Abstract

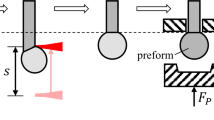

Selective laser melting (SLM) is a popular additive manufacturing process that creates 3D metal parts by fusing fine metal powders together. Modeling and optimization of SLM prototypes has been extensively studied deterministically in the literature considering different properties such as bead width, compressive strength, and tensile strength. However, due to existence of uncertainty sources in input parameters, material properties, and measurement instruments, it is very desirable to develop robust methods to deal with such uncertainties. In this paper, a multi-objective genetic programming algorithm integrating Monte Carlo simulations (MCSs) has been used for modeling and prediction of the bead width of prototypes in SLM process by taking into account probabilistic uncertainty in experimental data. The necessity of such probabilistic robust approach is shown by stochastic analysis and uncertainty quantification (UQ) of existing deterministic mathematical models in the literature. The objective functions that have been considered for multi-objective modeling process are the mean and standard deviation of the training errors, prediction errors, and the number of nodes which the latter is employed to use as a complexity index of the evolved GP-type models. The robustness of both deterministic and probabilistic models are compared and shown based on the cumulative distribution function (CDF) and probability density function (PDF) of statistical performance of objective functions. The results reveal that the suggested deterministic models in the literature are not trustworthy for practical usages due to large variations in objective functions while the model proposed by this study shows an acceptable robustness performance.

Similar content being viewed by others

References

Pupo Y, Monroy KP, Ciurana J (2015) Influence of process parameters on surface quality of CoCrMo produced by selective laser melting. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7040-3

Song C, Yang Y, Liu Y, Luo Z, Yu J (2015) Study on manufacturing of W-Cu alloy thin wall parts by selective laser melting. Int J Adv Manuf Technol 78(5–8):885–893

Sun S, Zheng L, Liu Y, Liu J, Zhang H (2015) Selective laser melting of Al-Fe-V-Si heat-resistant aluminum alloy powder: modeling and experiments. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7137-8

Song C, Yang Y, Wang Y, Wang D, Yu J (2014) Research on rapid manufacturing of CoCrMo alloy femoral component based on selective laser melting. Int J Adv Manuf Technol 75(1–4):445–453

Cherry JA, Davies HM, Mehmood S, Lavery NP, Brown SG, Sienz J (2015) Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int J Adv Manuf Technol 76(5–8):869–879

Czelusniak T, Amorim FL, Higa CF, Lohrengel A (2014) Development and application of new composite materials as EDM electrodes manufactured via selective laser sintering. Int J Adv Manuf Technol 72(9–12):1503–1512

Wang D, Yang Y, Yi Z, Su X (2013) Research on the fabricating quality optimization of the overhanging surface in SLM process. Int J Adv Manuf Technol 65(9–12):1471–1484

Paggi RA, Beal VE, Salmoria GV (2013) Process optimization for PA12/MWCNT nanocomposite manufacturing by selective laser sintering. Int J Adv Manuf Technol 66(9–12):1977–1985

Verma A, Tyagi S, Yang K (2014) Modeling and optimization of direct metal laser sintering process. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6443-x

Jamali A, Nariman-zadeh N, Darvizeh A, Masoumi A, Hamrang S (2009) Multi-objective evolutionary optimization of polynomial neural networks for modelling and prediction of explosive cutting process. Eng Appl Artif Intell 22:676–687

Nariman-zadeh N, Darvizeh A, Darvizeh M, Gharababaei H (2002) Modelling of explosive cutting process of plates using GMDH-type neural network and singular value decomposition. J Mater Process Technol 128:80–87

Nariman-zadeh N, Darvizeh A, Jamali A, Moeini A (2005) Evolutionary design of generalized polynomial neural networks for modelling and prediction of explosive forming process. J Mater Process Technol 164–165:1561–1571

Garg A, Tai K, Lee CH, Savalani MM (2013) A hybrid M5’-genetic programming approach for ensuring greater trustworthiness of prediction ability in modelling of FDM process. J Intell Manuf. doi:10.1007/s10845-013-0734-1

Garg A, Rachmawati L, Tai K (2013) Classification-Driven model selection approach of genetic programming in modelling of turning process. Int J Adv Manuf Technol 69(5–8):1137–1151

Garg A, Bhalerao Y, Tai K (2013) Review of empirical modelling techniques for modelling of turning process. Int J Model Identif Control 20(2):121–129

Garg A, Tai K, Vijayaraghavan V, Singru PM (2014) Mathematical modelling of burr height of the drilling process using a statistical based multi-gene genetic programming approach. Int J Adv Manuf Technol 73:113–126. doi:10.1007/s00170-014-5817-4

Garg A, Tai K, Savalani MM (2014) Formulation of bead width model of an SLM prototype using modified multi-gene genetic programming approach. Int J Adv Manuf Technol 73:375–388

