Abstract

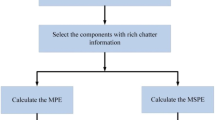

Chatter is a kind of unstable vibration in high-speed milling process, leading to poor surface quality of workpiece, significant tool wear, and severe noise. In order to avoid these negative effects of milling chatter, the detection of chatter at early stage is highly needed. In this paper, an early-stage chatter detection method based on variational mode decomposition (VMD) and difference of power spectral entropy (ΔPSE) is presented. Considering that the existence of possible colored noise in the monitoring signals, which might lead to the misjudgment of chatter detection, the signals monitored at spindle’s idling is utilized to identify these noise components. In order to separate the needed chatter-sensitive sub-signals, VMD is utilized to decompose the original signals into a series of intrinsic mode functions (IMFs), and the chatter-sensitive sub-signals are obtained by adding the IMFs whose central frequencies are closed to the milling system’s natural frequency. After that, an adaptive filter is utilized to filter out the harmonics of spindle-speed frequency and the identified colored noise components. Then, a dimensionless indicator is designed, which is determined as the difference of power spectral entropy (ΔPSE) of signals without and with filtering. A series of experiments are also performed, and the results indicate that the presented methodology can detect the chatter at early stage and is applicable in different cutting conditions, which is very important in the practical application.

Similar content being viewed by others

References

Yue C, Gao H, Liu X et al (2019) A review of chatter vibration research in milling. Chin J Aeronaut 32:215–242. https://doi.org/10.1016/j.cja.2018.11.007

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann Manuf Technol 53:619–642. https://doi.org/10.1016/S0007-8506(07)60032-8

Schmitz TL (2003) Chatter recognition by a statistical evaluation of the synchronously sampled audio signal. J Sound Vib 262:721–730. https://doi.org/10.1016/S0022-460X(03)00119-6

Yao Y, Chen Y, Liu C, Shih WP (2019) Real-time chatter detection and automatic suppression for intelligent spindles based on wavelet packet energy entropy and local outlier factor algorithm. Int J Adv Manuf Technol 103:297–309. https://doi.org/10.1007/s00170-019-03551-2

Chen Z, Li Z, Niu J, Zhu L (2020) Chatter detection in milling processes using frequency-domain Rényi entropy. Int J Adv Manuf Technol 106:877–890. https://doi.org/10.1007/s00170-019-04639-5

Wang G, Dong H, Guo Y, Ke Y (2018) Early chatter identification of robotic boring process using measured force of dynamometer. Int J Adv Manuf Technol 94:1243–1252. https://doi.org/10.1007/s00170-017-0941-6

Feng J, Sun Z, Jiang Z, Yang L (2016) Identification of chatter in milling of Ti-6Al-4V titanium alloy thin-walled workpieces based on cutting force signals and surface topography. Int J Adv Manuf Technol 82:1909–1920. https://doi.org/10.1007/s00170-015-7509-0

Gao J, Song Q, Liu Z (2018) Chatter detection and stability region acquisition in thin-walled workpiece milling based on CMWT. Int J Adv Manuf Technol 98:699–713. https://doi.org/10.1007/s00170-018-2306-1

Cao H, Yue Y, Chen X, Zhang X (2017) Chatter detection in milling process based on synchrosqueezing transform of sound signals. Int J Adv Manuf Technol 89:2747–2755. https://doi.org/10.1007/s00170-016-9660-7

Nair U, Krishna BM, Namboothiri VNN, Nampoori VPN (2010) Permutation entropy based real-time chatter detection using audio signal in turning process. Int J Adv Manuf Technol 46:61–68. https://doi.org/10.1007/s00170-009-2075-y

Niroomand MR, Forouzan MR, Heidari A (2019) Experimental analysis of vibration and sound in order to investigate chatter phenomenon in cold strip rolling. Int J Adv Manuf Technol 100:673–682. https://doi.org/10.1007/s00170-018-2639-9

Dong X, Zhang W (2017) Chatter identification in milling of the thin-walled part based on complexity index. Int J Adv Manuf Technol 91:3327–3337. https://doi.org/10.1007/s00170-016-9912-6

Zhu L, Liu C, Ju C, Guo M (2020) Vibration recognition for peripheral milling thin-walled workpieces using sample entropy and energy entropy. Int J Adv Manuf Technol:3251–3266. https://doi.org/10.1007/s00170-020-05476-7

Han Z, Jin H, Han D, Fu H (2017) ESPRIT- and HMM-based real-time monitoring and suppression of machining chatter in smart CNC milling system. Int J Adv Manuf Technol 89:2731–2746. https://doi.org/10.1007/s00170-016-9863-y

Ji Y, Wang X, Liu Z, Yan Z, Jiao L, Wang D, Wang J (2017) EEMD-based online milling chatter detection by fractal dimension and power spectral entropy. Int J Adv Manuf Technol 92:1185–1200. https://doi.org/10.1007/s00170-017-0183-7

Liu J, Hu Y, Wu B, Jin C (2017) A hybrid health condition monitoring method in milling operations. Int J Adv Manuf Technol 92:2069–2080. https://doi.org/10.1007/s00170-017-0252-y

Liu Y, Wang X, Lin J, Zhao W (2016) Early chatter detection in gear grinding process using servo feed motor current. Int J Adv Manuf Technol 83:1801–1810. https://doi.org/10.1007/s00170-015-7687-9

Li Y, Zhou S, Lin J, Wang X (2017) Regenerative chatter identification in grinding using instantaneous nonlinearity indicator of servomotor current signal. Int J Adv Manuf Technol 89:779–790. https://doi.org/10.1007/s00170-016-9117-z

