Abstract

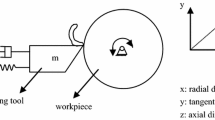

Chatter is a harmful phenomenon in metal cutting process. The turning process with variable spindle speed is an effective means for chatter suppression. In this paper, the reconstructed semi-discretization method (RSDM) is used to analyze the stability in turning process with variable spindle speed which is constructed as the dynamic model of delay differential equations with varying delay term (VDDE). Firstly, the dynamic model in turning with variable spindle speed is established. Secondly, stability analysis of VDDE based on the RSDM is introduced. For the turning process with variable spindle speed, the RSDM has been proved to be more calculation speed without reducing calculation accuracy than the well-accepted semi-discretization method (SDM) via an example of single degree of freedom turning. Finally, three types of chatter, period-one, flip, and secondary Hopf bifurcations are discussed in detail based on the RSDM. The proposed method is a good alternative method to the stability analysis in turning with variable spindle speed.

Similar content being viewed by others

Data availability

All data are available selectively from the corresponding author upon reasonable request.

Abbreviations

- Ω(t):

-

Spindle speed

- w :

-

Radial cutting depth

- h(t) :

-

Dynamic chip thickness

- m x :

-

Modal mass

- k x :

-

Modal stiffness

- c x :

-

Modal damping

- F x, F y :

-

Cutting forces respectively in x and y direction

- K f :

-

Cutting constant in the feed direction

- w n :

-

Natural angular frequency.

- ζ:

-

Modal damping rate

- τ(t):

-

Time delay

- RVA :

-

The ratios of modulation amplitude and

- RVF :

-

The ratios of modulation frequency

References

Guo Q, Jiang Y, Zhao B, Ming P (2016) Chatter modeling and stability lobes predicting for non-uniform helix tools. Int J Adv Manuf Technol 87:251–266. https://doi.org/10.1007/s00170-016-8458-y

Jiang S, Yan S, Liu Y, Duan C, Xun J, Sun Y (2019) Analytical prediction of chatter stability in turning of low-stiffness pure iron parts by nosed tool. Int J Adv Manuf Technol 102:1227–1237. https://doi.org/10.1007/s0017001829599

Zhan D, Jiang S, Niu J, Sun Y (2020) Dynamics modeling and stability analysis of five-axis ball-end milling system with variable pitch tools. Int J Mech Sci 182:105774. https://doi.org/10.1016/j.ijmecsci.2020.105774

Wang X, Song Q, Liu Z (2021) Dynamic model and stability prediction of thin-walled component milling with multi-modes coupling effect. J Mater Process Technol 288:116869. https://doi.org/10.1016/j.jmatprotec.2020.116869

Zhang Z, Luo M, Wu B, Zhang D (2020) Dynamic modeling and stability prediction in milling process of thin-walled workpiece with multiple structural modes. Proc Inst Mech Eng B J Eng Manuf:095440542093371. https://doi.org/10.1177/0954405420933710

Jiang S, Sun Y (2020) Stability analysis for a milling system considering multi-point-contact cross-axis mode coupling and cutter run-out effects. Mech Syst Signal Process 141:106452. https://doi.org/10.1016/j.ymssp.2019.106452

Qin C, Tao J, Shi H, Xiao D, Li B, Liu C (2020) A novel Chebyshev-wavelet-based approach for accurate and fast prediction of milling stability. Precis Eng 62:244–255. https://doi.org/10.1016/j.precisioneng.2019.11.016

Qin C, Tao J, Liu C (2018) A predictor-corrector-based holistic-discretization method for accurate and efficient milling stability analysis. Int J Adv Manuf Technol 96(5–8):2043–2054. https://doi.org/10.1007/s00170-018-1727-1

Qin C, Tao J, Liu C (2017) An Adams-Moulton-based method for stability prediction of milling processes. Int J Adv Manuf Technol 89(9–12):3049–3058. https://doi.org/10.1007/s00170-016-9293-x

Qin C, Tao J, Liu C (2019) A novel stability prediction method for milling operations using the holistic-interpolation scheme. J Mech Eng Sci 233(13):4463–4475. https://doi.org/10.1177/0954406218815716

Zhang X, Xiong C, Ding Y, Ding H (2017) Prediction of chatter stability in high speed milling using the numerical differentiation method. Int J Adv Manuf Technol 89:2535–2544. https://doi.org/10.1007/s00170-016-8708-z

Dong X, Qiu Z (2020) Stability analysis in milling based on updated numerical integration method. Mech Syst Signal Process 137:106435. https://doi.org/10.1016/j.ymssp.2019.106435

Zhu L, Liu C (2020) Recent progress of chatter prediction, detection and suppression in milling. Mech Syst Signal Process 146:1–37. https://doi.org/10.1016/j.ymssp.2020.106840

Liu C, Zhu L, Ni C (2018) Chatter detection in milling process based on VMD and energy entropy. Mech Syst Signal Process 105:169–182. https://doi.org/10.1016/j.ymssp.2017.11.046

