Abstract

During an engineering design process, designers create sequences of product models by switching between product models with different purposes. To enable an efficient use of these product models, researchers are required to anticipate the compatibility of the models in application by designers. This is necessary as the information in an existing product model may not be usable for a subsequent product model. However, the corresponding information on compatibility was not accessible to researchers as it was scattered across various publications. Hence, the objective of this contribution was to develop a structured overview, a landscape of linkable and non-linkable product models in embodiment design to merge the information. For this purpose, a literature review containing a grounded theory-based analysis was conducted and the results were visualized using the network visualization software Gephi. The key learnings of the visualized landscape of 52 product models can be summarized as follows: (1) some models are already closely linked to each other by compatible inputs and outputs; (2) other product models are noticeable with mostly unknown linking possibilities due to incompatible inputs and outputs or insufficient descriptions in the literature. 14 product models offer two linking possibilities or less. In these cases, it is unclear how they interact with other product models in an engineering design process. In conclusion, the product model landscape provides insight into the compatibility of product models to support the development of existing and new product models for sequential use by designers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Modeling serves designers as an essential tool in the engineering design process for describing, visualizing, and shaping thoughts for themselves or communication with others (e.g., Buur and Myrup Andreasen 1989; Maier et al. 2014). In addition, it is an aid for decision-making (e.g., Eckert and Hillerbrand 2022; Maier et al. 2017). While a design process can be considered as a sequence of models, modeling can be considered the language of designers (Andreasen 1994; Subrahmanian et al. 1993).

Andreasen et al. (2015: 42) define the resulting models as “[…] a human creation that carries attributes similar to the modeled phenomenon or object.” This definition can be elaborated by the main characteristics of models according to Stachowiak (1973: 131–133), representation, reduction, and pragmatism. Representation refers to models representing an original; reduction refers to capturing only some of the attributes of the original; and pragmatism refers to models fulfilling an intended function (Stachowiak 1973). In this contribution, we investigate a specific type of model used in product design: product models. The definition is, therefore, further specified through the purpose according to Eckert and Hillerbrand (2018), which is the depiction of function, behavior, or structure, or analysis of the behavior of a defined design. Based on the definitions by Andreasen et al. (2015), Stachowiak (1973), and Eckert and Hillerbrand (2018), a product model is defined in this contribution as a human-made, pragmatic, reductive representation of a technical product carrying attributes similar to the modeled original for the purpose of depicting its function, behavior, or structure, or for analyzing its behavior.

As designers create sequences of product models during an engineering design process (Andreasen 1994), they have to switch between models. Each of the models enables the designer to answer specific questions, for example concerning the functionality, reliability, or producibility of the product (Maier et al. 2014). The ability to switch between models allows the designer to select the most appropriate model for a given application case or optimize through design iterations (Jones et al. 2020). Similarly, design methods have different capabilities depending on the problem and context of the application (Reich 2010). Thereby, the switching, which depends on the availability of linkable models, affects the entire design process. Linkable, in this context, refers to the ability to use the outputs of one model as inputs for the subsequent model. Building on Buur and Myrup Andreasen’s (1989) understanding of a communication process, this means the transfer of information using a shared code, i.e., language. This can be done both automatically by a technical interface as well as a designer. In both cases, the shared code is essential to minimize the risk of misunderstandings which would lower accuracy. In contrast, the need to transform or supplement the transferred information, e.g., to reach another abstraction level, would affect the duration and risk of error. Differences in the level of abstraction that would affect the usability of the information, as discussed for example by Shaked and Reich (2021), are, therefore, not considered. Applying this to switching between models results in, as Jones et al. (2020: 43) state, “[…] the quicker and more accurately one can transition between models, the quicker the design process”. Hence, switching between different product models can delay the design process, and should, therefore, be considered when selecting or developing a product model.

The state of research on product models was outlined in the literature reviews by Matthiesen et al. (2019b) and Weidmann et al. (2017). Matthiesen et al. (2019b) reviewed product models in embodiment design, a specific section of product design, to develop a framework for product model selection to cope with the multitude of existing product models. The resulting framework clustered the product models by embodiment design phase and application purpose, in which the identified product models spanned all possible combinations. In contrast, Weidmann et al. (2017) examined the interdisciplinary character of product models in mechatronic design and identified a strong overlap across the disciplines of mechanical, electrical, and software engineering, in particular in the case of mechanical and electrical engineering. Altogether, the reviews identified 79 different product models and classified them according to multiple categories, such as the “type of depiction”, “type of information”, or application purpose. In addition to the classifications already included in the literature reviews, there are other distinctions, e.g., that were drawn by Jones et al. (2020) between virtual, physical, and cognitive models. These results illustrate the multitude and variety of product models available today and how researchers tried to structure the state of research for model researchers and model selection for designers by different classifications. The effort of switching between product models was not taken into account in these overviews.

The multitude of product models in engineering design is constantly growing with continuing model research. As modern systems become increasingly complex (Suh 2005) and multi-disciplinary (Tomiyama et al. 2007), the requirements for product models in product design evolve and call for the development of different new product models. The development based on shortcomings of existing models was illustrated in an example by Buur and Myrup Andreasen (1989) in the context of mechatronic product development. It was shown that the domains of mechanics, electronics, and software were merged at a stage when alternative concepts were no longer properly considered. Buur and Myrup Andreasen concluded that a new type of product model was required to describe the complex interaction of mechanics, electrics, and software in the overall product for concept development (Buur and Myrup Andreasen 1989). Such new product models aimed at specific use cases extend the variety and contribute to the relevance of continuously structuring the state of research of product models for model researchers and designers.

To enable designers to consider the switching between product models in product model selection, researchers have to anticipate both the linkability of product models and how to provide the knowledge of these linking possibilities. Examples of linkable product models have already been described in the literature, e.g., building FEM or MBS models from CAD models (Danjou et al. 2008) or building up a design structure matrix (DSM) from textual functional descriptions or a technical drawing (Wilschut et al. 2018). But the knowledge about these already described linkable product models has not yet been merged. Hence, a merged, structured depiction of the linking possibilities of the state of research is required so that researchers can consider and provide more than the individual examples they are familiar with. Consequently, the problem is the lack of an overarching, structured overview of product models presenting the links to capture the knowledge of linking possibilities. This is also necessary to support the integration of newly developed product models into the state of research.