Szydłowski M, Powałka B (2012) Chatter detection algorithm based on machine vision. Int J Adv Manuf Technol 62:517–528

Chen Y, Li H, Jing X, Hou L, Bu X (2019) Intelligent chatter detection using image features and support vector machine. Int J Adv Manuf Technol 102:1433–1442. https://doi.org/10.1007/s00170-018-3190-4

Khalifa O, Densibali A, Faris W (2006) Image processing for chatter identification in machining processes. Int J Adv Manuf Technol 31:443–449. https://doi.org/10.1007/s00170-005-0233-4

Lei N, Soshi M (2017) Vision-based system for chatter identification and process optimization in high-speed milling. Int J Adv Manuf Technol 89:2757–2769. https://doi.org/10.1007/s00170-016-9770-2

Van Dijk NJM, Doppenberg EJJ, Faassen RPH, Wouw NVD, Nijmeijer H (2010) Automatic in-process chatter avoidance in the high-speed milling process. J Dyn Syst Meas Control Trans ASME 132:1–14. https://doi.org/10.1115/1.4000821

Ye J, Feng P, Xu C, Ma Y, Huang S (2018) A novel approach for chatter online monitoring using coefficient of variation in machining process. Int J Adv Manuf Technol 96:287–297. https://doi.org/10.1007/s00170-017-1544-y

Cao H, Zhou K, Chen X (2015) Chatter identi fi cation in end milling process based on EEMD and nonlinear dimensionless indicators. Int J Mach Tools Manuf 92:52–59. https://doi.org/10.1016/j.ijmachtools.2015.03.002

Wang L, Liang M (2009) Robotics and computer-integrated manufacturing chatter detection based on probability distribution of wavelet modulus maxima. Robot Comput Integr Manuf 25:989–998. https://doi.org/10.1016/j.rcim.2009.04.011

Lange JH, Abu-Zahra NH (2002) Tool chatter monitoring in turning operations using wavelet analysis of ultrasound waves. Int J Adv Manuf Technol 20:248–254. https://doi.org/10.1007/s001700200149

Shrivastava Y, Singh B (2018) Estimation of stable cutting zone in turning based on empirical mode decomposition and statistical approach. J Braz Soc Mech Sci Eng 40:1–25. https://doi.org/10.1007/s40430-018-0989-8

Liu C, Zhu L, Ni C (2017) The chatter identification in end milling based on combining EMD and WPD. Int J Adv Manuf Technol 91:3339–3348. https://doi.org/10.1007/s00170-017-0024-8

Wan S, Li X, Chen W, Hong J (2018) Investigation on milling chatter identification at early stage with variance ratio and Hilbert–Huang transform. Int J Adv Manuf Technol 95:3563–3573. https://doi.org/10.1007/s00170-017-1410-y

Dragomiretskiy K, Zosso D (2014) Variational mode decomposition. IEEE Trans Signal Process 62:531–544. https://doi.org/10.1109/TSP.2013.2288675

Liu C, Zhu L, Ni C (2018) Chatter detection in milling process based on VMD and energy entropy. Mech Syst Signal Process 105:169–182. https://doi.org/10.1016/j.ymssp.2017.11.046

Yang K, Wang G, Dong Y, Zhang Q, Sang L (2019) Early chatter identification based on an optimized variational mode decomposition. Mech Syst Signal Process 115:238–254. https://doi.org/10.1016/j.ymssp.2018.05.052

Zhu L, Liu C (2020) Recent progress of chatter prediction, detection and suppression in milling. Mech Syst Signal Process 143:106840. https://doi.org/10.1016/j.ymssp.2020.106840

Kuljanic E, Sortino M, Totis G (2008) Multisensor approaches for chatter detection in milling. J Sound Vib 312:672–693. https://doi.org/10.1016/j.jsv.2007.11.006

Cao H, Yue Y, Chen X, Zhang X (2017) Chatter detection based on synchrosqueezing transform and statistical indicators in milling process. Int J Adv Manuf Technol 89:2747–2755

Yao Z, Mei D, Chen Z (2010) On-line chatter detection and identification based on wavelet and support vector machine. J Mater Process Technol 210:713–719. https://doi.org/10.1016/j.jmatprotec.2009.11.007

Tangjitsitcharoen S, Saksri T, Ratanakuakangwan S (2015) Advance in chatter detection in ball end milling process by utilizing wavelet transform. J Intell Manuf 26:485–499. https://doi.org/10.1007/s10845-013-0805-3

Ji Y, Wang X, Liu Z, Wang H, Jiao L, Wang D, Leng S (2018) Early milling chatter identification by improved empirical mode decomposition and multi-indicator synthetic evaluation. J Sound Vib 433:138–159. https://doi.org/10.1016/j.jsv.2018.07.019

Haykin SS (2008) Adaptive filter theory. Pearson Education, India

Wan S, Li X, Su W, Hong J (2019) Investigation on adaptive filter for on-line detection and active control of chatter vibration in milling process. In: Proceedings of the ASME Design Engineering Technical Conference

Funding

This work was supported by the National Key Research and Development Program of China (No. 2018YFB2000504) and Major technology projects of in Shaanxi province of China (No. 2018zdzx01-02-01) and Fundamental Research Funds for the Central Universities and National Science (No. xzd012019032). The authors express their gratitude for their support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Wan, S., Huang, X. et al. Milling chatter detection based on VMD and difference of power spectral entropy. Int J Adv Manuf Technol 111, 2051–2063 (2020). https://doi.org/10.1007/s00170-020-06265-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06265-y