Abstract

A further increase in the efficiency of low-temperature plasma modification of the metal product surface layer is possible on the basis of the process supervision. The article presents an approach and a developed model that allows to receive and study the behavior of signals arising in the electrical circuit of a technological unit under the interaction of electromagnetic and electrostatic fields that form a low-temperature plasma gas discharge near the product surface. Data confirming the validity of the model are presented. The analysis of electrical signals is carried out. The indicator reflecting the stability of the process of plasma interaction with the product surface by the degree of the signal form deviation from the sine curve is substantiated. The study of the possibility to control the modification process was carried out. The dependences of the stability index on the product parameter values as functions of the process operating parameters — bias potential or magnetron anode current — were obtained and studied. The reliability of the theoretical studies results was experimentally confirmed, which showed that the composite structure synthesis process remains the most stable with a smooth decrease in the bias potential, as well as a smooth and abrupt increase in the magnetron anode current.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

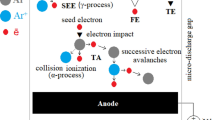

B. Brzhozovskii, S. Gestrin, V. Martynov, E. Zinina, The study of the physical processes of low-temperature plasma formation and its effects on metal product surface, IOP Conf. Series: Journal of Physics: Conf. 238, 891, 012297, 8 pp. (2017)

B M Brzhozovskii, N S Azikov, V V Martynov and E P Zinina, Composite structure formation on the surfaces of geometrically complex products, IOP Conf. Series: Journal of Physics: Conf. Series, 1281, 012006, 5 pp. (2019)

Wołowiec E, Kula P, Kołodziejczyk Ł, Dybowski K (2014) Mathematical Modelling of the vacuum carburizing process. Thermal Processing 9:34–38

Javaheri V, Pohjonen A, Asperheim JI, Ivanov D, Porter D (2019) Physically based modeling, characterization and design of an induction hardening process for a new slurry pipeline steel. Mater Des 182:108047

Barka N, Bocher P, Brousseau J, Galopin M, Sundararajan S (2006) Modeling and sensitivity study of the induction hardening process. Adv Mater Res 15-17:525–530

Mosavi A, Salehi F, Nadai L, Karoly S, Gorji NE (2019) Modeling the Temperature Distribution During Laser Hardening Process. Results in Physics 10:2019110285 (4 pp)

Yuan J, Kang J, Rong Y, Sisson RD Jr (2003) FEM modeling of induction hardening processes in steel. J Mater Eng Perform 12(5):589–596

V.N. Gololobov, Proteus VSM – Russian manual (SI), 26 p. UK: Labcenter Electronics Co. (2015)

M.A. Amelina, S.A. Amelin, Micro-cap schematic simulator. Versions 9, 10. 617 p. Smolensk: Smolensk branch of NRU MPEI (2012)

AutoCad Electrical 2016. Connecting 3D / А.М. Alekseeva, M. Weber, V. Gurav, L.E. Galashkina, 384 p. Moscow: DMK-Press (2016)

A.N. Shesterkin Multisim 10 system for modeling and research of electronic devices, 360 p. Moscow: DMK-Press (2015)

Novatec ELECTRO. Microprocessor relay devices. Current relays and power limiters // Web site “NOVATEC ELECTRO” https://novatek-electro.ru

Brzhozovskii B, Brovkova M, Gestrin S, Martynov V, Zinina E (2019) Study of the properties of the asymmetric microwave low pressure gas discharge. Journal of Physics D: Appl. Phys 52:485202, 11 pp

Morozov VA, Mikheev AGM (2019) Determination of the equivalent circuit of a high-frequency plasma capacitor. Chemical Physics and Mesoscopy 21(1):142–155

V.A. Morozov, G.M. Mikheev, R.G. Zonov, High-frequency capacitive plasma excitation load systems for film technology. Proceedings of the conference “Nanotechnology for Manufacturing – 2006”, pp. 266-280, Moscow: Janus-K (2006)

Roldugin VI (2011) Physicochemistry of the surface: a monograph textbook, 568 pp. Intellect Publishing House, Dolgoprudny

Rubin AB (1987) Biophysics: 2 volumes: textbook for biol. Special. of universities: V.1, 448 p. Moscow State University, Moscow

Surface Engineering / Ed. A.G. Suslova, 320 p. Moscow: Mechanical Engineering (2008)

Yu.M. Lakhtin, V.P. Leontiev, Materials science, 510 p. Moscow: Mechanical Engineering (1972)

V.F. Kiselev, S.N. Kozlov, A.V. Zoteev, Fundamentals of solid surface physics, 284 p. Moscow: Moscow University Press. Faculty of Physics, Moscow State University (1999)

V.L. Granovsky, Electric current in gas: Vol.1 General issues of gas electrodynamics, 432 pp. Moscow – Leningrad: State Publishing House of technical and theoretical literature (1952)

G.V. Ashmarin, K.S. Kim, A.V. Tokarev, On the physical mechanisms of combustion of a linear corona torch discharge, Bulletin of KRSU, №2, 4 p. (2002)

M. Jaycock, G. Parfitt, Chemistry of interfaces: Transl. from English, 269 p. Moscow: Mir (1984)

G.S. Sapunov Elements of microwave engineering. Waveguides // Web site "Elremont.ru" https://www.elremont.ru/svch/bt_rem16.php (2007)

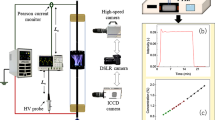

Brzhozovskii B, Zinina E, Martynov V, Sussky A (2020) Realization of electrical signal monitoring of metal surface modification by means of low-temperature plasma treatment. Vibroengineering PROCEDIA 32:135–140

Рandit SM, Wu SM (1983) Time series and system analysis with aррlications, 586 р. John Wiley and Sons, New York

V.V. Martynov, A.V. Syssky, The results of modeling electrical processes in low-temperature plasma modification of metal surfaces, 2020 4th Scientific School on Dynamics of Complex Networks and their Application in Intellectual Robotics (DCNAIR), pp. 169–171 (2020)

Funding

Russian Science Foundation (Project No. 19-19-00101).

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martynov, V.V., Brzhozovskii, B.M., Zinina, E.P. et al. Substantiation of the technology for controlling the process of low-temperature plasma modification of metal product surface layer by the electrical signal parameters. Int J Adv Manuf Technol 117, 2405–2419 (2021). https://doi.org/10.1007/s00170-021-07258-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07258-1