Abstract

This paper investigates the performance of elliptical vibration cutting (EVC) in machining of AISI 1045 steel using AdvantEdge finite element simulation. The effectiveness of two key parameters frequency and amplitude is discussed. The purpose is to explore the effect of EVC on machining performance and to compare it with conventional cutting process, to prove that the EVC technique could generate better surface finishing. To be specific, the following aspects are compared: cutting force, shear stress, normal stress, Mise stress contour, and temperature variation; the residual stress is also examined. It is found that EVC has lower cutting force, stress, and temperature, and the residual stress acts out small change compared with conventional cutting. The frequency and amplitude all have influence in their own way on machining process.

Similar content being viewed by others

Reference

Shamoto E, Moriwaki T (1994) Study on elliptical vibration cutting. In: CIRP annals manufacturing technology, vol 43, pp 35–38

Zhou M, Hu LH (2015) Development of an innovative device for ultrasonic elliptical vibration cutting. J Ultrasonics 60:76–81

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. J Precis Eng 32:153–172

Wx X, Zhang LC (2015) Ultrasonic vibration-assisted machining: principle, design and application. J Adv Manuf 3:173–192

Song YC, Park C, Moriwaki T (2010) Mirror finishing of Co-Cr-Mo alloy using elliptical vibration cutting. J Precis Eng 34:784–789

Saito H, Jung HJ, Shamoto E (2016) Elliptical vibration cutting of hardened die steel with coated carbide tools. J Precis Eng 45:44–54

Zhang XQ, Senthil KA, Rahman M, Nath C, Liu K (2011) Experimental study on ultrasonic elliptical vibration cutting of hardened steel using PCD tools. J Mater Proc Technol 211:1701–1709

Nath C, Rahman M, Neo KS (2009) Machinability study of tungsten carbide using PCD tools under ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 49:1089–1095

Zhang JG, Zhang JJ, Cui T, Hao ZW, Zahrani A (2017) Sculpturing of single crystal silicon microstructures by elliptical vibration cutting. J Manuf Proc 29:389–398

Nath C, Rahman M, Neo KS (2009) A study on the effect of tool nose radius in ultrasonic elliptical vibration cutting of tungsten carbide. Int J Mater Proc Technol 209:5830–5836

Yang Y, Gao S, Chen K, Pan Y, Guo P (2017) Vibration analysis and development of an ultrasonic elliptical vibration tool based on a portal frame structure. J Precis Eng 50:421–432

Sui H, Zhang XY, Zhang DY, Jiang XG, Wu RB (2017) Feasibility study of high-speed ultrasonic vibration cutting titanium alloy. J Mater Proc Technol 247:111–120

Zhang J, Suzuki N, Shamoto E (2013) Investigation on machining performance of amplitude control sculpturing method in elliptical vibration cutting. Procedia CIRP 8:328–333

Zhang C, Shi GL, Ehmann FK (2017) Investigation of hybrid micro-texture fabrication in elliptical vibration assisted cutting. Int J Mach Tool Manuf 120:72–84

Zhang JG, Suzuki N, Wang YL, Shamoto E (2015) Ultraprecision nano-structure fabrication by amplitude control sculpturing method in elliptical vibration cutting. J Precis Eng 39:86–99

Shamoto E, Suzuki N, Hino R (2008) Analysis of 3D elliptical vibration cutting with thin shear plane model. CIRP Ann Manuf Technol 57:57–60

Zhang XQ, Senthil KA, Rahman M, Nath C, Liu K (2012) An analytical force model for orthogonal elliptical vibration cutting technique. J Manuf Proc 14:378–387

Bai WB, Sun RL, Gao Y, Jr gen L (2016) Analysis and modeling of force in orthogonal elliptical vibration cutting. Int J Adv Manuf Technol 83:1025–1036

Ma CX, Ma J, Shamoto E, Moriwaki T (2011) Analysis of regenerative chatter suppression with adding the ultrasonic elliptical vibration on the cutting tool. J Precis Eng 35:329–338

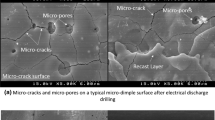

Wu J, Han RD (2009) A new approach to predicting the maximum temperature in dry drilling based on a finite element model. J Manuf Proc 11:19–30

Dali MNAM, Ghani JA, Haron C (2017) Comparison between dynamic and non-dynamic cutting tool option in FEM simulation for producing dimple structure. Procedia CIRP 58:613–616

Ma JF, Duong NH, Lei ST (2015) Numerical investigation of the performance of microbump textured cutting tool in dry machining of AISI 1045 steel. Int J Manuf Proc 19:194–204

Wan L, Wang DZ (2015) Numerical analysis of the formation of the dead metal zone with different tools in orthogonal cutting. J Simul Model Pract Theory 56:1–15

AdvantEdge FEM (2013) User’s manual. Version 6:0

Wu HB, Jia ZX, Liu G, Bi YB, Dong HY (2010) Finite element modeling of Ti6Al4V alloy high speed cutting. J Zhejiang University (engineering science) 44:982–987

Wan L, Wang DZ (2015) The investigation of serrated chip formation under different cutting speeds. Int J Adv Manuf Technol 82:951–959

Zhang JG, Suzuki N, Wang YL, Shamoto E (2014) Fundamental investigation of ultra-precision ductile machining of tungsten carbide by applying elliptical vibration cutting with single crystal diamond. Int J Mater Proc Technol 214:2644–2659

Huang K, Yang WY (2016) Analytical modeling of residual stress formation in workpiece material due to cutting. Int J Mech Sci 114:21–34

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, C., Wang, D. Numerical investigation of the performance of elliptical vibration cutting in machining of AISI 1045 steel. Int J Adv Manuf Technol 98, 715–727 (2018). https://doi.org/10.1007/s00170-018-2277-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2277-2