.1007/s00170-018-1842-z

Zhang C, Zou R, Yu Z, Natsu W (2020) Micro EDM aided by ultrasonic vibration in nitrogen plasma jet and mist. Int J Adv Manuf Technol 106:5269–5276. https://doi.org/10.1007/s00170-020-05032-3

Li C, Xu M, Yu Z et al (2020) Electrical discharge-assisted milling for machining titanium alloy. J Mater Process Technol 285:116785. https://doi.org/10.1016/j.jmatprotec.2020.116785

Ying Z, Shu L, Sugita N (2020) Experimental and finite element analysis of force and temperature in ultrasonic vibration assisted bone cutting. Ann Biomed Eng 48:1281–1290. https://doi.org/10.1007/s10439-020-02452-w

Xiang D, Shi Z, Feng H et al (2019) Finite element analysis of ultrasonic assisted milling of SiCp/Al composites. Int J Adv Manuf Technol 105:3477–3488. https://doi.org/10.1007/s00170-019-04542-z

Lotfi M, Amini S (2017) Experimental and numerical study of ultrasonically-assisted drilling. Ultrasonics 75:185–193. https://doi.org/10.1016/j.ultras.2016.11.009

Lotfi M, Akbari J (2021) Finite element simulation of ultrasonic-assisted machining: a review. Int J Adv Manuf Technol 116:2777–2796. https://doi.org/10.1007/s00170-021-07205-0

Shao B, Rajurkar KP (2015) Modelling of the crater formation in micro-EDM. Procedia CIRP 33:376–381. https://doi.org/10.1016/j.procir.2015.06.085

Kurnia W, Tan PC, Tan PC et al (2007). Electro-thermal modelling of anode and cathode in micro-EDM. https://doi.org/10.1088/0022-3727/40/8/015

Liu JF, Guo YB (2016) Thermal modeling of EDM with progression of massive random electrical discharges. Procedia Manuf 5:495–507. https://doi.org/10.1016/j.promfg.2016.08.041

Chen G, Ren C, Yang X et al (2011) Finite element simulation of high-speed machining of titanium alloy (Ti-6Al-4V) based on ductile failure model. Int J Adv Manuf Technol 56:1027–1038. https://doi.org/10.1007/s00170-011-3233-6

Kurniawan R, Kumaran ST, Ko TJ (2021) Finite element analysis in ultrasonic elliptical vibration cutting (UEVC) during micro-grooving in AISI 1045. Int J Precis Eng Manuf. https://doi.org/10.1007/s12541-021-00554-6

Zhang YC, Mabrouki T, Nelias D, Gong YD (2011) Chip formation in orthogonal cutting considering interface limiting shear stress and damage evolution based on fracture energy approach. Finite Elem Anal Des 47:850–863. https://doi.org/10.1016/j.finel.2011.02.016

Özel T, Zeren E (2004) Determination of work material flow stress and friction for FEA of machining using orthogonal cutting tests. J Mater Process Technol 153–154:1019–1025. https://doi.org/10.1016/j.jmatprotec.2004.04.162

Ayed Y, Germain G, Ben SW, Hamdi H (2014) Experimental and numerical study of laser-assisted machining of Ti6Al4V titanium alloy. Finite Elem Anal Des 92:72–79. https://doi.org/10.1016/j.finel.2014.08.006

Kurniawan R, Ahmed F, Ali S et al (2021) Analytical, FEA, and experimental research of 2D-Vibration Assisted Cutting (2D-VAC) in titanium alloy Ti6Al4V. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-021-07831-8

Kurniawan R, Park GC, Park KM et al (2020) Machinability of modified Inconel 713C using a WC TiAlN-coated tool. J Manuf Process 57:409–430. https://doi.org/10.1016/j.jmapro.2020.06.032

Barnes S, Pashby IR, Mok DK (1996) The effect of workpiece temperature on the machinability of an aluminum/sic MMC. J Manuf Sci Eng Trans ASME 118:422–427. https://doi.org/10.1115/1.2831047

He CL, Zong WJ, Sun T (2016) Origins for the size effect of surface roughness in diamond turning. Int J Mach Tools Manuf 106:22–42. https://doi.org/10.1016/j.ijmachtools.2016.04.004

Funding

The Basic Science Research Program supported this research through the National Research Foundation of Korea (NRF), funded by the Ministry of Science, ICT, and Future Planning (grant number NRF-2020R1A2B5B02001755).

Author information

Authors and Affiliations

Contributions

Rendi Kurniawan: Writing — original draft, conceptualization, methodology, formal analysis, and software; Moran Xi, Jielin Chen: visualization, investigation; Chang Ping Li: validation; Gun Chul Park, Ye In Kwak: project administration, resources; Tae Jo Ko: writing – review and editing, supervision, funding acquisition.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kurniawan, R., Xu, M., Li, C.P. et al. Numerical analysis in ultrasonic elliptical vibration cutting (UEVC) combined with electrical discharge assistance (EDA) for Ti6Al4V. Int J Adv Manuf Technol 120, 471–498 (2022). https://doi.org/10.1007/s00170-022-08724-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08724-0