Abstract

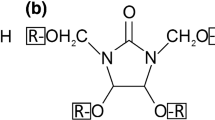

Not before the year 2016, the European standard system did allow for classifying the durability of treated wood in addition to natural durability of untreated wood species. After its latest revision, EN 350 (2016) allows a durability classification of solid wood and wood-based materials with the help of five durability classes (DC) between ‘very durable’ (DC 1) and ‘non-durable’ (DC 5). However, different test methods, assessment measures, and calculation methods can be used for durability classification. This inevitably leads to different assessments of the biological durability of wood. This study aimed therefore on a comparative durability classification of preservative-treated and chemically modified wood (here: treated with 1,3-dimethylol-4,5-dihydroxyethyleneurea, DMDHEU) using different laboratory and field test methods. Durability classes of the tested timbers differed not only between tested materials, but depended also on the applied test, assessment, and calculation method. In this respect, the use of relative values (x-values), i.e., mass loss (ML) or MOE loss data compared with a non-durable reference material can help to harmonize the classification and make DCs more comparable. The use of relative values can also help to reduce the effect of varying virulence of test fungi, activity of test soil substrates, and the climate-induced hazard of test sites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the building sector, wood needs to compete with many other materials. An important criterion within this competition is its biological durability. According to EN 1001 (2021) wood’s durability to biological agents is defined as the ‘inherent resistance of a wood species or a wood-based material against wood decay organisms’. Customers request an easy system for the classification of wood durability that allows comparative assessment of different wood species and treatments, ideally also with different non-wood materials.

Not before the year 2016, the European standard system did allow for classifying the durability of treated wood in addition to natural durability of untreated wood species. After its latest revision, EN 350 (2016) allows a durability classification of solid wood and wood-based materials with the help of five durability classes (DC) between ‘very durable’ (DC 1) and ‘non-durable’ (DC 5). Wood-based materials are defined as ‘any processed matrix containing and/or made of a specific percentage of wood. […] Wood-based materials are those derived from trees and include amongst others: untreated wood, heat treated wood, chemically modified wood, glue laminated wood, wood-based panels, wood polymer composites and wood treated with wood preservatives’ (EN 350, 2016).

In principle, the durability of wood-based materials against wood-destroying fungi can be determined in laboratory and field tests; and both can be performed with and without soil contact. Soil contact field tests, so-called grave-yard tests, can be conducted according to EN 252 (2015) where wood stakes are buried in the ground to half of their length and assessed annually with respect to the occurrence and extent of decay. In analogy, decay can be assessed on wood specimens exposed above ground. However, the few European standard methods were not intended for testing durability, but the efficacy of wood preservatives (EN/TS 12037, 2022; EN 330, 2015). Nevertheless, EN 350 (2016) allows to use both standardized and non-standardized above-ground field test methods for determining the biological durability of wood. Among the latter are ground proximity (AWPA 2018) and double-layer tests (Rapp and Augusta 2004) as well as the Bundle test (Brischke et al. 2023a) that was applied in this study. However, the standard EN 350 (2016) lacks guidance on durability classification for each of these above-ground test methods. Hence, the assessment scheme and related measures have been frequently adapted from in-ground tests according to EN 252 (2015) and so did we in this study.

In laboratory, mass loss (ML) data from agar plate tests with basidiomycete monocultures according to EN 113–2 (2021) can be used to assign DCs. Depending on the test material, different white and brown rot fungi are obligatory. The basis for durability classification is the median ML, but the variability in durability shall be regarded through looking at empirical distributions (EN 350, 2016). Different probability density functions can also be applied to the ML data to assign DCs, whereas the required procedure stays unclear to a certain extent (Brischke et al. 2023b). However, variability can get indicated through a range of DCs or the index ‘v’ (‘variable’). In contrast to EN 113–2 (2021), durability classification on the basis of data from soil bed tests (CEN/TS 15083–2, 2005) refer to relative values. Relative ML data are used for classifying hardwoods, and relative MOE (modulus of elasticity) loss data for softwoods. Consequently, different materials are treated differently during durability testing and classification. Further inhomogeneity comes into play with the spans of relative values (i.e., x-values) assigned to the five durability classes as shown in Table 1. It stays unclear whether these discrepancies are the result of an adaptation process to align with an existing durability classification of wood species, e.g., according to EN 350–2 (1994) or have been made arbitrarily. Different authors reported on the dependence of durability classification on the applied test methods and assessment measures such as differences between ML data and x-values (Van Acker et al. 1999; Plaschkies et al. 2014) and between ML and MOE loss data (Militz et al. 2003; Brischke et al. 2018), while others (e.g., Van Acker et al. 2003) found similar DCs using percentage ML and x-values from previous versions of EN 350, i.e., EN 350–1 (1994).

