Abstract

The wearable sensors have attracted a growing interest in different markets, including health, fitness, gaming, and entertainment, due to their outstanding characteristics of convenience, simplicity, accuracy, speed, and competitive price. The development of different types of wearable sensors was only possible due to advances in smart nanostructured materials with properties to detect changes in temperature, touch, pressure, movement, and humidity. Among the various sensing nanomaterials used in wearable sensors, the piezoresistive type has been extensively investigated and their potential have been demonstrated for different applications. In this review article, the current status and challenges of nanomaterials and fabrication processes for wearable piezoresistive sensors are presented in three parts. The first part focuses on the different types of sensing nanomaterials, namely, zero-dimensional (0D), one-dimensional (1D), two-dimensional (2D), and three-dimensional (3D) piezoresistive nanomaterials. Then, in second part, their fabrication processes and integration are discussed. Finally, the last part presents examples of wearable piezoresistive sensors and their applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

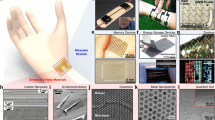

Smart wearable devices are classified into four main groups, (i) near-body electronics, (ii) on-body electronics, (iii) in-body electronics, and (iv) electronic textiles. This definition is in accordance with the international electrotechnical committee (IEC) and more details can be found in Fig. 1a. Furthermore, the evolution of wearable technologies as a function of materials and devices types is illustrated in Fig. 1b. Considering the used materials, wearable devices can be classified in three categories (Zulqarnain et al. 2020): (1) rigid devices, where all active components are rigid silicon integrated circuits (ICs), (2) hybrid devices, where sensors and/or front end elements are based on flexible materials/substrates while the rest of the system is implemented with rigid silicon ICs, and (3) flexible devices, where all components are built using flexible electronics. Currently, there is commercial availability of conventional wearable devices that are used as accessories for different applications, such as smart glasses, smart watches, smart shoes, medical devices, among others. Figure 2a illustrates some examples of such devices. There is also a lot of research and development focused on the design, fabrication and characterization of innovative wearable sensors that can be used as implants, for example, those shown in Fig. 2b. These advances in wearable sensors were only possible due to the recent progress in the synthesis and characterization of new emerging smart materials in micro/nanoscale, which detect and communicate changes in temperature, touch, pressure, movement and humidity in real time.

Therefore, flexible wearable devices (FWDs) are essential components of the flexible electronic technology because they have great potential for health monitoring and medical applications (Liu et al. 2017a; Wang et al. 2017a). The commercial scale-up of FWDs will depend on the successful development of flexible sensors, including pressure and temperature sensors (Graz et al. 2009; Gao et al. 2019), strain sensors (Zhou et al. 2008; Jung et al. 2019), and humidity sensors (Xuan et al. 2015). However, wearable technologies will become real progress from the point where components based on flexible materials are well enough integrated into items that can be used daily, such as our clothes. With the growing interest and rapid development of industrial and academic active research in flexible and stretchable strain/pressure sensors, wearable technologies tend to consolidate in a few years.

As seen in recent years, several flexible sensors with excellent performance have been reported. At the same time, flexible sensors have been applied to achieve self-healing (Huynh et al. 2017; Zhu et al. 2020), for drug monitoring and screening, for self-powered wearable health and biomedical sensing devices (Wang et al. 2019a), and has also been integrated with several other types of sensors. Several reviews have been published on flexible electronics, flexible sensors and their applications on wearable devices. Table 1 summarizes the recent review papers. As can be seen, the core of these articles is in the self-healing, biomedical sensors, soft electronics based on liquid metals, piezoelectric and triboelectric energy harvesting, actuators and sensors, piezoresistive and capacitive pressure sensors, electronic skin sensors, and electrochemical sensors for drug monitoring. However, few studies explicitly focused on the discussion of materials used, fabrication processes, and integration of piezoresistive sensors. It can be noted in Table 1 that 2021 was the year of review articles. This effect is a consequence of the pandemic caused by COVID-19 that generated a global lockdown, preventing the sequence of face-to-face scientific research. Thus, the beating mind of most researchers focused their efforts on publishing review articles. With this initiative, academic productivity was assured, and the thoughts were occupied to alleviate all the harmful consequences of the pandemic. Piezoresistive sensors (PRSs) are electromechanical sensors based on transduction mechanism called piezoresistivity (Santos et al. 2020; Li et al. 2020a). In addition to it, there are two other well-known electromechanical transduction mechanisms: piezocapacitance and piezoelectricity/triboelectricity (Santos et al. 2020; Li et al. 2020a).

It is worth mentioning that the electromechanical sensors convert mechanical signals into electrical ones by generating electrical charges under pressure/strain loads, which change the resistance or capacitance of electromechanical sensors. Among them, the PRSs are low-cost, robust, durable, easy to construct with precise reading circuits besides have a high sensitivity and fast reaction time in response to pressure/mechanical strain applied. All the qualities mentioned above make the piezoresistive materials attractive and bring tremendous attention for broad applications (Santos et al. 2020; Li et al. 2020a; Zheng et al. 2020). Table 2 compares the pressure sensitivity and reaction time for piezoresistive, piezoelectric, and piezocapacitive sensors constructed using different materials. It is noted that the devices operated in piezoresistive effect demonstrated excellent pressure sensitivity and time response in comparison with the values obtained by piezocapacitive and piezoelectric sensors (PESs). This behavior puts piezoresistive technology (PRT) in advantage for applications in monitoring devices of physical stimuli in real time. It is worth highlighting that Table 2 presents high-performance PRSs fabricated with a variety of raw materials. For example, Gunasekara et al. (2020) used micropatterned polypyrrole film as piezoresistive material (PRM) and achieved a sensitivity highest sensitivity was 10.69 ± 1.53 kPa−1 with 1 kPa and its lowest and highest limits of pressure detection were recorded as ranging from 0.05 to 119 kPa. On the other hand, Pan et al. (2014) used 3D hybrid porous Mxene-sponge to reach values of 133 kPa−1 and 50 ms.

The best sensitivity results for piezocapacitive sensors, 15 kPa−1 and 4.2 ms, were achieved by Li et al. (2017) using iontronic nano-fabric. Optimized sensitivity for PESs was reported by Zhang et al. (2019a), 5.8 kPa−1 and 190 ms, using lead zirconate-titanate (PZT) thin films. Also, as can be seen in Table 2, the PRT offers sensing performance strain over a wide range (< 1–147 kPa−1), in addition to short response times (0.2–138 ms), allowing for reliable sensing performance.

Due to the lack of manufacturing complications, high sensitivity, fast reaction time, low cost, and durability, flexible and elastic PRSs have become crucial for smart wearable electronics. With the advent of the Internet of Things (IoT) applied to Industry 4.0, sensors based on piezoresistive effects have become vital for monitoring people’s health and controlling machines. Therefore, wearable piezoresistive sensors are a current trend and a relevant research topic. This fact can be seen in Fig. 3, which illustrates the number of publications with the term “Wearable Piezoresistive.” CrossRef Metadata platform was used to carry out this survey, and as can be seen, in 2012, there were only 366 publications with this focus. When it looks at it ten years later, there is an increase of approximately ten-folds the number of publications. This increase year after year shows the importance of wearable piezoresistive sensors in our daily lives.

Based on this introduction, this review paper aims to show a comprehensive status and perspectives of the flexible and stretchable PRSs. This was divided into three main parts: (i) First, it focused on the distinct types of materials used in the construction of these sensors and, to make easy the compression, it was divided into four categories organized by dimensional structures, namely, zero-dimensional (0D), one-dimensional (1D), two-dimensional (2D), and three-dimensional (3D), (ii) Second, the fabrication processes and integration of PRSs are discussed and (iii) Finally, the last part presents some examples of wearable PRSs and their applications.

2 Nanomaterials for wearable piezoresistive sensors

This section exhibits the current status and challenges of the bottom-up-synthesized and top-down-processed nanomaterials for wearable piezoresistive sensors (WPS). For a better understanding of the synthesized and processed nanomaterials for WPS, this section was divided into four categories organized by dimensional structures, i.e., 0D, 1D, 2D, and 3D. The main example of 0D nanomaterials are the nanoparticles (NPs) based on metal compounds. In turn, 1D nanomaterials are represented by nanotubes such as carbon nanotubes (CNTs), 2D nanomaterials can be produced by dichalcogenide nanosheets or an allotrope of carbon consisting of two-dimensional honeycomb lattice called graphene, and 3D nanomaterials are based on conductive foam, for example.

2.1 Zero-dimensional piezoresistive nanomaterials

Metallic NPs have drawn tremendous attention in the fields of nanobiotechnology and nanotechnology due to their exceptional properties stemming from the nano-thickness, nano-width, and nano-length of the particles. In WPS applications, these NPs are often incorporated into a polymeric matrix or flexible membranes to maintain good flexibility, a good Young’s Modulus, while maintaining an excellent degree of piezoresistivity (Li et al. 2020b; Chen et al. 2019). Thus, 0D nanomaterials have acquired growing interest due to their capability to achieve greater sensitivity in WPS, holding the flexibility and electromechanical stretchability of the flexible matrices (polymers or membranes), enhancing the measurement of electrical signals through physical stimuli (Li et al. 2020b). When the external pressure (physical stimuli) varies slightly, the piezoresistive process does not sense the breaking of the ohmic contact or new defects formed in the material (Ramuz et al. 2012; Someya et al. 2004). Due to this fact, it can be supposed that 0D nanomaterials help the WPS to sense the least internal resistance caused by external stress, allowing devices to reach very high resolutions (Chen et al. 2019). Therefore, this mechanism that occurs between small distances that separate the NPs is responsible for controlling the tunneling and hopping processes among adjacent electrons into the PRSs (Sheng and Abeles 1972, 1973).