Chan KY, Kwong CK, Dillon TS, Tsim YC (2013) Reducing overfitting in manufacturing process modeling using a backward elimination based genetic programming. J Appl Soft Comput 11:1648–1656

Jamali A, Khaleghi E, Gholaminezhad I, Nariman-zadeh N (2014) Modelling and prediction of complex non-linear processes by using Pareto multi-objective genetic programming. Int J Syst Sci. doi:10.1080/00207721.2014.945983

Jamali A, Salehpour M, Nariman-zadeh N (2013) Robust Pareto active suspension design for vehicle vibration model with probabilistic uncertain parameters. Multi-body Syst Dyn 30:265–285

Eldred MS (2009) Recent advances in non-intrusive polynomial chaos and stochastic collocation methods for uncertainty analysis and design, 50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Palm Springs, CA, May 4–7, American Institute of Aeronautics and Astronautics Inc.

Bodla KK, Murthy JY, Garimella SV (2013) Optimization under uncertainty applied to heat sink design. ASME J. Heat Transfer Vol. 135

Pettersson MP, Iaccarino G, Nordstrom J (2015) Polynomial chaos methods for hyperbolic partial differential equations. Springer Math Eng. doi:10.1007/978-3-319-10714-1_1

Kato H, Mashiko H, Tokuyama Y, Funazaki K, and Takida J (2011) Robust aerodynamic shape optimization of supersonic turbine using non-intrusive polynomial chaos expansion, 9th World Congress on Structural and Multidisciplinary Optimization, June 13–17, Shizuoka, Japan

Senthamaraikkannan G, Prasad V, Gates I (2015) Stochastic proxy modelling for coalbed methane production using orthogonal polynomials, 9th International Symposium on Advanced Control of Chemical Processes, June 7–10, Whistler, British Columbia, Canada

Mandur J, Budman H (2012) A polynomial-chaos based algorithm for robust optimization in the presence of bayesian uncertainty, 8th IFAC Symposium on Advanced Control of Chemical Processes, Furama Riverfront, Singapore, July 10–13

Zhao Q, Chen X, Ma ZD, Lin Y (2015) Robust topology optimization based on stochastic collocation methods under loading uncertainties. Math Probl Eng. doi:10.1155/2015/580980

Witteveen JAS, Iaccarino G (2012) Simplex stochastic collocation with random sampling and extrapolation for nonhypercube probability spaces. SIAM J Sci Comput 34(2):814–835

Lazarov BS, Schevenels M, Sigmund O (2012) Topology optimization considering material and geometric uncertainties using stochastic collocation methods. Struct Multidiscip Optim 46(4):597–612

Li HS, Ma C (2013) Hybrid dimension-reduction method for robust design optimization. AIAA J 51(1):138–144. doi:10.2514/1.J051659

Lee I, Choi KK, Du L, Gorsich D (2008) Dimension reduction method for reliability-based robust design optimization. Comput Struct 86(13–14):1550–1562

Chenouri S, Liang J, Small CG (2015) Robust dimension reduction. WIREs Comput Stat 7:63–69. doi:10.1002/wics.1331

Zhang W (2007) Design for uncertainties of sheet metal forming process, PhD thesis, The Ohio State University

Ebrahimiasl S, Yunus WZ, Kassim A, Zainal Z (2010) Prediction of grain size, thikness and absorbnace of nanocrystalline tin oxide thin film by Taguchi robust design. Solid State Sci 12(8):1323–1327

Nejlaoui M, Houidi A, Affi Z, Romdhane L (2013) Multi-objective robust design optimization of rail vehicle moving in short radius curved tracks based on the safety and comfort criterta. Simul Model Pract Theory 30:21–34

Jamali A, Ahmadi B, Ghamati M, Nariman-zadeh N (2013) Reliabiity-based optimal controller design for systems with probabilistic uncertain parameters using fuzzy limit state function. J Vib Control. doi:10.1177/1077546313496298,2013

Crespo LG, Kenny SP (2005) Robust control deign for systems with probabilistic uncertainty, NASA report, TP-2005-213531

Smith BA, Kenny SP, Crespo LG (2005) Probabilistic parameter uncertainty analysis of single input single output control systems, NASA report TM-2005-213280

Field RV, Voulgaris PG, Bergman LA (1996) Methods to compute probabilistic measures of robustness for structural systems. J Vib Control 2(4):447–463

Khan RA, Datta TK (2010) Probabilistic risk assessment of fan type cable stayed bridges against earthquake forces. J Vib Control 16(6):779–799

Zhang C, Recknagel F, Guo J, Blanckaert K (2014) Adaptation and multiple parameter optimization of the simulation model SALMO as prerequisite for scenario analysis on a shallow eutrophic Lake. Ecol Model 273:109–116