Another shortcoming of the current normative specification is a lack of guidance on the sampling of wood-based materials, especially if those are impregnated with preservatives or other modifying chemicals. Solely, the following general instructions are provided by EN 350 (2016):

-

The sampling should take into account the variability of the wood-based material to be tested.

-

For each variation in processing parameters (e. g. change in temperature, particle size, wood species), a minimum of 30 specimens is required (from at least 3 produced items, e. g. boards) sampled at random from 3 different batches. A minimum of 5 specimens from each batch should be tested.

-

If the material contains sapwood and heartwood, care has to be taken that both sapwood and heartwood are used to produce test specimens.

From this, no exact sampling procedure can be derived, which will particularly have an impact on the durability assessment of heterogeneous or heterogeneously treated materials such as impregnated boards or poles. Hence, performance or product testing appears more appropriate compared to material testing (Brischke et al. 2023c), but respective test methods are neither standardized nor established, yet.

The aim of this study was the durability classification of chemically modified (1,3-dimethylol-4,5-dihydroxyethyleneurea, DMDHEU) and preservative-treated timber made from different hardwood and softwood species. The impact of different test methods (laboratory and field tests) and evaluation criteria on the durability classification should be examined and proposals for harmonization should be made. For this purpose, ML and MOE loss data from agar plate and soil bed tests respectively, as well as decay ratings from graveyard and Bundle-tests should be determined and used for assigning DC of the differently treated wood-based materials according to EN 350 (2016).

2 Materials and methods

2.1 Wood specimens

Specimens of 15 × 25 × 50 (ax.) mm3 (basidiomycete test), 5 × 10 × 100 (ax.) mm3 (soft rot test), 25 × 50 × 500 (ax.) mm3 (graveyard test), and 25 × 50 × 500 (ax.) mm3 and 25 × 50 × 250 (ax.) mm3 (Bundle-test) were made from Scots pine sapwood (Pinus sylvestris), Radiata pine sapwood (Pinus radiata), Poplar (Populus nigra), Beech (Fagus sylvatica), and Norway spruce (Picea abies). The Norway spruce specimens were used exclusively as additional untreated controls. All specimens were free from defects such as cracks, knots, resin pockets, discoloration and decay. The specimens were modified with 1,3-dimethylol-4,5-dihydroxyethyleneurea (DMDHEU) or treated with a water-based copper-containing wood preservative. All treatments were carried out in a semi-industrial scale impregnation plant at the University of Goettingen. Table 2 gives an overview of the wood species and treatment levels.

After conditioning at 20 °C, 65% relative humidity (RH), specimens of each wood species for the different tests were impregnated under vacuum pressure (1 h at 50 mbar, 2 h at 12 bar) with 20, 30 and 50% aqueous solutions of a commercially available DMDHEU formulation (active DMDHEU content: 70%). After impregnation, treated boards were wrapped in foil and stored under room climate conditions (20 °C) for 120 h. Subsequently, impregnated specimens were transferred to a superheated steam drying process and the modification chemical (DMDHEU) was cured at 120 °C (curing phase: 24 h).

Identic process conditions (1 h at 50 mbar, 2 h at 12 bar) were applied during the preservative treatment of corresponding wood specimens, which had been conditioned at 20 °C, 65% RH prior to the impregnation. A commercially available water-based copper-containing wood preservative was selected, which was marked as preventive against insects and fungi, suitable for weathered wood, and in soil or fresh water contact according to DIN 68800–3 (2020), and thus was permitted for use classes (UC) 1, 2, 3 and 4 applications (EN 335, 2013). Specimens were treated with the preservative concentration recommended for UC 3 applications (technical data sheet, 1.0) as well as one quarter (0.25), one half (0.5) and double (2.0) of this obligatory UC 3 concentration. Afterwards, the active ingredients were fixated inside the wooden structure by storing impregnated specimens at 20 °C, 65% RH for 504 h.