Figure 4 presents the most used NPs on piezoresistive, capacitive, and piezoelectric sensors. In PRSs, gold nanoparticles (Au-NPs) are widely used in flexible matrices. Farcau et al. (2011) integrated Au-NPs in flexible polyethylene terephthalate (PET) and used electron tunneling to fabricate highly sensitive resistive strain gauges without any lithographic pre-patterning. Therefore, the simplicity of fabrication through convective self-assembly makes this approach potentially useful for developing other types of PRSs. Jiang et al. (2015) used Au-NPs in thin film strain sensors on flexible polyimide substrates. The PRSs presented disorderly interparticle tunneling that introduced a microscopic deviation of the charge conduction. They observed a considerable change in resistance when the current flow is perpendicular to a unidirectional strain. For daily usages, the strength and stability of these PRSs were validated with 70,000 cycles of bending. Lee et al. (2015) embedded Au-NPs and silver nanoparticles (Ag-NPs) in flexible insulating polyurethane (PU) elastomer. They combined Au-NPs and Ag-NPs to make piezoresistive pressure sensors composed of sea-urchin-shaped metal nanoparticles (SSNPs). The sensor has a sensitivity of 2.46 kPa−1 with a response time of 30 ms with a quantum tunneling effect between SSNPs and flexible PU.

Recently, Wang et al. (2020a) reported the fabrication of PRSs based on Au-NPs assembled and interconnected with graphene microchannel-embedded PDMS film. The 3D coating consists of porous nickel foam/Au-NPs/graphene/embedded PDMS, being a useful and sensitive pressure and strain sensor. The sensors show a broad detection range (50 kPa) and a sensitivity of 5.37 kPa−1 in the range from 10 to 50 kPa with a response time equal to 20 ms and strain factor up to 15. Compared with 1D films (porous nickel foam/Au-NPs/graphene/embedded PDMS), the sensitivity improved 40-fold between 0 and 1 kPa pressure range. These characteristics put this device as a candidate for wearable biomedical and traditional sensors.

In addition to Au-NPs, the Ag-NPs on flexible substrates are also widely used. As gold, the silver is a transition metal with exciting properties to apply on piezoresistive devices. Lee et al. (2014a) reported a combination of a roll-to-roll (R2R) slot-die coating and laser direct-writing process to fabricate uniform Ag films embedded with Ag-NPs over a broad area of flexible substrates of polyimide (PI) and PET with low sheet resistance. They showed that the gauge factor for these PRSs is 40% higher than the tested commercial product, in addition to demonstrating excellent linearity over a range of static loads regardless of the initial resistance. Hoang et al. (2016) fabricated a simple, low-cost, and easy to scale up PRSs based on Ag-NPs/CNTs involved in PI/polydimethylsiloxane (PDMS) substrates, resulting in durable sensors that remain active after 500 stretching cycles (0.5% of maximum strain) without sensitivity degradation. As an impressive result, they showed that the Ag-NPs/carbon deposited on the PDMS/PI substrate presented a substantially broad resistance change about 22-fold greater than film on the PI substrate. Shen et al. (2020) improved sensitivity of PRSs based on a traditional polyanion hydrogel-poly(acrylic acid) (PAAc) introducing a pre-compressed double-cross-linked (DC) lignocellulosic hydrogel with uniformly and regularly distributed big pores coated with polydopamine (pDA) followed by in situ deposition of Ag-NPs. They reported excellent properties, such as water content of about 82% with abundant ions, superior mechanical properties, maximum strain from 76.8 to 94.8%, and sensitivity up to 9.34 MPa−1. Ko et al. (2021) fabricated a sensitive PDMS-based WPS based on Ag-NPs/CNT films prepared by a low-cost, environmentally-friendly, and simple scalability at an industrial level approach of tip-sonification spray process. They observed a sensitivity approximately from 0.02 kPa−1 at low-pressure (< 11.67 kPa) and 0.004 kPa−1 at high-pressure (~ 11.67–33.3 kPa) better than the sensitivity of polymer-based pressure sensors. Another critical point is the mechanical reliability exhibited under loading–unloading pressures of 6.67 kPa and 16.67 kPa tested on wearable sensors.

Besides Au-NPs and Ag-NPs, another two transition metals, namely, platinum (Pt) and Palladium (Pd), emerges as 0D nanomaterials applied on flexible piezoresistive sensors. Hwang et al. (2018) used Pt-NPs embedded on hydrogels based on ethylenediamine (EDA) and functionalized graphene oxide (GO) to improve the piezoresistive effect of the material. Pt-NPs incorporated into EDA-GO hydrogel improved the linear strain range by 52.8% and raised the compressive modulus by 873% due to the multi-scale reinforcing. This mechanism of reinforcement was attributed to the powerful interaction between Pt-NPs and graphene platelets. Hence, the piezoresistivity of the hydrogels can have a great appeal in the field of high-performance pressure sensors. On the other hand, Radha et al. (2011) fabricated flexible semitransparent PRSs based on Pd-NPs on micro molded carbon-micro-stripes deposited on PI substrates. They showed a direct relationship among Pd-NPs size, base resistance, and gauge factor. When the nanoparticle size varied from 2 to 25 nm, the base resistance increases drastically from 19.3 Ω to 15.68 × 106 Ω. Another parameter that grows with a decrease of nanoparticle size is the gauge factor, which varied from 0 to 176. Therefore, they report a method that produced flexible PRSs and, on the other hand, flexible conduits with unchanging resistance, adjusting only the size of the nanoparticles.

It is worth mentioning the work of Rizvi and Naguib (2014), where carbon nanoparticles (C-NPs) were studied in polyethylene (PE) composites. The C-NPs fillers investigated were single-wall carbon nanotube (SWCNT), multi-wall carbon nanotube (MWCNT), and graphene nanoplatelets (GNP). They demonstrated that the piezoresistance response to MWCNT had a strong dependence on stress and filler content. In contrast, the reaction of SWCNT was stable with a networked state of nanoparticles.

As a perspective of application in PRSs, we can mention the zinc oxide nanoparticles (ZnO-NPs) and cadmium sulphide nanoparticles (CdS-NPs), which were reported by Prashanthi et al. (2011) and Goud et al. (2016), respectively. In a theoretical article, Clayton et al. (2020) explored a new numerical approach to explain an unexplained physical behavior that can be used to design PRSs with specific characteristics. They used a basic model using quantum tunneling, and the percolation theory focusing on a simple analytical model for isotropic orientation distribution and subsequent Poisson-based gap evolution. The model used a nanocomposite sensor comprised of a silicone matrix with nickel nanoparticles (Ni-NPs), which demonstrated a great potential for application in PRSs.

2.2 One-dimensional piezoresistive nanomaterials

1D nanomaterials can be divided into (i) nanowires based on metallic, metal oxide, and conducting polymer; and (ii) nanotubes based on carbon, called carbon nanotubes (CNTs). Due to the high-aspect-ratio (HAR), exceptional optical, electronic, and mechanical properties, 1D nanomaterials can contribute to the development of wearable devices by raising the optical and electronic performance. They also have a lower fabrication cost and can expand the possibilities of integration with other nanomaterials (Gong and Cheng 2016). Another unique property that can be highlighted is the high persistence length that provides direct transport of the charge and reduces the grain boundaries. This property decreases the considerable dependence of resistance on the strain and overcomes the issues caused by gaps and cracks in the material (Qi et al. 2020). Based on these properties, this subsection focuses on CNTs which are the most 1D nanomaterials used as conductive filler incorporated in conductive polymeric matrices used in PRSs.

Table 3 summarizes the main articles that used CNTs in PRSs published recently. As can be seen, the most used matrices include polymers and elastomers, namely, poly(vinylidene fluoride) (PVDF), polymethyl methacrylate (PMMA), acrylonitrile butadiene styrene (ABS), PDMS, Ecoflex, PU, elastomer–styrene–butadiene–styrene copolymer (SBS), and Epoxy. However, recent progress in the synthesis, architecture and characterization of novel conductive polymeric matrices shows new perspectives for CNTs applications. For example, Qi et al. (2020) used CNTs-embedded PU nanofiber (PU-NF) to fabricate PRSs. They took advantage of the coaxial structure (CNTs/PU-NF) to promote the retention of intimate contact between the CNTs/PU-NF layer and the core electrode during the strain and fabricated a multimodal textile sensor, which is woven by smart nanofiber sensing yarns based onto a stretchable fiber-shaped core electrode through a simple electrospinning process. Tran et al. (2020) developed a hybrid nanocomposite based on graphene combined with carbon nanotubes to build a robust hierarchical conducting architecture. This nanocomposite was used to fabricate quantum resistive pressure sensors (QRPS). The proof of concept of pressure monitoring and mapping, with a flexible and integrable array of four hybrid QRPS, demonstrated real-time sensing capabilities. An example of novel conductive matrices was showed by Kumar et al. (2020) who applied CNTs to reinforce nanofiller in high-temperature vulcanized (HTV) and room-temperature vulcanized (RTV) silicone rubber. Their results showed a higher gauge factor with RTV silicone rubber compared to HTV silicone rubber, and both showed stretchability > 100%. Sencadas et al. (2020) reported how biodegradation improved the sensitivity and electromechanical performance of piezoresistive sensors. They used the poly(glycerol sebacate) (PGS) elastomer as a matrix, and the porous sensor was synthesized and blended with CNTs and sodium chloride (NaCl). As a result, a linear behavior over an extensive range of pressures was reached. An increase in their sensitivity from 0.12 to 8.00 kPa−1 was achieved after eight weeks in a simulated body fluid media.

