Abstract

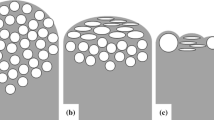

The possibilities to manufacture gold-based foams are explored. Gold powder and various powdered alloying elements are mixed with a small volume fraction of a gas-releasing blowing agent. The blend is compacted to a dense precursor, which is then melted in a further step in order to trigger foam formation. We find that gold-silicon alloys containing 2–3 wt.% of silicon or around 8 wt.% of germanium can be foamed using TiH2 or ZrH2 as a blowing agent. Foams with about 85% porosity are obtained.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

J. Banhart and D. Weaire,On the road again — metal foams find favour, Physics Today, 2003,55, 37–42

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson and H.N.G. Wadley, Metal foams — A design guide, Butterworth-Heinemann, Boston (2000)

J. Banhart, Manufacture, characterisation and application of cellular metals and metallic foams,Progress in Materials Science, 2001,46, 559–632

L.-P. Lefebvre, J. Banhart, D. Dunand, Porous metals and metallic foams — current status and developments,Advanced Engineering Materials, 2008,10, 775–787

H.P. Degischer and B. Kriszt, Handbook of cellular metals, Wiley-VCH, Weinheim (2002)

F.C. Meldrum and R. Seshadri, Porous gold structures through templating by echinoid skeletal plates,Chemical Communications, 2000, 29–30

J. Erlebacher, M.J. Aziz, A. Karma, N. Dimitrov, and K. Sieradzki, Evolution of nanoporosity in dealloying,Nature, 2001,410, 450–453

O.D. Velev, P.M. Tessier, A.M. Lenhoff, E.W. Kaler, A class of porous metallic nanostructures,Nature, 1999,401, 548–548

K. Nagai, D. Wada, M. Nakai, T. Norimatsu, Electrochemical fabrication of low-density metal foam with mono-dispersed-sized micro and submicrometre pore,Fusion Science and Technology, 2006,49, 686–690

J. Banhart, Metal foams: production and stability,Advanced Engineering Materials, 2006,8, 781–794

J. Banhart, D. Bellmann, and H. Clemens, Investigation of metal foam formation by microscopy and ultra small-angle neutron scattering,Acta Materialia, 2001,49, 3409–3420

A. Irretier and J. Banhart, Lead and lead alloy foams,Acta Materialia, 2005,53, 4903–4917

H.D. Kunze and M. Knüwer, About the foamability of iron — carbon alloys,Steel Research, 1999,70, 513–518

C.J. Yu, H. Eifert, J. Banhart, and J. Baumeister, Metal foaming by a powder metallurgical method: production, properties and applications,Journal of Materials Research and Innovations 1998,2, 181–188

C. Körner, M. Arnold, and R.F. Singer, Metal foam stabilization by oxide network particles,Materials Science and Engineering A, 2005,396, 28–40

A. Dudka, F. García-Moreno, N. Wanderka, J. Banhart, Structure and distribution of oxides in aluminium foam,Acta Materialia, 2008,56, 3990–4001

B. Matijasevic, J. Banhart, S. Fiechter, O. Görke, and N. Wanderka, Modification of titanium hydride for improved aluminium foam manufacture,Acta Materialia, 2006,54, 1887–1900

V. Gergely, D.C. Curran, and T.W. Clyne, The FOAMCARP process: foaming of aluminium MMCs by the chalk-aluminium reaction in precursors,Composites Science and Technology, 2003,63, 2301–2310

B. Predel, Au-Si (gold-silicon), Landolt-Börnstein — New Series, Group IV Physical Chemistry, Vol. 5a, Springer-Verlag (1991)

T.B. Massalski, Binary Phase Diagrams, ASM Information Society, Materials Park (1986)

S. Mechler, Private communication (2008)

D.M. Jacobsen, S.P.S. Sangha, A low melting poind solder for 22 carat yellow gold,Gold Bulletin, 1996,29, 3–9

C. Cretu and E. van der Lingen, Coloured gold alloys,Gold Bulletin, 1999,32, 31–40

C.W. Corti, Blue, black and purple! The special colours of gold, 5th International Jewellery Symposium, St. Petersburg, 3. July 2006

B. Matijasevic and J. Banhart, Improvement of aluminium foam technology by tailoring of blowing agent,Scripta Materialia, 2006,54, 503–508

Author information

Authors and Affiliations

Additional information

Experimental work was carried out at the Fraunhofer-Institute for Manufacturing Technology and Applied Materials Research, Bremen, Germany

About the author John Banhart is a professor in the Faculty of Materials Science and Technology at the Technical University of Berlin and head of the Department of Engineering Materials of the Helmholtz Centre for Materials and Energy (formerly Hahn-Meitner-Institute) in Berlin. Current research interests are aluminium alloys, metal foams and Xray and neutron imaging methods. He is a physicist and earned his PhD in physical chemistry at the University of Munich in 1989. He worked at the Fraunhofer-Institute in Bremen for 10 years where a process for foaming metals was developed in close cooperation with industry.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Banhart, J. Gold and Gold Alloy foams. Gold Bull 41, 251–256 (2008). https://doi.org/10.1007/BF03214878

Issue Date:

DOI: https://doi.org/10.1007/BF03214878