2.2 Durability tests with monocultures of Coniophora puteana and Trametes versicolor

Laboratory decay resistance tests were conducted according to a modified EN 113–2 (2021) protocol as follows: Thirty replicate specimens were oven-dried at 103 °C until constant mass, and weighed to the nearest 0.001 g. Afterwards, all specimens underwent a leaching procedure according to EN 84 (2020), were oven-dried, weighed again, and conditioned at 20 °C/65%RH to constant mass. Two specimens of the same material were steam-sterilized (20 min at 121 °C in an autoclave) and placed on fungal mycelium in a Kolle flask. To avoid direct contact between wood and overgrown malt agar (4%) stainless steel washers were placed in between. The incubation time was 16 weeks. The following test fungi were used: Coniophora puteana = (Schum.:Fr.) P. Karsten BAM Ebw. 15 and Trametes versicolor = (L.:Fr.) Pilat CTB 863A. Each wood-based material was incubated with both test fungi. After incubation, the specimens were cleaned from adhering mycelium, weighed to the nearest 0.001 g, oven-dried, weighed again, and mass loss (MLF) was calculated according to Eq. 1.

Calculation of percentage mass loss by fungal decay MLF [%]:

- m0,L:

-

oven-dry mass before incubation after leaching [g]

- m0,F:

-

oven-dry mass after incubation [g]

2.3 Durability tests in terrestrial microcosms against soft-rot causing micro fungi

Prior to a soil bed test in unsterile soil according to CEN/TS 15083–2 (2005), the specimens underwent a leaching procedure according to EN 84 (2020). Before and after leaching, the specimens were oven-dried at 103 °C and weighed to the nearest 0.001 g. In accordance with CEN/TS 15083–2 (2005), treated and untreated hardwoods were tested as follows:

-

After 16 weeks of exposure in a compost-sand soil substrate (produced at the University of Goettingen), the test specimens were removed from the soil and oven-dried. The mean water holding capacity (WHC) of the soil substrate was 60% and the soil moisture was maintained at 95% of its WHC. After 16 weeks of exposure, the required minimum ML of 20% was exceeded and the test was terminated. The reference wood species for hardwoods was beech.

Treated and untreated softwoods were tested according to CEN/TS 15083–2 (2005) as follows:

-

Before exposure to soil contact, the specimens were immersed in water for 2 h as described in EN 84 (2020), and then subjected to 3-point-bending tests using the universal testing machine Zwick 10 kN (ZWICK GmbH and Co. KG, Ulm, Germany) for determining the flexural modulus of elasticity (MOE). Afterwards, the test specimens were conditioned at 20 °C/65% RH to constant mass and exposed to the soil.

-

After 32 weeks, the test specimens were removed from the soil, immersed in water for 2 h according to EN 84 (2020) and submitted again to a 3-point-bending test for determining the MOE. The difference in MOE before and after the test was used to determine the decrease in MOE (MOE loss, Eq. 2)). Subsequently, the test specimens were oven-dried again to determine their ML.

Calculation of percentage MOE loss by fungal decay [%]:

- MOEL:

-

MOE before incubation of wet specimens after leaching [N/mm²]

- MOEF:

-

MOE of wet specimens after incubation [N/mm²]

2.4 Durability field tests (Graveyard and Bundle-tests)

Durability field tests with all materials were conducted at the North Campus test site of the University of Goettingen. In-ground durability tests were performed according to EN 252 (2015). Therefore, n = 10 specimens were buried to half of their length and assessed annually with respect to the occurrence of decay. With the help of a pick-test using a pointed knife, depth and distribution of decay were rated according to EN 252 (2015) on a five-step scale as 0 (sound), 1 (slight attack), 2 (moderate attack), 3 (severe attack), or 4 (failure).