2.3 Two-dimensional piezoresistive nanomaterials

The 2D nanomaterials applied in PRSs can be divided into (i) dichalcogenide nanosheets and (ii) a carbon allotrope that consists of a two-dimensional honeycomb structure called graphene. In particular, graphene has attracted attention since the segregation of its single layer in 2004, through the novel mechanical exfoliation technique developed to synthesize it (Novoselov et al. 2004). Due to the 2D structure with carbon atoms (monolayer) arranged in hexagonal network, particularly suitable and extraordinary characteristics have emerged for flexible PRS applications, including exceptional mechanical, electrical and thermal properties, besides tunable 2D assembly, lightweight, flexibility, and high transport properties (Zheng et al. 2011; Niu et al. 2018; Mohan et al. 2018).

As occur to CNTs, the most used conductive matrices for PRSs developed with 2D nanomaterials including polymers and elastomers, namely, PVDF (Costa et al. 2017), PDMS (Rajitha and Dash 2018), Ecoflex (Zhang et al. 2019b) (Joo et al. 2015), Silly Putty (Boland et al. 2016), poly (lactic acid) (PLA) (Scaffaro et al. 2018), and other blends of elastomers. In most cases, PRSs based on graphene/polymer composite are more sensitive due to the large surface area of 2D graphene and its high carrier mobility (Chen et al. 2017b).

Recently, to promote the improvement of graphene-based PRS, Cao et al. (2020a) framed a loofah sponge and coated it with graphene-modified by carbon black nanoparticles (CB-NPs) using a facile and environment friendly solvothermal method. They showed that CB-NPs decreased the contact resistance between the graphene sheets and improved the sensitivity and conductivity of 3D PRS. Sankar et al. (2020) used hydrogen-exfoliated graphene (HEG) to fabricated PRSs. They used a waterproof and flexible PVDF polymer as conductive material and incorporated the polystyrene sulfonate sodium salt (PSS) polymer-functionalized HEG in a PVDF-based flexible PRSs. The electrical conductivity of PVDF/PSS-HEG-based is two-fold higher than the PVDF/HEG-based, and the PSS-HEG promotes stable dispersion in the hydrophobic polymer matrix without harming the intrinsic characteristics of the device. Cao et al. (2020b) developed a novel nanofiber reinforced graphene aerogel (aPANF/GA). They showed that PRSs based on aPANF/GA have an excellent sensitivity of 28.62 kPa−1 with fast response time (37 ms), and the structural stability and durability were present after 2600 cycles. Zhu et al. (2019) prepared a PRSs based on hollow MXene spheres/reduced graphene composite aerogel and flexible interdigital electrodes. This process exhibits 609 kPa−1 of sensitivity in the range of 6.4–10 kPa, a short response time of 232 ms, and durability of 6000 cycles. An interesting multi-application was shown by Jing et al. (2020); the PRSs were applied to detect blood pressure, heartbeat and human movements, including finger bending, elbow movement, and knee squatting. They fabricated a PRS based on graphene-PDMS sponge with high elasticity (strain up to 85%), high sensitivity (0.075 kPa−1), a wide responding range (0–50 kPa), and increased stability (2000 cycles pressure test). These results showed the right consistency and stability of the as-prepared sensor through the sponge, PDMS, and graphene synergy. Khalifa et al. (2020) manufactured a PRS and fast response humidity sensor based on graphene-coated cellulose paper. The humidity sensor obtained a response 290% greater than the uncoated cellulose paper and the piezoresistive response was 250% greater than the uncoated one. The low-cost, lightweight and biocompatible cellulose paper combined with graphene shows to be a promising material for smart and wearable electronic devices (Chen et al. 2020).

2.4 Three-dimensional piezoresistive nanomaterials

3D nanomaterials are based on conductive foam with a pore surface decorated with 0D, 1D, and 2D nanomaterials. The advantages of foams are low-cost, fast and scalable features, and easy fabrication methods. For example, Wu et al. (2017) reported a new and easy strategy for making highly elastic channel crack-based Au-NPs/PU foam piezoresistive material. They used a flexible 3D conductive network prepared by gold ion sputtering, being the channel cracks are designed on the 3D sponge skeletons. The PRSs had excellent elasticity, a response time of 9 ms and an ultra-low detection limit of 0.568 Pa, with good reproducibility up to 1000 cycles. Owing to the new structure, these PRSs can monitor both short and long human movements that derive from the nano crack joint sensing mechanism and physical contact of conductive interconnected networks. De Meo et al. (2020) used CNT embedded into a polymeric foam (PU) that showed an increase in electrical and mechanical properties. They manufactured three kinds of PRSs based on PU-CNT foam, (i) PU-CNT 1.5%, (ii) PU-CNT-COOH 1.0%, and (iii) PU-CNT-COOH 1.5%. The samples with COOH presented an insulating-conductive transition phenomenon at 80% of its compression strain with a gauge factor of 30. Instead, the samples without COOH showed conductivity at 1.5% of filler concentration and a steady piezoresistive behavior with a gauge factor of 80. Fortunato et al. (2020) fabricated PRSs bases on novel 3D Ecoflex open-cell foams using different concentrations of graphene nanoplatelets (GNPs). As a result, it was noted that PRSs infiltrated with 1 mg of ethanol/GNP solution with a GNP concentration of 3 mg/mL was more sensitive than those implanted with the same amount of ethanol/GNP solution and a lower concentration of GNP. It was observed that the PRSs were sensitive at very low deformations with a maximum sensitivity of 0.28 kPa−1 for pressures lower than 10 kPa.

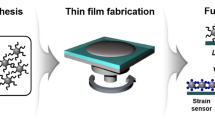

3 Fabrication processes for wearable piezoresistive sensors

In addition to the nanostructured materials used in wearable piezoresistive sensors, there are still challenging issues for the implementation of wearable sensors on an industrial scale. For example, many of the flexible and extensible wearable sensors so far involve complicated or cumbersome manufacturing processes, such as multiple coating cycles, printing or photolithographic techniques and deposition of conductive materials. Moreover, since most wearable sensors are composed of metal-based micro/nano structures and hybrid composites with nanomaterials (such as metallic NWs and graphene sheets), the fabrication process requires high temperature (such as chemical and physical vapor deposition), electroplating, and delicate transfer processes (Huang et al. 2019). In this topic we will present some of the main techniques used in the manufacturing process that were broken down as: Surface decoration methods and Porous architecture methods. This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

3.1 Surface coating (decoration) methods

3.1.1 Electroplating

Electroplating, also known as the electrodeposition, is the process of depositing elemental or compound metals or semiconductors on a conducting substrate by passing an electric current through an ionic electrolyte in which metal or semiconductor ions are present. In sum, it is a galvanic or electrochemical cell that acts in reverse (Yang et al. 2018; Ojo and Dharmadasa 2018).

Recently, Li et al. (2020b) used electroplating PPy decorated sponge with multiscale porous structures to extend the pressure sensing range of PPy-based piezoresistive sensors. In other recent study, Wang et al. (2020c) presented a flexible device integrated with piezo-resistive sensing element and voltage-sensing element to simultaneously measure human respiration and electro-cardiac signal. When applied to the measurement of respiratory pressure, the piezo-resistive performance of the device was enhanced by electrodeposited nano-copper.

3.1.2 Electropraying

Electrospraying, also known as electrodynamic spraying, is capable of producing diminutive droplets with submicron sizes by means of an electric field. For the purpose of nanoparticle production, the common setup of electrospraying consists of a high-voltage power supply, a plastic/glass syringe capped by a metallic capillary to hold a polymer solution, a syringe pump to control the flow of the solutions, and a grounded collector. When a high electric field is applied at the needle, a charged liquid jet will break up into droplets, which form small particles with generally narrow size distribution on the collector (Wang et al. 2019b).

Recently, Masa et al. (2020) investigate the electrospray technique for the preparation of graphene layers for use in chemiresistive gas sensors. They dispersed reduced graphene oxide (rGO) in isopropyl alcohol (0.1 mg/mL) that was electrosprayed and the rGO flakes are deposited onto a polymeric substrate with printed interdigitated electrodes.

3.1.3 Vapor deposition techniques

The majority of Physical or Chemical Vapor Deposition methods (PVD or CVD) has been tailored to create 1D nanoscale materials such as nanotubes, nanorods or nanowires, using the original geometric shape of specific nanomaterials as templates or scaffolds (Rodrigues et al. 2019). This field is still evolving, with several fabrication methods reported in the literature for the synthesis of nanostructures with great potential for technological applications. For the purpose of freestanding materials, the vapor deposition technique must give excellent conformality and deposition control at the nanoscale level (Dias et al. 2020; Chiappim et al. 2020a, b). Among them, the atomic layer deposition (ALD) proved to be the key to this specific problem. ALD is a versatile technique that can be used to coat and functionalize surfaces with single or multiple components (Pessoa et al. 2019). The foremost advantage of ALD is its ability to control the coating thickness down to the subnanometer range as a function of the number of reaction cycles (Chiappim et al. 2021). ALD does not depend on the line of view to reach secluded spots; thus, it can be applied to almost any kind of high aspect ratio structures producing pinhole-free conformal coatings and chemically bonded layers by the use of sequential self-limiting surface reactions and low temperatures (Rodrigues et al. 2019). Several metals, metallic oxides, nitrides and sulfides can be produced by ALD, however, there is a limitation of the technique for the synthesis of carbides and carbonaceous materials (Fraga and Pessoa 2020, 2021; Chiappim Junior et al. 2021; Pessoa et al. 2018). Such difficulties are believed to be overcome in the next decade with the advancement of technology and chemical routes between precursors.

