Abstract

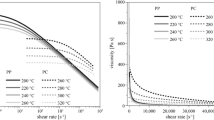

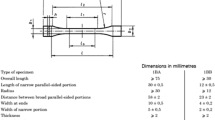

The embossing of polymeric materials is widely used for manufacturing of micro-parts. The thermoplastic amorphous polymers are always selected to get micro-components. The paper consists to characterise the thermal mechanical properties of three amorphous polymers: polystyrene (PS), poly(methyl methacrylate) (PMMA) and polycarbonate (PC). A set of experiments such as differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA) have been carried out with PS, PMMA and PC. The thermoplastic polymers’ behaviours have been characterised above their glass transition temperature. Then, flexible micro-fluidic devices have been manufactured with the polymers by hot embossing process. The surface topography of mould die cavity insert and the micro-fluidic devices have been observed and analysed by a 3D optical microscopy viewing and measurement system in order to compare the replication accuracy for polymeric replicas. The surface roughness of the micro-fluidic devices has been measured to characterise the effect of the compression load and temperature in the hot embossing process. The paper is mainly concentrated on the effect of the process parameters with different amorphous thermoplastic polymers to achieve the process optimization. The results concerning the micro- and nano-scale cavities filling provide information on the reliability about the facilities to replicate complex surface topographies. In this paper, the flow behaviour of polymer during forming process thus process parameters would be investigated. The mould instrumented with micro-structured patterns will be presented. The relationship between embossing conditions and parts quality will be established.

Similar content being viewed by others

References

Martinez AW, Phillips ST, Whitesides GM (2010) Diagnostics for the developing world: microfluidic paper-based analytical devices. Anal Chem 82:3–10

Coltro WKT, De Jesus DP, Da Silva JAF, Do Lago CL, Carrilho E (2010) Toner and paper-based fabrication techniques for microfluidic applications. Electrophoresis 31:2487–2498

Tandon V, Bhagavatula SK, Kirby BJ (2009) Transient f-potential measurements in hydrophobic, TOPAS microfluidic substrates. Electrophoresis 30:2656–2667

Castaño-Álvarez M, Fernández-Abedul MT, Costa-García A (2005) Poly(methylmethacrylate) and Topas capillary electrophoresis microchip performance with electrochemical detection. Electrophoresis 26:3160–3168

Okagbare PI, Emory JM, Datta P, Goettert J, Soper SA (2010) Fabrication of a cyclic olefin copolymer planar waveguide embedded in a multi-channel poly(methyl methacrylate) fluidic chip for evanescence excitation. Lab Chip 10:66–73

Ogilvie IRG, Sieben VJ, Floquet CFA, Zmijan R, Mowlem MC, Morgan H (2010) Reduction of surface roughness for optical quality microfluidic devices in PMMA and COC. J Micromech Microeng 20:065016

Auroux PA, Iossifidis D, Reyes DR, Manz A (2002) Micro total analysis systems. 2. Analytical standard operations and applications. Anal Chem 74:2637–2652

Jena RK, Chester SA, Srivastava V, Yue CY, Anand L, Lam YC (2011) Large-strain thermo-mechanical behavior of cyclic olefin copolymers: application to hot embossing and thermal bonding for the fabrication of microfluidic devices. Sensors Actuator B Chem 155:93–105. doi:10.1016/j.snb.2010.11.031

Sahli M, Millot C, Roques-Carmes C, Khan Malek C, Barriere T, Gelin JC (2009) Quality assessment of polymer replication by hot embossing and micro-injection moulding processes using scanning mechanical microscopy. J Mater Process Technol 209:5851–5861. doi:10.1016/j.jmatprotec.2009.06.011

Becker H, Gärtner C (2008) Anal Bioanal Chem 390:89–111

Xia W, Luyan Z, Gang C (2011) Hot embossing and thermal bonding of poly(methylmethacrylate) microfluidic chips using positive temperature coefficient ceramic heater. Anal Bioanal Chem 401:2657–2665

Worgull M, Kolew A, Heilig M, Schneider M, Dinglreiter H, Rapp B (2011) Hot embossing of high performance polymers. Microsyst Technol 17:585–592. doi:10.1007/s00542-010-1155-0

Hutter I, Muller E, Kristiansen PM, Kresak S, Tiefenauer L (2013) Polymer-based microfluidic device for measuring membrane protein activities. Microfluid Nanofluid 14:421–429. doi:10.1007/s10404-012-1061-0

Heckele and Schomburg (2004) Review on micro molding of thermoplastic polymer. Journal of Micromechanics and Microengineering, J Micromech Microeng 14 R1 doi:10.1088/0960-1317/14/3/R01

Becker H, Heim U (2000) Hot embossing as a method for the fabrication of polymer high aspect ratio structures. Sensors Actuator A Phys 83:130–135. doi:10.1016/S0924-4247(00)00296-X

