Abstract

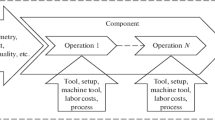

This article is a detailed case study of a particular FMS that will be operational in 1989. It describes the daily planning and operating problems that will need to be addressed. The algorithms that will operate this system are presented. Given the daily changing production requirements, the algorithms begin with an aggregate planning feasibility check. Then planning, scheduling, inventory management, and breakdowns are addressed.

The key problems in operating this system are tool management problems. Detailed tooling data and their analysis are presented in an appendix to address these problems.

Similar content being viewed by others

References

Berrada, Mohammed, and Stecke, Kathryn E., “A Branch-and-Bound Approach for Machine Load Balancing in Flexible Manufacturing Systems,” Management Science, Vol. 32, No. 10, pp. 1316–1335 (October 1986).

Carrie, Alan S., and Perera, D.T.S., “Work Scheduling in FMS under Tool Availability Constraints,” International Journal of Production Research, Vol. 24, No. 6, pp. 1299–1308 (1986).

Cavaillé, Jean-Bernard, and Dubois, Didier, “Heuristic Methods Based on Mean-Value Analysis for Flexible Manufacturing Systems Performance Evaluation,” Proceedings of the 21st IEEE Conference on Decision and Control, Orlando, Florida, pp. 1061–1065 (December 1982).

Hwang, Syming, “Part Selection Problems in Flexible Manufacturing Systems Planning Stage,” Proceedings of the Second ORSA/TIMS Conference on Flexible Manufacturing Systems: Operations Research Models and Applications, Ann Arbor, Michigan, K.E. Stecke and R. Suri (editors), Elsevier Science Publishers B.V., Amsterdam, pp. 297–309 (August 12–15, 1986).

Johnson, D. S., “Near Optimal Bin Packing Algorithms,” Ph.D. dissertation, M.I.T., Mathematics Department, Cambridge, Mass. (1973).

Menga, Giuseppe; Bruno, G.; Conterno, Renato; and Actis Dato, M., “Modeling FMS by Closed Queueing Network Analysis Methods,” IEEE Transactions on Components, Hybrids, and Manufacturing, CHM 7, No. 3, pp. 3–12 (September 1984).

Reiser, M., and Lavenberg, S. S., “Mean-Value Analysis of Closed Multichain Queueing Networks,” Journal of the Association for Computing Machinery, Vol. 27, No. 2, pp. 313–322 (April 1980).

Schrage, Linus E., Linear Programming Models with LINDO, The Scientific Press, Palo Alto, Calif. (1981).

Stecke, Kathryn E., “A Hierarchical Approach to Solving Machine Grouping and Loading Problems of Flexible Manufacturing Systems,” European Journal of Operational Research, Vol. 24, No. 3, pp. 369–378 (March 1985).

Stecke, Kathryn E., “Formulation and Solution of Nonlinear Integer Production Planning Problems for Flexible Manufacturing Systems,” Management Science, Vol. 29, No. 3, pp. 273–288 (March 1983).

Stecke, Kathryn E., and Talbot, F. Brian, “Heuristics for Loading Flexible Manufacturing Systems,” Flexible Manufacturing: Recent Developments in FMS, Robotics, CAD/CAM, CIM, A. Raouf and S. I. Ahmad (editors), Elsevier Science Publishers B.V., Amsterdam, pp. 73–84 (1985).

Suri, Rajan, and Hildebrandt, Richard R., “Modeling Flexible Manufacturing Systems Using Mean Value Analysis,” Journal of Manufacturing Systems, Vol. 3, No. 1, pp. 27–38 (January 1984).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stecke, K.E. Algorithms for efficient planning and operation of a particular FMS. Int J Flex Manuf Syst 1, 287–324 (1989). https://doi.org/10.1007/BF00183873

Issue Date:

DOI: https://doi.org/10.1007/BF00183873