1.1 Contribution of this article

The purpose of this contribution is to develop a structured overview of linkable and non-linkable product models to enable researchers to access the knowledge of linking possibilities between product models and simplify the integration of new models into the state of research. A particular relevance of the linking possibilities is expected during the development of the shape of the technical system starting from concepts, since this represents a major change in the product description and the fulfillment of requirements must be ensured by testing activities with models. This development from concept to shape aligns with the embodiment design phase as defined by Pahl and Beitz (1996: 199): “Embodiment design is that part of the design process in which, starting from the working structure or concept of a technical product, the design is developed, in accordance with technical and economic criteria and in the light of further information, to the point where subsequent detail design can lead directly to production […].” According to Pahl and Beitz (1996), this phase is characterized by repeated corrective steps, the constant alternation of analysis and synthesis, and the intersection of function, durability, production, assembly, and operation. Since this multitude of elements is addressed by different models, the repeated steps result in repeated switching between product models and thus also in a greater relevance of links in embodiment design. For this reason, the structured overview of linkable and non-linkable product models is narrowed to the embodiment design phase hereafter referred to as the landscape of product models in embodiment design.

To be able to identify the linkable product models, the components of the links, the inputs and outputs, have to be investigated first. Concerning the objective of identifying links between product models, similarities between inputs and outputs are particularly relevant. Therefore, the following research question is formulated:

RQ1: Which categories of similar inputs and outputs of product models in embodiment design can be identified in the literature?

Based on the investigation for RQ1, Research Question 2 is subsequently answered to achieve the aim of this contribution:

RQ2: Which links between product models in embodiment design can be formed based on the inputs and outputs from the literature?

The research questions are answered through a literature review, as the literature contains descriptions of the currently used and recently developed product models as well as their inputs and outputs. The three steps of the literature review, consisting of the creation of a literature collection, grounded theory-based literature analysis, and subsequent visualization, are explained in detail in Sect. 2. Section 3 contains the results, with the landscape of product models as the main result, and the discussion in a structure analogous to that of the methods section. Section 4 presents the main conclusions regarding the links between product models, as well as their implications for the development of new product models.

2 Methodology

To answer the research questions, a stepwise approach was chosen to create a literature collection and subsequently analyze it. Figure 1 shows an overview of the three steps of the procedure and their relations to the research questions. In the first step, creating the literature collection, an existing literature collection was updated to obtain a representative collection of the literature. The second step, grounded theory-based literature analysis, aimed at identifying the product models in the literature and analyzing the inputs, outputs, and categories of these. In the final step, consolidation and visualization, the gathered information was combined to map linkable product models and categories. The individual steps of the procedure are described in detail in the following sections.

2.1 Creating the literature collection

As described in the introduction, Matthiesen et al. (2019b) conducted a literature review regarding product models in embodiment design containing publications between 2009 and 2018. The literature identified by Matthiesen et al. was, therefore, used as a basis and updated to cover the period from 2009 to August 2022. The procedure for the systematic literature search used by Matthiesen et al., which was based on Dresch et al. (2015), was replicated for the period since 2018. The sources, search terms, and inclusion criteria defined by Matthiesen et al. (2019b) were as follows:

The search terms embodiment design, embodiment design AND model, embodiment design AND analysis, embodiment design AND synthesis, embodiment function relation, function model*, product model, and system* modeling were applied to the databasesFootnote 1ASME digital collection, Google Scholar, IEEE, ResearchGate, Scopus, and Web of Science. The matches in the databases were filtered using three sets of inclusion criteria increasing in requirements. The first set of inclusion criteria applied simultaneously in the search in the databases were:

-

Published in 2018Footnote 2 or later

-

Published in the field of engineering design

-

Published in English

After applying the first set of inclusion criteria, the remaining matches were transferred to the reference management program Citavi 6.Footnote 3 Before applying the second set of inclusion criteria, duplicates were filtered using the tool included in Citavi 6 and manually. The second set of inclusion criteria were:

-

The abstract or title mentions a product model or modeling process

-

The keywords indicate the context of embodiment designFootnote 4

The remaining publications were filtered using the third set of inclusion criteria considering the full-text sources:

-

A product model is described

-

The type of depiction and the type of information of the model are specified

-

The source is published in a peer-reviewed journal or conference proceeding

The publications following all inclusion criteria were merged with the literature collection by Matthiesen et al. (2019b). Due to the overlap of search periods in 2018, the merged literature collection was again checked for duplicates to achieve a consistent collection of literature for the period from 2009 until August 2022.

2.2 Grounded theory-based literature analysis

The aim of the literature analysis was to answer Research Question 1 by creating a table of model inputs and outputs, and subsequently building categories from them. To begin with, the product models described in the publications had to be identified, as many models and their inputs and outputs were described in multiple publications. The definition for product models, human-made, pragmatic, reductive representations of a technical product carrying attributes similar to the modeled original, specified in the introduction was applied. For the following extraction of the inputs and outputs from the publications and to build categories, the step Analyze of Wolfswinkel et al.’s (2013) grounded theory literature review method was chosen. This method was selected as the inputs and outputs of the product models were expected to be described differently in each publication. The method enables the merging of differently described constructs into overarching categories, as will be shown in Sect. 3.2.

The method started with the highlighting of excerpts containing inputs and outputs, which can be words, sentences, or paragraphs. Due to the specific context of this analysis, figures were considered as well. The extracts were then merged for each product model. The product models, corresponding publications, and merged excerpts of their inputs and outputs were documented in an overview table.

Subsequently, three coding processes were applied to the excerpts to build categories based on similarities of the excerpts. The three coding processes, open coding, axial coding, and selective coding, were defined by Wolfswinkel et al. (2013: 51) as follows: “In sum, open coding is the analytical process of generating higher abstraction level type categories from sets of concepts/variables. Axial coding is the further development of categories and relating them to their possible sub-categories. With selective coding, the categories are integrated and refined.” The coding processes were first applied separately to the inputs and outputs and finally joined to create overarching categories. This resulted in a hierarchical structure of categories of inputs and outputs.

2.3 Consolidation and visualization

In the following, we describe how we consolidated and visualized the results from the literature analysis to answer Research Question 2. From the overview table, model pairs were formed based on matches between the outputs of one model and the inputs of another model. Gathering every possible model pair and category each model belonged to resulted in the characteristics of each model.

We did not visualize model inputs without corresponding model outputs and vice versa. Due to the missing links, these inputs and outputs do not contribute to answering the research question and reduce the clarity of the network. But if there was a subset of inputs without corresponding outputs, we still displayed the model with all inputs and the corresponding outputs. These could be, for example, mental images as input for sketches as described by Andreasen et al. (2015) or the material behavior in the case of FEM models as described by Rajaguru et al. (2010). While the mental images are supplied by the designers themselves, the material behavior originates from material science and thus does not fall within the product models considered in this publication. Still, other inputs of the FEM model have corresponding outputs of other models, which are, therefore, visualized.