Above-ground durability tests were performed using the Bundle-test method (Brischke et al. 2023a). Therefore, specimens were exposed horizontally on aluminium L-profiles on racks 20 cm from the ground, which was kept free from vegetation. The specimens consisted of three segments, one bottom segment of 25 × 50 x 500 (ax.) mm3, and two upper segments of 25 × 50 x 250 (ax.) mm3 held together with cable straps (Fig. 1).

The specimens were dismantled and assessed annually with respect to the occurrence of decay. In analogy to the in-ground test specimens, the EN 252 (2015) rating scheme was used, but slightly modified with respect to the failure criterion. As soon as the decayed cross-sectional area exceeded 50% the test specimen was considered to fail.

2.5 Durability classification and statistical analysis

The durability of the differently treated materials was classified according to EN 350 (2016). In addition, and deviating from the standard, the durability classification was based on different measures for comparison as follows (Table 1):

-

median mass loss MLF (EN 113–2, 2021)

-

x-value based on median MLF (CEN/TS 15083–2, 2005, see Eq. 3)

-

x-value based on median MOE loss (CEN/TS 15083–2, 2005, see Eq. 4)

-

f-value based on the median decay rate v (Brischke et al. 2023a, Eq. 7)

Calculation of x-values based on median mass loss by fungal decay [-]:

- MLmedian,test:

-

percentage mass loss of tested material [%]

- MLmedian,reference:

-

percentage mass loss of untreated reference [%]

Calculation of x-values based on median MOE loss by fungal decay [-]:

- MOE lossmedian,test:

-

percentage mass loss of tested material [%]

- MOE lossmedian,reference:

-

percentage mass loss of untreated reference [%]

Calculation of x-values based on mean Lifetime [-]:

Calculation of inverse x-values based on mean Lifetime [-]:

- Lifetimemean,reference:

-

Mean lifetime of the untreated reference specimens [years]

- Lifetimemean,test:

-

Mean lifetime of the tested material [years]

Calculation of f-values (durability factors) based on the median decay rate [-]:

- vmedian,reference:

-

highest median decay rate of the reference species under test [%/year]

- vmedian,test:

-

median decay rate of test wood material [%/year]

The decay rate was calculated after each inspection, separately for each test wood specimen and each reference specimen (Eq. 8). The quotient of decay rating d and the time of exposure t was multiplied with 25% in accordance with the calculation of the index of decay as suggested by Borsholt and Henriksen (1990). The latter refers to the four different levels of fungal decay according to EN 252 (2015).

Calculation of the percentage decay rate v% [%/year]:

- d:

-

decay rating [0–4].

- t:

-

time of exposure [years].

The durability classification was based on the highest median ML determined for all the test specimens within one test. Additional information about the spread of individual ML values was sought and identified using the following criteria given in EN 113–2. If individual ML values were distributed over two durability classes (x and y) with at least 40% of values being in each of them, the retained DC was not based on the median ML but expressed as falling between x and y. If individual ML values were distributed over three or more DCs (x to z) with at least 15% of values being in each of them, the retained DC was not based on the median ML but as falling between x and z. If more than three individual test specimens (10% of the replicates) existed that differed from the assigned batch DC by more than one class, the letter “v” was appended to the class number to indicate the variability. The same applied for x- and f-values.

Two statistical tests were performed to verify normal distribution. First, the corresponding datasets were tested using a Shapiro–Wilk test (Shapiro and Wilk 1965), since this is the most sensitive test for detecting deviations from normal distribution (Razali and Wah 2011). In addition, the Anderson–Darling goodness of fit test (Anderson and Darling 1952) was used. This test is considered being very reliable, but less sensitive due to a weaker weighting of boundary values (Stephens 1974; Dormann 2013). Additional visual evaluation was also performed.

For the evaluation of the ML after tests according to EN 113–2 (2021), the arithmetic mean and the median were determined. Furthermore, the standard deviation was determined. However, mean value and standard deviation are meaningful only if the data show a symmetrical distribution (Dormann 2013).

