Abstract

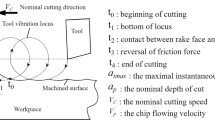

This research report deals with an experimental and analytical study of the ultrasonic elliptical vibration cutting (UEVC) process on medium steel alloy (AISI 1045) for sustainable machining of round-shaped (R-shaped) microgrooves via relatively low-speed machining (0.5–2.5 m/min). The need for microgroove patterns on planar surfaces in the tribology field has increased significantly owing to superior lubrication performance in decreasing the coefficient of friction. Analyzing the surface roughness, microgroove morphology, cutting force, and chip formation during microgrooving are the main objectives of this experimental study. The experimental results showed that the UEVC process evidently produces lower surface roughness, lower cutting forces, better groove shape morphology, thinner chip thickness, and higher flow shear angle when compared to the conventional cutting process. A new approach in methods to analyze surface roughness and cutting force in UEVC microgrooving has also been developed and validated with the experimental results. Finally, these experimental studies indicate the achievement of sustainable machining of the R-shaped microgroove pattern using the UEVC process.

Similar content being viewed by others

References

Gachot C, Rosenkranz A, Hsu SM, Costa HL (2017) A critical assessment of surface texturing for friction and wear improvement. Wear 372–373:21–41. https://doi.org/10.1016/j.wear.2016.11.020

Yuan S, Huang W, Wang X (2011) Orientation effects of micro-grooves on sliding surfaces. Tribol Int 44:1047–1054. https://doi.org/10.1016/j.triboint.2011.04.007

Kurniawan R, Ko TJ (2015) Friction reduction on cylindrical surfaces by texturing with a piezoelectric actuated tool holder. Int J Precis Eng Manuf 16:861–868. https://doi.org/10.1007/s12541-015-0113-2

Wakuda M, Yamauchi Y, Kanzaki S, Yasuda Y (2003) Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 254:356–363. https://doi.org/10.1016/S0043-1648(03)00004-8

Etsion I (2013) Modeling of surface texturing in hydrodynamic lubrication. Friction 1:195–209. https://doi.org/10.1007/s40544-013-0018-y

Sharma V, Pandey PM (2016) Recent advances in turning with textured cutting tools: a review. J Clean Prod 137:701–715. https://doi.org/10.1016/j.jclepro.2016.07.138

Arslan A, Masjuki HH, Kalam MA, Varman M, Mufti RA, Mosarof MH, Khuong LS, Quazi MM (2016) Surface texture manufacturing techniques and tribological effect of surface texturing on cutting tool performance: a review. Crit Rev Solid State Mater Sci 8436:1–35. https://doi.org/10.1080/10408436.2016.1186597

Chetan GS, Venkateswara Rao P (2015) Application of sustainable techniques in metal cutting for enhanced machinability: a review. J Clean Prod 100:17–34. https://doi.org/10.1016/j.jclepro.2015.03.039

Kawasegi N, Sugimori H, Morimoto H, Morita N, Hori I (2009) Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis Eng 33:248–254. https://doi.org/10.1016/j.precisioneng.2008.07.005

Sugihara T, Enomoto T (2009) Development of a cutting tool with a nano/micro-textured surface—improvement of anti-adhesive effect by considering the texture patterns. Precis Eng 33:425–429. https://doi.org/10.1016/j.precisioneng.2008.11.004

Xie J, Luo MJ, Wu KK, Yang LF, Li DH (2013) Experimental study on cutting temperature and cutting force in dry turning of titanium alloy using a non-coated micro-grooved tool. Int J Mach Tools Manuf 73:25–36. https://doi.org/10.1016/j.ijmachtools.2013.05.006

Shamoto E, Moriwaki T (1994) Study on elliptical vibration cutting. CIRP Ann Manuf Technol 43:35–38. https://doi.org/10.1016/S0007-8506(07)62158-1

Kim GD, Loh BG (2007) An ultrasonic elliptical vibration cutting device for micro V-groove machining: kinematical analysis and micro V-groove machining characteristics. J Mater Process Technol 190:181–188. https://doi.org/10.1016/j.jmatprotec.2007.02.047

Saito H, Jung H, Shamoto E, Wu TC, Chien JT (2017) Mirror surface machining of high-alloy steels by elliptical vibration cutting with single-crystalline diamond tools: influence of alloy elements on diamond tool damage. Precis Eng 49:200–210. https://doi.org/10.1016/j.precisioneng.2017.02.008