The characteristics of all models were subsequently sorted and transformed into a set of tables as inputs for the network visualization software Gephi.Footnote 5 The categories were represented as their own type of nodes and linked by undirected graphs. The product models were modeled as different types of nodes and linked to each other and the categories by directed graphs. If a model belonged to a category with sub-categories, the model was only linked to the lowest sub-category. The link of such a model to the higher category was established by the link between the sub-category and the higher category. The layout was calculated using the force-directed Yifan Hu layout algorithm.Footnote 6 “Force-directed algorithms model the graph layout problem by assigning attractive and repulsive forces between vertices [i.e. nodes], and finding the optimal layout by minimizing the energy of the system” (Hu 2005: 40). This resulted in the product model landscape as a mixed network.

3 Results and discussion

The results and discussion are presented according to the structure of the method section. The results of the literature search are presented in Sect. 3.1 and discussed in terms of the quality of the literature collection as a foundation for the following analysis. Section 3.2 presents the results and discussion of the literature analysis as an answer to Research Question 1. The landscape of product models as the answer to Research Question 2 is presented in Sect. 3.3.

3.1 Literature collection

The literature search was conducted in August 2022. The result was 2853 publications after applying the first set of inclusion criteria. After applying all inclusion criteria, 26 publications remained. Table 1 shows an overview of the number of publications found in each database per set of inclusion criteria. Combining the remaining 26 publications with the 48 publications identified by Matthiesen et al. (2019b) resulted in a literature collection containing 74 publications.

Considering the number of publications in the individual steps across all databases, several aspects are notable. The number of publications after the first step is very high (2853). We can, therefore, assume that due to the openness of the search terms, the majority of the publications relevant to this review have been included into consideration in the following steps. From this initial amount, only 0.9% of the publications remained in the end. Thereby, the second set of inclusion criteria excluded the most publications, evaluating the mentioning of a product model or modeling process and the context of embodiment design. Based on the search terms used, this indicates the presence of many other types of models, e.g., process models, or models outside of embodiment design. This is consistent with the expectations based on the breadth of model use in product design and models identified in literature reviews alongside product models (e.g., Wynn and Clarkson (2018) for process models). A comparison of the number of remaining publications of this search with the number of publications identified by Matthiesen et al. (2019b) shows that the number of identified publications has increased from 4.8 publications per year in the search by Matthiesen et al. (2019b) to 6.5 publications per year in the search of this publication. This is in line with the expectation given the trend of increasing scientific publications observed by Bornmann and Mutz (2015). Considering the institutions involved, in Matthiesen et al. (2019b), the corresponding authors of the 48 publications came from 36 institutions, and the 26 newly identified publications came from 13 institutions. Accordingly, the institutions involved in the publications have become more concentrated. Nevertheless, this is not a situation where a single institution determines the number of publications or research landscape. Hence, the literature collection appears to be an appropriate sample based on the number of considered publications.

3.2 Categories of similar inputs and outputs

The examination of the literature collection containing 74 publications revealed 52 different product models. The publications by Zhan and Huang (2018) and Zheng et al. (2017), which were adopted from Matthiesen et al. (2019b), were excluded as they did not include a product model according to the definition used in this review. An overview of the product models and associated publications is presented in Table 2 in the Appendix. Compared to Matthiesen et al.’s (2019b) list including 34 product models, this table contains 18 more product models. This expansion is partly due to new models identified in the 26 additional publications, and partly due to the breakdown of frameworks that Matthiesen et al. (2019b) counted as one model. For example, the framework of models by He et al. (2013) was subdivided into the individual product models contained therein to achieve a more thorough examination of the individual models.

The literature analysis resulted in the extension of Table 2 by inputs and outputs. The subsequent coding steps resulted in 11 categories of inputs and 14 categories of outputs. Figure 5 and Fig. 6 in the Appendix present the categories developed separately based on the inputs and outputs, as well as descriptions merged under the categories for traceability. These figures thus illustrate the merging of differently described constructs into overarching categories, as in the case of the physical system in Fig. 5 or the relations between components in Fig. 6. Combining these categories of similar descriptions of inputs and outputs resulted in 17 categories across the inputs and outputs which are presented in Fig. 2. The hierarchical relations between categories resulted from the axial coding step. In addition, Fig. 2 presents the number of models belonging to each category. Five models did not belong to any of the developed categories since none of their inputs or outputs could be categorized. These were four feature-based models by He et al. (2013), where the description was limited to the inputs and outputs among each other due to the intended use within the same framework. Thereby, the description was too specific to be comparable to descriptions of other models outside of the framework. In addition, there was the SAPPhIRE Model, for which no classification was possible due to insufficiently described inputs and outputs due to the specific context of the use case.

Sectors of the landscape of product models in embodiment design with the labeled examples used in the discussion. (Sectors = blue labels; product models = empty black circles; categories of inputs and outputs = filled green squares; links starting at product models = solid gray edges; links starting at categories = dashed green edges)

Concerning the identified product models, an anticipated model, i.e., the technical drawing, is missing. Technical drawings were only mentioned but not sufficiently described for inclusion in the table. It can be assumed that due to the general and thus presupposed understanding of technical drawings in the publications of recent years, a new description has been omitted, as well as the interest in further research has been limited. Nevertheless, comparing the product models included in this sample to the product models included in the literature reviews by Matthiesen et al. (2019b) and Weidmann et al. (2017) shows a substantial overlap of product models in embodiment design, confirming the appropriateness of this sample.

Considering the diversity of inputs and outputs displayed in Table 2, the types of categories derived are particularly relevant. The categories correspond to types of representations, specific models that serve as inputs themselves, as well as exchanged information. The representations, e.g., graph representation, overlap with the “type of depiction” from the state of research used by Matthiesen et al. (2019b) and Weidmann et al. (2017) for classification. Thus, the top-down approach of classification converges with the bottom-up approach of the grounded theory-based analysis. However, since the coding steps and thus also the classification are based on the similarities of the descriptions of the inputs and outputs, there is the possibility of an influence by classifications from the state of research. Besides, if the authors of the product models know the classifications and use them for their model descriptions, these classifications also flow into the bottom-up classification. In terms of categories corresponding to product models, the technical drawing stands out in particular, as it did not emerge as a product model. Although it was not sufficiently described in any of the publications, it can still be used as an input for several product models and consequently will find its way into the landscape of product models as a category. The categories of exchanged information, again, show similarities to the state of research in which the “type of information” was used in the classification. However, with the description of the information instead of the type, these are more specific than the classes in the state of research. Hence, the derived categories cover a wider range of abstraction levels in comparison to the state of research, from exchanged information to types of representation comparable to classes in the state of research.