3 Results and discussion

3.1 Mass loss by fungal decay (ML)

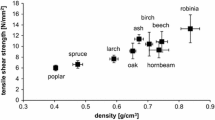

The mass loss (ML) data from the basidiomycete tests according to EN 113–2 (2021) are summarized in Table 3. The ML of all control species by C. puteana was well above 30% and T. versicolor caused more than 20% ML on the two hardwood species. Hence, the entire test was considered valid. Unexpectedly, the preservative treated specimens were heavily degraded by C. puteana. Solely at the double concentration, their ML was below 3%, which is the threshold in efficacy tests according to EN 113–1 (2021). Significant ML by T. versicolor occurred only on beech wood treated at 0.25 × concentration, although hardwoods are generally considered more susceptible to white rot compared to brown rot fungi (Schmidt 2006; Zabel and Morrell 2012). The ML of DMDHEU treated wood decreased with increasing WPG (Fig. 2). At 50% WPG the ML was well below 3% for all four wood species. Generally, ML of DMDHEU treated softwood was lower compared to hardwoods at a given WPG. Both findings coincided with previous studies, e.g., by Bollmus (2011) and Emmerich et al. (2021).

The ML of all five untreated timbers after exposure to unsterile soil was above 30% (Table 4). The ML of the Scots pine sapwood references was even close to 80%, which indicates that soft rot decay did not occur exclusively (Edlund and Nilsson 1998). However, as exemplarily shown in Fig. 3 both softwood and hardwood specimens were attacked by soft rot fungi as well. Furthermore, the reference specimens were so badly decayed that bending testing was not possible (Fig. 3) not at least because the remaining cross section could not be determined accurately anymore. The MOE loss of untreated groups of references was therefore rated as 100%.

Untreated specimens after 16 (hardwoods), and 32 weeks (softwoods) respectively, of exposure to unsterile soil in soil bed tests according to CEN/TS 15083–2 (2005)

Generally, ML decreased with increasing preservative concentration and WPG respectively (Fig. 2), except against C. puteana. The latter caused slightly increasing ML up to a concentration of 1.00x before it dropped significantly. However, the ML of preservative treated beech and Scots pine sapwood wood was still above 3% even at the double concentration. Solely, the poplar specimens treated at 0.50, 1.00, and 2.00x showed ML below 3%. The DMDHEU treated hardwoods showed ML above 3% even at the highest WPG. In contrast, the DMDHEU treated softwood showed ML below 2% independent of the WPG. Similarly, Verma et al. (2009) reported about higher durability of DMDHEU treated softwoods at a given WPG compared to hardwoods.

The relationship between ML and MOE loss was not well pronounced – most likely due to variation of MOE and additional impacts on MOE such as the treatment with DMDHEU and the copper salt themselves (Xie et al. 2013; Yuan et al. 2013; Humar et al. 2015).

Relative ML and MOE loss were calculated as x-values for all tested materials (Table 4) and afterwards used for durability classification as described and discussed below. The MOE loss of the reference species was rated as 100% although they showed ML between 31 and 79%. Consequently, the differences in decay intensity cannot be reflected by the MOE loss figures for calculating x-values. Thus, a systematic error came into play.

3.2 Decay rates in field tests

As expected, the decay rates in soil contact field tests were remarkably higher compared to those in above-ground tests (Fig. 4). The untreated hardwood control specimens in soil contact failed after two years of exposure and the softwood controls after three and five years respectively. In contrast and unexpectedly, none of the softwood above-ground control specimens showed decay after five years, and the average decay rating of the hardwood control specimens was between 1 and 2. Hence, the results from the above-ground bundle test has not been used for durability classification yet.

Decay ratings of differently treated wood materials including untreated references in graveyard tests according to EN 252 (2015) and above-ground Bundle tests. (a) European beech, (b) Poplar, (c) Scots pine sapwood, and (d) Radiata pine sapwood

In soil contact, the preservative treated wood decayed more rapidly than the DMDHEU treated wood. In contrast, only DMDHEU treated beech specimens showed some decay above ground. The decay rates after five years of exposure were used to calculate durability factors f as a basis for a durability classification (Table 5).

