Abstract

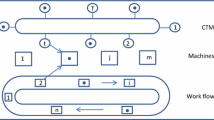

An integrated approach is discussed in this article to solve the sub-problems like tool-part grouping, job allocation on machines and minimization of make-span in a FMS. Tool and part grouping is performed using “principal component analysis”, and tool allocation has been carried out using priority-based approach by developing a potency index. Thereafter, the concept has evolved based on threshold machining time, minimum operation time, and maximum possible operation time to minimize the make-span of the system. In order to validate the result “analysis of variance” has been employed, and on a simulated example the F ratio is enumerated.

Similar content being viewed by others

References

Mukhopadhyay SK, Sahu SK (1996) Priority based tool allocation in a flexible manufacturing system. Int J Prod Res 34(7):1995–2018

Co HC, Biermann JS, Chen SK (1995) A methodical approach to the flexible manufacturing system batching loading and tool configuration problems. Int J Prod Res 28:2171–2186

Stecke KE (1989) Algorithms for efficient planning and operation of a particular FMS. Int J Flex Manuf Syst 1:287–324

Ram B, Sarin S, Chen CS (1990) A model and a solution approach for the machine loading and tool allocation problem in a flexible manufacturing system. Int J Prod Res 28:637–645

Arizono I, Kato M, Yamatoto A, Ohta HA (1995) New stochastic neural network model and its application to grouping parts and tools in a flexible manufacturing system. Int J Prod Res 33:1535–1548

Ventura JA, Chen FF, Wu CH (1990) Grouping of parts and tools in flexible manufacturing systems production planning. Int J Prod Res 28:1039–1056

Alfonso THD, Ventura JA (1995) Assignment of tools to machines in a flexible manufacturing system. Eur J Oper Res 81:115–133

Suri R, Whitney CK (1988) Developing an efficient schedule for minimization of throughput time of parts. Int J Prod Res 28:2121–2158

Mukhopadhyay SK, Maiti B, Garg S (1991) Heuristic solution to scheduling problems in flexible manufacturing systems. Int J Prod Res 30:2213–2228

Lamond BF, Sodhi MS (1996) Using tool life models to minimize processing time on a flexible machine. IIE Trans 29:611–621

Sarin SC, Chen CS (1987) Machine loading and tool allocation problem in a FMS. Int J Prod Res 25:1081–1094

Arvindh B, Irani SA (1995) Principal component analysis for evaluating the feasibility of cellular manufacturing without initial machine-part matrix clustering. Int J Prod Res 32:1909–1938

Chan FTS (2004) Impact of operation flexibility and dispatching rules on the performance of a flexible manufacturing system. Int J Adv Manuf Technol 24:447–459

Balogun OO, Popplewell K (1999) Toward the integration of flexible manufacturing systems scheduling. Int J Prod Res 37(15)

Low C, Wu TH (2001) Mathematical modelling and heuristic approaches to operation scheduling problems in an FMS environment. Int J Prod Res 39(4)

Gerrero F (1999) Machine loading and part type selection in flexible manufacturing systems. Int J Prod Res 37(6)

Sabuncuoglu I, Kizilisik OB (2003) Reactive scheduling in a dynamic and stochastic FMS environment. Int J Prod Res 41(17)

Sabuncuoglu I (1998) A study of scheduling rules of flexible manufacturing system: a simulation approach. Int J Prod Res 36(2)

Chan FTS, Chung SH, Chan PLY (2006) Application of genetic algorithms with dominant genes in a distributed scheduling problem in flexible manufacturing systems. Int J Prod Res 44(3)

Jeong KC, Kim D (1998) A real-time scheduling mechanism for a flexible manufacturing system using simulation and dispatch rules. Int J Prod Res 36(9)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goswami, M., Tiwari, M.K. & Mukhopadhyay, S.K. An integrated approach to solve tool-part grouping, job allocation and scheduling problems in a flexible manufacturing system. Int J Adv Manuf Technol 35, 1145–1155 (2008). https://doi.org/10.1007/s00170-006-0796-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0796-8