Abstract

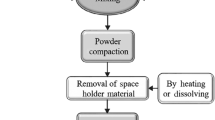

A method for fabricating metal foams based on the powder metallurgy process is presented. This foaming process allows for the production of complex-shaped foam parts, metal foam sandwich panels and foam filled hollow profiles. A range of alloys can be foamed using this method including aluminum, zinc, tin, lead and steel. The as-produced part has a closed-cell microstructure and a high fraction of porosity (typical range from 40–90% porosity). Selected mechanical properties of metal foams are evaluated, including the loading of foam samples with and without face skins and the axial crushing of tubular structures with foam reinforcement. Potential applications are discussed such as light-weight construction and energy absorption for both military and civilian uses.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 22 July 1998 / Accepted: 4 September 1998

Rights and permissions

About this article

Cite this article

Yu, CJ., Eifert, H., Banhart, J. et al. Metal foaming by a powder metallurgy method: Production, properties and applications. Mat Res Innovat 2, 181–188 (1998). https://doi.org/10.1007/s100190050082

Issue Date:

DOI: https://doi.org/10.1007/s100190050082