Abstract

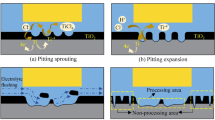

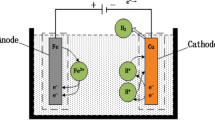

In electrochemical machining of aero structural components, the allowance distribution between the blank and the model is generally not uniform, which may influence the final precision of components. However, proper leveling can reduce the negative impacts of this nonuniformity and enhance machining accuracy. This paper proposes a mathematical model for pulse electrochemical machining (ECM) to simulate the corrosion process in order to improve the leveling. Several machining parameters, such as power voltage, pulse duty, and frequency, are considered to optimize the leveling ratio. The optimal parameters are obtained from the simulation. The simulation results show that the leveling ratio improves with the decrease of pulse duty and voltage and the increase of frequency. Furthermore, the pulse duty has a more significant effect on the leveling ability than the voltage and the frequency. In addition, verified experiments are carried out and the results are consistent with the simulation. It indicates that the proposed model is effective and can be used for complex structural components in ECM.

Similar content being viewed by others

References

Hennig W, Feldmann G, Haubold T (2014) Shot peening method for aerofoil treatment of blisk assemblies. Pro CRIP 13:355–358

Gaetani P, Persico G, Mora A, Dossena V, Osnaghi C (2012) Impeller-vaned diffuser interaction in a centrifugal compressor at off design conditions. J Turbomach 134(6):061034-1–061034-9

Klocke F, Zeis M, Klink A, Veselovac D (2012) Technological and economical comparison of roughing strategies via milling, EDM and ECM for titanium- and nickel-based blisks. Proc CRIP 2:98–101

Klocke F, Zeis M, Harst S, Klink A, Veselovac D, Baumgärtner M (2013) Modeling and simulation of the electrochemical machining (ECM) material removal process for the manufacture of aero engine components. Proc CRIP 8:265–270

Rajurkar KP, Sundaram MM, Malshe AP (2013) Review of electrochemical and electrodischarge machining. Proc CRIP 6:13–26

Hocheng H, Sun YH, Lin SC, Kao PS (2003) A material removal analysis of electrochemical machining using flat-end cathode. J Mater Process Tech 140:264–268

Bähre D, Rebschläger A, Weber O, Steuer P (2013) Reproducible, fast and adjustable surface roughening of stainless steel using pulse electrochemical machining. Proc CRIP 6:384–389

De Slka AKM, Altena HSJ, McGeough JA (2003) Influence of electrolyte concentration on copying accuracy of precision-ECM. Ann CRIP 52(1):165–168

Rajurkar KP, Zhu D, Wei B (1998) Minimization of machining allowance in electrochemical machining. Ann CRIP 47(1):165–168

De Silva AKM, Altena HSJ, McGeough JA (2000) Precision ECM by process characteristic modelling. Ann CRIP 49(7):151–155

Kozak J, Chuchro M, Ruszaj A, Karbowski K (2000) The computer aided simulation of electrochemical process with universal spherical electrodes when machining sculptured surfaces. J Mater Process Technol 107:283–287

Idrisov TR, Zaitzev AN, Zhitnikov VP (2004) Estimation of the process localization at the electrochemical machining by microsecond pulses of bipolar current. J Mater Process Technol 149:479–485

Li ZY, Niu ZW, Li L (2013) Experimental investigation for characteristics of the localized dissolution of micro-hole in ECM aided by ultrasonic wave. Key Eng Mat 567:21–26

Qian SQ, Ji F, Qu NS, Li HS (2014) Improving the localization of surface texture by electrochemical machining with auxiliary anode. Mater Manuf Process 29:1488–1493

Wang DY, Zhu ZW, Bao J, Zhu D (2015) Reduction of stray corrosion by using iron coating in NaNO3 solution during electrochemical machining. Int J Adv Manuf Tech 76:1365–1370

Hackert-Oschazchen M, Martin A, Meichsner G, Zinecker M, Schubert A (2013) Microstructuring of carbide metals applying jet electrochemical machining. Precis Eng 37:621–634

De Silva AKM, Pajak PT, Harrison DK, McGeough JA (2004) Modelling and experimental investigation of laser assisted jet electrochemical machining. Ann CRIP 53(1):179–182

Brusilovsky Z (2008) Adjustment and readjustment of electrochemical machines and control of the process parameters in machining shaped surfaces. J Mater Process 196:311–320

Chen XZ, Xu ZY, Zhu D, Fang ZD, Zhu D (2015) Experimental research on electrochemical machining of titanium alloy Ti60 for a blisk. China J of Aero, online

Chen XL, Qu NS, Li HS (2015) Improvement of dimensional uniformity on micro-dimple arrays generated by electrochemical micro-machining with an auxiliary electrode. Int J Adv Manuf Technol 80:1577–1585

Mukherjee R, Chakraborty S (2013) Selection of the optimal electrochemical machining process parameters using biogeography-based optimization algorithm. Int J Adv Manuf Technol 64:781–791

Xu ZY, Xu Q, Zhu D, Gong T (2013) A high efficiency electrochemical machining method of blisk channels. Ann CRIP 62:187–190

Zhu D, Zhu D, Xu ZY, Xu Q, Liu J (2010) Investigation on the flow field of W-shape electrolyte flow mode in electrochemical machining. J Appl Electrochem 41:525–532

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, D., Zhou, Y., Zhang, R. et al. Investigation of leveling ability improvement in pulse electrochemical machining for aero structural components. Int J Adv Manuf Technol 86, 1723–1732 (2016). https://doi.org/10.1007/s00170-015-8295-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8295-4