Abstract

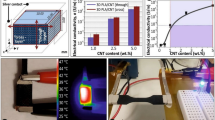

High-stability piezoresistive sensors are an important part of smart wearable systems. In this study, an in situ polymerization method was used to polymerize a layer of polydopamine (PDA) and poly-pyrrole (PPy) on the surface of the macro-porous sponge (MPS). The deposition of PDA was done using para toluene sulfonic acid (p-TSA), the pH of the solution being used to control the thickness of the PDA, that followed by PPy coating. The thin layer of PDA effects to give better adherent in-between MPS surface and PPy coating. The morphology, chemical composition, and pressure-sensing properties of the fabricated PDA/PPy pressure sensors have been widely investigated. The experimental results show that the PDA/PPy-MPS pressure sensor with the concentration of p-TSA is 0.05 M with PDA coating shows better performance in the pressure range of 1–10 kPa. The pressure sensor performance of PDA (0.05 M p-TSA)/PPy-MPS near 1000 pressure cycles related to average sensitivity, hysteresis, and non-linear errors are 7.20 ± 2.46 kPa−1, 13.51 ± 0.03%, and 3.30 ± 0.59%, respectively. The repeatability error of up and down near conductive signals are reported as 2.70 ± 0.93% and 2.25 ± 0.63%. Its minimum resistance is reported as 9.94 Ω when the pressure increased up to 119 kPa. The developed applications of PDA/PPy-MPS show promising ability to use as a pressure sensor and switching element in smart wearable devices.

Similar content being viewed by others

Data availability

More generally, the authors declare that the data used in this study to arrive at the findings are available within the article or from the corresponding author upon reasonable request.

References

A. Chortos, J. Liu, Z. Bao, Pursuing prosthetic electronic skin. Nat. Mater. 15(9), 937–950 (2016)

S. Xu et al., Plasma modification of PU foam for piezoresistive sensor with high sensitivity, mechanical properties and long-term stability. Chem. Eng. J. 381, 122666 (2020)

Y. He et al., A novel method for fabricating wearable, piezoresistive, and pressure sensors based on modified-graphite/polyurethane composite films. Materials (Basel) 10(7), 684 (2017)

M. Hussain, S.M. Imran, Y.H. Choa, Fabrication of pressure-sensitive multi-walled carbon nanotubes-poly(methyl methacrylate) nanocomposites for pressure-sensing applications. J. Nanosci. Nanotechnol. 19(3), 1315–1322 (2019)

N. Khalili, X. Shen, H.E. Naguib, An interlocked flexible piezoresistive sensor with 3D micropyramidal structures for electronic skin applications. Soft Matter 14(33), 6912–6920 (2018)

K.-S. Teh, L. Lin, MEMS sensor material based on polypyrrole–carbon nanotube nanocomposite: film deposition and characterization. J. Micromech. Microeng. 15(11), 2019–2027 (2005)

Y. Zang et al., Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horizons 2(2), 140–156 (2015)

B.D.S. Rosa, et al., Development of poly (butylene adipate-co-terephthalate) filled with montmorillonite-polypyrrole for pressure sensor applications. Mater. Res. 22(2) (2019).

J. Pan et al., Stretchable and highly sensitive braided composite yarn@polydopamine@polypyrrole for wearable applications. ACS Appl. Mater. Interfaces 11(7), 7338–7348 (2019)

D. Hao, B. Xu, Z. Cai, Polypyrrole coated knitted fabric for robust wearable sensor and heater. J. Mater. Sci. Mater. Electron. 29(11), 9218–9226 (2018)

J. Molina et al., Conducting fabrics of polyester coated with polypyrrole and doped with graphene oxide. Synth. Met. 204, 110–121 (2015)

J. Tsang et al., Effect of fabrication temperature on strain-sensing capacity of polypyrrole-coated conductive fabrics. Polym. Int. 56(7), 827–833 (2007)

D.-V. Brezol, Polypyrrole films prepared by chemical oxidation of pyrrole in aqueous fecl3 solution. J. Sci. Arts 12, 53–58 (2010)

J. Xue et al., Wearable and visual strain sensors based on Zn2GeO4@polypyrrole core@shell nanowire aerogels. J Mater Chem C (2017)

Y. Tan, K. Ghandi, Kinetics and mechanism of pyrrole chemical polymerization. Synth. Met. 175, 183–191 (2013)

C.R.K. Rao et al., Synthesis and properties of polypyrrole obtained from a new Fe (III) complex as oxcidizing agent. Indian J. Chem. 52A, 744–748 (2013)

