Abstract

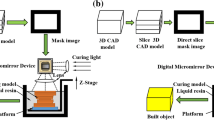

The mask-image-projection-based stereolithography (MIP-SL) is one of the most promising methods for preparing biological scaffolds. In this paper, a mask image planning method based on grayscale regulation is proposed based on the characteristics of the bio-scaffold structure. It is based on support vector machine method and iterative method to intelligently regulate mask pixel gray value, which can achieve low exposure error and accordingly better curing quality. Furthermore, in order to discuss the properties of grayscale regulation, single pixel light intensity function acquisition experiment and stereolithography simulation based on light intensity function and mask grayscale regulation experiment were carried out. Results show that the light intensity distribution function of single pixel follows Gaussian distribution, and the light intensity energy between adjacent pixels will affect each other. The grayscale regulation scheme can improve the degree of reduction of the cured shape of the resin and is beneficial to the curing accuracy.

Similar content being viewed by others

Data availability

The data used or obtained in the current research can be obtained from the corresponding author upon reasonable request.

Code availability

The custom code in the current study can be obtained from the corresponding author upon reasonable request.

References

Melchels FPW, Feijen J, Grijpma DW (2010) A review on stereolithography and its applications in biomedical engineering. Biomaterials 31:6121–6130. https://doi.org/10.1016/j.biomaterials.2010.04.050

Armillotta A, Pelzer R (2008) Modeling of porous structures for rapid prototyping of tissue engineering scaffolds. Int J Adv Manuf Technol 39:501–511. https://doi.org/10.1007/s00170-007-1247-x

Ambrosio D, Gabrion X, Malecot P, Amiot F, Thibaud S (2020) Influence of manufacturing parameters on the mechanical properties of projection stereolithography-manufactured specimens. Int J Adv Manuf Technol 106:265–277. https://doi.org/10.1007/s00170-019-04415-5

Xu K, Chen Y (2015) Mask image planning for deformation control in projection-based stereolithography process. J Manuf Sci Eng-Trans ASME 137:12. https://doi.org/10.1115/1.4029802

Liu W, Deng T, Sun D, Jia Z, Li M, Tang A (2019) A study of mask planning in projection-based stereolithography using digital image correlation. Int J Adv Manuf Technol 104:451–461. https://doi.org/10.1007/s00170-019-03778-z

Limaye AS, Rosen DW (2007) Process planning method for mask projection micro-stereolithography. RAPID PROTOTYPING J 13:76–84. https://doi.org/10.1108/13552540710736759

Huang Q (2016) An analytical foundation for optimal compensation of three-dimensional shape deformation in additive manufacturing. J Manuf Sci Eng-Trans ASME 138:8. https://doi.org/10.1115/1.4032220

Huang YM, Lan HY (2006) Compensation of distortion in the bottom exposure of stereolithography process. Int J Adv Manuf Technol 27:1101–1112. https://doi.org/10.1007/s00170-004-2313-2

Huang Q, Zhang J, Sabbaghi A, Dasgupta T (2014) Optimal offline compensation of shape shrinkage for three-dimensional printing processes. IIE Transactions 47:431–441. https://doi.org/10.1080/0740817x.2014.955599

Huang Q, Nouri H, Xu K, Chen Y, Sosina S, Dasgupta T (2014) Statistical predictive modeling and compensation of geometric deviations of three-dimensional printed products. J Manuf Sci Eng-Trans ASME 136:10. https://doi.org/10.1115/1.4028510

Huang Y-M, Lan H-Y (2005) CAD/CAE/CAM integration for increasing the accuracy of mask rapid prototyping system. Comput Ind 56:442–456. https://doi.org/10.1016/j.compind.2005.01.002

Huang YM, Jiang CP (2003) Numerical analysis of a mask type stereolithography process using a dynamic finite-element method. Int J Adv Manuf Technol 21:649–655. https://doi.org/10.1007/s00170-002-1388-x

Zhou C, Chen Y (2012) Additive manufacturing based on optimized mask video projection for improved accuracy and resolution. Journal of Manufacturing Processes 14:107–118 https://doi.org/

Emami MM, Barazandeh F, Yaghmaie F (2015) An analytical model for scanning-projection based stereolithography. Journal of Materials Processing Technology 219:17–27. https://doi.org/10.1016/j.jmatprotec.2014.12.001