Dong X, Zhang W (2017) Chatter identification in milling of the thin-walled part based on complexity index. Int J Adv Manuf Technol 91:3327–3337. https://doi.org/10.1007/s00170-016-9912-6

Dun Y, Zhu L, Yan B, Wang S (2021) A chatter detection method in milling of thin-walled TC4 alloy workpiece based on auto-encoding and hybrid clustering. Mech Syst Signal Process 158:1–23. https://doi.org/10.1016/j.ymssp.2021.107755

Dong X, Zhang W (2019) Chatter suppression analysis in milling process with variable spindle speed based on the reconstructed semi-discretization method. Int J Adv Manuf Technol 105:2021–2037. https://doi.org/10.1007/s00170-019-04363-0

Wan M, Liang X, Yang Y, Zhang W (2020) Suppressing vibrations in milling-trimming process of the plate-like workpiece by optimizing the location of vibration absorber. J Mater Process Technol 278:116499. https://doi.org/10.1016/j.jmatprotec.2019.116499

Wang C, Zhang X, Liu J, Cao H, Chen X (2019) Adaptive vibration reshaping based milling chatter suppression. Int J Mach Tools Manuf 41:30. https://doi.org/10.1016/j.ijmachtools.2019.04.001

Dang X, Wan M, Zhang W, Yang Y (2021) Chatter analysis and mitigation of milling of the pocket-shaped thin-walled workpieces with viscous fluid. Int J Mech Sci 194:106214. https://doi.org/10.1016/j.ijmecsci.2020.106214

Tlusty J, Polacek M (1963) The stability of the machine tool against self-excited vibration in machining. Mach Sci Technol 1:465–474

Tobias SA (1965) Machine tool vibration. Blackie, London

Insperger T, Stepan G (2004) Stability analysis of turning with periodic spindle speed modulation via semidiscretization. J Vib Control 10(12):1835–1855. https://doi.org/10.1177/1077546304044891

Altintaş Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann Manuf Technol 44(1):357–362. https://doi.org/10.1016/S0007-8506(07)62342-7

Budak E, Altintas Y (1998) Analytical prediction of chatter stability in milling—part I: general formulation. ASME Journal of Dynamic Systems Measurement and Control 120(1):22–30. https://doi.org/10.1115/1.2801317

Merdol S, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng 126(3):459–466. https://doi.org/10.1115/1.1765139

Insperger T, Stepan G (2002) Semi-discretization method for delayed systems. Int J Numer Methods Eng 55(5):503–518. https://doi.org/10.1002/nme.505

Insperger T, Mann B, Stépán G, Bayly P (2003) Stability of up-milling and down-milling, part 1: alternative analytical methods. Int J Mach Tools Manuf 43(1):25–34. https://doi.org/10.1016/S0890-6955(02)00159-1

Insperger T, Stépán G (2004) Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Methods Eng 61(1):117–141. https://doi.org/10.1002/nme.1061

Insperger T, Stépán G, Turi J (2007) State-dependent delay in regenerative turning processes. Nonlinear Dynamics 47(1–3):275–283. https://doi.org/10.1007/s11071-006-9068-2

Seguy S, Insperger T, Arnaud L, Dessein G, Peigne G (2011) Suppression of period doubling chatter in high speed milling by spindle speed variation. Mach Sci Technol 15(2):153–171. https://doi.org/10.1080/10910344.2011.579796

Insperger T, Stépán G, Turi J (2008) On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib 313(1):334–341. https://doi.org/10.1016/j.jsv.2007.11.040

Davies M, Pratt J, Dutterer B, Burns T (2002) Stability prediction for low radial immersion milling. J Manuf Sci Eng 124(2):217–225. https://doi.org/10.1115/1.1455030

Campomanes M, Altintas Y (2003) An improved time domain simulation for dynamic milling at small radial immersions. J Manuf Sci Eng 125(3):416–422. https://doi.org/10.1115/1.1580852

Li Z, Liu Q (2008) Solution and analysis of chatter stability for end milling in the time-domain. Chin J Aeronaut 21(2):169–178. https://doi.org/10.1016/S1000-9361(08)60022-9

Ding Y, Zhu L, Zhang X, Ding H (2010) A full-discretization method for prediction of milling stability. Int J Mach Tool Manu 50(5):502–509. https://doi.org/10.1016/j.ijmachtools.2010.01.003

Bayly P, Halley J, Mann B, Davies M (2003) Stability of interrupted cutting by temporal finite element analysis. J Manuf Sci Eng 125(2):220–225. https://doi.org/10.1115/1.1556860

Ding Y, Zhu L, Zhang X, Ding H (2011) Numerical integration method for prediction of milling stability. ASME Journal of Manufacturing Science and Engineering 133(3):031005. https://doi.org/10.1115/1.4004136

Dong X, Zhang W, Deng S (2016) The reconstruction of a semi-discretization method for milling stability prediction based on Shannon standard orthogonal basis. Int J Adv Manuf Technol 85(5–8):1501–1511. https://doi.org/10.1007/s00170-015-7719-5

Dong X, Zhang W (2017) Stability analysis in milling of the thin walled part considering multiple variables of manufacturing systems. Int J Adv Manuf Technol 89(1–4):515–527. https://doi.org/10.1007/s00170-016-9072-8

