Abstract

Optimising the cutting tool geometries can reduce waste while increasing timber yield. The industry is moving towards thin-kerf bandsawing of timber, and therefore, the geometry of the minor cutting edge and minor first flanks of cutting teeth become more important. Six cutting teeth with varying minor cutting edge angles (\(0^{\circ }\), \(2^{\circ }\), \(4^{\circ }\), \(6^{\circ }\)) and minor cutting edge clearance angles (\(2^{\circ }\), \(4^{\circ }\), \(6^{\circ }\)) were tested by cutting into the heartwood and sapwood of frozen and non-frozen Norway spruce (Picea abies (L.) Karst.) and Scots pine (Pinus sylvestris L.). Single cutting tooth tests were conducted, and the cutting and feeding forces were measured. The cutting forces were higher for Scots pine due to its higher density. Frozen sapwood resulted in higher cutting forces. The feeding force of frozen sapwood stood out as it was highly negative (i.e. self-feeding) compared to frozen heartwood, non-frozen heartwood and non-frozen sapwood. An increase in the minor cutting edge angle and minor cutting edge clearance angles, and therefore more room for elastic spring-back, can lead to up to less friction and 40% lower cutting forces. Higher minor cutting edge angles and minor cutting edge clearance angles resulted in less-negative feeding forces (i.e. less self-feeding) for frozen sapwood but remained relatively unchanged for the other wood conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Swedish sawmill industry is developing cutting tools that produce fewer by-products such as sawdust and that produce a higher volume of sawn timber. More efficient tools for bandsawing of timber could result in economic benefits and environmental gains as the volume of end products that can bind carbon dioxide for a longer time. Wasielewski et al. (2012) state that the kerf width as well as the position and sawing accuracy can increase the volume yield of a sawmill. They found that it is possible to reduce the sawdust (waste) by 16% when altering a circular saw blades geometry to have a higher static and dynamic stiffness. In bandsawing, the saw kerf width, for example, can be reduced by decreasing the major cutting edge width which can result in significant improvements in the sawing yield (Orlowski 2007; Orlowski et al. 2009; Li et al. 2018) but also give lateral stability problems to the tool and its cutting teeth. It is therefore very important to study the forces involved with cutting when altering the tooth geometry.

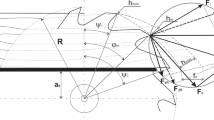

The cutting forces that act on sawing teeth indicate the sawing tool performance. The conventional cutting forces on a cutting tooth are defined by the cutting force (responsible for removing material), the feeding force (also called the normal force), and the lateral force. In the 1950s, Kivimaa (1950) carried out the first cutting force measurements and many since have linked the cutting forces to the fracture mechanics of wood during chip formation and flow (Orlowski et al. 2013; Hlásková et al. 2015; Williams et al. 2010). Parameters such as the wood conditions and feeding conditions were tested in addition to tooth geometry parameters. There are three edges on a cutting tooth that cut for the bandsawing of logs: the major cutting edge (\(S_t\)) and the two minor cutting edges (\(S'_t\)) as shown in Fig. 1. Kivimaa (1950) and other researchers after him have mainly studied the cutting forces on the major cutting edge, but when the saw kerf width is reduced, force contributions from the minor cutting edges and minor first flanks \(\left( A'_{\alpha 1}\right)\) of the cutting teeth start to play a more important role (Li et al. 2018; Meulenberg et al. 2022). The interaction between the tooth and the workpiece determines the stability of sawing, and as cutting with the minor cutting edge starts to play a more crucial role in thin kerf bandsawing, it is essential to study the effect of the tooth minor cutting edge geometry, such as the minor cutting edge angle, \(\kappa '_r\) (also called the radial clearance angle), and minor cutting edge clearance angle, \(\alpha '_p\) (also called the tangential clearance angle or tool back clearance angle), on the cutting process. These angles can be seen in Fig. 2.

