Abstract

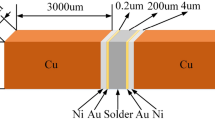

A mechanical alloying (MA) process was used to produce lead-free solder pastes of Sn-3.5Ag and the Sn-3.5Ag-4Bi system. Because of the high energy induced by repeated fracturing and welding, the grinding media played an important role during the MA process. A ceramic container was used to provide stronger impact force, which could induce phase transformation better than a Teflon container. In addition, it was found that 1-cm balls could fracture Bi particles and promote their dissolution into the Sn matrix. On the contrary, the milling process tended to achieve homogeneous mixing when using 3-mm balls. The MA powders, after milling with 3-mm balls, showed a small endothermic peak from the differential scanning calorimetry (DSC) profile at around 138°C, which was the eutectic temperature of Sn-Bi. The melting points of the MA powders in the ceramic container were measured to be 221°C and 203°C, respectively, for Sn-3.5Ag and Sn-3.5Ag-4Bi from the DSC curves. The reduced melting point ensured the complete melting during reflow with a peak temperature of 240°C. The formation of Ag3Sn was also observed from the x-ray diffraction peaks, indicating successful alloying by MA. The solder pastes could, thus, be produced by adding flux into the MA powders. The wetting property of the solder joint was also evaluated. The as-prepared solder pastes on electroless Ni-P/Cu/Si showed good metallurgical bonding with a contact angle less than 20°.

Similar content being viewed by others

References

M. Abtew and G. Selvaduray, Mater. Sci. Eng. R: Rep. 27, 95 (2000).

H. Reichl, A. Schubert, and M. Töpper, Microelectron. Reliab. 40, 1243 (2000).

S. Topani, S. Gopakumar, P. Borgesen, and K. Srihari, Annual Reliability Maintainability Symp. 423 (IEEE, 2002).

T.Y. Lee, W.J. Choi, K.N. Tu, J.W. Jang, S.M. Kuo, J.K. Lin, D.R. Frear, K. Zeng, and J.K. Kivilahti, J. Mater. Res. 17, 291 (2002).

D.R. Frear, J.W. Jang, J.K. Lin, and C. Zhang, JOM 53, 28 (2001).

W.H. Tao, C. Chen, C.E. Ho, W.T. Chen, and C.R. Kao, Chem. Mater. 13, 1051 (2001).

S.K. Kang et al., 2001 Electronics Components Technol. Conf. (IEEE, 2001) pp. 448–454.

S.K. Kang, H. Mavoori, S. Chada et al., J. Electron. Mater. 30, 1049 (2001).

J.W. Jang, D.R. Frear, T.Y. Lee, and K.N. Tu, J. Appl. Phys. 88, 6359 (2000).

P.T. Vianco, S.N. Burchett, M.K. Nielsen, J. Electron. Mater. 28, 1127 (1999).

R.S. Rai, S.K. Kang, and S. Purushothaman, Electronic Components and Technology Conf., 45th Proc. (Piscataway, NJ: IEEE, 1995), p. 1197.

L.L. Ye, Z. Lai, J. Liu, and A. Thölén, Electronic Components and Technology Conf. (Piscataway, NJ: IEEE, 2000), p. 134.

M.E. Loomans and M.E. Fine, Metall. Mater. Trans. A 31A, 1155 (2000).

T.M. Korhonen, P. Su, S.J. Hong, M.A. Korhonen, and C.-Y. Li, J. Electron. Mater. 29, 1194 (2000).

J.R. Oliver, J. Liu, and Z. Lai, Int. 2000 Symp. on Advanced Packaging Mater. 152 (2000).

W.R. Lewis, Notes on Soldering (Uxbridge, U.K.: Tin Research Inst., 1961), p. 66.

J.W. Morris, Jr., J.L. Freer Goldstein, and Z. Mei, JOM 45, 25 (1993).