Due to the varying abstraction levels, these categories may be used for different purposes in model research. The types of representation structure the state of research, enabling researchers to position newly developed models in comparison to existing models and possibly point out blank spaces. Specific product models demonstrate frequent inputs and outputs in the state of research, such as the Function Structure or the Technical Drawing. When developing a new product model, these categories can be used as a reference to see which models can already be created from frequently used inputs and outputs. As references, the models offer the possibility to adapt or learn from components of the model or the way they work with frequently used inputs and outputs.

Summarizing, Table 2 as the result of the literature analysis answers Research Question 1, “Which categories of similar inputs and outputs of product models in embodiment design can be identified in the literature?” The 17 categories identified across the inputs and outputs range from exchanged information to types of representation. As the types of representation converge with the classes known in the state of research, especially the categories on lower abstraction levels, exchanged information, and specific product models, supplement the state of research and provide assistance to model developers.

3.3 Landscape of product models

Consolidating the product models and categories resulted in the landscape of product models in embodiment design presented in Fig. 3. For readability reasons, only three sections are represented with labeled product models and categories. Product models are represented as empty black circles and categories as filled green squares. As hierarchies of categories do not represent links, they are represented as undirected dashed green edges. Links starting at product models are represented as solid gray edges, while links starting at categories are represented as dashed green edges. These links between two product models represent the possibility of using an output of the source model as input for the target model of the directed edge. The size of the nodes (circles and squares) represents their degree, the number of edges connected to a particular node. The network contains 69 nodes and 183 edges. The average degree of the nodes is 5.3. The maximum degree is 23 and is found for the 2D/3D CAD Model. The Gephi file underlying the network is available as supplementary material.

Examining the landscape from the perspective of the force-directed algorithm underlying the structuring of the network, three exemplary areas can be analyzed: (1) the arrangement consisting of three nodes at the bottom left, (2) the single node with edge to the center at the left corner, and (3) the model without an edge. The comparison of (1) and (2) shows that they are repelled from the center as expected. The greater distance of (1) from the center reflects the fact that the arrangement (1) is pushed further away from the center by the lack of attraction of the outer nodes. If we add (3) to the comparison, the smaller distance of (3) seems unjustified due to the lack of an attractive force. Accordingly, a weakness of the structure becomes apparent here, since the distance cannot be considered meaningful in this individual case and possibly resulted from the algorithm. Consequently, the structure and exemplary comparisons within the landscape correspond to the expectation as long as a determining edge is present. The position of the individual model cannot be considered meaningful.

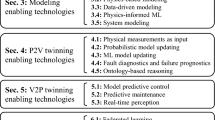

The sections in Fig. 3 illustrate product models with varying amounts of links. For discussion, the network can be divided into three sectors based on the number of links of the product models: surrounding the Graph Representation category and the 2D/3D CAD Model, there is a center of densely linked models (e.g., Design Structure Matrix); the center flows into a margin of models (e.g., Function Means Tree) that are repeatedly but not as densely linked; located away from the center are the satellite sectors, with only weak (e.g., Pseudo Rigid Body Model) or the unlinked SAPPhIRE/-lite Model. The sectors and mentioned examples are pictured in Fig. 4.

The positioning of the 2D/3D CAD Model in or as the center based on the highest degree elevates it as a binding point even over the categories that emerged from the literature analysis (see Fig. 2). Thus, the use of a 2D/3D CAD Model provides the most possible links for the use with other models in embodiment design. As a result, it can serve as a linking point, as also described by Danjou et al. (2008), to switch between existing models with minimum effort, or as an access point to integrate newly developed models into the state of research. Although a 2D/3D CAD Model may contain additional information in addition to the geometry information that is always included, the required information for linked models may exceed this. If this information cannot be integrated into or transferred by the 2D/3D CAD Model, it must be transferred via another interface, possibly the designers themselves. For a more formal transfer, approaches such as category theory can be used as they offer more advanced expressiveness but require a translation into a mediation language (see Breiner et al. 2018; Wisnesky et al. 2017). As a result, the effort of switching via the 2D/3D CAD Model as a linking point can grow due to additional required information until the use of another interface is more efficient.

In the case of the models at the margin in particular, it is noticeable that in some cases, for example, the NVH Model or Pseudo Rigid Body Model, no link leads back to the center. Accordingly, the landscape of product models does not include a solution as to how the outputs and findings of these models are incorporated back into other models or, for that matter, the product design process, as the return is not described in the publications. A possible answer is provided in the publications by Jones et al. (2020) and Maier et al. (2014), who distinguish three types of models: physical, virtual, and cognitive/mental models. As cognitive/mental models are only conceived by the designer and do not exist in virtual or physical space, no cognitive/mental model is included in the landscape. This leads to the assumption that for the models without a link to the center, the output of the model flows back into the design process through a mental model or mental interpretation. In these cases, the contribution or support offered by the product models is potentially dependent on the individual abilities of the designer using the model. In this process, errors such as misinterpretations could occur and diminish the value of the product model. For clarification of how the outputs and insights of these models are integrated back into the product design process and how the potential for error can be reduced, additional research is necessary as this has been out of the scope of the literature review.

A noticeable feature of the satellite sector is the cluster of linked models in the upper right corner of the map. These models were all identified in the publication by He et al. (2013) and described including their links to each other. The positioning apart from the center creates the impression that in the introductory description of these models, more consideration was given to describing the links to one another in their own framework than to describing links to other product models at the state of research. This results in the circumstance that after entering this cluster, there is no known way back to the center available as described for product models in the margin in the previous paragraph. Within the satellite sector, this problem also exists for the completely unlinked SAPPhIRE/-lite Model. In the use case of this model described by Sarkar et al. (2017), it can be seen that this model was used as a data repository within an approach for synthesizing designs. Therefore, although the model does not link to any other product model in the map, it can be integrated into a design process through a suitable technical implementation. As a result, due to very few explicitly described links to models at the state of research, the models in the satellite sector are far from the center, and linking possibilities remain partly unknown.

Summarizing, the links identified in the landscape of product models in embodiment design (see Fig. 3) answer Research Question 2, “Which links between product models in embodiment design can be formed based on the inputs and outputs from the literature?” Based on the number of links, the landscape can be divided into the densely linked center, the more loosely linked margin, and the distant satellite sector. In the center, the 2D/3D CAD Model serves as a linking point between different models. In the margin and satellite sector, insufficiencies of the descriptions in the literature become apparent: In the margin, possibilities to return to the center for a continuous design process are not traceable, and in the satellite sector, very few described links result in unknown or missing linking possibilities.