Faces and cutting edges of a single cutting tooth as defined by ISO 3002:1 (1982)

Typical geometry of a single cutting tooth indicating the minor cutting edge angle and minor cutting edge clearance angles as defined by ISO 3002:1 (1982)

Sawing teeth have a side clearance (distance between the major cutting edge width and band thickness) which avoids contact between the back of the band and the wood as the cutting teeth create kerfs. In addition, this side clearance should be sufficient to allow for the resharpening of the cutting teeth. The clearance angle leaves room for elastic spring-back of the wood and avoids contact with the major first flank. This clearance angle directly affects the cutting forces. A clearance angle of \(12^{\circ }\) is commonly used in Swedish sawmills, and researchers have found that the cutting force is at its lowest for clearance angles between \(10^{\circ }\) and \(15^{\circ }\) (Kivimaa 1950; Ekevad et al. 2019; Schmidt et al. 2019). The \(\kappa '_r\) and \(\alpha '_p\) angles of a sawing tooth minimize contact between the minor first flanks of the tooth and wood. \(\kappa '_r\) is largely responsible for the timber surface quality after sawing and determines the minor cutting edge geometry. Li et al. (2017) showed that a smaller \(\kappa '_r\) and longer minor cutting edges result in lower surface roughness. A low \(\kappa '_r\) might, however, result in higher cutting forces due to increased friction forces, and therefore vibrations as the contact area between the tooth and wood is increased. Wood has a significant degree of elastic spring-back which can cause contact and friction forces on the major and minor first flanks of the teeth.

Cutting by the minor cutting edges occurs in a different direction than cutting by the major cutting edge. For example, when the major cutting edge is cutting in the \(90^{\circ }\)–\(90^{\circ }\) direction, the minor cutting edges cut in the \(0^{\circ }\)–\(90^{\circ }\) direction. The cutting direction can significantly affect the cutting forces (Kivimaa 1950; Axelsson et al. 1993; Lhate et al. 2019; Kuljich et al. 2013; Moradpour et al. 2013; Krenke et al. 2018; Li et al. 2018; Ekevad et al. 2019). Li et al. (2018) considered the resultant force of the major cutting edge as well as the contribution from minor cutting edge forces by creating open and closed cuts into birch wood. Tests were performed with single cutting teeth at low cutting speeds with a \(3^{\circ }\) minor cutting edge clearance angle and minor cutting edge angles of \(0^{\circ }\), \(1.5^{\circ }\) and \(3^{\circ }\). The authors concluded that a larger minor cutting edge angle decreases the main and minor cutting edge forces as there is less cutting of the “elastic spring-back wood” by the minor cutting edges.

The Scandinavian species Norway spruce (Picea abies (L.) Karst.) and Scots pine (Pinus sylvestris L.) are processed in all environmental conditions, even when temperatures drop well below zero. Sawmills, therefore, process frozen logs with different moisture contents, which affects the cutting behaviour significantly (Kivimaa 1950; Axelsson et al. 1993; Vazquez-Cooz and Meyer 2006; Meulenberg et al. 2021). When high moisture content wood freezes, the free water in the cell lumina freezes and expands, which exerts a compressive force on the cell walls, making it harder to cut as the cell walls are more rigid (Hernández et al. 2014). Furthermore, when freezing, the moisture in the cell walls can migrate out and condense onto the cell walls as ice crystals. This then acts as additional reinforcement, as well as drying the cell wall out, which increases the mechanical properties of the wood, making it harder to cut (Kubler et al. 2007; Shmulsky and Shvets 2006). It has been found that frozen high moisture content wood results in high cutting forces (Axelsson et al. 1993; Vazquez-Cooz and Meyer 2006; Orlowski et al. 2009; Meulenberg et al. 2021) and in negative feeding forces (Meulenberg et al. 2021).

This paper describes results from cutting and feeding force measurements on sawing teeth with varying \(\kappa '_r\) and \(\alpha '_p\) angles. The sawing process aimed at was bandsawing. Tests were conducted in non-frozen and frozen wood where both the heartwood and sapwood of Norway spruce and Scots pine were tested. To the author’s knowledge, such measurements are not reported earlier in the literature. Thus, this research can provide insight into the most suited combinations of tooth parameters to develop narrow kerf cutting tools with stable behaviour when bandsawing timber with varying properties.

