Abstract

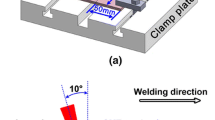

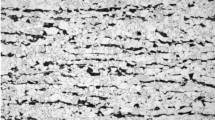

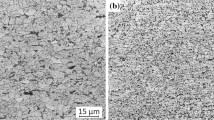

A series of experiments of high-power fiber laser-arc hybrid welding of pure copper was carried out. It could be seen that the microstructure of weld metal was obviously coarsened, and the columnar grain spacing at fusion zone and the massive grain size at heat-affected zone were both linearly increased with the increase of heat input. The weld conductivity decreased with the increase of heat input because the widening weld increased the microstructure nonuniformity of test samples. The heat input as well as welding parameter has no obvious effect on the ultimate tensile strength (UTS) of cross-weld but has obvious effect on the elongation. The UTS of all the welds was 200 MPa or so. The elongation was bigger than 20% when the heat input was in the optimization range from 250 to 380 J/cm. The decrease of the elongation was attributed to either high porosity at insufficient heat input or coarser grain at excessive heat input.

Similar content being viewed by others

References

Li Y, Peng Z (2013) N2-Ar tungsten arc welding of copper plates using Cu-xTi welding alloys. Inform Tech J 12(13):2526–2532

Pohja R, Vestman H, Jauhiainen P, Hanninen H (2003) Narrow gap arc welding experiments of thick copper sections. Helsinki University of Technology, Finland

Zhang LJ, Bai QL, Ning J, Wang A, Yang JN, Yin XQ, Zhang JX (2016) A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding. Mater Des 110:35–50

Pashazadeh H, Teimournezhad J, Masoumi A (2016) Experimental investigation on material flow and mechanical properties in friction stir welding of copper sheets. Int J Adv Manuf Technol 88:1961–1970

Kanigalpula PKC, Pratihar DK, Jha MN, Derose J, Bapat AV, Rudra Pal A (2016) Experimental investigations, input-output modeling and optimization for electron beam welding of Cu-Cr-Zr alloy plates. Int J Adv Manuf Technol 85:711–726

Engler S, Ramsayer R, Poprawe R (2011) Process studies on laser welding of copper with brilliant green and infrared lasers. Phys Procedia 12:339–346

Biro E, Weckman DC, Zhou Y (2001) Pulsed Nd:YAG laser welding of copper using oxygenated assist gases. Metall Mater Trans A 33A:2002–2019

Chen H, Bi G, Nai MSL, Wei J (2015) Enhanced welding efficiency in laser welding of highly reflective pure copper. J Mater Process Tech 216:287–293

Li CB, Liu LM (2013) Investigation on weldability of magnesium alloy thin sheet T-joints: arc welding, laser welding, and laser-arc hybrid welding. Int J Adv Manuf Technol 65:27–34

Heider A, Stritt P, Hess A, Weber R, Graf T (2011) Process stabilization at welding copper by laser power modulation. Phys Procedia 12:81–87

Hess A, Schuster R, Heider A, Weber R, Graf T (2011) Continuous wave laser welding of copper with combined beams at wavelengths of 1030 nm and of 515 nm. Phys Procedia 12:88–94

Zhang C, Li G, Gao M, Yan J, Zeng XY (2013) Microstructure and process characterization of laser-cold metal transfer hybrid welding of AA6061 aluminum alloy. Int J Adv Manuf Technol 68:1253–1260

Zhang C, Gao M, Li G, Chen C, Zeng XY (2013) Strength improving mechanism of laser arc hybrid welding of wrought AlCu6Mn alloy using AlMg5 wire. Sci Tech Weld Join 18:703–710

Yan J, Gao M, Li G, Zhang C, Zeng XY, Jiang M (2013) Microstructure and mechanical properties of laser-MIG hybrid welding of 1420 Al-Li alloy. Int J Adv Manuf Technol 66:1467–1473

Gao M, Mei SW, Wang ZM, Li XY, Zeng XY (2012) Process and joint characterizations of laser-MIG hybrid welding of AZ31 magnesium alloy. J Mater Process Tech 212:1338–1346

Gu XY, Li H, Jiang XB, Sheng HC, Wan XM (2016) Effect of laser on droplet transfer and welding process stability in hybrid laser + double arc welding. Int J Adv Manuf Technol:1–11

Bagger C, Olsen FO (2005) Review of laser hybrid welding. J Laser Appl 17:2–14

Zhang L, Ning J, Zhang X, Zhang G, Zhang J (2015) Single pass hybrid laser-MIG welding of 4-mm thick copper without preheating. Mater Des 74:1–18

Chen YL, Chen C, Gao M, Zeng XY (2016) Achieving high strength joint of pure copper via laser-cold metal transfer arc hybrid welding. Metall Mater Trans A 47:2866–2874

Sindo K (2002) Welding metallurgy. 2nd edn. Wiley, New York, p 154–166

Gale WF, Totemeier TC (2004) Smithells metals reference book. In: Brandes EA, Brook GB (eds) General physical and chemical constants, 8th edn. Elsevier, Amsterdam, p 12–14

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier, Amsterdam, p 107–112

Zhang L, Zhang C, Ning J, Zhang X, Zhang J (2015) Microstructure and properties of the laser butt welded 1.5-mm thick T2 copper joint achieved at high welding speed. Mater Des 88:720–736

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, M., Kawahito, Y., Gao, M. et al. Weld characterization of laser arc hybrid welding of pure copper. Int J Adv Manuf Technol 92, 561–567 (2017). https://doi.org/10.1007/s00170-017-0163-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0163-y