Abstract

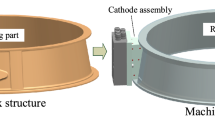

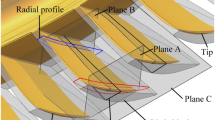

Electrochemical machining (ECM) using tube electrodes is an effective approach for the rough machining of turbo engine blisks. The uniformity of the channel allowance decisively influences the accuracy of subsequent ECM precision for the blisk. A voltage regulation strategy to minimize allowance differences in the ECM is proposed. Simulation and experimental investigations are performed to determine the relationships between the channel width and the applied voltage. Comparative experiments using the conventional constant voltage method and the proposed voltage regulation method are performed. The experimental results show that the allowance differences on the back and basin surfaces of the blade are reduced by 47.81% and 51.57%, respectively, using the proposed method. Thus, the experimental results verify that the voltage regulation strategy is effective for the ECM of blisk channels.

Similar content being viewed by others

Availability of data and materials

All data generated or analyzed during this study are included in this article.

References

Rajurkar KP, Sundaram MM, Malshe AP (2013) Review of electrochemical and electrodischarge machining. Proc CIRP 6:13–26

Krauss W, Holstein N, Konys J (2010) Advanced electro-chemical processing of tungsten components for He-cooled divertor application. Fusion Eng Design 85:2257–2262

Klocke F, Zeis M, Klink A, Veselovac D (2013) Experimental research on the electrochemical machining of modern titanium- and nickel-based alloys for aero engine components. Proc CIRP 6:368–372

Gu Z, Zhu D, Xue T, Liu A, Zhu D (2017) Investigation on flow field in electrochemical trepanning of aero engine diffuser. Int J Adv Manuf Technol 89:877–884

Mukherjee R, Chakraborty S (2013) Selection of the optimal electrochemical machining process parameters using biogeography-based optimization algorithm. Int J Adv Manuf Technol 64:781–791

Klocke F, Zeis M, Klink A, Veselovac D (2013) Technological and economical comparison of roughing strategies via milling, sinking-EDM, wire-EDM and ECM for titanium- and nickel-based blisks. CIRP J Manuf Sci Technol 6:198–203

Fujisawa T, Inaba K, Yamamoto M, Kato D (2008) Multi-physics simulation of electro-chemical machining process for three-dimensional compressor blade. J Fluids Eng 130:1–8

Bogoveev NA, Firsov AG, Filatov EI, Tikhonov AS (2001) Computer support for “all-round” ECM processing of blades. J Mater Process Technol 109:324–326

Tsuboi R, Yamamoto M (2009) Modeling and applications of electrochemical machining process. Proc. ASME FEDSM 2009-12552:377–384

Ernst A, Heib T, Hall T, Schmidt G, Bährea D (2018) Simulation of the tool shape design for the electrochemical machining of jet engine vanes. Proc CIRP 68:762–767

Xu Z, Liu J, Xu Q, Gong T, Zhu D, Qu N (2015) The tool design and experiments on electrochemical machining of a blisk using multiple tube electrodes. Int J Adv Manuf Technol 79:531–539

Tang L, Gan WM (2014) Utilization of flow field simulations for cathode design in electrochemical machining of aerospace engine blisk channels. Int J Adv Manuf Technol 72:1759–1766

Xu Z, Sun L, Hu Y, Zhang J (2014) Flow field design and experimental investigation of electrochemical machining on blisk cascade passage. Int J Adv Manuf Technol 71:459–469

Zhu D, Zhou Y, Zhang R, Qin P (2016) Investigation of leveling ability improvement in pulse electrochemical machining for aero structural components. Int J Adv Manuf Technol 86:1723–1732

Klocke F, Klink A, Veselovac D, Aspinwall DK, Soo SL, Schmidt M, Schilp J, Levy G, Kruth JP (2014) Turbomachinery component manufacture by application of electrochemical, electro-physical and photonic processes. CIRP Ann Manuf Technol 63:703–726

Zhang J, Zhu D, Xu Z, Zhang K, Liu J, Qu N, Zhu D (2016) Improvement of trailing edge accuracy in blisk electrochemical machining by optimizing the electric field with an extended cathode. J Mater Process Technol 231:301–311

Zhu D, Zhang J, Zhang K, Liu J, Chen Z, Qu N (2015) Electrochemical machining on blisk cascade passage with dynamic additional electrolyte flow. Int J Adv Manuf Technol 80:637–645

Yang T, Zeng YB, Sang YM, Li SY (2020) Effect of structural parameters of array of holes in the tube electrode for electrochemical cutting. Int J Adv Manuf Technol 107:205–216

Tang L, Feng X, Huang TQ, Liu J, Zhang JJ, Lei QB, Wang Z (2019) Research on the combined electrochemical machining and electrical discharge machining technology for closed integer impeller. Int J Adv Manuf Technol 102:3419–3429

Zhu D, Hu X, Lin J, Xu Z, Liu J (2019) Investigation into the blade-formation process in electrochemical trepanning of diffusers. Mach Sci Technol 24:489–507

Funding

This study was supported by the Joint Funds of the Natural Science Foundation of China and Guangdong Province (Grant U1601201) and the National Science and Technology Major Project (Grant 2017-VII-0004-0097).

Author information

Authors and Affiliations

Contributions

Yawei Zong conceived of the study, designed the study, and collected the data. All authors analyzed the data and were involved in writing the manuscript.

Corresponding author

Ethics declarations

Ethics approval

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zong, Y., Liu, J. & Zhu, D. Study of voltage regulation strategy in electrochemical machining of blisk channels using tube electrodes. Int J Adv Manuf Technol 114, 3489–3501 (2021). https://doi.org/10.1007/s00170-021-07065-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07065-8