2 Materials and methods

2.1 Wood specimen

Norway spruce (Picea abies (L.) Karst.) and Scots pine (Pinus sylvestris L.) logs were collected from the same forest in the north of Sweden during spring. Specimen of 70 \(\times\) 70 \(\times\) 200 mm were cut from the logs at different locations in the butt end. The specimen moisture contents (mass of water/mass of dry wood), green density and dry density are indicated in Table 1. The non-frozen test pieces were tested at \(20\,\,^{\circ }\hbox {C}\), whereas the frozen specimen was tested at \(-\,20\,\,^{\circ }\hbox {C}\). The green density was measured using a CT scanner. Examples of the cross-sections can be seen in Fig. 3.

2.2 Cutting teeth

Stellite tipped cutting teeth were cut from a new industrial steel bandsaw blade. The different tested geometries (as defined in Figs. 1 and 2) can be seen in Table 2. The geometry was chosen based on a questionnaire from several Swedish sawmillers and tool producers to ensure that the parameters were realistic for practical manufacturing and use. Tooth no. 1 is the reference tooth that is currently used in many Swedish sawmills.

2.3 Cutting force measurements

A custom-made cutting force machine first described by Axelsson et al. (1993) was used to conduct tests in the 90\(^{\circ }\)–90\(^{\circ }\) cutting direction (Fig. 4). A 1 m long arm held the wood specimen and rotated at a speed of 15 ms\(^{-1}\). A cutting tooth was fed into the wood using a tooth holder controlled by a stepper motor. Piezoelectric sensors on the tooth holder measured the cutting and feeding forces as the kerfs were created, see Fig. 5. The depth of cut was 0.9 mm, and ten cuts were made per kerf, which means that the total kerf depth was 9 mm. Ten kerfs were made per cutting tooth and per wood sample, which means that 100 data points were collected per tooth. The charges obtained by the piezoelectric sensors were amplified using three charge amplifiers for each force (Type 2635 Brüel & Kjær) and converted using an A/D converter. Signals were read at a frequency of 25 kHz and processed using a custom-made LabView program removing unwanted noise and vibration signals using a bandpass filter. The signals were averaged in time after the entrance, and exits of the kerfs were filtered out as shown in Fig. 6. The time-averaged force signals per cut were averaged for each kerf. The presented data are the averages and standard deviations of all ten kerfs.

2.4 Elastic spring-back

The elastic spring-back of the different wood species and conditions was determined by measuring the kerf width directly after the cuts were made. First, the average width of each kerf was measured using a DSX1000 (Olympus) digital microscope. The elastic spring-back was then calculated with respect to each exact major cutting edge width (also measured using the digital microscope) using equation 1.

where \(S_t\), major cutting edge width; k, kerf width.

3 Results and discussion

3.1 Cutting force

The cutting force as a function of \(\kappa '_r\) for both Norway spruce and Scots pine can be seen in Fig. 7. The cutting forces of Scots pine were higher than Norway spruce due to the differences in density between the two species. Frozen sapwood resulted in significantly higher cutting forces. The other wood conditions resulted in very similar cutting forces, except for non-frozen Scots pine sapwood (Fig. 7b), for which the cutting force was slightly higher than non-frozen and frozen heartwood.

In Norway spruce sapwood, the cutting force maximum is at \(2^{\circ }\), whereas, in heartwood, it is slightly higher at \(4^{\circ }\). The lowest cutting force occurs at the highest tested value of \(6^{\circ }\) for both Norway spruce and Scots pine. At a \(\kappa '_r\) angle of \(6^{\circ }\), it seems that the clearance is sufficient to avoid contact with the elastic spring-back occurring during the cut. A lower \(\kappa '_r\) results in more contact between the wood and the minor cutting edges of the tooth, increasing friction and temperature during cutting. In general, however, it can be seen that \(\kappa '_r\) does not have a large effect on the cutting forces, except for frozen pine sapwood. This is unexpected as \(\kappa '_r\) affects the minor cutting edge geometry, influencing the minor cutting edge force contribution.