3.3 Durability classes

After five years of exposure in soil contact, the reference specimens made from four different wood species had failed. Hence, the graveyard durability test according to EN 252 (2015) was considered valid. In contrast, the reference specimens in the above ground bundle-tests were on average still below a decay rating of 3.0, and therefore only a preliminary durability classification has been conducted for these tests. Similarly, the very high decay activity of the Goettingen North campus in-ground field, and the comparatively low decay hazard in above-ground situations at the same test site has been shown in previous studies (Augusta 2007; Welzbacher and Rapp 2007; Alfredsen et al. 2017; Brischke et al. 2023a). Durability factors f were calculated for both tests (Table 5) and used for durability classification (Table 6). Even if it is only a preliminary classification so far, it became evident that not only the decay rate was higher in soil contact, but also the durability as a relative measure was lower in soil contact. Similar observations were previously made by Brischke et al. (2009, 2021) and Emmerich et al. (2020).

In its initial version, EN 350 referred to durability classes, which were based on graveyard test results, e.g., at the BRE (Building Research Establishment) test site in Princess Risborough, in Buckinghamshire, England. Consequently, one may consider DCs based on EN 252 (2015) data as a reference. All other ways of assigning DCs (see Table 6) led to some extent to deviations from those based on EN 252 (2015). Those based on EN 113–2 (2021) differed most, i.e., by 34–37 classes for all tested materials. Those based on CEN/TS 15083–2 (2005) are more similar to the EN 252–derived DCs, i.e., a difference by 13–20 classes. The highest accordance was found between EN 252-derived DCs and those based on ML in soil-bed tests using the inverse EN 252 x-value ranges for assignment of DCs. Generally, the use of inverse EN 252-derived x-values led to an improved accordance with the EN 252-derived DCs. A comparison between EN 113–2-derived DCs and those based on Bundle test results was not possible yet, but will also be interesting after a longer exposure period.

Provided that laboratory tests should serve to predict in a shorter time and under defined conditions what can be expected under field conditions in the long term, an adjustment to the current classification system appears to be appropriate. First, due to different wetting regimes and dominating decay types between soil and non-soil exposures, one needs to differentiate between lab and field test that refer to use classes (UC) 3 and 4 (EN 335, 2013). Secondly, the technical and mathematical procedures for classifying durability need to be as similar as possible when using laboratory and field methods to assure the highest possible accordance between DCs based on different test methods. Currently, neither of the two requirements mentioned is fully met by the relevant European standards.

4 Conclusion

In this study, the durability of preservative-treated and chemically modified wood was determined on the basis of different test methods in laboratory and field as well as different assessment and calculation methods. The following can be concluded from the results of the different decay tests within this study:

-

Durability classes differ not only between tested materials, but depend also on the applied test, assessment, and calculation method. The use of relative values (x-values), i.e., ML or MOE loss data compared with a non-durable reference material can help to harmonize the classification and make DCs more comparable.

-

Since some test methods deliver positive measures, such as the lifetime of specimens, and others reveal negative measures, such as ML and MOE loss, the use of inverse x-values is required.

-

The use of relative values can also help to reduce the effect of varying virulence of test fungi, activity of test soil substrates, and the climate-induced hazard of test sites.

-

Future comparative tests and the meta-analysis of existing test data on untreated and differently treated timber shall help to validate the findings from this study and to improve the current set of European test and classification standards, in particular with respect to their power to predict the real outdoor performance of wood.

Data Availability

Data are available from the authors on request.

References

Alfredsen G, Brischke C, Meyer-Veltrup L, Humar M, Flæte PO (2017) The effect of different test methods on durability classification on modified wood. Pro Ligno 13:290–297

Anderson T, Darling DA (1952) Asymptotic theory of certain “goodness of fit” criteria based on stochastic processes. Ann Math Stat 23:193–212

Augusta U (2007) Untersuchung der natürlichen Dauerhaftigkeit wirtschaftlich bedeutender Holzarten bei verschiedener Beanspruchung im Außenbereich [Investigation of the natural durability of economically important wood species under different outdoor exposures]. Dissertation, University of Hamburg.

