Abstract

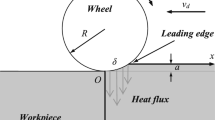

Creep feed grinding is a mechanical process that allows for a higher removal rate of material when compared to surface grinding. The risk of thermal damage is also present in creep feed grinding and must be avoided. In this work an experimental process to determine the temperature evolution on the surface of a steel workpiece, during a creep feed grinding operation is described. The workpiece is placed on a piezoelectric dynamometer and one thermocouple is placed on the workpiece, inside a small hole. The force acting on the workpiece, measured by the piezoelectric dynamometer and the temperature measured by the thermocouple are registered simultaneously and continuously during a passage of the grinding wheel. The obtained results are then compared with the numerical results, obtained using the finite element method (Mamalis et al., Int J Adv Manuf Technol 22:761–767, 2003). The authors show that it is possible to use a simplified finite element model to obtain the temperature field during a creep feed grinding operation, while using significantly different grinding wheels. The proposed finite element model is based on the model proposed by Jaeger (Proc R Soc NSW 76:203–224, 1942). The grinding thermal process is simulated using the commercial finite element code ABAQUS (SIMULIA 2007).

Similar content being viewed by others

References

Aguiar Vieira A, Monteiro Baptista A, Natal Jorge RM, Lages Parente MP (2009) On the temperature field during superficial grinding: an experimental study. Int J Adv Manuf Technol 40:1084–1092

Brandin H (1978) Pendelscheifen und tiefschleifen vergleichende untessuchunger, beim shieifen von rechteckprofilem. Dissertation TU Braunschweig, Germany

Choi HZ (1986) Beitrag zur Ursachenanalyse der Randzonenbeeinflussung bein Schleifen, Dissertatiobn. Hanover University, Germany

Jin T, Cai GQ (2001) Analytical thermal models of oblique moving heat source for deep grinding and cutting. J Manuf Sci Eng 123(2):185–190

Jin T, Brian Rowe W, McCornck D (2002) Temperatures in deep grinding of finite workpieces. Int J Mach Tools Manuf 42:53–59

Jaeger JC (1942) Moving sources of heat and the temperature at sliding contacts. Proc R Soc NSW 76:203–224

Lavine A, Malkin S (1990) The role of cooling in creep feed grinding. Int J Adv Manuf Technol 5(2):97–111

Lee D (1971) An experimental study of thermal aspects of grinding. Dissertation Univ. of Cincinnati

Malkin S (1989) Grinding technology, theory and applications of machining with abrasives. Soc Manuf Eng, Dearborn, MI

Mamalis AG, Kundrák J, Manolakos DE, Gyani K, Markopoulos A, Horvath M (2003) Effect of the workpiece material on the heat affected zones during grinding: a numerical simulation. Int J Adv Manuf Technol 22:761–767

Mamalis AG, Kundrák J, Manolakos DE, Gyani K, Markopoulos A (2003) Thermal modelling of surface grinding using implicit element techniques. Int J Adv Manuf Technol 21:929–934

Nguyen TA, Butler DL (2005) Simulation of surface grinding process, part 2: interaction of the abrasive grain with the workpiece. Int J Mach Tools Manuf 45(11):1329–1336

Rowe WB, Morgan MN, Black SC, Mills B (1996) A simplified approach to control of thermal damage in grinding. AMT Research Laboratory, Liverpool John Moores University, UK. CIRP Ann - Manuf Technol 45(1):299–302

Rowe WB, Morgan MN, Black SC (1998) Validation of Thermal Properties in Grinding. AMT Research Laboratory, Liverpool John Moores University, UK, CIRP Ann - Manuf Technol 47(1):275–279

SIMULIA (2007) Abaqus analysis: user’s manual. Dassault Systèmes

Tawakoli T (1993) High efficiency deep grinding. VDI-Verlag and Mechanical Engineering Publications

Werner PG, Younis MA, Schlingersiepen R (1980) Creep feed—an effective method to reduce work surface temperatures in high-efficiency grinding processes. In: 8th annual North American manufacturing research conference. Dearborn, pp 312–319

Author information

Authors and Affiliations

Corresponding author

Additional information

Funding by Ministério da Ciência, Inovação e do Ensino Superior, FCT, Portugal, under grant PTDC/EME-TME/81239/2006 is gratefully acknowledged.

Rights and permissions

About this article

Cite this article

Parente, M.P.L., Natal Jorge, R.M., Aguiar Vieira, A. et al. Experimental and numerical study of the temperature field during creep feed grinding. Int J Adv Manuf Technol 61, 127–134 (2012). https://doi.org/10.1007/s00170-011-3711-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3711-x