Abstract

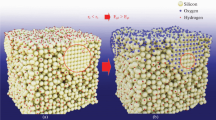

In this study, the process of hydrogenated amorphous silicon (a-Si:H) thin films is prepared by plasma enhanced chemical vapor deposition (PECVD) in conjunction with the in situ plasma diagnostic tool of optical emission spectrometer (OES). The passivation quality of a-Si:H thin films was measured, and the results show that the quality of the passivation layer was strongly influenced by chamber background environment via two different predeposition times. The minority lifetime can be greatly increased from approximately 300 to 777 μs for the predeposition time of 60 and 150 min, respectively, primarily attributed to the stabilization of the chamber environment and gas discharge during the predeposition process. Transmission electron microscopy photograph showed a compact a-Si:H layer (of approximately 10 nm) interface passivation layer with a void-free and crystallite-free interface after a predeposition time of 150 min. In addition, correlations between the plasma characteristics (OES spectra) and passivation quality (minority lifetime) of deposited a-Si:H thin films are explored by applying the techniques of principal component analysis (PCA). The PECVD process health condition was established as high lifetime at predeposition time of 150 min with the mean health value of 0.58 and the control limits of 0.28. The health value generated can be interpreted and reflected the PECVD process which will provide valuable information for passivation quality of higher lifetime.

Similar content being viewed by others

References

Olibet S, Vallat-Sauvain E, Ballif C (2007) Model for a-Si:H/c-Si interface recombination based on the amphoteric nature of silicon dangling bonds. Phys Rev B 76:035326

Docampo P, Ball JM, Darwich M, Eperon GE, Snaith HJ (2013) Efficient organometal trihalide perovskite planar-heterojunction solar cells on flexible polymer substrates. Nat Commun 4:2761

Seo J, Park S, Chan Kim Y, Jeon NJ, Noh JH, Yoon SC, Seok SI (2014) Benefits of very thin PCBM and LiF layers for solution-processed p-i-n perovskite solar cells. Energy Environ Sci 7:2642–2646

Stranks SD, Eperon GE, Grancini G, Menelaou C, Alcocer MJ, Leijtens T, Herz LM, Petrozzaa A, Snaith HJ (2013) Electron-hole diffusion lengths exceeding 1 micrometer in an organometal trihalide perovskite absorber. Science 342:341–344

Taguchi M, Yano A, Tohoda S, Matsuyama K, Nakamura Y, Nishiwaki T, Fujita K, Maruyama E (2014) 24.7% record efficiency HIT solar cell on thin silicon wafer. IEEE J Photovoltaics 4:96–99

Masuko K, Shigematsu M, Hashiguchi T, Fujishima D, Kai M, Yoshimura N, Yamaguchi T, Ichihashi Y, Mishima T, Matsubara N (2014) Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell. IEEE J Photovoltaics 4:1433–1435

Descoeudres A, Holman ZC, Barraud L, Morel S, De Wolf S, Ballif C (2013) >21% efficient silicon heterojunction solar cells on n- and p-type wafers compared. IEEE J Photovoltaics 3:83–89

De Wolf S, Kondo M (2007) Abruptness of a-Si:H / c-Si interface revealed by carrier lifetime measurements. Appl Phys Lett 90:042111–1–042111–3

Koida T, Fujiwara H, Kondo M (2008) Reduction of optical loss in hydrogenated amorphous silicon/crystalline silicon heterojunction solar cells by high-mobility hydrogen-doped In2O3 transparent conductive oxide. Appl Phys Exp 1:04501–1–04501-3

Strahm B, Howling AA, Sansonnens L, Hollenstein C (2007) Plasma silane concentration as a determining factor for the transition from amorphous to microcrystalline silicon in SiH4/H2 discharges. Plasma Sources Sci Technol 16:80–89

Rech B, Roschek T, Müller J, Wieder S, Wagner H (2001) Amorphous and microcrystalline silicon solar cells prepared at high deposition rates using RF (13.56 MHz) plasma excitation frequencies. Sol Energ Mater Sol Cells 66:267–273

Moutinho HR, Jiang CS, Perkins J, Xu Y, Nelson BP, Jones KM, Romero MJ, Jassim MMA (2003) Effects of dilution ratio and seed layer on the crystallinity of microcrystalline silicon thin films deposited by hot-wire chemical vapor deposition. Thin Solid Films 430:135–140

Birkholz M, Selle B, Conrad E, Lips K, Fuhs W (2000) Evolution of structure in thin microcrystalline silicon films grown by electron-cyclotron resonance chemical vapor deposition. J Appl Phys 88:4376–4379

MK VV, Chm VDW, Schropp R (2004) Tandem solar cells deposited using hot- wire chemical vapor deposition. J Non-Cryst Solids 338:655–658

Finger F, Hapke P, Luysberg M, Carius R, Wanger H (1994) Improvement of grain size and deposition rate of microcrystalline silicon by use of very high frequency glow discharge. Appl Phys Lett 65:2588–2590

Graf U, Meier J, Kroll U, Bailat J, Droz C, Sauvain EV, Shah A (2003) High rate growth of microcrystalline silicon by VHF-GD at high pressure. Thin Solid Films 427:37–40

Peng S, Wang D, Yang F, Wang Z, Ma F (2015) Grown low-temperature microcrystalline silicon thin film by VHF PECVD for thin films solar cell. J Nanomater 5:327596

Shah AV, Meier J, Vallat-Sauvain E, Wyrsch N, Droz C, Graf U (2003) Material and solar cell research in microcrystalline silicon. Sol Energy Mater Sol Cells 78:469–491

Lee SE, Park YC (2014) Highly-conductive B-doped nc-Si:H thin films deposited at room temperature by using SLAN ECR-PECVD. J Korean Phys Soc 65:651–656