4 Conclusion and outlook

In this contribution, a structured overview of linkable and non-linkable product models was developed to capture the knowledge of linking possibilities between product models for researchers and simplify the integration of newly developed models into the state of research. For the development of the structured overview, two research questions were answered concerning the categories of inputs and outputs of product models and possible links between the outputs and inputs of different models. These research questions were answered using a literature review approach, consisting of a literature search, grounded theory-based analysis, and visualization. The results, categories of inputs and outputs of the identified product models (see Fig. 2), and a landscape of product models containing the linking possibilities (see Fig. 3) revealed strengths and weaknesses about the state of research of product models in embodiment design as well as possibilities for future model development.

Based on the inputs and outputs, common categories were derived using a grounded theory-based analysis. The categories reflect similarities of different models across multiple levels of abstraction. The categories range from exchanged information, like relations between components, over specific models, like the technical drawing or 2D/3D CAD Model, to types of representation, like the graph representation. While the types of representation blend into and support the existing categories used for classification in the state of research, the categories representing a specific product model can point to potential references that show how frequently used inputs and outputs are worked with.

The consolidation of the identified inputs, outputs, and categories delivered a structured landscape of the product models in embodiment design. This can be divided from the inside out into three sectors: the center, the margin, and the satellite sector. With each sector, the degree of linkage decreases. A significant position is attributed to the 2D/3D CAD Model, which is located in the center and offers the most links. Therefore, it offers the possibility to act as a linking point in particular towards geometric information between product models or a point of entry for newly developed models. For example, the Integrated Function Model is linked via the Design Graph to the 2D/3D CAD Model. In this example, the 2D/3D CAD Model is a linking point to the Multibody System and FEM Simulation Model. The product models located in the margin offer only a few links back to the center. As a result, this raises the question of how the outputs of these models flow back into the design process. Hence, in future research, missing links, especially from the margin or satellite sectors to the center, should be investigated by example applications of these models combined with interviews. In addition, the observation of design engineers while using multiple product models can be used for gaining further insights into the application of links between specific models. In this respect, the data of the open-source software Gephi provide a continuously expandable knowledge basis for future research projects.

Looking from a user perspective, the landscape is a step towards anticipating the use of several product models during model selection. Starting from a Bond Graph Model, for example, a Behavioral Matrix and a Causal Graph can be built, but only for the Behavioral Matrix a link for continuation to a Functional Means Tree is known. Thus, the selection of the Behavioral Matrix, as described by Cao and Fu (2011), enables the continuation towards the Functional Means Tree for the computer-aided generation and evaluation of multiple design concepts. In contrast, building a Causal Graph, as described by Mokhtarian et al. (2017), enables a designer to analyze design solutions, but no link to the Functional Means Tree is known. In this example, the landscape thus allows designers to evaluate the model selection with regard to the following linking options but not with regard to the purpose of the product models. Based on Jones et al. (2020), accelerating the transitions can increase the efficiency of the design process. Compared to the overviews by Matthiesen et al. (2019b) and Weidmann et al. (2017), other information, such as the purpose of the application of each product model as defined by Andreasen et al. (2015), is not included. As shown in the example, the landscape displays which models can be created with little effort starting from an existing model. However, it does not clarify which of the possible models fits the use case and should, therefore, be chosen. To address this issue, the purpose of the models or a brief description of the application cases of the models has to be integrated into the landscape in the future to serve users as a decision-making tool.

5 Limitations

As a consequence of the applied method, the results and conclusions are subject to the following main limitations: (1) the literature search is limited to the period after 2008. Previously published product models that were not published or mentioned again were consequently not included. This restriction of the publication period was accepted, as the models investigated in the past years are more likely to be relevant in future model research; (2) the literature analysis is based on the textual and linguistic descriptions of inputs and outputs, which means that divergent descriptions of the same items were possibly not recognized as equivalent in exceptional cases. This limitation was addressed by the analysis based on the basic theory. Nevertheless, complete recognition cannot be guaranteed.

Data availability

The authors declare that the data supporting the findings are available within the article and its supplementary information files.

Notes

The TEMA database was not adopted from Matthiesen et al. (2019b), as this database is no longer available due to insolvency.

The time period under consideration was updated to begin at the end of Matthiesen et al.’s (2019b) time period in 2018 and end in August 2022.

For more information, visit https://www.citavi.com/en

Supplementing Matthiesen et al. (2019b), the title and abstract were searched for indicators of the context when no keywords were available.

For more information, see Bastian et al. (2009).

For more information, see Hu (2005).

References

Albers A, Matthiesen S, Revfi S, Schönhoff C, Grauberger P, Heimicke J (2019) Agile lightweight design—the extended target weighing approach in ASD—Agile systems design using functional modelling with the C&C2-approach. Proc Int Conf Eng Des 1:2667–2676. https://doi.org/10.1017/dsi.2019.273

Albers A, Braun A, Clarkson J, Enkler H-G, Wynn D (2009) Contact and Channel Modelling to support early design of technical systems. In: Proceedings of the 17th International Conference on Engineering Design (ICED09), pp. 61–72

Ameri F, Summers JD, Mocko GM, Porter M (2008) Engineering design complexity: an investigation of methods and measures. Res Eng Design 19:161–179. https://doi.org/10.1007/s00163-008-0053-2

Andreasen MM (1994) Modelling—the language of the designer. J Eng Des 5:103–115. https://doi.org/10.1080/09544829408907876

Andreasen MM, Hansen CT, Cash P (2015) Conceptual design. Springer International Publishing, Cham

Aranburu A, Justel D, Contero M, D. Camba J, (2022) Geometric variability in parametric 3D models: implications for engineering design. Procedia CIRP 109:383–388. https://doi.org/10.1016/j.procir.2022.05.266

Atherton M, Jiang P, Harrison D, Malizia A (2018) Design for invention: annotation of functional geometry interaction for representing novel working principles. Res Eng Design 29:245–262. https://doi.org/10.1007/s00163-017-0267-2

Bastian M, Heymann S, Jacomy M (2009) Gephi: an open source software for exploring and manipulating networks. ICWSM 3:361–362. https://doi.org/10.1609/icwsm.v3i1.13937

Baxter D, Gao J, Case K, Harding J, Young B, Cochrane S, Dani S (2008) A framework to integrate design knowledge reuse and requirements management in engineering design. Robot Comput-Integr Manuf 24:585–593. https://doi.org/10.1016/j.rcim.2007.07.010

Beetz J-P, Schlemmer PD, Kloberdanz H, Kirchner E (2018) Using the new working space model for the development of hygienic products. In: Proceedings of International Design Conference, Design, pp. 985–996

Berselli G, Meng Q, Vertechy R, Castelli VP (2016) An improved design method for the dimensional synthesis of flexure-based compliant mechanisms: optimization procedure and experimental validation. Meccanica 51:1209–1225. https://doi.org/10.1007/s11012-015-0276-z