Ma C, Shamoto E, Moriwaki T, Zhang Y, Wang L (2005) Suppression of burrs in turning with ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 45:1295–1300. https://doi.org/10.1016/j.ijmachtools.2005.01.011

Shamoto E, Moriwaki T (1999) Ultaprecision diamond cutting of hardened steel by applying elliptical vibration cutting. CIRP Ann Manuf Technol 48:441–444 https://doi.org/10.1016/S0007-8506(07)63222-3

Nath C, Rahman M, Neo KS (2009) Machinability study of tungsten carbide using PCD tools under ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 49:1089–1095. https://doi.org/10.1016/j.ijmachtools.2009.07.006

Nath C, Rahman M, Neo KS (2009) A study on ultrasonic elliptical vibration cutting of tungsten carbide. J Mater Process Technol 209:4459–4464. https://doi.org/10.1016/j.jmatprotec.2008.10.047

Zhang X, Senthil Kumar A, Rahman M et al (2011) Experimental study on ultrasonic elliptical vibration cutting of hardened steel using PCD tools. J Mater Process Technol 211:1701–1709. https://doi.org/10.1016/j.jmatprotec.2011.05.015

Suzuki N, Masuda S, Haritani M, Shamoto E (2004) Ultraprecision micromachining of brittle materials by applying ultrasonic elliptical vibration cutting. In: Micro-Nanomechatronics and Human Science, 2004 and The Fourth Symposium Micro-Nanomechatronics for Information-Based Society, 2004. Ieee, pp 133–138

Bai W, Sun R, Gao Y, Leopold J (2016) Analysis and modeling of force in orthogonal elliptical vibration cutting. Int J Adv Manuf Technol 83:1025–1036. https://doi.org/10.1007/s00170-015-7645-6

Geng D, Zhang D, Li Z, Liu D (2017) Feasibility study of ultrasonic elliptical vibration-assisted reaming of carbon fiber reinforced plastics/titanium alloy stacks. Ultrasonics 75:80–90. https://doi.org/10.1016/j.ultras.2016.11.011

Chen JB, Fang QH, Wang CC, Du JK, Liu F (2016) Theoretical study on brittle-ductile transition behavior in elliptical ultrasonic assisted grinding of hard brittle materials. Precis Eng 46:104–117. https://doi.org/10.1016/j.precisioneng.2016.04.005

Liu D, Yan R, Chen T (2017) Material removal model of ultrasonic elliptical vibration-assisted chemical mechanical polishing for hard and brittle materials. Int J Adv Manuf Technol 92:81–99. https://doi.org/10.1007/s00170-017-0081-z

Huang W, Yu D, Zhang M, Ye F, Yao J (2017) Analytical design method of a device for ultrasonic elliptical vibration cutting. J Acoust Soc Am 141:1238–1245. https://doi.org/10.1121/1.4976340

Jung H, Hayasaka T, Shamoto E (2016) Mechanism and suppression of frictional chatter in high-efficiency elliptical vibration cutting. CIRP Ann Manuf Technol 65:369–372. https://doi.org/10.1016/j.cirp.2016.04.103

Lotfi M, Amini S (2017) FE simulation of linear and elliptical ultrasonic vibrations in turning of Inconel 718. Proc Inst Mech Eng Part E J Process Mech Eng. https://doi.org/10.1177/0954408917715533

Zhang J, Suzuki N, Wang Y, Shamoto E (2015) Ultra-precision nano-structure fabrication by amplitude control sculpturing method in elliptical vibration cutting. Precis Eng 39:86–99. https://doi.org/10.1016/j.precisioneng.2014.07.009

Zhang J, Cui T, Ge C, Sui Y, Yang H (2016) Review of micro/nano machining by utilizing elliptical vibration cutting. Int J Mach Tools Manuf 106:109–126. https://doi.org/10.1016/j.ijmachtools.2016.04.008

Yang Y, Pan Y, Guo P (2017) Structural coloration of metallic surfaces with micro/nano-structures induced by elliptical vibration texturing. Appl Surf Sci 402:400–409. https://doi.org/10.1016/j.apsusc.2017.01.026