De Wolf S, Kondo M (2007) Abruptness of a-Si:H/c-Si interface revealed by carrier lifetime measurements. Appl Phys Lett 90:042111

Hsieh Y-L, Kau L-H, Huang H-J, Lee C-C, Fuh Y-K, Li TT (2018) In-situ plasma monitoring of PECVD a-Si:H(i)/a-Si:H (n) surface passivation for heterojunction solar cells application. IEEE Xplore. https://doi.org/10.1109/CSTIC.8369253

Hsieh Y-L, Tseng C-L, Lee C-C, Fuh Y-K, Chang J-Y, Lee J-Y, Li TT (2018) Improved process stability on an extremely thin amorphous / crystalline silicon interface passivation layer by using predeposition on the chamber wall. ECS J Solid State Sci Technol 7:355–361

Tochikubo F, Suzuki A, Kakuta S, Terazono Y, Makabe T (1990) Study of the structure in rf glow discharges in SiH4/H2 by spatiotemporal optical emission spectroscopy: influence of negative ions. J Appl Phys 68:5532–5539

Dingemans G, van den Donker MN, Gordijn A, Kessels WMM, van de Sanden MCM (2007) Probing the phase composition of silicon films in situ by etch product detection. Appl Phys Lett 91:161902

Lien SY, Chang YC, Cho YS, Chang YY, Lee SJ (2012) Deposition and characterization of high-efficiency silicon thin-film solar cells by HF-PECVD and OES technology. IEEE Trans Electron Devices 59:1245–1254

Fu HG, Hua GX, Dan ZX, Jian S, Jun ZJ, Ying Z (2011) Evolution of infrared spectra and optical emission spectra in hydrogenated silicon thin films prepared by VHF-PECVD. Chin Phys B 20:077802

Matsuda A, Tanaka K (1982) Plasma spectroscopy—glow discharge deposition of hydrogenated amorphous silicon. Thin Solid Films 92:171–187

Takagi T, Hayashi R, Payne A, Futako W, Nisimoto T, Takai M, Kondo M, Matsuda A (1999) “High-rate growth of stable a-Si:H” Mater. Res Soc Symp 557:105

Veprek S, Marecek V (1968) The preparation of thin layers of Ge and Si by chemical hydrogen plasma transport. Solid State Electro 11:683–684

Torres P, Meier J, Fluckiger R, Kroll U, Anna Selvan JA, Keppner H, Shah A (1996) Device grade microcrystalline silicon owing to reduced oxygen contamination. Appl Phys Lett 69:1373–1375

Siegel D, Lee J (2011) An auto-associative residual processing and K-means clustering approach for anemometer health assessment. Int. J. Prognostics Health Manage 2:1–12

Jia X, Jin C, Buzza M, Wang W, Lee J (2016) Wind turbine performance degradation assessment based on a novel similarity metric for machine performance curves. Renew Energy 99:1191–1201

Joe Qin S (2003) Statistical process monitoring: basics and beyond. J Chemometrics 17:480–502

Lapira E, Brisset D, Ardakani HD, Siegel D, Lee J (2012) Wind turbine performance assessment using multi-regime modeling approach. Renew Energy 45:86–95

Lee J (1995) Machine performance monitoring and proactive maintenance in computer-integrated manufacturing: review and perspective. Int J Comput Integr Manuf 8:370–380

Lee J (2016) Measurement of machine performance degradation using a neural network model. Int J Model Simulat 38:192–199

Nagel H, Berge C, Aberle AG (1999) Generalized analysis of quasi-steady-state and quasi-transient measurements of carrier lifetimes in semiconductors. J Appl Phys 86:6218–6221

Ge J, Ling ZP, Wong J, Mueller T, Aberle AG (2012) Optimisation of intrinsic a-Si:H passivation layers in crystalline-amorphous silicon heterojunction solar cells. Energy Procedia 15:107–117

Ge J, Ling PZ, Wong J et al (2013) Analysis of intrinsic hydrogenated amorphous silicon passivation layer growth for use in heterojunction silicon wafer solar cells by optical emission spectroscopy. J Appl Phys 133:234310

Hsieh YL, Kau LH, Huang HJ, Lee CC, Li YKTT (2018) In situ plasma monitoring of PECVD nc-Si:H films and the influence of dilution ratio on structural evolution. Coatings 8:238

Jolliffe IT (2002) Principal component analysis. Springer-Verlag, New York

Ouwens JD, Schropp REI (1996) Hydrogen micro structure in hydrogenated amorphous silicon. Phys Rev B 54:17759–17762

Guha S, Yang J, Jones SJ, Chen Y, Williamson DL (1992) Effect of micro voids on initial and light degraded efficiencies of hydrogenated amorphous silicon alloy solar cells. Appl Phys Lett 61:1444–1446

Matsuda A, Takai M, Nishimoto T, Kondo M (2003) Control of plasma chemistry for preparing highly stabilized amorphous silicon at high growth rate. Sol Energy Mater Sol Cells 78:3–26

Nishimoto T, Takai M, Miyahara H, Kondo M (2002) A. Matsuda “Amorphous silicon solar cells deposited at high growth rate”. J Non-Cryst Solids 1116:299–302

Acknowledgments

This study was financially supported by the Delta electronics, Inc. Taiwan and Department of Mechanical Engineering, Optical Science Center, and Department of Optics and Photonics, National Central University, Taiwan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, HJ., Kau, LH., Wang, HS. et al. Large-scale data analysis of PECVD amorphous silicon interface passivation layer via the optical emission spectra for parameterized PCA. Int J Adv Manuf Technol 101, 329–337 (2019). https://doi.org/10.1007/s00170-018-2938-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2938-1