Abstract

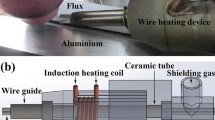

Butt welding of titanium alloy TA15 to aluminum alloy Al2024 dissimilar lightweight metals was conducted using gas tungsten arc welding. Pulsed current was adopted in the welding process. Influence of pulsed current on morphologies and microstructure of Ti-Al intermetallics near the Ti/Al interface was investigated. Microstructure characteristics and phase constitution of weld zone near the Ti/Al interface were analyzed. In top surface and upper region of the joint, Ti base metal was partially melted, and continuous intermetallic layers with Ti3Al, TiAl, and TiAl3 were formed in the fusion zone. In middle and bottom regions of the joint, Ti base metal was not melted and a thin TiAl3 layer was formed near the Ti/Al-brazed interface. Most of the Ti-Al intermetallics formed into discrete TiAl3 precipitations in the weld metal in upper and middle regions of the joint. No precipitation was observed in bottom region of the joint. Thickness of continuous Ti-Al intermetallic layers in the fusion zone was controlled at a low degree by adopting pulsed current in the welding. Crack sensitivity of weld zone near the Ti/Al interface was decreased.

Similar content being viewed by others

References

Zhu ZQ, Lee KY, Wang XL (2012) Ultrasonic welding of dissimilar metals, AA6061 and Ti6Al4V. Int J Adv Manuf Technol 59:569–574

Song ZH, Nakata K, Wu AP, Liao JS (2013) Interfacial microstructure and mechanical property of Ti6Al4V/A6061 dissimilar joint by direct laser brazing without filler metal and groove. Mater Sci Eng A 560:111–120

Chen YB, Chen SH, Li LQ (2010) Influence of interfacial reaction layer morphologies on crack initiation and propagation in Ti/Al joint by laser welding-brazing. Mater Des 31:227–233

Chen SH, Li LQ, Chen YB, Dai JM, Huang JH (2011) Improving interfacial reaction nonhomogeneity during laser welding-brazing aluminum to titanium. Mater Des 32:4408–4416

Cam G, Kocak M, Dobi D, Heikinheimo L, Siren M (1997) Fracture behaviour of diffusion bonded bimaterial Ti-Al joints. Sci Technol Weld Join 2(3):95–101

Alhazaa AN, Khan TI (2010) Diffusion bonding of Al7075 to Ti-6Al-4V using Cu coating and Sn-3.6Ag-1Cu interlayer. J Alloys Compd 494:351–358

Mirjalili M, Soltanieh M, Matsuura K, Ohno M (2013) On the kinetics of TiAl3 intermetallic layer formation in the titanium and aluminum diffusion couple. Intermetallics 32:297–302

Dressler U, Biallas G, Alfaro Mercado U (2009) Friction stir welding of titanium alloy TiAl6V4 to aluminium alloy AA2024-T3. Mater Sci Eng A 526:113–117

Bang HS, Bang HS, Song HJ, Joo SM (2013) Joint properties of dissimilar Al6061-T6 aluminum alloy/Ti-6%Al-4%V titanium alloy by gas tungsten arc welding assisted hybrid friction stir welding. Mater Des 51:544–551

Vaidya WV, Horstmann M, Ventzke V, Petrovski B, Kocak M, Kocik R, Tempus G (2010) Improving interfacial properties of a laser beam welded dissimilar joint of aluminium AA6056 and titanium Ti6Al4V for aeronautical applications. J Mater Sci 45:6242–6254

Meoller F, Grden M, Thomy C, Vollertsen F (2011) Combined laser beam welding and brazing process for aluminum titanium hybrid structures. Phys Procedia 12:215–223

Chen YB, Chen SH, Li LQ (2009) Effects of heat input on microstructure and mechanical property of Al/Ti joints by rectangular spot laser welding-brazing method. Int J Adv Manuf Technol 44:265–272

Lv SX, Jing XJ, Huang YX, Xu YQ, Zheng CQ, Yang SQ (2012) Investigation on TIG arc welding-brazing of Ti/Al dissimilar alloys with Al based fillers. Sci Technol Weld Join 17(7):519–524

Sambasiva Rao A, Madhusudhan Reddy G, Satya Prasad K (2011) Microstructure and tensile properties of dissimilar metal gas tungsten arc welding of aluminium to titanium alloy. Mater Sci Technol 27(1):65–70

Ma ZP, Wang CW, Yu HC, Yan JC, Shen HR (2013) The microstructure and mechanical properties of fluxless gas tungsten arc welding-brazing joints made between titanium and aluminum alloys. Mater Des 45:72–79

Cam G, Ozdemir U, Ventzke V, Kocak M (2008) Microstructure and mechanical characterization of diffusion bonded hybrid joints. J Mater Sci 43:3491–3499

Kreimeyer M, Wagner F, Vollertsen F (2005) Laser processing of aluminum titanium tailored blanks. Opt Lasers Eng 43:1021–1035

Lv SX, Cui QL, Huang YX, Jing XJ (2013) Influence of Zr addition on TIG welding-brazing of Ti-6Al-4V to Al5A06. Mater Sci Eng A 568:150–154

Lv SX, Yang T, Huang YX, Shi JW, Jing XJ, Qu J (2013) Interface characteristics and fracture behavior of TIG arc welding-brazed Ti/Al dissimilar alloys. Rare Metal Mater Eng 42(3):478–482

Gupta SP (2003) Intermetallic compounds in diffusion couples of Ti with an Al-Si eutectic alloy. Mater Charact 49:321–330

Wang B, Jiang SS, Zhang KF (2013) Pulse current auxiliary TLP diffusion bonding of SiCp/2024Al composite sheet using Al-Cu-Ti powder interlayer. Int J Adv Manuf Technol 65:1779–1784

Chen SH, Li LQ, Chen YB, Huang JH (2011) Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process. J Alloys Compd 509:891–898

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shouzheng, W., Yajiang, L., Juan, W. et al. Improving of interfacial microstructure of Ti/Al joint during GTA welding by adopting pulsed current. Int J Adv Manuf Technol 73, 1307–1312 (2014). https://doi.org/10.1007/s00170-014-5929-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5929-x