Finally, although CNTs and graphene could be generally fabricated with CVD method, the complexity of experimental conditions limited their mass production and practical application.

3.2 Porous architectures methods

3.2.1 Electrospinning

In an electrospinning process, high voltages are applied to the droplets at the nozzle; when the electric force becomes larger than the surface tension force, a jet shoots out from the Taylor cone. The diameter of the fiber is usually much smaller than ones made from 3D printing, i.e., of the order or lower than micrometers (Huang et al. 2019). The experimental setup for this process is similar to that of electrospraying, the difference is concerning the concentration of the polymer solution, where it dictates the structures of the resulting materials. Spherical particles are observed at lower solution concentrations. As the concentration approaches a critical value, column strand morphologies are usually generated, that is, electrically spun fibers with particles. Above the critical concentration of the solution, uniform fibers can be produced.

Electrospinning process can be used in the fabrication of nanofibers (NFs) or microfibers composed of numerous materials, such as elastic polymers, conductive materials, and graphene (Kweon et al. 2018). In addition, electrospinning is suitable for rapidly producing large-area membranes with adjustable properties (high surface area, pore volume, and material type) under ambient conditions (Lou et al. 2016). Flexible and porous polymer mesh fabricated through electrospinning can function as a layer of dielectric or piezoelectric materials with tunable properties. The nonconductive polymer mesh can be converted to piezoresistive materials through carbonization (Wang et al. 2017b) or surface coating (Cheng et al. 2017). A recent review highlighted that the electrospinning technique is a promising method for constructing 3D graphene-based structures for wearable piezoresistive pressure sensors (Cao et al. 2021).

3.2.2 Roll-to-roll inkjet printing and screen printing

The roll-to-roll (R2R) inkjet printing (non-contact) and screen-printing (contact) processes are particularly suitable approaches for fabricating 2D patterns, such as flexible sensor array (Riza and Du 2020) and sensing electrodes (Chang et al. 2009).

Inkjet printing uses a digital image signal to print the design by propelling ink droplets onto the substrate instead of any physical image carriers. Typically, in inkjet printing, the inks will be in a liquid state with low viscosities and can be directly printed onto the substrate (Maddipatla et al. 2020).

Screen-printing is typically done either by hand or using a semi or fully automated system. The screen printer consists of a squeegee, stencil, and a screen with the design on it. Typically, screen fibers are made of plastic, natural silk, or metal fibers, and the squeeze is made of rubber. A section in the screen will be imposed by the design of the desired print and the ink is allowed to pass through it, and the desired design is created on the substrate being used. The ink is transferred either by pushing or forcing the ink by squeezing through the screen, and thus, this printing process is also referred as push through process. The print quality mainly depends on the mesh count, wire diameter, emulsion thickness, off-set height, and deflection angle of the screen (Maddipatla et al. 2020).

The advantage of the screen-printing technique over inkjet is mainly the ability to print in a large area, which facilitates its implementation at an industrial level. However, the screen-printing technique still has relatively low resolution, which makes it difficult to miniaturize devices.

Concern the use of R2R printing technology in the synthesis of wearable piezoresistive sensor onto polymeric substrate, Lee et al. fabricated all-printed high-density SWCNT thin film transistor (TFT) arrays, where the pressure sensing function was achieved by integrating with piezoresistive rubbers (Lee et al. 2016). The recent review of Maddipatla et al. (2020) presents the recent progresses in manufacturing techniques of printed and flexible sensors.

Recently, a few ultrahigh-resolution R2R systems have been developed based on flexures and advanced control, which may be used to produce next-generation high-resolution pressure sensor arrays (Huang et al. 2019).

3.2.3 Hydrogel

Hydrogels show a strong capability to absorb a high amount of water, and possess biological and elastic (i.e., softness) compatibility: these are desirable features for biological applications in wearable chemical (bio)sensors, which require mechanical flexibility to result comfortable to the body (Scarpa et al. 2020). Several designs of resonating MEMSs, in particular piezoresistive-based MEMSs, have been proposed and realized in combination with hydrogels (Millet et al. 2012).

4 Examples of wearable piezoresistive sensors and their applications

An interesting application of wearable piezoresistive sensors has been reported by Jeong et al. (2009) that evaluated the accurate performance of this device type for monitoring biosignal. In this study, the piezoresistive fabric sensors were prepared by knitting a single conductive yarn on the shirt and tested by detecting the respiratory effort signal through the thorax movement. It was observed that the results of the respiratory rate are in a quite good agreement with the reference values even in the fast running movement. In a previous publication, Huang et al. (2008) demonstrated the feasibility wearable yarn-based piezoresistive sensor to track the respiratory signals precisely. Besides, they report the performance testing of yarn-based piezoresistive sensors, the fabrication process of these devices using piezoresistive fibers, elastic, and regular polyester fibers is discussed in detail. Still on the use of wearable piezoresistive sensors in biosignals monitoring, another interesting example is in automobile safety belt as reported by Hamdani and Fernando (2015). These authors proposed a cardiorespiratory sensor system prototype constructed in an automobile safety belt using a copper ink based nonwoven material, which works based on the piezoresistive effect due to the pressure exerted on the sensor as a result of expansion of the thorax/abdomen area of the body for respiration and due to the principle of ballistocardiography (BCG) in heart signal sensing. More recent, Wang et al. developed a wearable piezoresistive sensor capable of capturing cardiorespiratory signals fabricated by sandwiching a nano silver electro-conductive ink impregnated nonwoven material between two layers of knitted silver fabric that function as sensor electrodes. The analysis of the performance of this sensor, together with a comparison against a commercially available, portable, cardiorespiratory signal monitoring device, shows that it is a highly sensitive, accurate and reliable device for capturing cardiorespiratory signals (Wang et al. 2018b).

Recent publications in the monitoring of physiological parameters using wearable piezoresistive sensors are numerous, as for example the article “Smart Textile Based on Piezoresistive Sensing Elements for Respiratory Monitoring” (Massaroni et al. 2019), which discussed the use of piezoresistive elements to develop a smart textile for respiratory monitoring concluding that it is suitable for respiratory frequency monitoring in a wide range of values. There is also a recent study on the application of knitted piezoresistive smart chest band for respiration patterns assessment (Raji et al. 2019). Experiments were conducted under several test conditions and results showed a successful application of this chest band with result patterns being in congruence with studies conducted using other related respiratory measurement technologies and instruments. Moreover, Choundry et al. (2020) have proposed to develop wearable piezoresistive sensors based on e-textiles fabricated using a new easy scalable stitching technique, which allows to create free-form sensor designs. After the extensive characterization, the developed sensor was embedded inside a garment and used to measure small pressure changes exerted by human muscles. The tests showed that this low cost piezoresistive sensor is capable of monitoring breathing rate through ribcage and step counting through hamstring muscle. One last example of wearable piezoresistive devices for human physiological signals monitoring is a flexible piezoresistive sensor based on conducting polymer-coated fabric developed by Lin et al. (2020). This sensor can be attached on different positions of body and applied to recording physiological signals. Its advantages include rapid response, recovery speed and excellent durability.

Another important field of application for wearable piezoresistive sensors is human body movement monitoring. Orengo et al. (2010) reported wearable devices instrumented with commercial piezoresistive sensors for human body movement tracking. They developed a simple and accurate RLC model fitted on sensor electrical response under fast deformation and relaxation movements, which allowed to predict the actual device behavior in tracking body fast movements. A highly cited article in this area, published in 2014, explores the use of graphene woven fabrics (GWFs) based piezoresistive strain sensors for human motion monitoring. The sensor exhibited relatively good sensitivity, high reversibility, superior physical robustness, easy fabrication and ease to follow human skin deformation. These characteristics demonstrate its potential not only for body monitoring but also for displays, robotics, fatigue detection, among other (Wang et al. 2014). Another important article of this period discussed a new type of stretchable strain sensor for human motion detection fabricated. This flexible piezoresistive pressure sensor uses a thin PDMS membrane as a deformable diaphragm and an Ag NP based serpentine metallic pattern as the piezoresistive element. It was noted that the developed sensor can be applied to detect multiple human motions such as finger and wrist motions and for measuring the pressure with high sensitivity to a low pressure which demonstrates which it can provide an efficient and economic approach to such applications (Lee et al. 2014b). A pressure sensor based on irregular microhump patterns has been also proposed for body motion sensing (Wang et al. 2016). The active layer of this sensor is fabricated by spin coating PEDOT: PSS on top of the patterned PDMS. This flexible device exhibited high sensitivity, showing its great potential in the next generation of smart sensors for robotics, real‐time health monitoring, and biomedical applications. More recent Mai et al. (2019) reported a self-standing piezoresistive sensors fabricated using a simple method based on blending multiwall carbon nanotubes (MWCNTs) with a stretchable elastomeric matrix (Ecoflex).