Stoferle T, Grab H (1972) Vermeiden von Ratterschwingungen durch periodische Drehzahlanderung. Werkstatt und Betrieb 105:727

Pakdemirli M, Ulsoy A (1997) Perturbation analysis of spindle speed variation in machine tool chatter. J Vib Control 3(3):261–278. https://doi.org/10.1177/107754639700300302

Jayaram S, Kapoor S, Devor R (2000) Analytical stability analysis of variable spindle speed machining. J Manuf Sci Eng 122(3):391–397. https://doi.org/10.1115/1.1285890

Sastry S, Kapoor S, Devor R, Dullerud G (2001) Chatter stability analysis of the variable speed face-milling process. J Manuf Sci Eng 123(4):753–756. https://doi.org/10.1115/1.1373649

Yilmaz A, Al-Regib E, Ni J (2002) Machine tool chatter suppression by multilevel random spindle speed variation. J Manuf Sci Eng 124(2):208–216. https://doi.org/10.1115/1.1378794

Namachchivaya S, Beddini (2003) Spindle speed variation for the suppression of regenerative chatter. Journal of Nonlinear Science 13(3):265–288. https://doi.org/10.1007/s00332-003-0518-4

Long X, Balachandran B (2005) Stability analysis of a variable spindle speed milling process. ASME 2005 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference850: 899–908. https://doi.org/10.1115/DETC2005-85065

Zatarain M, Bediaga I, Muñoa J, Lizarralde R (2008) Stability of milling processes with continuous spindle speed variation: analysis in the frequency and time domains, and experimental correlation. CIRP Ann Manuf Technol 57(1):379–384. https://doi.org/10.1016/j.cirp.2008.03.067

Seguy S, Insperger T, Arnaud L, Dessein G, Peigné G (2010) On the stability of high-speed milling with spindle speed variation. Int J Adv Manuf Technol 48(9–12):883–895. https://doi.org/10.1007/s00170-009-2336-9

Wu D, Chen K (2010) Chatter suppression in fast tool servo-assisted turning by spindle speed variation. International Journal of Machine Tools & Manufacture 50(12):1038-1047.https://doi.org/10.1016/j.ijmachtools.2010.09.001

Long X, Balachandran B (2010) Stability of up-milling and down-milling operations with variable spindle speed. J Vib Control 16(16):1151–1168. https://doi.org/10.1177/1077546309341131

Xie Q, Zhang Q (2012) Stability predictions of milling with variable spindle speed using an improved semi-discretization method. Math Comput Simul 85(3):78–89. https://doi.org/10.1016/j.matcom.2012.09.017

Otto A, Radons G (2013) Application of spindle speed variation for chatter suppression in turning. CIRP J Manuf Sci Technol 6(2):102–109. https://doi.org/10.1016/j.cirpj.2013.02.002

Liang XG, Yao ZQ, Luo L, Hu J (2013) An improved numerical integration method for predicting milling stability with varying time delay. Int J Adv Manuf Technol 68(9–12):1967–1976. https://doi.org/10.1007/s00170-013-4813-4

Totis G, Albertelli P, Sortino M, Monno M (2014) Efficient evaluation of process stability in milling with spindle speed variation by using the Chebyshev collocation method. J Sound Vib 333(3):646–668. https://doi.org/10.1016/j.jsv.2013.09.043

Ding Y, Niu J, Zhu L, Ding Y (2015) Numerical integration method for stability analysis of milling with variable spindle speeds. J Vib Acoust 138(1):0110101–01101011. https://doi.org/10.1115/1.4031617

Urbikain G, Olvera D, Lacalle L, Elías-Zúñiga A (2016) Spindle speed variation technique in turning operations: modeling and real implementation. J Sound Vib 383:384–396. https://doi.org/10.1016/j.jsv.2016.07.033

Ding Y, Niu J, Zhu L, Ding H (2016) Numerical integration method for stability analysis of milling with variable spindle speeds. J Vib Acoust 138(1):011010.1–011010.11. https://doi.org/10.1115/1.4031617

Niu J, Ding Y, Zhu L, Ding H Stability analysis of milling processes with periodic spindle speed variation via the variable-step numerical integration method. J Manuf Sci Eng 138(11):11450111. https://doi.org/10.1115/1.4033043

Acknowledgements

The corresponding author would like to thank Professor Tamás Insperger, Budapest University of Technology and Economics, who provides help for the research.

Code availability

All code can be provided selectively from the corresponding author upon reasonable request.

Funding

This study is supported, respectively, by the “Excellent Doctoral Program of Weifang University,” “Research start-up funds of Weifang University.”

Author information

Authors and Affiliations

Contributions

The first author completed the main work, and the second author completed the auxiliary work.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dong, X., Shen, X. & Fu, Z. Stability analysis in turning with variable spindle speed based on the reconstructed semi-discretization method. Int J Adv Manuf Technol 117, 3393–3403 (2021). https://doi.org/10.1007/s00170-021-07869-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07869-8