Bilancia P, Berselli G, Bruzzone L, Fanghella P (2017) A practical method for determining the pseudo-rigid-body parameters of spatial compliant mechanisms via CAE tools. Procedia Manuf 11:1709–1717. https://doi.org/10.1016/j.promfg.2017.07.374

Boersting P, Keller R, Alink T, Eckert C, Albers A, Clarkson PJ (2008) The relationship between functions and requirements for an improved detection of component linkages. In: 10th International Design Conference, Design 2008, pp. 309–316

Bonev M, Hvam L, Clarkson J, Maier A (2015) Formal computer-aided product family architecture design for mass customization. Comput Ind 74:58–70. https://doi.org/10.1016/j.compind.2015.07.006

Bornmann L, Mutz R (2015) Growth rates of modern science: a bibliometric analysis based on the number of publications and cited references. J Assn Inf Sci Tec 66:2215–2222. https://doi.org/10.1002/asi.23329

Breiner S, Subrahmanian E, Jones A (2018) Categorical foundations for system engineering. In: Madni AM, Boehm B, Ghanem RG, Erwin D, Wheaton MJ (eds) Disciplinary convergence in systems engineering research. Springer International Publishing, Cham, pp 449–463

Browning TR (2016) Design structure matrix extensions and innovations: a survey and new opportunities. IEEE Trans Eng Manage 63:27–52. https://doi.org/10.1109/TEM.2015.2491283

Buur J, Myrup Andreasen MM (1989) Design models in mechatronic product development. Des Stud 10:155–162. https://doi.org/10.1016/0142-694X(89)90033-1

Cao DX, Fu MW (2011) A knowledge-based prototype system to support product conceptual design. Comput-Aided Design Appl 8:129–147. https://doi.org/10.3722/cadaps.2011.129-147

Chakrabarti A, Shea K, Stone R, Cagan J, Campbell M, Hernandez NV, Wood KL (2011) Computer-based design synthesis research: an overview. J Comput Inf Sci Eng 11:21003. https://doi.org/10.1115/1.3593409

Chen RR, Liu YS, Cao Y, Zhao JJ, Yuan L, Fan HR (2018) ArchME: a systems modeling language extension for mechatronic system architecture modeling. AIEDAM 32:75–91. https://doi.org/10.1017/S0890060417000245

Danjou S, Lupa N, Koehler P (2008) Approach for automated product modeling using knowledge-based design features. Comput-Aided Design Appl 5:622–629. https://doi.org/10.3722/cadaps.2008.622-629

Dantan JY, Qureshi AJ, Antoine JF, Eisenbart B, Blessing L (2013) Management of product characteristics uncertainty based on formal logic and characteristics properties model. CIRP Ann 62:147–150. https://doi.org/10.1016/j.cirp.2013.03.077

Dresch A, Lacerda DP, Antunes JAV (eds) (2015) Design science research. Springer International Publishing, Cham

Eckert C, Hillerbrand R (2018) Models in Engineering Design: Generative and Epistemic Function of Product Models. In: Vermaas P, Vial S (eds) Advancements in the Philosophy of Design, Design Research Foundations. Springer, Cham. https://doi.org/10.1007/978-3-319-73302-9_11

Eckert C, Hillerbrand R (2022) Models in engineering design as decision-making aids. Eng Stud 14:134–157. https://doi.org/10.1080/19378629.2022.2129061

Eifler T, Howard TJ (2018) The importance of robust design methodology: case study of the infamous GM ignition switch recall. Res Eng Design 29:39–53. https://doi.org/10.1007/s00163-017-0251-x

Eisenbart B, Gericke K, Blessing LTM (2017) Taking a look at the utilisation of function models in interdisciplinary design: insights from ten engineering companies. Res Eng Design 28:299–331. https://doi.org/10.1007/s00163-016-0242-3

Elwert M, Ramsaier M, Eisenbart B, Stetter R (2019) Holistic digital function modelling with graph-based design languages. Proc Int Conf Eng Des 1:1523–1532. https://doi.org/10.1017/dsi.2019.158

Elwert M, Ramsaier M, Eisenbart B, Stetter R, Till M, Rudolph S (2022) Digital function modeling in graph-based design languages. Applied Sciences (switzerland). https://doi.org/10.3390/app12115301

Eppinger SD, Browning TR (2012) Design structure matrix methods and applications. MIT Press, Cambridge, Mass, USA, Engineering systems

Fang HC, Ong SK, Nee A (2014) Product remanufacturability assessment based on design information. Procedia CIRP 15:195–200. https://doi.org/10.1016/j.procir.2014.06.050

Favi C, Mandolini M, Campi F, Germani M (2021) A CAD-based design for manufacturing method for casted components. Procedia CIRP 100:235–240. https://doi.org/10.1016/j.procir.2021.05.061

Feldhusen J, Grote K-H (eds) (2013) Pahl/Beitz konstruktionslehre: methoden und anwendung erfolgreicher produktentwicklung, 8th edn. Springer Vieweg, Berlin, Heidelberg

Freund T, Kloberdanz H, Wuertenberger J, Lotz J (2015) An Approach to Analysing Interface Uncertainty using the Contact and Channel Model. In: DS 80–6 Proceedings of the 20th International Conference on Engineering Design (ICED 15) Vol 6: Design Methods and Tools—Part 2. pp.53–62

Gadeyne K, Pinte G, Berx K (2014) Describing the design space of mechanical computational design synthesis problems. Adv Eng Inform 28:198–207. https://doi.org/10.1016/j.aei.2014.03.004

Gao FJL, Qian ZQ, Wang XJ, Bi ZM, Zhang WJ (2015) A novel approach to embodiment design of a robotic system for maximum workspace. IEEE 10th Conf Ind Electron Appl. https://doi.org/10.1109/ICIEA.2015.7334170

Gericke K, Eisenbart B (2017) The integrated function modeling framework and its relation to function structures. AIEDAM 31:436–457. https://doi.org/10.1017/S089006041700049X

Gladysz B, Albers A (2018a) C&C2-AFM—An embodiment design- and function-based approach for analysis of failure mechanisms. Procedia CIRP 70:53–58. https://doi.org/10.1016/j.procir.2018.03.244

Gladysz B, Albers A (2018) How Do C&C2-Models Improve Efficiency, Comprehensibility and Scope In Failure Analysis-an Empirical Study Based on Two Live-Labs. In: Proceedings of International Design Conference, Design, pp.1127–1138

Gladysz B, Megner T, Mayer MP, Albers A (2018) How do C&C2-models improve the understanding of system behaviour in failure analysis?. In: DS 91: Proceedings of NordDesign 2018

Goel AK, Vattam S, Wiltgen B, Helms M (2012) Cognitive, collaborative, conceptual and creative—four characteristics of the next generation of knowledge-based CAD systems: a study in biologically inspired design. Comput Aided Des 44:879–900. https://doi.org/10.1016/j.cad.2011.03.010