These sensors exhibited remarkable mechanical and electromechanical response features which are essential for wearable applications to monitor human motion with minimal discomfort, e.g., finger bending, walking or speaking, and even detecting a hot liquid poured into a cup. Also, Rezaei et al. (2019) developed a core–sheath fiber strain sensor from readily available materials in a one-step dip-coating process and demonstrate the development of a smart sleeveless shirt for measuring the kinematic angles of the trunk relative to the pelvis in complicated three-dimensional movements. This year, the design of a flexible piezoresistive sensor based on interlocked graphene microarrays on a flexible substrate was reported by Cheng et al. (2020). This sensor exhibits good performance and fast-response characteristic of this sensor, which allows meticulous detection of complicated stimuli from various human motions. In addition, Zheng et al. (2021) explored the use of a MXene/cotton fabric (MCF) in wearable pressure sensor for human motion detection and E-skin applications. It was observed that MCF based pressure sensor can be employed to detect and distinguish various human health signals, including finger motion, early-stage Parkinson’s static tremor and wrist pulse.

Other applications of wearable piezoresistive sensors include human facial expression detection and assessing remission in mental health. The potential of a low-cost stretchable piezoresistive strain sensor based on stretchable silver ink to distinguish three facial expressions (happy, sad and disgust) was explored by Ramli et al. (2020). The obtained results indicate that this sensor is promising for applications in the field of facial expression detection, human body monitoring and robotics. Regarding to wearable monitoring system based on piezoresistive sensors, Lanata et al. (2015) proposed a system called PSYCHE, which comprises a comfortable t-shirt with embedded sensors, such as textile electrodes, to monitor electrocardiogram heart rate variability (HRV) series, piezoresistive sensors for respiration activity, and triaxial accelerometers for activity recognition. The authors presented experimental results gathered from ten bipolar patients, wearing the PSYCHE system, with severe symptoms who exhibited mood states among depression, hypomania, mixed state, and euthymia, which confirm that the developed system is suitable for this application type. Finally, Table 4 shows some medical parameters measured by these sensors.

5 Conclusions

In recent years, the efforts to gain a better understanding of the dynamics of fabricating foldable, flexible, and elastic wearable sensors has increased and gained an interdisciplinary approach that enables fabricating miniaturized, low-cost sensors via high-throughput techniques, which can be used as monitoring of the health, e-skins, flexible displays, and epidermal sensors. The foldable, elastic, and miniaturized wearable sensors can potentially have applications in aerospace, automotive, environmental, packaging, biomedical, and defense. Thanks to the revolutionary progress of nanomaterials processing methods and an understanding of novel sensing mechanisms, nanomaterials-based flexible piezoresistive physical sensors, such as pressure sensors, strain sensors, and temperature sensors, have been very quickly developed with excellent optical, physical, mechanical, and transport properties. In this paper, we showed a global review of recent advances in nanomaterials-based piezoresistive wearable sensors. The synthesis of nanomaterials used on sensing structures, including Zero-dimensional, One-dimensional, Two-dimensional, and Three-dimensional piezoresistive nanomaterial, and interconnected nanoarchitectures, are summarized.

The piezoresistive sensor manufacturing involves two major fabrication processes, including the (i) surface coating (decoration) methods, which can be divided into electroplating, electrospraying, vapor deposition techniques, and (ii) porous architectures methods that can be divided into electrospinning, roll-to-roll inkjet printing and screen printing, and hydrogel. The structures and performance of nanomaterials-based pressure, strain, and temperature sensors are presented. Practical applications are showed of artificial e-skins, human activity detection, health monitoring (respiration rate, heart rate, blood pressure, facial expression recognition, intracranial pressure (ICP), and intraocular pressure (IOP)), and wearable entertainment. Although admirable progress has been made in developing nanomaterials-based piezoresistive sensors, considerable challenges need to be overcome for future applications. The main advantages and disadvantages are presented as follows:

Among the wearable sensors, those based on piezoresistive effect are the earliest and most widely used type. The piezoresistive sensors are robust with excellent resistance to vibration, shock, and dynamic pressure changes due to used materials. The circuits are straightforward and allow higher resolution in the measurement. The output is quasi-linear, and the response time is below one millisecond. They can be used for a broad range of pressure measurements from 21 kPa to about 150 MPa. The output is also stable over time. Alternatively, thin-film resistors can be created directly on the membrane. The chief disadvantage is related to the necessity of power that makes them unsuitable for battery operated or low power systems. The size is directly proportional to the resistance, and a decrease in the size increases the power consumption. Another disadvantage is related to the limitations on scaling due to strain averaging reduces the piezoresistive sensor's sensitivity. Another disadvantage is that the sensor output is temperature-dependent and becomes significant harm for applications such as tire pressure measurement. There are large temperature changes over the operating cycle.

References

Al-Handarish Y, Omisore OM, Duan W, Chen J, Zebang L, Akinyemi TO, Du W, Li H, Wang L (2020) Facile fabrication of 3D porous sponges coated with synergistic carbon black/multiwalled carbon nanotubes for tactile sensing applications. Nanomaterials 10(10):1941

Amjadi M, Yoon YJ, Park I (2015) Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes-ecoflex nanocomposites. Nanotechnology 26:375501

Blount DS, McDonough DJ, Gao Z (2021) Effect of wearable technology-based physical activity interventions on breast cancer survivors’ physiological, cognitive, and emotional outcomes: a systematic review. J Clin Med 10:2015

Boland CS, Khan U, Ryan G, Brawich S, Charifou R, Harvey A, Backes C, Li Z, Ferreira MS, Möbius ME et al (2016) Sensitive electromechanical sensors using viscoelastic graphene-polymer nanocomposites. Science 354(6317):1257–1260

Cao M, Fan S, Qiu H, Su D, Li L, Su J (2020a) CB Nanoparticles optimized 3D wearable graphene multifunctional piezoresistive sensor framed by loofah sponge. ACS Appl Mater Interfaces 12(32):36540–36547

Cao X, Zhang J, Chen S, Varley RJ, Pan K (2020b) 1D/2D nanomaterials synergistic, compressible, and response rapidly 3D graphene aerogel for piezoresistive sensor. Adv Funct Mater 30(35):2003618

Cao M, Su J, Fan S, Qiu H, Su D, Li L (2021) Wearable piezoresistive pressure sensors based on 3D graphene. Chem Eng J 406:126777

Chandel RS, Sharma S, Kaur S, Singh S, Kumar R (2021) Smart watches: a review of evolution in biomedical sector. Mater Today: Proc 50:1053–1066. https://doi.org/10.1016/j.matpr.2021.07.460

Chang W-Y, Fang T-H, Lin H-J, Shen Y-T, Lin Y-C (2009) A large area flexible array sensors using screen printing technology. J Disp Technol 5(6):178–183

Chang Y, Zuo J, Zhang H, Duan X (2020) State-of-the-art and recent developments in micro/nanoscale pressure sensors for smart wearable devices and health monitoring systems. Nanotechnol Precis Eng 3:43

Channa A, Popescu N, Skibinska J, Burget R (2021) The rise of wearable devices during the COVID-19 pandemic: a systematic review. Sensors 21:5787

Chen Y-H, Sawan M (2021) Trends and challenges of wearable multimodal technologies for stroke risk prediction. Sensors 21:460

Chen W, Yan X (2020) Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: a review. J Mater Sci Technol 43:175–188

Chen Z, Wang Z, Li X, Lin Y, Luo N, Long M, Zhao N, Xu J-B (2017a) Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures. ACS Nano 11(5):4507–4513

Chen S, Jiang K, Lou Z, Chen D, Shen G (2017b) Recent developments in graphene-based tactile sensors and e-skins. Adv Mater Technol 3(2):1700248

Chen M, Luo W, Xu Z, Zhang X, Xie B, Wang G, Han M (2019) An ultrahigh resolution pressure sensor based on percolative metal nanoparticles arrays. Nat Commun 10:4024

Chen X, Xie X, Liu Y, Zhao C, Wen M, Wen Z (2020) Advances in healthcare electronics enabled by triboelectric nanogenerators. Adv Funct Mater 30(43):2004673. https://doi.org/10.1002/adfm.202004673

Chen J, Tran V-T, Du H, Wang J, Chen C (2021) A direct-writing approach for fabrication of CNT/paper-based piezoresistive pressure sensors for airflow sensing. Micromachines 12(5):504

Chen K-Y, Xu Y-T, Zhao Y, Li J-K, Wang X-P, Qu L-T (2022) Recent progress in graphene-based wearable piezoresistive sensors: From 1D to 3D device geometries. Nano Mater Sci. https://doi.org/10.1016/j.nanoms.2021.11.003

Cheng C, Zhang J, Li S, Xia Y, Nie C, Shi Z, Camacho-Cuellar JL, Ma N, Haag R (2017) A water-processable and bioactive multivalent graphene nanoink for highly flexible bioelectronic films and nanofibers. Adv Mater 30(5):1705452

Cheng L, Qian W, Wei L, Zhang H, Zhao T, Li M, Liu A, Wu H (2020) A highly sensitive piezoresistive sensor with interlocked graphene microarrays for meticulous monitoring of human motions. J Mater Chem C 8:11525–11531

Chiappim W, Fraga MA, Maciel HS, Pessoa RS (2020a) An experimental and theoretical study of the impact of the precursor pulse time on the growth per cycle and crystallinity quality of TiO2 thin films grown by ALD and PEALD technique. Front Mech Eng 6:551085

