Abstract

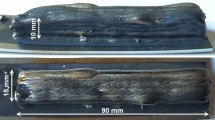

The mechanical alloying (MA) process was employed as an alternative method to produce the lead-free solder pastes of Sn-3.5Ag-xNi (x=0.1, 0.5, 1.0, 1.5, and 2.0) in this study. When the Ni concentration was low (x=0.1, 0.5), MA particles agglomerated to a flat ingot with particle sizes >100 µm. For higher Ni concentration (x=1.0, 1.5, and 2.0), MA particles turned into fragments with particle sizes <100 µm. The particle size of the solders appeared to be dependent on the Ni concentration. To reduce the particle size of SnAgNi alloys with low Ni concentration, Ni3Sn4 nanoparticles were doped into Sn and Ag powders to derive a Ni3Sn4-doped solder. For the Ni3Sn4-doped solder, the particle size was smaller than that doped by the pure Ni. The distinction of milling mechanism between Ni3Sn4-doped solder and the pure Ni-doped solder by MA process was probed and discussed. In addition, differential scanning calorimetry (DSC) results ensured its feasibility in applying the solder material in the reflow process. Wettability tests between solders and Cu substrate also revealed that the wetting angles for Ni3Sn4-doped solder with low Ni concentration (0.1 and 0.5 wt.%) were smaller than those for pure Ni-doped solder. The wetting angles on both Cu substrate and electroplated Ni metallization for SnAgNi solders were also comparable with commercial Sn-3.5Ag and Sn-3.0Ag-0.5Cu solders. Favorable wettability of the as-derived solder in this study was clearly demonstrated.

Similar content being viewed by others

References

T.Y. Lee, W.J. Choi, K.N. Tu, J.W. Jang, S.M. Kuo, J.K. Lin, D.R. Frear, K. Zeng, and J.K. Kivilahti, J. Mater. Res. 17, 291 (2002).

D.R. Frear, J.W. Jang, J.K. Lin, and C. Zhang, JOM 53, 28 (2001).

W.H. Tao, C. Chen, C.E. Ho, W.T. Chen, and C.R. Kao, Chem. Mater. 13, 1051 (2001).

S.K. Kang et al., J. Electron. Mater. 30, 1049 (2001).

J.W. Jang, D.R. Frear, T.Y. Lee, and K.N. Tu, J. Appl. Phys. 88, 6359 (2000).

P.T. Vianco et al., J. Electron. Mater. 28, 1127 (1999).

M.E. Loomans and M.E. Fine, Metall. Mater. Trans. A 31, 1155 (2000).

T.M. Korhonen, P. Su, S.J. Hong, M.A. Korhonen, and C.Y. Li, J. Electron. Mater. 29, 1194 (2000).

F. Guo, S. Choi, J.P. Lucas, and K.N. Subramanian, Soldering Surf. Mount Technol. 13, 7 (2001).

W.K. Choi and H.M. Lee, J. Electron. Mater. 28, 1251 (1999).

J.G. Lee, F. Guo, K.N. Subramanian, and J.P. Lucas, Soldering Surf. Mount Technol. 14, 11 (2002).

M. Li, F. Zhang, W.T. Chen, K. Zeng, K.N. Tu, H. Balkan, and P. Elenius, J. Mater. Res. 17, 1612 (2002).

D.R. Frear and S. Thomas, MRS Bull. 28, 68 (2003).

A. Zribi, A. Clark, L. Zavalij, P. Borgesen, and E.J. Cotts, J. Electron. Mater. 30, 1157 (2001).

C.W. Hwang, J.G. Lee, K. Suganuma, and H. Mori, J. Electron. Mater. 32, 52 (2003).

K.S. Kim, S.H. Huh, and K. Suganuma, Microelectron. Reliab. 43, 259 (2003).

W.K. Choi, J.H. Kim, S.W. Jeong, and H.M. Lee, J. Mater. Res. 17, 43 (2002).

I.E. Anderson, B.A. Cook, J. Harringa, and R.L. Terpstra, J. Electron. Mater. 31, 1166 (2002).

J.P. Lucas, F. Guo, J. McDougall, T.R. Bieler, K.N. Subramanian, and J.K. Park, J. Electron. Mater. 28, 1268 (1999).

S.K. Kang and T.G. Ference, J. Mater. Res. 8, 1063 (1993).

F. Guo, J. Lee, J.P. Lucas, K.N. Subramanian, and T.R. Bieler, J. Electron. Mater. 30, 1222 (2001).

C.M. Chuang and K.L. Lin, J. Electron. Mater. 32, 1426 (2003).

J.Y. Tsai, Y.C. Hu, C.M. Tsai, and C.R. Kao, J. Electron. Mater. 32, 1203 (2003).

M.L. Huang, C.M.L. Wu, and J.K.L. Lai, J. Mater. Sci. Mater. Elec. 11, 57 (2000).

C.M.L. Wu, M.L. Huang, J.K.L. Lai, and Y.C. Chan, J. Electron. Mater. 29, 1015 (2000).

M.L. Huang, C.M.L. Wu, J.K.L. Lai, and Y.C. Chan, J. Electron. Mater. 29, 1021 (2000).

C. Suryanarayana, Prog. Mater. Sci. 46, 1 (2001).

H.L. Lai and J.G. Duh, J. Electron. Mater. 32, 215 (2003).

J.S. Benjamin, Sci. Am. 234, 40 (1976).

S.T. Kao and J.G. Duh, J. Electron. Mater. 33, 1445 (2004).

R.R. Chromik, R.P. Vinci, S.L. Allen, and M.R. Notis, J. Mater. Res. 18, 2251 (2003).

G.Y. Jang, J.W. Lee, and J.G. Duh, J. Electron. Mater. 33, 1103 (2004).

L. Lu, M.O. Lai, and S. Zhang, J. Mater. Process. Technol. 67, 100 (1997).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, HY., Duh, JG. Influence of Ni concentration and Ni3Sn4 nanoparticles on morphology of Sn-Ag-Ni solders by mechanical alloying. J. Electron. Mater. 35, 494–503 (2006). https://doi.org/10.1007/BF02690537

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02690537