Abstract

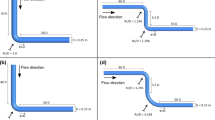

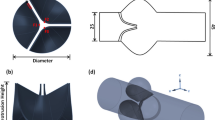

As fluid flow effects on the actuation and dynamic response of a vibrating membrane are crucial to micropump design in drug delivery, this paper presents both a mathematical and finite-element analysis (FEA) validation of a solution to fluid damping of a valveless micropump model. To further understand the behavior of the micropump, effects of geometrical dimensions and properties of fluid on the resonant frequency are analyzed to optimize the design of the proposed micropump. The analytical and numerical solutions show that the resonant frequency decreases with the slenderness ratio of the diffuser and increases with the opening angle, high aspect ratio, and thickness ratio between the membrane and the fluid chamber depth. A specific valveless micropump model with a 6-mm diameter and 65-μm thickness polydimethylsiloxane (PDMS) composite elastic membrane was studied and analyzed when subjected to different fluids conditions. The resonant frequency of a clamped circular membrane is found to be 138.11 Hz, neglecting the fluid. For a gas fluid load, the frequency is attenuated by slightly shifting to 104.76 Hz and it is significantly reduced to 5.53 Hz when the liquid fluid is loaded. Resonant frequency remarkably shifts the flow rate of the pump; hence, frequency-dependent characteristics of both single-chamber and dual-chamber configuration micropumps were investigated. It was observed that, although the fluid capacity is doubled for the latter, the maximum flow rate was found to be around 27.73 μl/min under 0.4-A input current with an excitation frequency of 3 Hz. This is less than twice the flow rate of a single chamber of 19.61 μl/min tested under the same current but with an excitation frequency of 4.36 Hz. The proposed double-chamber model analytical solution combined with the optimization of the nozzle/diffuser design and assuming the effects of damping proved to be an effective tool in predicting micropump performance and flow rate delivery.

Similar content being viewed by others

References

Laser DJ, Santiago JG (2004) A review of micropumps. J Micromech Microeng 14(6):35–64. doi:10.1088/0960-1317/14/6/R01

Jin X, Ladabaum I, Degertekin FL, Calmes S, Khuri-Yakub BT (1999) Fabrication and characterization of surface micromachined capacitive ultrasonic immersion transducers. IEEE ASME J Microelectromech Syst 8(1):100–114

Maeda R, Tsaur JJ, Lee SH, Ichiki M (2005) Microactuators based on thin films. In: Setter N (ed) Electroceramic-based MEMS: fabrication-technology and applications. Springer, Heidelberg, pp 19–35

Defa E, Millon C, Malhaire C, Barbier D (2002) PZT thin films integration for the realisation of a high sensitivity pressure microsensor based on a vibrating membrane. Sens Actuators A Phys 99(1–2):64–67. doi:10.1016/S0924-4247(01)00883-4

Crescini D, Marioli D, Taroni A (1998) Piezoelectric thick-film fluid density sensor based on resonant frequency vibration. In: Proceedings of the IEEE Instrumentation and Measurement Technology Conference, p. 1368–1371

Gifford RM Jr (2004) Resonant frequency characterization of a novel MEMS based membrane engine. Washington State University, Pullman, p 90

Lee C-Y, Chang H-T, Wen C-Y (2008) A MEMS-based valveless impedance pump utilizing electromagnetic actuation. J Micromech Microeng 18(35044):1–9

Machauf A, Nemirovsky Y, Dinnar U (2005) A membrane micropump electrostatically actuated across the working fluid. J Micromech Microeng 15:2309–2316. doi:10.1088/0960-1317/15/12/013

Crowe CT, Elger DF, Roberson JA (2001) Engineering fluid mechanics. Wiley, New York, p 18

Olsson A, Stemme G, Stemme E (1995) A valve-less planar fluid pump with two pump chambers. Sens Actuators A Phys 47:549–556. doi:10.1016/0924-4247(94)00960-P

Pan LS, Ng TY, Wu XH, Lee HP (2003) Analysis of valveless micropumps with inertial effects. J Micromech Microeng 13(3):390–399. doi:10.1088/0960-1317/13/3/307

Fan B, Song G, Hussain F (2005) Simulation of a piezoelectrically actuated valveless micropump. Smart Mater Struct 14:400–405. doi:10.1088/0964-1726/14/2/014

Yang Kai-shing, Chen I-Y, Wang Chi-Chuan (2006) Performance of nozzle/diffuser micro-pumps subject to parallel and series combinations. Chem Eng Technol 29(6):703–709. doi:10.1002/ceat.200500275

Amabili M (1996) Free vibrations of annular plates coupled with fluids. J Sound Vibrat 191(5):825–846. doi:10.1006/jsvi.1996.0158

Brand S (2006) Microdosing systems: micropumps the beating heart of microfluidics. http://www.mstonline.de/news/events/micropumps