Chiappim W, Watanabe M, Dias V, Testoni G, Rangel R, Fraga M, Maciel H, dos Santos FS, Pessoa R (2020b) MOS capacitance measurements for PEALD TiO2 dielectric films grown under different conditions and the impact of Al2O3 partial-monolayer insertion. Nanomaterials 10(2):338

Chiappim W, Testoni G, Miranda F, Fraga M, Furlan H, Saravia DA, da Silva SA, Petraconi G, Maciel H, Pessoa R (2021) Effect of plasma-enhanced atomic layer deposition on oxygen overabundance and its influence on the morphological, optical, structural, and mechanical properties of Al-doped TiO2 coating. Micromachines 12(6):588

Chiappim Junior W, Moreno LX, Pessoa RS, da Cunha AF, Salomé PMP, Leitão JP (2021) Novel dielectrics compounds grown by atomic layer deposition as sustainable materials for chalcogenides thin films photovoltaics technologies. In: Fraga MA, Amos D, Subramaniam V (eds) Sustainable material solutions for solar energy technologies, 1st edn. Elsevier, Amsterdam, The Netherlands, pp 71–100

Choundry NA, Rasheed A, Ahmad S, Arnold L, Wang L (2020) Design, development and characterization of textile stitch-based piezoresistive sensors for wearable monitoring. IEEE Sens J 20(18):10485–10494

Chu M, Nguyen T, Pandey V, Zhou Y, Pham HN, Bar-Yoseph R, Radom-Aizik S, Jain R, Cooper DM, Khine M (2019) Respiration rate and volume measurements using wearable strain sensors. NPJ Digit Med 2:8

Clayton MF, Bilodeau RA, Bowden AE, Fullwood DT (2020) Nanoparticle orientation distribution analysis and design for polymeric piezoresistive sensors. Sens Actuators A 303:111851

Costa P, Nunes-Pereira J, Oliveira J, Silva J, Moreira JA, Carabineiro SAC, Buijnsters JG, Lanceros-Mendez S (2017) High-performance graphene-based carbono nanofillers/polymer composites for piezoresisitive sensor applications. Compos Sci Technol 153:241–252

Dai S, Wang S, Yan H, Xu J, Hu H, Ding J, Yuan N (2019) Stretchable and self-healable hydrogel-based capacitance pressure and strain sensor for electronic skin systems. Mater Res Express 6(8):0850b9

Dañová R, Olejnik R, Slobodian P, Matyas J (2020) The piezoresisitive highly elastic sensor based on carbon nanotubes for the detection of breath. Polymers 12(3):713

De Fazio R, De Vittorio M, Visconti P (2021) Innovative IoT solutions and wearable sensing systems for monitoring human biophysical parameters: a review. Electronics 10:1660

De Meo E, Agnelli S, Veca A, Brunella V, Zanetti M (2020) Piezoresistive and mechanical behavior of CNT based polyurethane foam. J Compos Sci 4(3):131

Deng W, Yang T, Jin L, Yan C, Huang H, Chu X, Wang Z, Xiong D, Tian G, Gao Y et al (2019) Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy 55:516–525

Dias VM, Chiappim W, Fraga MA, Maciel MA, Marciano FR, Pessoa RS (2020) Atomic layer deposition of TiO2 and Al2O3 thin films for electrochemical study of corrosion protection in aluminum alloy cans used in beverage. Mater Res Express 7:076408

Dickey MD (2017) Stretchable and soft electronics using liquid metals. Adv Mater 29(27):1606425

Dul S, Pegoretti A, Fambri L (2020) Fused filament fabrication of piezoresistive carbon nanotubes nanocomposites for strain monitoring. Front Mater 7:12

Esmaeli A, Sbarufatti C, Jiménez-Suárez A, Hamouda AMS, Rovatti L, Ureña A (2020) Synergistic effects of double-walled carbon nanotubes and nanoclays on mechanical, electrical, and piezoresistive properties of epoxy based nanocomposites. Compos Sci Technol 200:108459

Farcau C, Moreira H, Viallet B, Grisolia J, Ciuculescu-Pradines D, Amiens C, Ressier L (2011) Monolayered wires of gold colloidal nanoparticles for high-sensitivity strain sensing. J Phys Chem C 115(30):14494–14499

Fortunato M, Bellagamba I, Tamburrano A, Sarto MS (2020) Flexible ecoflex/graphene nanoplatelet foams for highly sensitive low-pressure sensors. Sensors 20(16):4406

Fraga M, Pessoa R (2020) Progresses in synthesis and application of SiC films: from CVD to ALD and from MEMS to NEMS. Micromachines 11(9):799

Gao B, He Z, He B, Gu Z (2019) Wearable eye health monitoring sensors based on peacock taik-inspired inverse opal carbon. Sens Actuators B Chem 288:734–741

Gong S, Cheng W (2016) One-dimensional nanomaterials for soft electronics. Adv Electron Mater 3(3):1600314

Goud BS, Suresh Y, Annapurna S, Singh AK, Bhikshamaiah G (2016) Green synthesis and characterization of cadmium sulphide nanoparticles. Mat Today Proc 3(10):4003–4008

Graz I, Krause M, Bauer-Gogonea S, Bauer S, Lacour SP, Ploss B, Zirki M, Stadlober B, Wagner S (2009) Flexible active-matrix cells with selectively poled bifunctional polymer-ceramic nanocomposite for pressure and temperature sensing skin. J Appl Phys 106:034503

Gunasekara DS, He Y, Fang S, Zhao L, Liu H, Liu L (2020) High-repeatability macro-porous sponge piezoresistive pressure sensor with polydopamine/polypyrrole composite coating based on in situ polymerization method. Appl Phys A 126:789

Hamdani STA, Fernando A (2015) The application of a piezo-resistive cardiorespiratory sensor system in an automobile safety belt. Sensors 15(4):7742–7753

Heikenfeld J, Jajack A, Rogers J, Gutruf P, Tian L, Pan T, Li R, Khine M, Kim J, Wang J, Kim J (2018) Wearable sensors: modalities, challenges, and prospects. Lab Chip 18:217–248

Henderson J, Condell J, Connolly J, Kelly D, Curran K (2021) Review of wearable sensor-based health monitoring glove devices for rheumatoid arthritis. Sensors 21:1576

Herren B, Saha MC, Liu Y (2019) Carbon nanotube-based piezoresistive sensors fabricated by microwave irradiation. Adv Eng Mater 22(2):1901068

Herren B, Webster V, Davidson E, Saha MC, Altan MC, Liu Y (2021) PDMS sponges with embedded carbon nanotubes as piezoresistive sensors for human motion detection. Nanomaterials 11(7):1740

Hoang PT, Salazar N, Porkka TN, Joshi K, Liu T, Dickens TJ, Yu Z (2016) Engineering crack formation in carbon nanotube silver nanoparticle composite films for sensitive and durable piezoresistive sensors. Nano Express 11:422

Huang C-T, Shen C-L, Tang C-F, Chang S-H (2008) A wearable yarn-based piezo-resistive sensor. Sens Actuators A Phys 141:396–403

Huang Y, Fan X, Chen S-C, Zhao N (2019) Emerging technologies of flexible pressure sensors: materials, modeling, devices, and manufacturing. Adv Funct Mater 29(12):1808509

Huang L, Chen J, Xu Y, Hu D, Cui X, Shi D, Zhu Y (2021) Three-dimensional light-weight piezoresistive sensors based on conductive polyurethane sponges coated with hybrid CNT/CB nanoparticles. Appl Surf Sci 548:149268

Huynh T-P, Sonar P, Haick H (2017) Advanced materials for use in soft self-healing devices. Adv Mater 29(19):1604973

Hwang S-H, Park Y-B, Hur S-H, Chae HG (2018) Pt nanoparticle-decorated reduced graphene oxide hydrogel for high-performance strain sensor: tailoring piezoresistive property by controlled microstructure of hydrogel. ACS Appl Nano Mater 1(6):2836–2843

Imtiaz SA (2021) A systematic review of sensing technologies for wearable sleep staging. Sensors 21:1562

Iqbal SMA, Mahgoub I, Du E, Leavitt MA, Asghar W (2021) Advances in healthcare wearable devices. NPJ Flexible Electronics 5:9

Jayathilaka WADM, Qi K, Qin Y, Chinnappan A, Serrano-Garcia W, Baskar C, Wang H, He J, Cui S, Thomas SW et al (2018) Significance of nanomaterials in wearable: a review on wearable actuators and sensors. Adv Mater 31(7):1805921

Jeong JW, Jang YW, Lee I, Shin S, Kim S (2009) Wearable respiratory rate monitoring using piezoresistive fabric sensor. In: Proceedings of the World Congress on Medical Physics and Biomedical Engineering, Munich, Germany, September 7–12, 2009

Jiang C-W, Ni I-C, Tzeng S-D, Kuo W (2015) Nearly isotropic piezoresistive response due to charge detour conduction in nanoparticle thin films. Sci Rep 5:11939

Jiang Y, Wang Y, Mishra YK, Adelung R, Yang Y (2018) Stretchable CNTs-ecoflex composite as variable-transmittance skin for ultrasensitive strain sensing. Adv Mater Technol 3(12):1800248

Jing Z, Zhang Q, Cheng Y, Ji C, Zhao D, Liu Y, Jia W, Pan S, Sang S (2020) Highly sensitive, reliable and flexible piezoresistive pressure sensors based on graphene-PDMS@sponge. J Micromech Microeng 30:085012