Kurniawan R, Kiswanto G, Ko TJ (2016) Micro-dimple pattern process and orthogonal cutting force analysis of elliptical vibration texturing. Int J Mach Tools Manuf 106:127–140. https://doi.org/10.1016/j.ijmachtools.2016.03.007

Kurniawan R, Kiswanto G, Ko TJ (2017) Surface roughness of two-frequency elliptical vibration texturing (TFEVT) method for micro-dimple pattern process. Int J Mach Tools Manuf 116:77–95. https://doi.org/10.1016/j.ijmachtools.2016.12.011

Kim GD, Loh BG (2007) Characteristics of chip formation in micro V-grooving using elliptical vibration cutting. J Micromech Microeng 17:1458–1466. https://doi.org/10.1088/0960-1317/17/8/007

Xu W, Zhang LC, Wu Y (2014) Elliptic vibration-assisted cutting of fibre-reinforced polymer composites: understanding the material removal mechanisms. Compos Sci Technol 92:103–111. https://doi.org/10.1016/j.compscitech.2013.12.011

Zhang J, Suzuki N, Wang Y, Shamoto E (2014) Fundamental investigation of ultra-precision ductile machining of tungsten carbide by applying elliptical vibration cutting with single crystal diamond. J Mater Process Technol 214:2644–2659. https://doi.org/10.1016/j.jmatprotec.2014.05.024

Suzuki H, Hamada S, Okino T, Kondo M, Yamagata Y, Higuchi T (2010) Ultraprecision finishing of micro-aspheric surface by ultrasonic two-axis vibration assisted polishing. CIRP Ann Manuf Technol 59:347–350. https://doi.org/10.1016/j.cirp.2010.03.117

Ma C, Ma J, Shamoto E, Moriwaki T (2011) Analysis of regenerative chatter suppression with adding the ultrasonic elliptical vibration on the cutting tool. Precis Eng 35:329–338. https://doi.org/10.1016/j.precisioneng.2010.12.004

Kim GD, Loh BG (2011) Direct machining of micro patterns on nickel alloy and mold steel by vibration assisted cutting. Int J Precis Eng Manuf 12:583–588. https://doi.org/10.1007/s12541-011-0075-y

Kim GD, Loh BG (2010) Machining of micro-channels and pyramid patterns using elliptical vibration cutting. Int J Adv Manuf Technol 49:961–968. https://doi.org/10.1007/s00170-009-2451-7

Kim GD, Loh BG (2008) Characteristics of elliptical vibration cutting in micro-V grooving with variations in the elliptical cutting locus and excitation frequency. J Micromech Microeng 18:025002. https://doi.org/10.1088/0960-1317/18/2/025002

Zhang C, Ehmann K, Li Y (2015) Analysis of cutting forces in the ultrasonic elliptical vibration-assisted micro-groove turning process. Int J Adv Manuf Technol 78:139–152. https://doi.org/10.1007/s00170-014-6628-3

Guo P, Lu Y, Pei P, Ehmann KF (2014) Fast generation of micro-channels on cylindrical surfaces by elliptical vibration texturing. J Manuf Sci Eng 136:041008. https://doi.org/10.1115/1.4027126

Ma C, Shamoto E, Moriwaki T, Wang L (2004) Study of machining accuracy in ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 44:1305–1310. https://doi.org/10.1016/j.ijmachtools.2004.04.014

Shamoto E, Suzuki N, Hino R (2008) Analysis of 3D elliptical vibration cutting with thin shear plane model. CIRP Ann Manuf Technol 57:57–60. https://doi.org/10.1016/j.cirp.2008.03.073

Zhang X, Senthil Kumar A, Rahman M et al (2012) An analytical force model for orthogonal elliptical vibration cutting technique. J Manuf Process 14:378–387. https://doi.org/10.1016/j.jmapro.2012.05.006

Jieqiong L, Jinguo H, Xiaoqin Z, Zhaopeng H, Mingming L (2016) Study on predictive model of cutting force and geometry parameters for oblique elliptical vibration cutting. Int J Mech Sci 117:43–52. https://doi.org/10.1016/j.ijmecsci.2016.08.004

Wen JODO, Apa JOCP, Eimers JAR et al (2017) Design , fabrication , and testing of convex reflective diffraction gratings. Opt Express 25:808–816

Zhang Y, Wang S, Ding P (2017) Effects of channel shape on the cooling performance of hybrid micro-channel and slot-jet module. Int J Heat Mass Transf 113:295–309. https://doi.org/10.1016/j.ijheatmasstransfer.2017.05.092

