Abstract

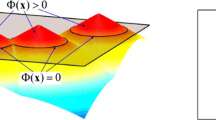

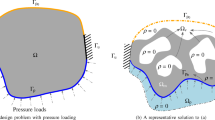

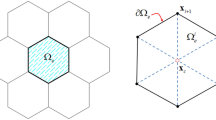

A new multiscale shape and topology optimization method is presented to design closed liquid cell materials based on the extended multiscale finite element method, which directly captures the small scale features to the large scale computation. The multiscale optimization method firstly focuses on seeking the optimum geometrical parameters and volume expansion of the fluid in the closed liquid cells in the microscale level in terms of maximizing the macroscale mechanical response of the structure. Furthermore, a new hierarchical multiscale optimization method is developed to optimize the macroscale distributions of closed liquid cells and the microscale shape of the fluid inclusion in the cells. In the macroscale level of the multiscale optimization method, the macroscale design domain is discretized by the multiscale coarse elements, while the shape of the fluid inclusions is set to be the design parameters in the microscale level. This method is firstly utilized to minimize the system compliance of the closed liquid cell structure. Moreover, due to the fact that non-uniform volume expansions of the fluid in cells can induce the elastic action, the multiscale optimization method is further extended to design biomimetic compliant actuators of the closed liquid cell materials. The multiscale optimization methods developed are implemented in the FE-package SiPESC, and the numerical examples are carried out to validate the accuracy of the methods proposed.

Similar content being viewed by others

References

Andreasen CS (2011) Multiscale topology optimization of solid and fluid structures. Dept of Mechanical Engineering, Technical University of Denmark, PhD thesis

Andreasen C, Sigmund O (2011) Saturated poroelastic actuators generated by topology optimization. Struct Multidiscip Optim 43:693–706

Andreassen E, Clausen A, Schevenels M, Lazarov BS, Sigmund O (2011) Efficient topology optimization in MATLAB using 88 lines of code. Struct Multidiscip Optim 43:1–16

Bendsoe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71:197–224

Bendsøe MP, Sigmund O (2003) Topology optimization. Theory, methods, and applications. Springer, New York

Chen BS, Liu G, Kang J, Li YP (2007) Design optimization of stiffened storage tank for spacecraft. Struct Multidiscip Optim 36:83–92

Coelho PG, Fernandes PR, Guedes JM (2008) A hierarchical model for concurrent material and topology optimization of three-dimensional structures. Struct Multidiscip Optim 35:107–115

Freeman E, Weiland LM (2009) High energy density nastic materials: parameters for tailoring active response. J Intell Mater Syst Struct 20(2):233–243

Georget MDR, Smith AC, Waldron KW (2003) Modeling of carrot tissue as a fluid-filled foam. J Mater Sci 38(9):1933–1938

Giurgiutiu V, Matthews L, Leo DJ, et al (2005) Concepts for power and energy analysis in nastic structures. Proceedings of ASME-IMECE. International mechanical engineering conference and exposition, Orlando

Guest JK, Prévost JH (2006) Optimizing multifunctional materials: design of microstructures for maximized stiffness and fluid permeability. Int J Solids Struct 43:7028–7047

Guest JK, Prévost JH (2007) Design of maximum permeability material structures. Comput Methods Appl Mech 196:1006–1017

Guo X, Cheng GD (2010) Recent development in structural design and optimization. Acta Mech Sinica 26:807–823

Hartmann C, Delgado A (2004) Numerical simulation of the mechanics of yeast cell under high hydrostatic pressure. J Biomech 37:977–987

Hartmann C, Mathmann K, Delgado A (2006) Mechanical stresses in cellular structures under high hydrostatic pressure. Innov Food Sci Emerg 7:1–12

Hou TY, Wu XH (1997) A multiscale finite element method for elliptic problems in composite materials and porous media. J Comput Phys 134:169–189

Hou TY, Wu XH, Cai ZQ (1999) Convergence of a multiscale finite element method for elliptic problems with rapidly oscillating coefficients. Math Comput 68:913–943

Ken-ichiro M, Kozo O, Masanori S (1991) Finite element modeling of forming process of solid metal with liquid phase. J Mater Process Technol 27:111–118

Liu ST, Su WZ (2010) Topology optimization of couple-stress material structures. Struct Multidiscip Optim 40:319–327