Joo Y, Byun J, Seong N, Ha J, Kim H, Kim S, Kim T, Im H, Kim D, Hong Y (2015) Silver nanowire-embedded PDMS with a multiscale structure for a highly sensitive and robust flexible pressure sensor. Nanoscale 7:6208–6215

Jung Y, Jung K, Park B, Choi J, Kim D, Park J, Ko J, Cho H (2019) Wearable piezoresistive strain sensor based on graphene-coated three-dimensional micro-porous PDMS sponge. Micro Nano Syst Lett 7:20

Karmakar RS, Wang J-C, Huang Y-T, Lin K-J, Wei K-C, Hsu Y-H, Huang Y-C, Lu Y-J (2020) Real-time intraoperative pressure monitoring to avoid surgically induced localized brain injury using a miniaturized piezoresistive pressure sensor. ACS Omega 5(45):29342–29350

Ke K, Pötschke P, Wiegand N, Krause B, Voit B (2016) Tuning the network structure in poly(vinylidene fluoride)/carbon nanotube nanocomposites using carbon black: toward improvements of conductivity and piezoresistive sensitivity. ACS Appl Mater Interfaces 8(22):14190–14199

Khalifa M, Wuzella G, Lammer H, Mahendran AR (2020) Smart paper from graphene coated cellulose for high-performance humidity and piezoresistive force sensor. Synth Met 266:116420

Khan MUA, Raad R, Tubbal F, Theoharis PI, Liu S, Foroughi J (2021) Bending analysis of polymer-based flexible antennas for wearable, general IoT applications: a review. Polymers 13:357

Kim S, Dong Y, Hossain MM, Gorman S, Towfeeq I, Gajula D, Childress A, Rao AM, Koley G (2019) Piezoresitive graphene/P(VDF-TrFE) heterostructure based highly sensitive and flexible pressure sensor. ACS Appl Mater Interfaces 11(17):16006–16017

Ko W-Y, Huang L-T, Lin K-J (2021) Green technique solvent-free fabrication of silver nanoparticle-carbon nanotube flexible films for wearable sensors. Sens Actuators A 317:112437

Kumar V, Lee G, Monika Choi J, Lee D-J (2020) Studies on composites based on HTV and RTV silicone rubber and carbon nanotubes for sensors and actuators. Polymer 190:122221

Kweon OY, Lee SJ, Oh JH (2018) Wearable high-performance pressure sensors based on three-dimensional electrospun conductive nanofibers. NPG Asia Materials 10:540–551

Lanata A, Valenza G, Nardelli M, Gentili C, Scilingo EP (2015) Complexity index from a personalized wearable monitoring system for assessing remission in mental health. IEEE J Biomed Health Inform 19(1):132–139

Lee H, Lee D, Hwang J, Nam D, Byeon C, Ko SW, Lee S (2014a) Silver nanoparticle piezoresistive sensors fabricated by roll-to-roll slot-die coating and laser direct writing. Opt Express 2(8):8919–8927

Lee J, Kim S, Lee J, Yang D, Park BC, Ryu S, Park I (2014b) A stretchable strain sensor based on a metal nanoparticle thin film for human motion detection. Nanoscale 6:11932–11939

Lee W, Koo H, Sun J, Noh J, Kwon K-S, Yeom C, Choi Y, Chen K, Javey A, Cho G (2015) A fully roll-to-roll gravure-printed carbon nanotube-based active matrix for multi-touch sensors. Sci Rep 5:17707

Lee D, Lee H, Jeong Y, Ahn Y, Nam G, Lee Y (2016) Highly sensitive, transparent, and durable pressure sensors based on sea-urchin shaped metal nanoparticles. Adv Mater 28(42):9364–9369

Lee S, Chu Y, Ryu J, Park YJ, Yang S, Koh SB (2021) Artificial intelligence for detection of cardiovascular-related diseases from wearable devices: a systematic review and meta-analysis. Yonsei Med J 63:S93–S107

Li T, Luo H, Qin L, Wang X, Xiong Z, Ding H, Gu Y, Liu Z, Zhang T (2016) Flexible capacitive tactile sensor based on micropatterned dielectric layer. Small 12(36):5042–5048

Li R, Si Y, Zhu Z, Guo Y, Zhang Y, Pan N, Sun G, Pan T (2017) Supercapacitive iontronic nanofabric sensing. Adv Mater 29(36):1700253

Li J, Fang L, Sun B, Li X, Kang SH (2020a) Review—recent progress in flexible and stretchable piezoresistive sensors and their applications. J Electrochem Soc 167:037561

Li Y, Jiang C, Han W (2020b) Extending the pressure sensing range of porous polypyrrole with multiscale microstructures. Nanoscale 12:2081–2088

Lin X, Zhang T, Cao J, Wen H, Fei T, Liu S, Wang R, Ren H, Zhao H (2020) Flexible piezoresistive sensors based on conducting polymer-coated fabric applied to human physiological signals monitoring. J Bionic Eng 17:55–63

Liu M, Pu X, Jiang C, Liu T, Huang X, Chen L, Du C, Sun J, Hu W, Wang ZL (2017a) Large-area all-textile pressure sensors for monitoring human motion and physiological signals. Adv Mater 29(41):1703700

Liu Y, Pharr M, Slavatore GA (2017b) Lab-on-Skin: a review of flexible and stretchable electronics for wearable health monitoring. ACS Nano 11(10):9614–9635

Liu W, Liu N, Yue Y, Rao J, Luo C, Zhang H, Yang C, Su J, Liu Z, Gao Y (2018a) A flexible and highly sensitive pressure sensor based on elastic carbon foam. J Mater Chem C 6:1451–1458

Liu W, Liu N, Yue Y, Rao J, Cheng F, Su J, Liu Z, Gao Y (2018b) Piezoresistive pressure sensor based on synergistical innerconnect polyvinyl alcohol nanowires/wrinkled graphene film. Small 14(15):1704149

Lou Z, Chen S, Wang L, Jiang K, Shen G (2016) An ultra-sensitive and rapid response speed graphene pressure sensors for electronic skin and health monitoring. Nano Energy 23:7–14

Maddipatla D, Narakathu BB, Atashbar M (2020) Recent progress in manufacturing techniques of printed and flexible sensors: a review. Biosensors 10(12):199

Mai H, Mutlu R, Tawk C, Alici G, Sencadas V (2019) Ultra-stretchable MWCNT-ecoflex piezoresisitve sensors for human motion detection applications. Compos Sci Technol 173:118–124

Mamdiwar SD, Akshith R, Shakruwala Z, Chadha U, Srinivasan K, Chang C-Y (2021) Recent advances on IoT-assisted wearable sensor systems for healthcare monitoring. Biosensors 11:372

Masa S, Mena MJ, Hontañón E, Lozano J, Eqtesadi S, Narros A (2020) Electrospray printing of graphene layers for chemiresistive gas sensors. Eng Proc 2(1):66

Massaroni C, Di Tocco J, Lo Presti D, Longo UG, Miccinilli S, Sterzi S, Formica D, Saccomandi P, Schena E (2019) Smart textile based on piezoresistive sensing elements for respiratory monitoring. IEEE Sens J 19(17):7718–7725

Michel TR, Capasso MJ, Cavusoglu ME, Decker J, Zeppilli D, Zhu C, Bakrania S, Kadlowec JA, Xue W (2020) Evaluation of porous polydimethylsiloxane/carbon nanotubes (PDMS/CNTs) nanocomposites as piezoresistive sensor materials. Microsyst Technol 26:1101–1112

Millet LJ, Corbin EA, Free R, Park K, Kong H, King WP, Bashir R (2012) Characterization of mass and swelling of hydrogel microstructures using MEMS resonant mass sensor arrays. Small 8(16):2555–2562

Mohan VB, Lau K-T, Hui D, Bhattacharyya D (2018) Graphene-based materials and their composites: a review on production, applications and product limitations. Comp B Eng 142:200–220

Monaco V, Stefanini C (2021) Assessing the tidal volume through wearables: a scoping review. Sensors 21:4124

Niu D, Jiang W, Ye G, Wang K, Yin L, Shi Y, Chen B, Luo F, Liu H (2018) Graphene-elastomer nanocomposites based flexible piezoresistive sensors for strain and pressure detection. Mater Res Bull 102:92–99

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Electric field effect in atomically thin carbon films. Science 306(5696):666–669

Ojo AA, Dharmadasa IM (2018) Electroplating of semiconductor materials for applications in large area electronics: a review. Coatings 8(8):262

Ometov A, Shubina V, Klus L, Skibinska J, Saafi S, Pascacio P, Flueraturu L, Gaibor DQ, Chukhno N, Chukhno O et al (2021) A survey on wearable technology: history, state-of-the-art and current challenges. Comput Netw 193:108074

Orengo G, Saggio G, Bocchetti S, Giannini G (2010) Advanced characterization of piezoresistive sensors for human body movement tracking. In: Proceedings of 2010 IEEE International Symposium on Circuits and Systems, Paris, France, 30 May–2 June 2010

Pan L, Chortos A, Yu G, Wang Y, Isaacson S, Allen R, Shi Y, Dauskardt R, Bao Z (2014) An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat Commun 5:3002

Paulson GG, Antony JK (2016) Design of NEMS based intraocular pressure sensing system. Procedia Technol 25:100–106

Pessoa RS, Fraga MA (2019) Biomedical applications of ultrathin atomic layer deposited metal oxide films on polymeric materials. In: Benelmekki M, Erbe A (eds) Frontiers of nanoscience, 1st edn. Elsevier, Amsterdam, The Netherlands, pp 291–307