Y.Y. Chen, J.G. Duh, and B.S. Chiou, J. Mater. Sci.: Mater. Electron. 11, 279 (2000).

H.W. Miao and J.G. Duh, Mater. Chem. Phys. 71, 255 (2001).

H.W. Miao, J.G. Duh, and B.S. Chiou, J. Mater. Sci.: Mater. Electron. 11, 609 (2000).

Y.Y. Wei and J.G. Duh, J. Mater. Sci.: Mater. Electron. 9, 373 (1998).

S.L. Chen (M.S. thesis, National Tsing Hua University, 1998).

T.Y. Lee, W.J. Choi, and K.N. Tu, J. Mater. Res. 17, 291 (2002).

M. McCormack, S. Jin, G.W. Kammlott, and H.S. Chen, Appl. Phys. Lett. 63, 15 (1993).

Z. Mei, F. Hua, and J. Glazer, Proc. Design and Reliability of Solders and Solder Interconnects (Warrendale, PA: TMS, 1997), p. 229.

Y. Kariya, Y. Hirata, and M. Otsuka, J. Electron. Mater. 28, 1263 (1999).

K. Habu, N. Takeda, H. Watanabe, H. Ooki, J. Abe, T. Saito, Y. Taniguchi, and K. Takayama, Proc. 1999 IEEE Int. Symp. on Electronics and the Environment (Piscataway, NJ: IEEE, 1999), pp. 21–24.

P.T. Vianco et al., U.S. patent 5,439,639 Aug. 8, (1995).

K. Suganuma, 1st Int. Symp. on Environmentally Conscious and Design Inverse Manufacturing (Piscataway, NJ: IEEE, 1999), pp. 620–625.

C. Chen, C.E. Ho, A.H. Lin, G.L. Luo, and C.R. Kao, J. Electron. Mater. 29, 1200 (2000).

J.S. Hwang, Modern Solder Technology for Competitive Electronics Manufacturing (New York: McGraw-Hill, 1996), pp. 209–223.

C. Suryanarayana, Process. Mater. Sci. 46, 1 (2001).

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys (New York: Van Nostrand Reinhold, 1980), pp. 66–68.

L. Lu, M.O. Lai, and S. Zhang, J. Mater. Process. Technol. 67, 100 (1997).

M.L. Huang, C.M.L. Wu, and J.K.L. Lai, J. Mater. Sci.: Mater. Electron. 11, 57 (2000).

J.S. Benjamin, Sci. Am. 234, 40 (1976).

E.Y. Ivanov and T.F. Grigorieva, Solid State Ionics 101–103, 235 (1997).

V.M. López-Hirata and E.M. Arce-Estrada, Electron. Acta 42, 61 (1997).

J. Eckert, Nanostr. Mater. 6, 413 (1995).

D. Oleszak and H. Matyja, Nanostr. Mater. 6, 425 (1995).

J.J. Jiang and M. Gasik, J. Power Sources 89, 117 (2000).

N.H. Goo and K.S. Lee, Int. J. Hydrogen Energy 27, 433 (2002).

L. Bolin, Met. Powder Rep. 53, 38 (1998).

C.M.L. Wu, M.L. Huang, J.K.L. Lai, and Y.C. Chan, J. Electron. Mater. 29, 1015 (2000).

M.L. Huang, C.M.L. Wu, J.K.L. Lai, and Y.C. Chan, J. Electron. Mater. 29, 1021 (2000).

V.M. Lopez Hirata, M. Saucedo Munñoz, J.C. Rodriguez Hernandez, and Y.H. Zhu, Mater. Sci. Eng. A247, 8 (1998).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lai, H.L., Duh, J.G. Lead-free Sn-Ag and Sn-Ag-Bi solder powders prepared by mechanical alloying. J. Electron. Mater. 32, 215–220 (2003). https://doi.org/10.1007/s11664-003-0212-1

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-003-0212-1