Sun C, Fang N, Wu DM, Zhang X (2005) Projection micro-stereolithography using digital micro-mirror dynamic mask. Sensors and Actuators A: Physical 121:113–120. https://doi.org/10.1016/j.sna.2004.12.011

Kuang X, Wu J, Chen K, Zhao Z, Ding Z, Hu F, Fang D, Qi HJ (2019) Grayscale digital light processing 3D printing for highly functionally graded materials. Sci Adv 5. https://doi.org/10.1126/sciadv.aav5790

Zheng XY, Deotte J, Alonso MP, Farquar GR, Weisgraber TH, Gemberling S, Lee H, Fang N, Spadaccini CM (2012) Design and optimization of a light-emitting diode projection micro-stereolithography three-dimensional manufacturing system. Rev Sci Instrum 83:6. https://doi.org/10.1063/1.4769050

Zhou C, Chen Y, Waltz RA (2009) Optimized mask image projection for solid freeform fabrication. J Manuf Sci Eng-Trans ASME 131:12. https://doi.org/10.1115/1.4000416

Bikas H, Stavropoulos P, Chryssolouris G (2015) Additive manufacturing methods and modelling approaches: a critical review. Int J Adv Manuf Technol 83:389–405. https://doi.org/10.1007/s00170-015-7576-2

Chua CK, Leong KF, Cheah CM, Chua SW (2003) Development of a tissue engineering scaffold structure library for rapid prototyping. Part 1: investigation and classification. Int J Adv Manuf Technol 21:291–301 https://doi.org/

Chua CK, Leong KF, Cheah CM, Chua SW (2003) Development of a tissue engineering scaffold structure library for rapid prototyping. Part 2: parametric library and assembly program. Int J Adv Manuf Technol 21:302–312

Kang H-W, Park JH, Cho D-W (2012) A pixel based solidification model for projection based stereolithography technology. Sensors and Actuators A: Physical 178:223–229. https://doi.org/10.1016/j.sna.2012.01.016

Wang N, Liu W, Tang A, Huang J, Lin Z, Lei S (2014) Strain isolation: a simple mechanism for understanding and detecting structures of zero Poisson’s ratio. Physica Status Solidi B-Basic Solid State Physics 251:2239–2246. https://doi.org/10.1002/pssb.201451376

Huang JL, Liu WY, Tang AM (2018) Effects of fine-scale features on the elastic properties of zero Poisson’s ratio honeycombs. Materials Science and Engineering B-Advanced Functional Solid-State Materials 236:95–103. https://doi.org/10.1016/j.mseb.2018.11.005

Li MK, Liu WY (2018) A novel parameterized digital-mask generation method for projection stereolithography in tissue engineering. Rapid Prototyping J 24:935–944. https://doi.org/10.1108/rpj-06-2017-0110

Cortes C, Vapnik V (1995) Support-vector networks. Mach Learn (Netherlands) 20:273–297. https://doi.org/10.1023/a:1022627411411

Chang CC, Lin CJ (2011) LIBSVM: a library for support vector machines. ACM Trans Intell Syst Technol 2:27–27. https://doi.org/10.1145/1961189.1961199

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (Nos. 51875214 and 11972161), the Science and Technology Program of Guangzhou, China (No. 201804010452), and the Department of Science and Technology of Guangdong Province (Grant No. 2019A1515110352).

Funding

The work was supported by the National Natural Science Foundation of China (Nos. 51875214 and 11972161), the Science and Technology Program of Guangzhou, China (No. 201804010452), and the Department of Science and Technology of Guangdong Province (Grant No. 2019A1515110352).

Author information

Authors and Affiliations

Contributions

Tao Deng: Investigation, methodology, simulation and experiment, writing-original draft, modification.

Wangyu Liu: Writing–review and editing, supervision, project administration, funding acquisition.

Weigui Xie: Writing–review and editing, supervision.

Jiale Huang: Writing–review and editing

Aimin Tang: Project administration, funding acquisition.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Deng, T., Liu, W., Xie, W. et al. Mask image grayscale regulation for projection stereolithography in tissue engineering. Int J Adv Manuf Technol 113, 3011–3026 (2021). https://doi.org/10.1007/s00170-021-06756-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06756-6