Abstract

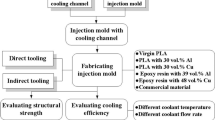

Wax patterns can be used in precision casting. Developing a low-cost approach to rapid fabrication of customized wax patterns with complex geometry is an important research issue. In this study, a wax filament with low melting point is developed for fabricating wax patterns using additive manufacturing technology. The optimal process parameters for producing wax pattern were investigated using the Taguchi design method. The results show that the most important control factor affecting the form accuracy of the fabricated wax patterns is the flow of nozzle, followed by print speed. The form accuracy of the fabricated wax patterns has the lower impact for the nozzle temperature and bed temperature. The optimal process parameters for producing wax patterns are nozzle temperature of 64 °C, print speed of 60 mm/s, bed temperature of 40 °C, and flow of nozzle of 100%. An injection molding tooling is fabricated by wax conformal cooling channels fabricated by the optimal process parameters.

Similar content being viewed by others

References

Thomas D (2016) Costs, benefits, and adoption of addi0074ive manufacturing: a supply chain perspective. Int J Adv Manuf Technol 85(5–8):1857–1876

Liu F, Fan Z, Liu X, He J, Li F (2016) Aqueous gel casting of water-soluble calcia-based ceramic core for investment casting using epoxy resin as a binder. Int J Adv Manuf Technol 86(5):1235–1242

Wang D, He B, Liu S, Liu C, Fei L (2016) Dimensional shrinkage prediction based on displacement field in investment casting. Int J Adv Manuf Technol 85(1):201–208. https://doi.org/10.1007/s00170-015-7836-1

Holker R, Tekkaya AE (2016) Advancements in the manufacturing of dies for hot aluminum extrusion with conformal cooling channels. Int J Adv Manuf Technol 83(5–8):1209–1220

Gaha R, Yannou B, Benamara A (2016) Selection of a green manufacturing process based on CAD features. Int J Adv Manuf Technol 87(5–8):1335–1343

Akıncıoglu S, Gokkaya H, Uygur I (2016) The effects of cryogenic-treated carbide tools on tool wear and surface roughness of turning of Hastelloy C22 based on Taguchi method. Int J Adv Manuf Technol 82(1–4):303–314

Choi SG, Kim SH, Choi WK, Lee ES (2016) The optimum condition selection of electrochemical polishing and surface analysis of the stainless steel 316L by the Taguchi method. Int J Adv Manuf Technol 82(9–12):1933–1939

Pinar AM, Filiz S, Ünlü BS (2016) A comparison of cooling methods in the pocket milling of AA5083-H36 alloy via Taguchi method. Int J Adv Manuf Technol 83(9–12):1431–1440

Gong G, Chen JC, Guo G (2017) Enhancing tensile strength of injection molded fiber reinforced composites using the Taguchi-based six sigma approach. Int J Adv Manuf Technol 91(9–12):3385–3393

Zhou M, Kong L, Xie L, Fu T, Jiang G, Feng Q (2017) Design and optimization of non-circular mortar nozzles using finite volume method and Taguchi method. Int J Adv Manuf Technol 90(9–12):3543–3553. https://doi.org/10.1007/s00170-016-9675-0

Azadeh A, Gharibdousti MS, Firoozi M, Baseri M, Alishahi M, Salehi V (2016) Selection of optimum maintenance policy using an integrated multi-criteria Taguchi modeling approach by considering resilience engineering. Int J Adv Manuf Technol 84(5–8):1067–1079

Costa DMD, Paula TI, Silva PAP, Paiva AP (2016) Normal boundary intersection method based on principal components and Taguchi’s signal-to-noise ratio applied to the multiobjective optimization of 12L14 free machining steel turning process. Int J Adv Manuf Technol 87(1–4):825–834