Grauberger P, Goetz S, Schleich B, Gwosch T, Matthiesen S, Wartzack S (2020a) A conceptual model combination for the unification of design and tolerancing in robust design. Proc Des Soc: Des Conf 1:157–166. https://doi.org/10.1017/dsd.2020.12

Grauberger P, Bremer F, Sturm C, Hoelz K, Wessels H, Gwosch T, Wagner R, Lanza G, Albers A, Matthiesen S (2020c) Qualitative modelling in embodiment design—investigating the contact and channel approach through analysis of projects. Proc Design Society: Design Conf 1:897–906. https://doi.org/10.1017/dsd.2020.260

Grauberger P, Heimicke J, Nann S, Albers A, Matthiesen S (2020b) A guideline for modelling relations of embodiment and function in agile development. Appl Sci. https://doi.org/10.1007/s42452-020-03271-3

Grauberger P, Wessels H, Gladysz B, Bursac N, Matthiesen S, Albers A (2020d) The contact and channel approach–20 years of application experience in product engineering. J Eng Des 31:241–265. https://doi.org/10.1080/09544828.2019.1699035

Grauberger P, Eisenmann M, Stoitzner J, Matthiesen S (2021) Enhancing design method training with insights from educational research–improving and evaluating a training course for a qualitative modelling method. SN Appl Sci. https://doi.org/10.1007/s42452-021-04817-9

Grauberger P, Bremer F, Pfaff F, Tröster P, Nelius T, Eisenmann M, Stöberl T, Albers A, Matthiesen S (2022) Gaining insights through qualitative modelling—industrial project analysis with focus on derived hypotheses based on the contact and channel approach. Procedia CIRP 109:478–483. https://doi.org/10.1016/j.procir.2022.05.281

Gu C-C, Hu J, Peng Y-H, Li S (2012) FCBS model for functional knowledge representation in conceptual design. J Eng Des 23:577–596. https://doi.org/10.1080/09544828.2011.629318

He B, Huang S (2016) Functional synthesis of mechanisms under cost consideration. Proc Institution Mech Eng, Part b: J Eng Manuf 230:91–99. https://doi.org/10.1177/0954405414542138

He B, Cao JT, He XL, Jin ZX, Fang ML (2012) Lifting platform in jack-up offshore platform based on virtual prototyping. AMM. https://doi.org/10.4028/www.scientific.net/AMM.198-199.154

He B, Song W, Wang Y (2013) A feature-based approach towards an integrated product model in intelligent design. Int J Adv Manuf Technol 69:15–30. https://doi.org/10.1007/s00170-013-4991-0

He B, Song W, Wang Y (2015) Computational conceptual design using space matrix. J Comput Inf Sci Eng 15:11004. https://doi.org/10.1115/1.4029062

Hmina K, Sallaou M, Ait Taleb A, Lasri L, El Amine M (2021) A preliminary design embodiment analysis through the graph theory implementation. Int J Interact Des Manuf 15:21–33. https://doi.org/10.1007/s12008-020-00706-4

Hu Y (2005) Efficient, high-quality force-directed graph drawing. Mathematica Journal 10:37–71

Jones DE, Snider C, Hicks B (2020) A framing of design as pathways between physical, virtual and cognitive models. Proc Design Soc: Design Conf 1:41–50. https://doi.org/10.1017/dsd.2020.128

Köhler C (2009) Technische Produktänderungen—Analyse und Beurteilung von Lösungsmöglichkeiten auf Basis einer Erweiterung des CPM/PDD-Ansatzes. Dissertation, Universität des Saarlandes

Künne B, Wieczorek D (2010) Research to optimize the embodiment design of modules and components used in roller conveyors. 2010 IEEE Int Conf Autom Logist. https://doi.org/10.1109/ICAL.2010.5585333

Langeveld L (2011) Product design with embodiment design as a new perspective. In: Coelho D (ed) Industrial design. New frontiers, pp 121–146

Leu MC, Wu JC, Liu XF (2009) Axiomatic functional and object-oriented product design framework. CIRP Ann 58:147–152. https://doi.org/10.1016/j.cirp.2009.03.017

Maier AM, Wynn DC, Howard TJ, Andreasen MM (2014) Perceiving design as modelling: a cybernetic systems perspective. In: Chakrabarti A, Blessing LTM (eds) An anthology of theories and models of design: philosophy, approaches and empirical explorations. Springer, London, pp 133–149

Maier JF, Eckert CM, John Clarkson P (2017) Model granularity in engineering design. Des Sci. https://doi.org/10.1017/dsj.2016.16

Matthiesen S, Grauberger P, Schrempp L (2019a) Extended sequence modelling in design engineering—gaining and documenting knowledge about embodiment function relations with the C&C2-approach. Proc Int Conf Eng Des 1:1483–1492. https://doi.org/10.1017/dsi.2019.154

Matthiesen S, Grauberger P, Bremer F, Nowoseltschenko K (2019b) Product models in embodiment design: an investigation of challenges and opportunities. SN Appl Sci. https://doi.org/10.1007/s42452-019-1115-y

Mokhtarian H, Coatanéa E, Paris H (2017) Function modeling combined with physics-based reasoning for assessing design options and supporting innovative ideation. AIEDAM 31:476–500. https://doi.org/10.1017/S0890060417000403

Morales F, Osorio-Gómez G, Morales J (2022) Proto-arch: guidance tool for prototyping of mechanical systems at the embodiment design phase. Proc Design Soc 2:425–434. https://doi.org/10.1017/pds.2022.44

Muenzer C, Shea K (2017) Simulation-based computational design synthesis using automated generation of simulation models from concept model graphs. J Mech Des 139:71101. https://doi.org/10.1115/1.4036567

Müller JR, Panarotto M, Isaksson O (2019a) Connecting functional and geometrical representations to support the evaluation of design alternatives for aerospace. Proc Int Conf Eng Des 1:1423–1432. https://doi.org/10.1017/dsi.2019.148

Müller JR, Isaksson O, Landahl J, Raja V, Panarotto M, Levandowski C, Raudberget D (2019b) Enhanced function-means modeling supporting design space exploration. Artif Intell Eng Design, Anal Manuf: AIEDAM 33:502–516. https://doi.org/10.1017/S0890060419000271

Müller JR, Panarotto M, Isaksson O (2020) Design space exploration of a jet engine component using a combined object model for function and geometry. Aerospace. https://doi.org/10.3390/aerospace7120173