In Fig. 8, the elastic spring-back can be seen in the different wood conditions. The spring-back is greater in non-frozen wood and less for frozen wood due to its higher mechanical properties, such as the modulus of elasticity. On average, the frozen kerfs were between 0 and 0.15 mm narrower than the major cutting edge width. The non-frozen kerfs were between 0.3 and 0.45 mm narrower than the major cutting edge width. It can also be seen that sapwood has a higher spring-back in frozen and non-frozen conditions than heartwood. The elastic spring-back can be as high as 0.45 mm, which means that each minor first flank comes into contact with approximately 0.2 mm of wood. This is quite significant for wood sawing teeth as \(\kappa '_r=2^{\circ }\) which leaves only 0.03 mm of space for elastic spring-back. This will result in a significant compressive force by the wood on the tooth minor first flanks, resulting in high friction. Increasing \(\kappa '_r\) to \(6^{\circ }\) does not, however seem to reduce the force significantly as can be seen in Fig. 7. Furthermore, it would be expected that non-frozen wood is more sensitive to the changes in \(\kappa '_r\) because the minor cutting edges are cutting a higher amount of elastic spring-back. However, Fig. 7b shows that the cutting force of frozen Scots pine sapwood is more reactive toward the change in minor cutting edge angle.

From these results, it can be said that the current \(\kappa '_r\) value used in Swedish sawmills (\(2^{\circ }\)) does not seem to be the most efficient when working towards obtaining lower cutting forces, especially when sawing frozen pine sapwood. Changing the angles is possible just by changing the settings of the grinding machine, but using larger values as high as \(6^{\circ }\) could pose a problem since the grinding wheels may unintentionally touch the band. This must be avoided in order not to reduce the stiffness or structural integrity of the band. Furthermore, repeatedly regrinding cutting teeth with large clearance angles will reduce the kerf width, allowing less exact control on the cutting process.

\(\alpha '_p\) should be sufficient to avoid contact between the wood and minor first flanks as the tooth moves upwards to create the kerf. \(\alpha '_p\) is expected to have a lower effect on the cutting force than \(\kappa '_r\) since it does not largely influence the minor cutting edges but more determines the shape of the minor first flanks. It is, therefore, more influential on the friction and contact between the spring-back and the tooth minor first flanks. In Fig. 9, the cutting force with respect to \(\alpha '_p\) can be seen for Norway spruce and Scots pine. Although the differences are small, especially considering the scatter, for non-frozen heartwood and sapwood and frozen heartwood, a higher \(\alpha '_p\) value of \(6^{\circ }\) resulted in a reduced cutting force. This is related to the reduced contact area between the minor first flanks (due to the higher \(\alpha '_p\)) and the “elastic spring-back wood”, reducing friction. The reduction in cutting force is higher for frozen sapwood, especially in the drastic case of Scots pine at a high \(\alpha '_p\). This is unexpected because the elastic spring-back in frozen sapwood is significantly lower than that of non-frozen wood and for pine, as seen in Fig. 8.

3.2 Feeding force

The effect of \(\kappa '_r\) on the feeding force can be seen in Fig. 10 for Norway spruce and Scots pine. In general, the feeding force behaviour is similar between the two species. The feeding force is negative for frozen sapwood, and the tooth is being pulled into the wood, i.e. self-feeding occurs. Self-feeding is normally undesirable in sawmills as it can cause instabilities in the band. The feeding force is therefore required to be slightly positive or close to zero. Frozen sapwood is more rigid due to the reinforcement from ice in the cell walls and lumina, reducing the elastic spring-back (see Fig. 8).