Nguyen NT, Wereley ST (2002) Fundamentals and applications of microfluidics. Artech House, London, pp 293–341

Maillefer D, van Lintel H, Rey-Mermet G, Hirschi R (1999) A high-performance silicon micropump for an implantable drug delivery system. In: Proceedings of 12th International Workshop on Micro Electro Mechanical Systems—MEMS. IEEE, Orlando, FL, USA, p 541–546

Wong CC, Flemming JH, Adkins DR (2002) Evaluation of mini/micro-pumps for micro-chem-lab. In: Proc. 2002 ASME Int. Mechanical Engineering Congress and Exposition, New Orleans, LA, p 477–486

Xia DD, Bai J (2005) Simulation study and function analysis of micro-axial blood pumps. In: 27th Annual International Conference of the Engineering in Medicine and Biology Society, 2005, IEEE-EMBS 2005, p 2971–2974

Diaz J, Lopera JM, Pernia AM, Nuno F, Martinez JA, Comas JV, Galletti L (2007) A micropump for pulmonary blood flow regulation. IEEE Ind Electron Mag 1(1):39–44. doi:10.1109/MIE.2007.357173

Stemme E, Stemme G (1993) A valveless diffuser/nozzle-based fluid pump. Sens Actuators A Phys 39(2):159–167. doi:10.1016/0924-4247(93)80213-Z

Yamahata C, Lotto C, Al-Assaf E, Gijs MAM (2005) A PMMA valveless micropump using electromagnetic actuation. Microfluidics Nanofluidics 1(3):197–207. doi:10.1007/s10404-004-0007-6

Yin HL, Huang YC, Fang W, Hsieh J (2007) A novel electromagnetic elastomer membrane actuator with a semi-embedded coil. Sens Actuators A Phys 139(1–2):194–202. doi:10.1016/j.sna.2007.01.003

Pan T, McDonald SJ, Kai EM, Ziaie B (2005) A magnetically driven PDMS micropump with ball check-valves. J Micromech Microeng 15(5):1021–1026. doi:10.1088/0960-1317/15/5/018

Khoo M, Liu C (2000) A novel micromachined magnetic membrane microfluid pump. In: Engineering in Medicine and Biology Society, Proceedings of the 22nd Annual International Conference of the IEEE, p 2394–2397

Su Y, Chen W, Cui F, Zhang W (2006) Electromagnetically actuated valveless micropump with two flexible diaphragms. J Adv Manuf Technol 30:215–220. doi:10.1007/s00170-005-0030-0

Weisong W, Zhongmei Y, Chen JC, Fang J (2004) Composite elastic magnet films with hard magnetic feature. J Micromech Microeng 14(10):1321–1327. doi:10.1088/0960-1317/14/10/005

Olsson A, Stemme G, Stemme E (1999) A numerical design study of the valveless diffuser pump using a lumped-mass model. J Micromech Microeng 9(1):34–44. doi:10.1088/0960-1317/9/1/004

Soedel W (2004) Natural frequencies and modes, in vibrations of shells and plates. Marcel Dekker, New York, pp 102–109

Weinberg MS, Dube CE, Petrovich A (2003) Fluid damping in resonant flexural plate wave device. J Microelectromech Syst 12(5):567–575. doi:10.1109/JMEMS.2003.818452

Olsson A, Stemme G, Stemme E (2000) Numerical and experimental studies of flat-walled diffuser elements for valve-less micropumps. Sens Actuators A Phys 84(1–2):165–175. doi:10.1016/S0924-4247(99)00320-9

Jiang XN, Zhou ZY, Huang XY, Li Y, Yang Y, Liu CY (1998) Micronozzle/diffuser flow and its application in micro valveless pumps. Sensors Actuators A 70:81–87. doi:10.1016/S0924-4247(98)00115-0

Yang K-S, Chen I-Y, Shew B-Y, Wang C-C (2004) Investigation of the flow characteristics within a micronozzle/diffuser. J Micromech Microeng 14:26–31. doi:10.1088/0960-1317/14/1/304

Gerlach T, Wumus H (1995) Working principle and performance of the dynamic micropump. Sens Actuators 9:135–140. doi:10.1016/0924-4247(96)80097-5

Dow Corning Corporation (2007) Sylgard184 Silicone Elastomer Data Sheet

Nagel JJ, Mikhail G, Noh HM, Koo J (2006) Magnetically actuated micropumps using an Fe-PDMS composite membrane. In: Smart Structures and Materials 2006: Smart Electronics, MEMS, BioMEMS, and Nanotechnology, San Diego, CA, USA. pp 617213.1–617213.9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Y., Amirouche, F. Study of fluid damping effects on resonant frequency of an electromagnetically actuated valveless micropump. Int J Adv Manuf Technol 45, 1187 (2009). https://doi.org/10.1007/s00170-009-2053-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-009-2053-4