Koerner T, Brown L, Xie R, Oleschuk RD (2005) Epoxy resins as stamps for hot embossing of microstructures and microfluidic channels. Sensors Actuator B Chem 107:632–639. doi:10.1016/j.snb.2004.11.035

Jucius D, Grigaliunas V, Mikolajunas M, Guobiene A, Kopustinskas V, Gudonyte A, Narmontas P (2011) Hot embossing of PTFE: Towards superhydrophobic surfaces. Appl Surf Sci 257:2353–2360. doi:10.1016/j.apsusc.2010.09.102

Gottschlich N (2004) Production of plastic components for micro-fluidic applications. Business briefing: future drug discovery, Available at http://www.touchbriefings.com/pdf/855/fdd041_greiner_tech.pdf, Accessed February 2007

Qi S, Liu X, Ford S, Barrows J, Thomas G, Kelly K, McCandless A, Lian K, Goettert J, Soper SA (2002) Micro-fluidic devices fabricated in poly(methyl methacrylate) using hot-embossing with integrated sampling capillary and fiber optics for fluorescence detection. Lab Chip 2:88–95

Sassi AP, Paulus A, Cruzado ID, Bjornson T, Hooper HH (2000) Rapid, parallel separations of D1S80 alleles in a plastic micro-channel chip. J Chromatogr A 894:203–217

Heckele M, Guber AE, Truckenmüller R (2006) Replication and bonding techniques for integrated micro-fluidic systems. Microsyst Technol 12:1031–1035

Zhou X-M, Shao S-J, Xu G-D, Zhong R-T, Liu D-Y, Tang J-W, Gao Y-N, Cheng S-J, Lin B-C (2005) Highly sensitive determination of the methylated gene in cancer patients by microchip electrophoresis. J Chromatogr B 816:145–151

Sung W-C, Lee G-B, Tzeng C-C, Chen S-H (2001) Plastic microchip electrophoresis for genetic screening: the analysis of polymerase chain reactions products of fragile X (CGG)n alleles. Electrophoresis 22:1188–1193

Becker H, Gärtner C (2000) Polymer microfabrication methods for microfluidic analytical applications. Electrophoresis 21:12–26

Seunarine K, Gadegaard N, Riehle MO, Wilkinson CDW (2006) Optical heating for short hot embossing cycle times. Microelectron Eng 83:859–863

Rotting O, Ropke W, Becker H, Gartner C (2002) Polymer microfabrication technologies. Microsyst Technol 8:32–36

Shinohara H, Mizuno J, Shoji S (2007) Fabrication of a microchannel device by hot embossing and direct bonding of poly(methyl methacrylate). Jpn J Appl Phys 46:3661–3664

Datta P, Goettert J (2007) Method for polymer hot embossing process development. Microsyst Technol 13:265–270

Fujii T (2002) PDMS-based microfluidic devices for biomedical applications. Microelectron Eng 61–62:907–914

Wabuyele MB, Ford SM, Stryjewski W, Barrow J, Soper SA (2001) Single molecule detection of double-stranded DNA in poly(methylmethacrylate) and polycarbonate microfluidic devices. Electrophoresis 21:3939–3948

Li C, Yang Y, Craighead HG, Lee KH (2005) Isoelectric focusing in cyclic olefin copolymer microfluidic channels coated by polyacrylamide using a UV photografting method. Electrophoresis 2:1800–1806

Lin CR, Chen RH, Hung C (2003) Preventing non-uniform shrinkage in open-die hot embossing of PMMA microstructures. J Mater Process Technol 140:173–178

Lan S, Lee H-J, Kim E, Ni J, Lee S-H, Lai X, Song J-H, Lee NK, Lee MG (2009) A parameter study on the micro hot-embossing process of glassy polymer for pattern replication. Microelectron Eng 86:2369–2374

Juang YJ, James L (2002) Polym Eng Sci 42:539–550

Li JM, Liu C, Peng J (2008) Effect of hot embossing process parameters on polymer flow and micro-channel accuracy produced without vacuum. journal of materials processing technology 207:163-171

Heyderman LJ, Schift H, David D (2000) Microelectron Eng 54:229–245

Leil KF, Li WJ (2005) Effects of contact-stress on hot-embossed PMMA micro-channel wall profile. Microsyst Technol 11:113–119

Juang Y-J, James LL (2002) Hot embossing in micro-fabrication. I. Experimental. Polym Eng Sci 42:539–550

Chien RD (2006) Int Commun Heat Mass 33:645–653

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, G., Sahli, M., Gelin, JC. et al. Process parameter effects on dimensional accuracy of a hot embossing process for polymer-based micro-fluidic device manufacturing. Int J Adv Manuf Technol 75, 225–235 (2014). https://doi.org/10.1007/s00170-014-6135-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6135-6