AWPA E18 (2018) Standard field test for evaluation of wood preservatives to be used above ground (UC3B); Ground Proximity Decay Test. American Wood Protection Association, Birmingham, AL

Bollmus S (2011) Biologische und technologische Eigenschaften von Buchenholz nach einer Modifizierung mit 1, 3-dimethylol-4, 5-dihydroxyethyleneurea (DMDHEU) [Biological and technological properties of beech wood after modification with 1, 3-dimethylol-4, 5-dihydroxyethyleneurea (DMDHEU)]. Dissertation, University of Göttingen, Göttingen

Borsholt E, Henriksen KH (1990) Guideline for EN 252: Field test method for determining the relative protective effectiveness of wood preservatives in ground contact. Inspection and evaluation of the attack of stakes caused by micro-organisms. Nordic Wood Preservation Council, NWPC Information No. 23/90

Brischke C, Welzbacher CR, Rapp AO, Augusta U, Brandt K (2009) Comparative studies on the in-ground and above-ground durability of European oak heartwood (Quercus petraea Liebl. and Quercus robur L.). Europ J Wood Wood Products 67:329–338

Brischke C, Hesse C, Meyer-Veltrup L, Humar M (2018) Studies on the material resistance and moisture dynamics of Common juniper, English yew, Black cherry, and Rowan. Wood Mat Sci Eng 13:222–230

Brischke C, Alfredsen G, Humar M, Conti E, Cookson L, Emmerich L, Flæte PO, Fortino S, Francis L, Hundhausen U, Irbe I, Jacobs K, Klamer M, Kržišnik D, Lesar B, Melcher E, Meyer-Veltrup L, Morrell JJ, Norton J, Palanti S, Presley G, Reinprecht L, Singh T, Stirling R, Venäläinen M, Westin M, Wong AHH, Suttie E (2021) Modelling the material resistance of wood - Part 3: Relative resistance in above and in ground situations - Results of a global survey. Forests 12:590

Brischke C, Alfredsen G, Emmerich L, Humar M, Meyer-Veltrup L (2023a) Durability of wood exposed above ground – experience with the Bundle test method. Forests 14:1460

Brischke C, Haase F, Bächle L, Bollmus S (2023b) Statistical Analysis of Wood Durability Data and Its Effect on a Standardised Classification Scheme. Standards 3:210–226

Brischke C, Sievert M, Schilling M, Bollmus S (2023c) Laboratory Durability Testing of Preservative-Treated Wood Products. Forests 14:1001

CEN/TS 15083-2 (2005) Durability of wood and wood-based products - Determination of the natural durability of solid wood against wood-destroying fungi, test methods - Part 2: Soft rotting micro-fungi. European Committee for Standardization, Brussels

DIN 68 800-3 (2020) Holzschutz - Teil 3: Vorbeugender schutz von holz mit holzschutzmitteln [Wood preservation - Part 3: Preventive protection of wood with wood preservatives]. Beuth, Berlin

Dormann CF (2013) Parametrische statistik. Verteilungen, maximum likelihood und GLM in R [Parametric statistics. Distributions, maximum likelihood and GLM in R]. Springer, Berlin, Heidelberg, Germany

Edlund ML, Nilsson T (1998) Testing the durability of wood. Mater Struct 31:641–647

Emmerich L, Militz H, Brischke C (2020) Long-term performance of DMDHEU-treated wood installed in different test set-ups in ground, above ground and in the marine environment. Int Wood Products J 11:27–37

Emmerich L, Ehrmann A, Brischke C, Militz H (2021) Comparative studies on the durability and moisture performance of wood modified with cyclic N-methylol and N-methyl compounds. Wood Sci Technol 55:1531–1554

EN 113-1 (2021) Durability of wood and wood-based products - Test method against wood destroying basidiomycetes - Part 1: Assessment of biocidal efficacy of wood preservatives. European Committee for Standardization, Brussels

EN 1001 (2021) Durability of wood and wood based products - Terminology. Europoean Committee for Standardization, Brussels

EN 113-2 (2021) Durability of wood and wood-based products - Test method against wood destroying basidiomycetes - Part 2: Assessment of inherent or enhanced durability. European Committee for Standardization, Brussels

EN 252 (2015) Field test method for determining the relative protective effectiveness of a wood preservative in ground contact. European Committee for Standardization, Brussels

EN 12037 (2022) Wood preservatives - Field test method for determining the relative protective effectiveness of a wood preservative exposed out of ground contact - Horizontal lap-joint method. European Committee for Standardization, Brussel