Effertz PS, Quintino L, Infante V (2017) The optimization of process parameters for friction spot welded 7050-T76 aluminium alloy using a Taguchi orthogonal array. Int J Adv Manuf Technol 91(9–12):3683–3695

Limon-Romero J, Tlapa D, Baez-Lopez Y, Maldonado-Macias A, Rivera-Cadavid L (2016) Application of the Taguchi method to improve a medical device cutting process. Int J Adv Manuf Technol 87(9–12):3569–3577

Adnan MF, AbdullahE AB, Samad Z (2017) Springback behavior of AA6061 with non-uniform thickness section using Taguchi Method. Int J Adv Manuf Technol 89(5–8):2041–2052

Yang Q, Lu Z, Zhou J, Miao K, Li D (2017) A novel method for improving surface finish of stereolithography apparatus. Int J Adv Manuf Technol 93(5–8):1537–1544

Chen J, Gong P, Liu Y, Zheng X, Ren F (2017) Optimization of hot stamping cooling system using segmented model. Int J Adv Manuf Technol 93(1–4):1357–1365

Kuo CC, Chen WH, Liu XZ, Liao YL, Chen WJ, Huang BY, Tsai RL (2017) Development of a low-cost wax injection mold with high cooling efficiency. Int J Adv Manuf Technol 93(5–8):2081–2088

Kuo CC, Chen WH, Zhang JW, Tsai DA, Cao YL (2017) A new method of manufacturing a rapid tooling with different cross-sectional cooling channels. Int J Adv Manuf Technol 92(9–12):3481–3487. https://doi.org/10.1007/s00170-017-0423-x

Scharowsky T, Bauereib A, Korner C (2017) Influence of the hatching strategy on consolidation during selective electron beam melting of Ti-6Al-4V. Int J Adv Manuf Technol 92(5–8):2809–2818. https://doi.org/10.1007/s00170-017-0375-1

Liu Y, Yang Y, Wang D (2016) A study on the residual stress during selective laser melting (SLM) of metallic powder. Int J Adv Manuf Technol 87(1–4):647–656

Leite JL, Salmoria GV, Paggi RA, Ahrens CH, Pouzada AS (2012) Microstructural characterization and mechanical properties of functionally graded PA12/HDPE parts by selective laser sintering. Int J Adv Manuf Technol 59(5–8):583–591. https://doi.org/10.1007/s00170-011-3538-5

Lin H, Luo H, Huang W, Zhang X, Yao G (2016) Diffusion bonding in fabrication of aluminum foam sandwich panels. J Mater Process Technol 230:35–41. https://doi.org/10.1016/j.jmatprotec.2015.10.034

Gorunov AI, Gilmutdinov AK (2016) Study of the effect of heat treatment on the structure and properties of the specimens obtained by the method of direct metal deposition. Int J Adv Manuf Technol 86(9–12):2567–2574. https://doi.org/10.1007/s00170-016-8405-y

AlMangour B, Yang JM (2017) Understanding the deformation behavior of 17-4 precipitate hardenable stainless steel produced by direct metal laser sintering using micropillar compression and TEM. Int J Adv Manuf Technol 90(1–4):119–126

Kuo CC, Chen WH, Xu WC (2017) A cost-effective approach for rapid manufacturing wax injection molds with complex geometrical shapes of cooling channels. Int J Adv Manuf Technol 91(5–8):1689–1695. https://doi.org/10.1007/s00170-016-9886-4

Funding

The authors sincerely acknowledge the financial support from the Ministry of Science and Technology of Taiwan under contracts nos. MOST 106-2221-E-131-010, MOST 106-2221-E-131-011, MOST 105-2221-E-131-012, MOST 104-2221-E-131-026, and MOST 103-2221-E-131-012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuo, CC., You, ZY. Development of injection molding tooling with conformal cooling channels fabricated by optimal process parameters. Int J Adv Manuf Technol 96, 1003–1013 (2018). https://doi.org/10.1007/s00170-018-1664-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1664-z