S.P. Armes, Optimum reaction conditions for the polymerization of pyrrole by iron(iii) chloride in aqueous solution. Synth. Met. 20, 365–371 (1987)

A. Chatterjee, S. Maity, A comparative study of reaction kinetics of in-situ chemical polymerization of polypyrrole onto various textile fibres. Surf. Coat. Technol. 324, 569–576 (2017)

F. Ferrero et al., Pyrrole chemical polymerization on textiles: kinetics and operating conditions. J. Appl. Polym. Sci. 102(5), 4121–4126 (2006)

L.-X. Wang, X.-G. Li, Y.-L. Yang, Preparation, properties and applications of polypyrroles. React. Funct. Polym. 47, 125–139 (2001)

N.N. Ha et al., Electronic properties of the polypyrrole-dopant anions ClO4(-) and MoO4(2-): a density functional theory study. J Mol Model 23(12), 336 (2017)

Y. Liu, Y. Liu, X. Zhao, The influence of dopant on the dielectric properties of flexible polypyrrole composites. J. Text. Inst. 108, 1–5 (2016)

H.K. Chitte et al., Synthesis of polypyrrole using ferric chloride (FeCl3) as oxidant together with some dopants for use in gas sensors. J. Sens. Technol. 01(02), 47–56 (2011)

Z. Deng et al., Rapid thermal responsive conductive hybrid cryogels with shape memory properties, photothermal properties and pressure dependent conductivity. J. Colloid Interface Sci. 526, 281–294 (2018)

Y. Zhao et al., A novel flexible sensor for respiratory monitoring based on in situ polymerization of polypyrrole and polyurethane coating. RSC Adv. 7(78), 49576–49585 (2017)

H. Liu et al., A novel two-step method for fabricating silver plating cotton fabrics. J. Nanomater. 2016, 1–11 (2016)

F.-F. Ma et al., Polydopamine-assisted deposition of polypyrrole on electrospun poly(vinylidene fluoride) nanofibers for bidirectional removal of cation and anion dyes. Chem. Eng. J. 354, 432–444 (2018)

H. Liu et al., A novel method for fabricating elastic conductive polyurethane filaments by in-situ reduction of polydopamine and electroless silver plating. Mater. Des. 113, 254–263 (2017)

F. Bernsmann et al., Dopamine-melanin film deposition depends on the used oxidant and buffer solution. Langmuir 27(6), 2819–2825 (2011)

M. Amjadi et al., Stretchable, skin-mountable, and wearable strain sensors and their potential applications: a review. Adv. Func. Mater. 26(11), 1678–1698 (2016)

T.N. Ly, S. Park, Highly sensitive ammonia sensor for diagnostic purpose using reduced graphene oxide and conductive polymer. Sci. Rep. 8(1), 18030 (2018)

H. Kato et al., Fourier transform infrared spectroscopy study of conducting polymer polypyrrole higher order structure of electrochemically synthesized film. J. Phys. Chem. 95, 6014–6016 (1990)

Y. He et al., Highly stable and flexible pressure sensors with modified multi-walled carbon nanotube/polymer composites for human monitoring. Sensors (Basel) 18(5), 1338 (2018)

C. Yang et al., Highly sensitive wearable pressure sensors based on three-scale nested wrinkling microstructures of polypyrrole films. ACS Appl. Mater. Interfaces. 10(30), 25811–25818 (2018)

S.J. Kim et al., Highly sensitive and flexible strain-pressure sensors with cracked paddy-shaped MoS2/graphene foam/ecoflex hybrid nanostructures. ACS Appl. Mater. Interfaces 10(42), 36377–36384 (2018)

H. Park et al., Microporous polypyrrole-coated graphene foam for high-performance multi-functional sensors and flexible supercapacitors. Adv. Funct. Mater. 28(33), 1707013 (2018)

Funding

The authors gratefully acknowledge the financial support provided by the Ministry of Science and Technology National Key R & D Program “Technology Winter Olympics” Key Special Project (2019YFF0302100), the Natural Science Foundation of Tianjin (Grant no. 18JCYBJC18500), the Postdoctoral Science Foundation of China (Grant no. 2016M591390), and the National Natural Science Foundation of China (Grant no. 51473122).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

Future investigations are necessary to validate the conclusions that can be drawn from this study and the authors declare they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gunasekara, D.S.W., He, Y., Fang, S. et al. High-repeatability macro-porous sponge piezoresistive pressure sensor with polydopamine/polypyrrole composite coating based on in situ polymerization method. Appl. Phys. A 126, 789 (2020). https://doi.org/10.1007/s00339-020-03962-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03962-z