Nagel RL, Stone RB, Hutcheson RS, McAdams DA, Donndelinger JA (2008) Function Design Framework (FDF): Integrated Process and Function Modeling for Complex Systems. In: Proceedings of the ASME 2008 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Volume 4: 20th International Conference on Design Theory and Methodology; Second International Conference on Micro- and Nanosystems. ASME, pp. 273–286

Pahl G, Beitz W (1996) Embodiment design. In: Pahl G, Beitz W, Wallace K (eds) Engineering design. Springer, London, pp 199–403

Rajaguru P, Stoyanov S, Tang YK, Bailey C, Claverley J, Leach R, Topham D (2010) Numerical modelling methodology for design of miniaturised integrated products—an application to 3D CMM micro-probe development. In: 2010 11th International Thermal, Mechanical & Multi-Physics Simulation, and Experiments in Microelectronics and Microsystems (EuroSimE). IEEE, pp. 1–8

Rasoulifar G, Prudhomme G, Brissaud D (2012) Coupling engineering knowledge with product design knowledge by the means of multiple view product model. In: Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis. Volume 3: Advanced Composite Materials and Processing; Robotics; Information Management and PLM; Design Engineering. ASME, pp. 777–783

Reich Y (2010) My method is better! Res Eng Design 21:137–142. https://doi.org/10.1007/s00163-010-0092-3

Riascos R, Levy L, Stjepandić J, Fröhlich A (2015) Digital Mock-up. In: Stjepandić J, Wognum N, Verhagen W (eds) Concurrent engineering in the 21st century. Springer International Publishing, Cham, pp 355–388

Rihtaršič J, Žavbi R, Duhovnik J (2012) Application of wirk elements for the synthesis of alternative conceptual solutions. Res Eng Design 23:219–234. https://doi.org/10.1007/s00163-012-0127-z

Sarkar B, Chakrabarti A, Ananthasuresh GK (2017) Synthesis of feedback-based design concepts for sensors. Res Eng Design 28:131–151. https://doi.org/10.1007/s00163-016-0231-6

Schmitt F, Kirchner E (2022) The quantitative Working Space Model. In: DS 118: Proceedings of Nord Design 2022, pp. 1–12

Seybold C, Mantwill F (2021) 3D sketches in virtual reality and their effect on development times. Proc Design Soc 1:1–10. https://doi.org/10.1017/pds.2021.1

Shaked A, Reich Y (2021) Using domain-specific models to facilitate model-based systems-engineering: development process design modeling with OPM and PROVE. Appl Sci-Basel 11:1532. https://doi.org/10.3390/app11041532

Stachowiak H (1973) Allgemeine modelltheorie. Springer Verlag, Wien

Subrahmanian E, Konda SL, Levy SN, Reich Y, Westerberg AW, Monarch I (1993) Equations aren’t enough: informal modeling in design. AIEDAM 7:257–274. https://doi.org/10.1017/S0890060400000354

Suh NP (2005) Complexity in engineering. CIRP Ann 54:46–63. https://doi.org/10.1016/S0007-8506(07)60019-5

Tomiyama T, D’Amelio V, Urbanic J, ElMaraghy W (2007) Complexity of multi-disciplinary design. CIRP Ann 56:185–188. https://doi.org/10.1016/j.cirp.2007.05.044

Vlah D, Čok V, Urbas U (2021) Vr as a 3d modelling tool in engineering design applications. Appl Sci (switzerland). https://doi.org/10.3390/app11167570

Weber C (2014) Modelling products and product development based on characteristics and properties. In: Chakrabarti A, Blessing LTM (eds) An anthology of theories and models of design: philosophy, approaches and empirical explorations. Springer, London, pp 327–352

Weber C (2005) CPM/PDD - An Extended Theoretical Approach to Modelling Products and Product Development Processes. In: Proceedings of the 2nd German—Israeli Symposium. Fraunhofer-IRB-Verlag, Stuttgart, Germany

Weidmann D, Isemann M, Kandlbinder P, Hollauer C, Kattner N, Becerril L, Lindemann U (2017) Product Models in Mechatronic Design: Literature Analysis on the Interdisciplinary Character of Product Models. In: 2017 Portland International Conerence on Management of Engineering and Technology (PICMET). IEEE, pp. 1–7

Wettstein A, Grauberger P, Matthiesen S (2021) Modeling dynamic mechanical system behavior using sequence modeling of embodiment function relations: case study on a hammer mechanism. SN Appl Sci. https://doi.org/10.1007/s42452-021-04149-8

Wilschut T, Etman LF, Rooda JE, Vogel JA (2018) Generation of a function-component-parameter multi-domain matrix from structured textual function specifications. Res Eng Design 29:531–546. https://doi.org/10.1007/s00163-018-0284-9

Wisnesky R, Breiner S, Jones A, Spivak DI, Subrahmanian E (2017) Using category theory to facilitate multiple manufacturing service database integration. J Comput Inf Sci Eng 10(1115/1):4034268

Wolfswinkel JF, Furtmueller E, Wilderom CPM (2013) Using grounded theory as a method for rigorously reviewing literature. Eur J Inf Syst 22:45–55. https://doi.org/10.1057/ejis.2011.51

Wölkl S, Shea K (2009) A Computational Product Model for Conceptual Design Using SysML. In: Proceedings of the ASME 2009 international design engineering technical conferences and computers and information in engineering conference. Volume 2: 29th computers and information in engineering conference, Parts A and B. ASME, pp. 635–645

Wynn DC, Clarkson PJ (2018) Process models in design and development. Res Eng Design 29:161–202. https://doi.org/10.1007/s00163-017-0262-7

Zhan W, Huang P (2018) Physics-based modeling for lap-type joints based on the iwan model. J Tribol 140:51401. https://doi.org/10.1115/1.4039530

Zheng C, Hehenberger P, Le Duigou J, Bricogne M, Eynard B (2017) Multidisciplinary design methodology for mechatronic systems based on interface model. Res Eng Design 28:333–356. https://doi.org/10.1007/s00163-016-0243-2

Zingel C, Albers A, Matthiesen S, Maletz M (2012) Experiences and advancements from one year of explorative application of an integrated model-based development technique using C&C 2-A in SysML. IAENG Int J Comput Sci 39:165–181

Acknowledgements

The research documented in this manuscript has been funded by the German Research Foundation (DFG) within the project “Research map of models for modelling embodiment and function of technical systems to support linked model usage” (446789859). The support by the German Research Foundation (DFG) is gratefully acknowledged.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

L. Paehler conducted the research of this contribution under the supervision of S. Matthiesen. The authors wrote and edited the manuscript in close collaboration and continuously reviewed each other's progress.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix

Appendix

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Paehler, L., Matthiesen, S. Mapping the landscape of product models in embodiment design. Res Eng Design (2024). https://doi.org/10.1007/s00163-024-00433-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00163-024-00433-x