Pessoa RS, Fraga MA, Chiappim W, Maciel HS (2018) Exploring the properties and fule cell applications of ultrathin atomic layer deposited metal oxide films. In: Cheong KY, Impellizzeri G, Fraga MA (eds) Emerging Materials for Energy Conversion and Storage (1st edn). Elsevier, Amsterdam, The Netherlands, pp 83–114

Pessoa RS, Chiappim Junior W, Fraga MA (2021) Atomic layer deposition of materials for solar water splitting. In: Fraga MA, Amos D, Subramaniam V (eds) Sustainable material solutions for solar energy technologies, 1st edn. Elsevier, Amsterdam, The Netherlands, pp 363–380

Prashanthi K, Zhang H, Rao VR, Thundat T (2011) Local piezoelectric response of ZnO nanoparticles embedded in a photosensitive polymer. Phys Status Solidi - Rapid Res Lett 6(2):77–79

Qi K, Zhou Y, Ou K, Dai Y, You X, Wang H, He J, Qin X, Wang R (2020) Weavable and stretchable piezoresistive carbon nanotubes-embedded nanofiber sensing yarns for highly sensitive and multimodal wearable textile sensor. Carbon 170:464–476

Qiu L, Coskun MB, Tang Y, Liu JZ, Alan T, Ding J, Truong V-T, Li D (2015) Ultrafast dynamic piezoresistive response of graphene-based cellular. Adv Mater 28(1):194–200

Radha B, Sagade AA, Kulkarni GU (2011) Flexible and semitransparent strain sensors based on micromolded Pd nanoparticle-carbon u-stripes. ACS Appl Mater Interfaces 3(7):2173–2178

Raji RK, Miao X, Wan A, Niu L, Li Y, Boakye A (2019) Knitted piezoresistive smart chest band and its applications for respiration patterns assessment. J Eng Fibers Fabr 14:1–14

Rajitha G, Dash RK (2018) Optically transparent and high dielectric constant reduced graphene oxide (RGO)-PDMS based flexible composite for wearable and flexible sensors. Sens Actuators A Phys 277:26–34

Ramli NA, Nordin AN, Azlan NZ (2020) Development of low cost screen-printed piezoresistive strain sensor for facial expressions recognition system. Microelectron Eng 234:111440

Ramuz M, Tee BC-K, Tok JBH, Bao Z (2012) Transparent, optical, pressure-sensitive artificial skin for large-area stretchable electronics. Adv Mater 24(24):3223–3237

Ren H, Zheng L, Wang G, Gao X, Tan Z, Shan J, Cui L, Li K, Jian M, Zhu L et al (2019) Transfer-medium-free nanofiber-reinforced graphene film and applications in wearable transparent pressure sensors. ACS Nano 13(5):5541–5548

Rezaei A, Cuthbert TJ, Gholami M, Menon C (2019) Application-based production and testing of a core-sheath fiber strain sensor for wearable electronics: feasibility study of using the sensors in measuring tri-axial trunk motion angles. Sensors 19(19):4288

Riza M, Du X (2020) Roll-to-roll printing of wearable sensors and devices for personalized health monitoring. Am J Biomed Sci Res 7(6):495–498. https://doi.org/10.34297/ajbsr.2020.07.001208

Rizvi R, Naguib H (2014) Effect of carbon nanoparticle type, content, and stress on piezoresistive polyethylene nanocomposites. Polym Eng Sci 55(7):1643–1651

Rodrigues BVM, Dias VM, Fraga MA, da Silva SA, Lobo AO, Maciel HS, Pessoa RS (2019) Atomic layer deposition of TiO2 thin films on electrspun poly(butylene adipate-co-terephthalate) fibers: freestanding TiO2 nanostructures via polymer carbonization. Mat Today Proc 14:656–662

Rong G, Sawan M (2021) Energy solutions for wearable sensors: a review. Sensors 21:3806

Rum L, Vendrame E, Belluscio V, Camomilla V, Vannozzi G, Truppa L, Notarantonio M, Sciarra T, Lazich A et al (2021) Wearable sensors in sports for persons with disability: a systematic review. Sensors 21:1858

Sankar V, Nambi A, Bhat VN, Sethy D, Balasubramaniam K, Das S, Guha M, Sundara R (2020) Waterproof flexible polymer-functionalized graphene-based piezoresistive strain sensor for structural health monitoring and wearable devices. ACS Omega 5(22):12682–12691

Santos A, Fortunato E, Martins R, Águas H, Igreja R (2020) Transduction mechanisms, micro-structuring techniques, and applications of electronic skin pressure sensors: a review of recent advances. Sensors 20(16):4407

Scaffaro R, Maio A, Re GL, Parisi A, Busacca A (2018) Advanced piezoresistive sensor achieved by amphiphilic nanointerfaces of graphene oxide and biodegradable polymer blends. Compos Sci Technol 156:166–176

Scarpa E, Mastronardi VM, Guido F, Algieri L, Qualtieri A, Fiammengo R, Rizzi F, De Vittorio M (2020) Wearable piezoelectric mass sensor based on pH sensitive hydrogels for sweat pH monitoring. Sci Rep 10:10854

Sencadas V, Tawk C, Alici G (2020) Environmentally friendly and biodegradable ultrasensitive piezoresistive sensors for wearable electronics applications. ACS Appl Mater Interfaces 12(7):8761–8772

Shao Q, Niu Z, Hirtz M, Jiang L, Liu Y, Wang Z, Chen X (2014) High-performance and tailorable pressure sensor based on ultrathin conductive polymer film. Small 10(8):1466–1472

Shen X, Zheng L, Tang R, Nie K, Wang Z, Jin C, Sun Q (2020) Double-network hierarchial-porous piezoresistive nanocomposite hydrogel sensors based on compressive cellulosic hydrogel deposited with silver nanoparticles. ACS Sustainable Chem Eng 8(19):7480–7488

Sheng P, Abeles B (1972) Voltage-induced tunneling conduction in granular metals at low temperatures. Phys Rev Lett 28:34

Sheng P, Abeles B (1973) Hopping conductivity in granular metals. Phys Rev Lett 31:44

Shu Y, Li C, Wang Z, Mi W, Li Y, Ren T-L (2015) A pressure sensing system for heart rate monitoring with polymer-based pressure sensors and anti-interference post processing circuit. Sensors 15(2):3224–3235

Someya T, Sekitani T, Iba S, Kato Y, Kawaguchi H, Sakurai T (2004) A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. PNAS 101(27):9966–9970

Stefana E, Marciano F, Rossi D, Cocca P, Tomasoni G (2021) Wearable devices for ergonomics: a systematic literature review. Sensors 21:777

Su B, Gong S, Ma Z, Yap LW, Cheng W (2014) Mimosa-inspired design of a flexible pressure sensor with touch sensitivity. Small 11(16):1886–1891

Tang X, Pöstschke P, Pionteck J, Li Y, Formanek P, Voit B (2020) Tuning the piezoresistive behavior of poly(vinylidene fluoride)/carbon nanotube composites using poly(methyl methacrylate). ACS Appl Mater Interfaces 12(38):43125–43137

Teymourian H, Parrilla M, Sempionatto JR, Montiel NF, Barfidokht A, Van Echelpoel R, De Wael K, Wang J (2020) Wearable electrochemical sensors for the monitoring and screening of drugs. ACS Sensors 5(9):2679–2700

Tran MT, Tung TT, Sachan A, Losic D, Castro M, Feller JF (2020) 3D sprayed polyurethane functionalized graphene/carbon nanotubes hybrid architectures to enhance the piezoresistive response of quantum resistive pressure sensors. Carbon 168:564–579

Turco A, Monteduro AG, Montagna F, Primiceri E, Frigione M, Maruccio G (2022) Nanoarchitectonics of highly sensitive and with large working range 3D piezoresistive microporous foam based on carbon nanotubes and elastomer. J Colloid Interface Sci 607:1436–1445

Walter P, Podsiadly B, Zych M, Kaminski M, Skalski A, Raczynski T, Janczak D, Jakubowska M (2022) CNT/Graphite/SBS conductive fibers for strain sensing in wearable telerehabilitation devices. Sensors 22(3):800

Wang X, Gu Y, Xiong Z, Cui Z, Zhang T (2013) Silk-molded flexible, ultrasensitive, and highly stable electronics skin for monitoring human physiological signals. Adv Mater 26(9):1336–1342

Wang Y, Wang L, Yang T, Li X, Zang X, Zhu M, Wang K, Wu D, Zhu H (2014) Wearable and highly sensitive graphene strain sensors for human motion monitoring. Adv Funct Mater 24(29):4666–4670

Wang Z, Wang S, Zeng J, Ren X, Chee AJY, You BYS, Chung WC, Yang Y, Yu ACH, Roberts RC et al (2016) High sensitivity, wearable, piezoresistive pressure sensors based on irregular microhump structures and its applications in body motion sensing. Small 12(28):3827–3836

Wang Q, Jian M, Wang C, Zhang Y (2017a) Carbonized silk nanofiber membrane for transparent and sensitive electronic. Adv Funct Mater 27(9):1605657

Wang X, Liu Z, Zhang T (2017b) Flexible sensing electronics for wearable/attachable health monitoring. Small 13(25):1602790

Wang X, Li J, Song H, Huang H, Gou J (2018a) Highly stretchable and wearable strain sensor based on printable carbon nanotube layers/polydimethylsiloxane composites with adjustable sensitivity. ACS Appl Mater Interfaces 10(8):7371–7380