When cutting frozen Scots pine sapwood, the cutting forces are more desirable (closer to zero) at \(\kappa '_r=6^{\circ }\), except for \(0^{\circ }\) where an anomaly occurs, and the feeding force is less negative. This could be due to the higher green density of Scots pine, local changes in the grain angle, reaction wood or even resin pockets. The trends are similar in the other wood conditions (non-frozen heartwood, non-frozen sapwood and frozen heartwood), where the feeding force is slightly positive for Norway spruce. The frozen and non-frozen sapwood tends to be slightly more negative in Scots pine but still close to zero. The optimum \(\kappa '_r\) can be at \(2^{\circ }\) as the feeding forces are most constant in most wood conditions, but when cutting into frozen sapwood, \(\kappa '_r\) of \(6^{\circ }\) seems better.

The effect of \(\alpha '_p\) on the feeding force can be seen in Fig. 11. From these results, it can be said that a higher \(\alpha '_p\) (\(6^{\circ }\)) is beneficial when sawing frozen sapwood since the feeding force is closer to zero from a highly negative feeding force (self-feeding) at \(\alpha '_p=2^{\circ }\). A \(\alpha '_p\) of \(2^{\circ }\) is optimum for the other conditions as the feeding force is closer to zero. In winter conditions, sawmills can opt to cut with a higher \(\alpha '_p\) of \(6^{\circ }\) since this seems to minimize self-feeding.

4 Conclusion

This research investigated the effect of varying minor cutting edge angles and minor cutting edge clearance angles of sawing teeth on the cutting and feeding forces in bandsawing. Tests were conducted in Norway spruce and Scots pine in non-frozen and frozen heartwood and sapwood. The main conclusions that can be drawn are:

-

Frozen sapwood stands out compared to the other wood conditions. It resulted in higher cutting forces and more negative feeding forces. Frozen sapwood also responded more drastically to the changes in minor cutting edge angles and minor cutting edge clearance angles, especially in Scots pine wood.

-

The non-frozen heartwood, non-frozen sapwood and frozen heartwood resulted in similar cutting and feeding forces for most minor cutting edge angles and minor cutting edge clearance angles. This means that no clear effect of changing the angles was found for these conditions.

-

A minor cutting edge angle and minor cutting edge clearance angle of 2\(^{\circ }\) resulted in a higher cutting force. Angles of 6\(^{\circ }\) are more appropriate for use in sawmills as they resulted in a lower cutting force (approximately 40% lower in frozen sapwood). In the other wood conditions, there was a reduction, but the reduction was not as substantial.

-

A higher minor cutting edge angle and minor cutting edge clearance angle resulted in a higher feeding force which is beneficial (less self-feeding), especially for cutting frozen Scots pine sapwood.

-

The elastic spring-back is higher in non-frozen wood and higher in sapwood for both conditions. However, the elastic spring-back did not seem to have a larger effect on the cutting and feeding forces when altering the minor cutting edge angle and minor cutting edge clearance angles.

References

Axelsson B, Lundberg A, Grönlund A (1993) Studies of the main cutting force at and near a cutting edge. Holz Roh- Werkst 51:43–48

Ekevad M, Öhman M, Guo X (2019) Single tooth cutting forces in green norway spruce: experimental results. In: Proceedings of the 24th international wood machining seminar (IWMS-24), Oregan State University, Corvallis, USA, pp 9–22

Hernández RE, Passarini L, Koubaa A (2014) Effects of temperature and moisture content on selected wood mechanical properties involved in the chipping process. Wood Sci Technol 48(6):1281–1301. https://doi.org/10.1007/s00226-014-0673-9

Hlásková L, Orlowski K, Kopecký Z et al (2015) Sawing processes as a way of determining fracture toughness and shear yield stresses of wood. BioRes 10(3):5381–5394

ISO 3002:1 (1982) Basic quantities in cutting and grinding—part 1: geometry of the active part of cutting tools—general terms, reference systems, tool and working angles, chip breakers. Standard, ISO, Geneva, CH

Kivimaa E (1950) Cutting forces in wood working. Helsinki, Finland

Krenke T, Frybort S, Müller U (2018) Cutting force analysis of a linear cutting process of spruce. Wood Mat Sci Eng 13(5):279–285. https://doi.org/10.1080/17480272.2017.1324916

Kubler H, Liang L, Chang L (2007) Thermal expansion of moist wood. Wood Fiber Sci 5(3):257–267. https://doi.org/10.1007/s001090000086