Takeuchi Y, Maeda S, Kawai T, Sawada K (2002) Manufacture of multiple focus micro fresnel lenses by means of nonrotational diamond grooving. CIRP Ann Manuf Technol 51:5–8

Sawada K, Kawai T, Takeuchi Y, Sata T (2000) Development of ultraprecisison micro grooving (manufacture of V-shaped groove). JSME Int J 43:170–176

Song KY, Chung DK, Soo M et al (2013) Fabrication of micro-lenticular patterns using WEDM-grooving and electrolytic polishing. J Micromech Microeng 23:11. https://doi.org/10.1088/0960-1317/23/12/125034

Yan J, Kaneko T, Uchida K (2010) Fabricating microgrooves with varied cross-sections by electrodischarge machining. 991–1002. doi: https://doi.org/10.1007/s00170-010-2563-0

Kiswanto G, Zariatin DL, Ko TJ (2014) The effect of spindle speed , feed-rate and machining time to the surface roughness and burr formation of Aluminum Alloy 1100 in micro-milling operation. 16:435–450 . doi: https://doi.org/10.1016/j.jmapro.2014.05.003

Guo P, Ehmann KF (2013) Development of a tertiary motion generator for elliptical vibration texturing. Precis Eng 37:364–371. https://doi.org/10.1016/j.precisioneng.2012.10.005

Zhang X, Kumar a S, Rahman M, Liu K (2013) Modeling of the effect of tool edge radius on surface generation in elliptical vibration cutting. Int J Adv Manuf Technol 65:35–42. https://doi.org/10.1007/s00170-012-4146-8

Merchant ME (1945) Mechanics of the metal cutting process. I. Orthogonal cutting and a type 2 Chip. J Appl Phys 16:267–275. https://doi.org/10.1063/1.1707586

Altintas Y (2012) Manufacturing automation-metal cutting mechanics, machine tool vibrations, and CNC design, 2nd edn. Cambridge University Press, United States

Zhu W, He Y, Ehmann KF, et al (2017) Modeling of the effects of phase shift on cutting performance in elliptical vibration cutting Modeling of the effects of phase shift on cutting performance in elliptical vibration cutting. doi: https://doi.org/10.1007/s00170-017-0366-2

Freitas VL de A, de AVHC, Silva E de M et al (2010) Nondestructive characterization of microstructures and determination of elastic properties in plain carbon steel using ultrasonic measurements. Mater Sci Eng A 527:4431–4437. https://doi.org/10.1016/j.msea.2010.03.090

Shaw M (1984) Metal cutting principles, 1st edition, Oxford University Press, United States, 1984.

Kurniawan R, Ko TJ, Ping LC, Kumaran ST, Kiswanto G, Guo P, Ehmann KF (2017) Development of a two-frequency, elliptical-vibration texturing device for surface texturing. J Mech Sci Technol 31:3465–3473. https://doi.org/10.1007/s12206-017-0635-x

Liu K, Melkote SN (2006) Effect of plastic side flow on surface roughness in micro-turning process. Int J Mach Tools Manuf 46:1778–1785. https://doi.org/10.1016/j.ijmachtools.2005.11.014

Özel T, Hsu TK, Zeren E (2005) Effects of cutting edge geometry, workpiece hardness, feed rate and cutting speed on surface roughness and forces in finish turning of hardened AISI H13 steel. Int J Adv Manuf Technol 25:262–269. https://doi.org/10.1007/s00170-003-1878-5

Nath C, Rahman M, Neo KS (2011) Modeling of the effect of machining parameters on maximum thickness of cut in ultrasonic elliptical vibration cutting. J Manuf Sci Eng 133:011007. https://doi.org/10.1115/1.4003118

Acknowledgements

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning (grant number NRF-2017R1A2B2003932). Also, this work was supported by the 2017 Yeungnam University Research Grant. This work has been also supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2017R1A4A1015581).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kurniawan, R., Kumaran, S.T., Ali, S. et al. Experimental and analytical study of ultrasonic elliptical vibration cutting on AISI 1045 for sustainable machining of round-shaped microgroove pattern. Int J Adv Manuf Technol 98, 2031–2055 (2018). https://doi.org/10.1007/s00170-018-2359-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2359-1