He J, Jones JW, Graham WD, Dukes MD (2010) Influence of likelihood function choice for estimating crop model parameters using the generalized likelihood uncertainty estimation method. Agric Syst 103:256–264

Diwekar UM, Kalagnaman JR (1997) Efficient sampling technique for optimization under uncertainty. Am Inst Chem Eng J 43(2):440–447

Ray L, Stengel RF (1993) A Monte Carlo approach to the analysis of control system robustness. Automatica 29(1):229–236

Wang Q, Stengel RF (2002) Robust control of nonlinear systems with parametric uncertainty. Automatica 38:1591–1599

Kalos MH, Whitlock PA (1986) Monte Carlo methods. Wiley, New York

Bi S, Deng Z, Chen Z (2013) Stochastic validation of structural FE-models based on hierarchical cluster analysis and advanced Monte Carlo simulation. Finite Elem Anal Des 67:22–33

Biwer A, Griffith S, Cooney C (2005) Uncertainty analysis of penicillin V production using Monte Carlo simulation. Biotechnol Bioeng 90(2):167–179

Paris AS, Tanase I, Tarkolea C, Dragomirescu C (2012) Application of the Monte Carlo simulation in the manufacturing processes. Proc Manuf Syst 7(4):253–258

Bieda B (2011) Stochastic Assessment by Monte Carlo simulation for LCI applied to steel process chain: The ArcelorMittal Steel Poland SA in Krakow, Poland case study. Innovations in Sharing Environmental Observations and Information, 787–798

Jamali A, Khaleghi E, Gholaminezhad I, Nariman-Zadeh N, Gholaminia B, Jamal-Omidi A (2014) Multi-objective genetic programming approach for robust modeling of complex manufacturing processes having probabilistic uncertainty in experimental data. J Intell Manuf. doi:10.1007/s10845-014-0967-7

Schumacher M, Meneses M, Xifro A, Domingo JL (2001) The use of Monte-Carlo simulation techniques for risk assessment: study of a municipal waste incinerator. Chemosphere 43(4):787–799

Booker JM, Ross TJ (2011) An evolution of uncertainty assessment and quantification. Sci Iran 18(3):669–676

Darbra RM, Eljarrat E, Barcelo D (2008) How to measure uncertainties in environmental risk assessment. Trends Anal Chem 27(4):377–385

Guyonnet D, Bourgine B, Dobois D, Fargier H, Côme B, Chilés JP (2003) Hybrid approach for addressing uncertainty in risk assessments. Environ Eng 129(1):68–78

Song KY, Seniuk GTG, Kozinski JA, Zhang WJ, Gupta MM (2015) An innovative Fuzzy-Neural decision analyzer for qualitative group decision making. Int J Inf Technol Decis Mak 14(3):659–696

Zaversky F, Garćıa-Barberena J, Sánchez M, Astrain D (2012) Probabilistic modeling of a parabolic trough collector power plant – An uncertainty and sensitivity analysis. Sol Energy 86:2128–2139

Kweon KE, Lee JH, Ko Y, Jeong M, Myoung J, Yun I (2007) Neural network based modeling of HfO2 thin film characteristicsusing Latin Hypercube Sampling. Exp Syst Appl 32:358–363

Koza J (1992) Genetic programming, on the programming of computers by means of natural selection. MIT Press, Cambridge

Jamali A, Nariman-Zadeh N, Atashkari K (2008) Multi-objective uniform diversity genetic algorithm (MUGA). In witoldkosinski (Eds.), Advanced in evolutionary algorithms. Vienna: IN-TECH

Jamali A, Hajiloo A, Nariman-zadeh N (2010) Reliability-based robust Pareto design of linear state feedback controllers using a multi-objective uniform-diversity genetic algorithm (MUGA). Exp Syst Appl 37:401–413

Jamali A, Ghamati M, Ahmadi B, Nariman-zadeh N (2013) Probability of failure for uncertain control systems using neural networks and multi-objective uniform-diversity genetic algorithms (MUGA). Eng Appl Artif Intell 26(2):714–723

Mumtaz KA, Erasenthiran P, Hopkinson N (2008) High density selective laser melting of Waspaloy. J Mater Process Technol 195:77–87

Garg A, Tai K, Savalani MM (2014) State-of-the-art in empirical modelling of rapid prototyping processes. Rapid Prototyp J. doi:10.1108/RPJ-08-2012-0072

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gholaminezhad, I., Assimi, H., Jamali, A. et al. Uncertainty quantification and robust modeling of selective laser melting process using stochastic multi-objective approach. Int J Adv Manuf Technol 86, 1425–1441 (2016). https://doi.org/10.1007/s00170-015-8238-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8238-0