Kuljich S, Hernández RE, Llavé AM et al (2013) Effects of cutting direction, rake angle, and depth of cut on cutting forces and surface quality during machining of balsam fir. Wood Fiber Sci 45(2):195–205

Lhate I, Cristòvão L, Ekevad M et al (2019) Cutting forces for wood of lesser used species from mozambique. In: Proceedings of the 20th international wood machining seminar (IWMS-20), LuleåUniversity of Technology, Skelleftå, Sweden, pp 444–451

Li W, Zhang Z, Peng X et al (2017) The influences of circular saws with sawteeth of mic-zero-degree radial clearance angles on surface roughness in wood rip sawing. Ann For Sci 74:37. https://doi.org/10.1007/s13595-017-0632-3

Li W, Zhang Z, Luo B (2018) Effects of sawtooth side edges with different radial clearance angles on the cutting force in wood sawing. Materialwiss Werkstofftech 49:1468–1475. https://doi.org/10.1002/mawe.201800074

Meulenberg V, Ekevad M, Svensson M (2021) Thin kerf cutting forces of frozen and non-frozen Norway spruce and scots pine wood. Wood Mat Sci Eng 2021:5. https://doi.org/10.1080/17480272.2021.1925964

Meulenberg V, Ekevad M, Svensson M, Broman O (2022) Minor cutting edge force contribution in wood bandsawing. J Wood Sci 68:18. https://doi.org/10.1186/s10086-022-02023-8

Moradpour P, Doosthoseini K, Scholz F et al (2013) Cutting forces in bandsaw processing of oak and beech wood as affected by wood moisture content and cutting directions. Eur J Wood Prod 71(6):747–754. https://doi.org/10.1007/s00107-013-0734-z

Orlowski K (2007) Experimental studies on specific cutting resistance while cutting with narrow-kerf saws. Adv Manuf Sci Technol 31(1):49–63

Orlowski K, Sandak J, Negri M et al (2009) Sawing frozen wood with narrow kerf saws: energy and quality effects. For Prod J 59(3):79–83

Orlowski K, Ochrymiuk T, Atkins A et al (2013) Application of fracture mechanics for energetic effects predictions while wood sawing. Wood Sci Technol 2013:47. https://doi.org/10.1007/s00226-013-0551-x

Schmidt C, Westermann HH, Steinhilper R (2019) An investigation of buzz saw blade cutting forces depending on tool geometry for cutting frozen wood. Proc Manuf 33:74–77. https://doi.org/10.1016/j.promfg.2019.04.098

Shmulsky R, Shvets V (2006) The effect of subzero temperatures on fsp of cottonwood. For Prod J 56(2):74–77

Vazquez-Cooz I, Meyer RW (2006) Cutting forces for tension and normal wood of maple. For Prod J 56(4):26–34

Wasielewski R, Orlowski K, Szyszkowski S (2012) Economical wood sawing with circular saw blades of a new design. Drvna Ind 63:27–32. https://doi.org/10.5552/drind.2012.1121

Williams J, Patel Y, Blackman B (2010) A fracture mechanics analysis of cutting and machining. Eng Fract Mech 77(2):293–308. https://doi.org/10.1016/j.engfracmech.2009.06.011

Acknowledgements

The involved partners are thanked for their support. The authors gratefully acknowledge the support of CT WOOD- a centre of excellence at Luleå University of Technology for the development of X-ray computed tomography applications for use in the forest products industry.

Funding

Open access funding provided by Lulea University of Technology. The strategic innovation program, BioInnovation under grant [2017-02697]- a joint venture by Vinnova, Formas and the Swedish energy agency (Energimyndigheten)- provided financial support as part of the IPOS project (Swedish wood- Innovation potential for the bio-based society).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Meulenberg, V., Ekevad, M. & Svensson, M. Minor cutting edge angles of sawing teeth: effect on cutting forces in wood. Eur. J. Wood Prod. 80, 1165–1173 (2022). https://doi.org/10.1007/s00107-022-01833-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-022-01833-3