Liu L, Yan J, Cheng GD (2008) Optimum structure with homogeneous optimum truss-like material. Comput Struct 86:1417–1425

Luo Z, Tong LY, Ma HT (2009) Shape and topology optimization for electrothermomechanical microactuators using level set methods. J Comput Phys 228:3173–3181

Ma LH, Rolfe BF, Yang QS, Yang CH (2011) The configuration evolution and macroscopic elasticity of fluid-filled closed cell composites: micromechanics and multiscale homogenization modeling. CMES-Comput Model Eng 72(2):131–158

Nilsson SB, Hertz CH, Falk S (1958) On the relation between turgor pressure and tissue rigidity II. Physiol Plant 11:818–837

Niu B, Yan J, Cheng GD (2009) Optimum structure with homogeneous optimum cellular material for maximum fundamental frequency. Struct Multidiscip Optim 39:115–132

O’Connell R, Budiansky B (1974) Seismic velocities in dry and saturated cracked solids. J Geophy Res 79:5412–5426

Ozgur M, Mullen RL, Welsch G (1996) Analysis of closed cell metal composites. Acta Mater 44(5):2115–2126

Rodrigues H, Guedes JM, Bendsoe MP (2002) Hierachical optimization of material and structure. Struct Multidiscip Optim 24:1–10

Rohan E (2006) Modeling large-deformation-induced microflow in soft biological tissues. Theor Comput Fluid Dyn 20(4):251–276

Sigmund O (2001a) Design of multiphysics actuators using topology optimization-Part I: One-material structures. Comput Methods Appl Mech Eng 190:6577–6604

Sigmund O (2001b) A 99 line topology optimization code written in Matlab. Struct Multidiscip Optim 21:120–127

Smith AE, Moxham KE, Middelberg APJ (1998) On uniquely determining cell-wall material properties with the compression experiment. Chem Eng Sci 53:3913–3922

Stenson JD, Thomas CR, Hartley P (2009) Modelling the mechanical properties of yeast cells. Chem Eng Sci 64:1892–1903

Sundaresan VB, Leo DJ (2006) Chemo-mechanical model for actuation based on biological membranes. J Intell Mater Syst Struct 17:863–870

Suquet PM (1987) Elements of homogenization theory for inelastic solid mechanics. In: Sanchez-Palencia E, Zaoui A (eds) Homogenization techniques for composite media. Springer, Berlin, pp 194–275

Svanberg K (1987) The method of moving asymptotes-a new method for structural optimization. Int J Numer Methods Eng 24(2):359–373

Terada K, Kikuchi N (2001) A class of general algorithms for multi-scale analyses of heterogeneous media. Comput Methods Appl Mech 190:5427–5464

Yan J, Cheng GD, Liu L (2008) A uniform optimum material based model for concurrent optimization of thermoelastic structures and materials. Int J Simul Multidiscip Des Optim 2:259–266

Yang CF, Chen BS, Zhang S, Li YP, Zhang HW (2011) Design and implementation of general integrated optimization design software SiPESC.OPT. Comput Aided Eng 20(4):42–48(in Chinese)

Zhang HW, Lv J (2011) Two-scale model for mechanical analysis of nastic materials and structures. J Intell Mater Syst Struct 22:593–609

Zhang HW, Lv J, Zheng YG (2010a) A new multiscale computational method for mechanical analysis of closed liquid cell materials. CMES-Comput Model Eng 68(1):55–93

Zhang HW, Wu JK, Lv J, Fu ZD (2010b) Extended multiscale finite element method for mechanical analysis of heterogeneous materials. Acta Mech Sinica 26:899–920

Zhang HW, Chen BS, Li YP, Peng HJ (2011) Advancement of design and implementation of SiPESC for development of integrated CAE software systems. Comput Aided Eng 20(2):39–49(in Chinese)

Acknowledgments

The supports of the National Natural Science Foundation (11232003, 11072051, 11302040, 91315302), the National Key Basic Research Special Foundation of China (2010CB832704), China Postdoctoral Science Foundation (2013M530908) and the 111 Project (No.B08014) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lv, J., Zhang, H.W. & Chen, B.S. Shape and topology optimization for closed liquid cell materials using extended multiscale finite element method. Struct Multidisc Optim 49, 367–385 (2014). https://doi.org/10.1007/s00158-013-0976-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-013-0976-8