Abstract

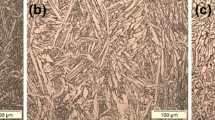

Argon is commonly used as root shielding gas in TIG-welding of stainless steels. As argon world-wide is in short supply and prices are rising, it is of interest to investigate what effects changing to alternative root shielding gases might have on weld metal microstructure. Manual TIG welding was used for root and hot pass welding in 304L pipe and plate material using Ar2 as shielding gas and Ar2, N2+10%H2 or N2 as root shielding gas. A significant increase in the nitrogen content of root beads was found when changing the root shielding gas from pure argon to a nitrogen-rich gas. Typically the root bead nitrogen content increased from 500–600 ppm for argon shielding to 1 100 ppm with nitrogen as root shielding gas. As a result the ferrite content decreased with up to 5 FN from about 8–9 FN to 3–5 FN. However, no indication of hot cracking was found and all root beads solidified as predicted by the WRC-92 diagram with ferrite as the leading phase. It is suggested that typical 304L steel and 308L consumable compositions will permit use of nitrogen-rich gases for root shielding without a significantly increased risk of hot cracking. However, the increased nitrogen level must be considered in the choice of steel and consumable. It is advised to use the WRC-92 diagram to make sure there is sufficient safety margin for actual compositions and, if possible, check root bead ferrite content.

Similar content being viewed by others

References

Jansson L.K., Karlsson L. and Holmberg B.: Can purging gas oxygen content be measured reliably with commercial instruments?, Proceedings of Stainless Steel World 2005 Conference & Expo, 8–10 Nov 2005, Maastricht, pp. 412-420.

Boulton L.H. and Avery R.E.: Heat tinted stainless steel welds — Guidelines for acceptance, Stainless Steel World, April 2004, pp. 42-49.

Ödegård L. and Fager S-.Å.: The root side pitting resistance of stainless steel welds, Welding Reporter, 1990, no. 1, Sandvik Steel, Sweden.

Turner S. and Robinson F.P.A.: The effect of the surface oxides produced during welding on the corrosion resistance of stainless steels, Corrosion, Sept 1989, pp. 710-716.

Troselius L. and Sender U.: The influence of weld-oxides on the resistance of stainless steel to local corrosion, Swedish Corrosion Institute Report 2001:9, Stockholm, Sweden.

Holmberg B.: Progress on welding of high nitrogen alloyed austenitic stainless steels, Doc. IIW-1545, Welding in the World, 2002, vol. 46, no. 1/2, pp. 3–9.

vanNassau L., Meelker H. and Hilkes J.: Welding duplex and super-duplex stainless steels, Doc. IIW-1165, Welding in the World, 1993, vol. 31, no. 5, pp. 322–343.

Hertzman S., Jargelius Petterssson R., Blom R., Kivineva E. and Eriksson J.: Influence of shielding gas composition and welding parameters on the N-content and corrosion properties of welds in N-alloyed stainless steel grades, ISIJ International, 1996, vol. 36, no. 7, pp 968–976.

DuToit M. and Pistorius P.C.: Shielding gas oxygen additions as a means of curbing nitrogen degassing during the autogenous arc welding of nitrogen-alloyed stainless steel, Doc. IIW-1928, Welding in the World, 2009, vol. 53, no. 1/2, pp. 38–47.

Hillert M. and Qiu C.: The effect of N and Mn on equilibria in austenitic stainless steels, illustrated with computer calculations, Proceedings of Application of stainless steel 1992, ISBN 91 971474-4-3, Kristianstad Boktryckeri, 1992, pp. 13-22.

Kotecki D.J. and Siewert T.A.: WRC-1992 Constitution Diagram for Stainless Steel Weld Metals: A modification of the WRC-1988 Diagram, Welding Journal, May 1992, vol. 71, no. 5, pp. 171–s–178–s.

Farrar J.C.M.: The measurement of ferrite number (FN) in real weldments — Final report, Doc. IIW-1666, Welding in the World, 2005, vol. 49, no. 5/6, pp. 13–21.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bergquist, EL., Huhtala, T. & Karlsson, L. The effect of PURGING GAS on 308L TIG root pass FERRITE CONTENT . Weld World 55, 57–64 (2011). https://doi.org/10.1007/BF03321287

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321287