EN 330 (2015) Wood preservatives - Determination of the relative protective effectiveness of a wood preservative for use under a coating and exposed out-of-ground contact - Field test: L-joint method. European Committee for Standardization, Brussels

EN 335 (2013) Durability of wood and wood-based products - Use classes: definitions, application to solid wood and wood-based products. European Committee for Standardization, Brussels

EN 350 (2016) Durability of wood and wood-based products - Testing and classification of the durability to biological agents of wood and wood-based materials. European Committee for Standardization, Brussels

EN 350-1 (1994) Durability of wood and wood based products - Natural durability of solid wood - Part 1: Guide to the principles of testing and classification of the natural durability of wood. European Committee for Standardization, Brussels

EN 350-2 (1994) Durability of wood and wood based products - Natural durability of solid wood - Part 2: Guide to the natural durability and treatability of selected wood species of importance in Europe. European Committee for Standardization, Brussels

EN 84 (2020) Durability of wood and wood-based products - Accelerated ageing of treated wood prior to biological testing - Leaching procedure. European Committee for Standardization, Brussels

Humar M, Kržišnik D, Brischke C (2015) The effect of preservative treatment on mechanical strength and structural integrity of wood. International Research Group On Wood Protection IRG/WP 15–30667. Stockholm, Sweden

Militz H, Busetto D, Hapla F (2003) Investigation on natural durability and sorption properties of Italian chestnut (Castanea sativa Mill.) from coppice stands. Eur J Wood Prod 61:133–141

Plaschkies K, Jacobs K, Scheiding W, Melcher E (2014) Investigations on natural durability of important European wood species against wood decay fungi. Part 1: Laboratory tests. Int Biodeterior Biodegradation 90:52–56

Rapp AO, Augusta U (2004) The full guideline for the “double layer test method” – A field test method for determining the durability of wood out of ground. International Research Group On Wood Protection IRG/WP 04–20290. Stockholm, Sweden

Razali NM, Wah YB (2011) Power comparisons of Shapiro-Wilk, Kolmogorov-Smirnov, Lilliefors and Anderson-darling tests. J Statist Modeling Anal 2:21–33

Schmidt O (2006) Wood and tree fungi. Springer, Berlin, Heidelberg

Shapiro SS, Wilk MB (1965) An analysis of variance test for normality (complete samples). Biometrika 52(3-4):591–611

Stephens MA (1974) EDF statistics for goodness of fit and some comparisons. J Am Stat Assoc 69:730–737

Van Acker J, Militz H, Stevens M (1999) The significance of accelerated laboratory testing methods determining the natural durability of wood. Holzforschung 53:449–458

Van Acker J, Stevens M, Carey J, Sierra-Alvarez R, Militz H, Le Bayon I, Kleist G, Peek RD (2003) Biological durability of wood in relation to end-use. Eur J Wood Prod 61:35–45

Verma P, Junga U, Militz H, Mai C (2009) Protection mechanisms of DMDHEU treated wood against white and brown rot fungi. Holzforschung 63:371–378

Welzbacher CR, Rapp AO (2007) Durability of thermally modified timber from industrial-scale processes in different use classes: Results from laboratory and field tests. Wood Mat Sci Eng 2:4–14

Xie Y, Fu Q, Wang Q, Xiao Z, Militz H (2013) Effects of chemical modification on the mechanical properties of wood. Eur J Wood Prod 71:401–416

Yuan J, Hu Y, Li L, Cheng F (2013) The Mechanical Strength Change of Wood Modified with DMDHEU. BioResources 8:1076–1088

Zabel RA, Morrell JJ (2012) Wood microbiology: decay and its prevention. Academic Press, Orlando

Acknowledgements

Lea Bächle and Ole-E. Z. Gröne are gratefully acknowledged for their diverse commitments

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

All authors designed and supervised the experiments, evaluated the results, wrote the main manuscript, and prepared the figures and tables.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Brischke, C., Bollmus, S. & Emmerich, L. Comparative durability tests of preservative-treated and chemically modified wood – Assessment and classification on the basis of different decay tests. Eur. J. Wood Prod. 82, 1083–1094 (2024). https://doi.org/10.1007/s00107-024-02065-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-024-02065-3