Abstract

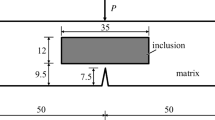

A model composite material system was designed to simulate typical damage mechanisms in unidirectional fiber reinforced brittle matrix composites. Experiments were performed at low to high quasistatic, macroscopic loading rates\((\dot \varepsilon = 10^{ - 5} - 10^{ - 3} s^{ - 1} )\). At all loading rates reversal of the transverse strain was observed and was correlated to matrix cracking and debonding. The optical method of coherent gradient sensing (CGS) was used to obtain qualitative information regarding the stress fields and to observe the progression of damage. It was found that the sequence of damage formation (damage path) depended on the macroscopic loading rate. At lower loading rates periodic matrix cracks developed; minimal debonding of the reinforcement-matrix interface occurred only much later in the experiment. At higher loading rates extensive debonding followed propagation of the initial matrix crack, and periodic cracking was not observed. Several features of the material response of the model material system were also observed in a previously studied unidirectional ceramic matrix composite.

Similar content being viewed by others

References

Gordon, J.E., The New Science of Strong Materials, Pitman, London (1979).

Evans, A.G., “Perspective on the Development of HIgh Toughness Ceramics,”J. Am. Ceram. Soc.,73,187–206 (1990).

Walter, M.E. andRavichandran, G., “An Experimental Investigation of Damage Evolution in a Ceramic Matrix Composite,”J. Eng. Mat. Tech.,117,101–108 (1995).

Evans, A.G. andMarshall, D.B., “The Mechanical Behavior of Ceramic Matrix Composites,”Acta Metall. Mater.,37,2567–2583 (1989).

Walter, M.E., “The Evolution of Damage in Ceramic Matrix Composites,” PhD thesis, California Institute of Technology (1996).

Botsis, J. andShafiq, A.B., “Crack Growth Characteristics of an Epoxy Reinforced with Long Aligned Glass Fibers,”Int. J. Fract.,58,R3-R10 (1992).

Botsis, J. andBeldica, C., “Strength Characteristics and Fatiguecrack Growth in a Composite with Long Aligned Fibers,”Int. J. Fract.,69,27–50 (1994).

He, M.-Y. andHutchinson, J.W., “Kinking of a Crack Out of an Interface,”J. Appl. Mech.,56,270–278 (1989).

Tippur, H.V. andRosakis, A.J., “Quasi-static and Dynamic Crack-growth along Bimaterial Interfaces—A Note on Crack-tip Field-measurements Using Coherent Gradient Sensing,” EXPERIMENTAL MECHANICS,31,243–251 (1991).

Singh, R. and Shukla, A., “Subsonic and Intersonic Crack Growth along a Bimaterial Interface,” J. Appl. Mech. (1995).

Dollar, A. andSteif, P.S., “Interface Blunting of Matrix Cracks in Fiber-reinforced Ceramics,”J. Appl. Mech.,59,796–803 (1992).

He, M.-Y. andHutchinson, J.W., “Crack Deflection at an Interface between Dissimilar Elastic Materials,”Int. J. Sol. Struct.,25,1053–1067 (1989).

Tippur, H.V., Krishnaswamy, S., andRosakis, A.J., “Optical Mapping of Crack Tip Deformations Using the Methods of Transmission and Reflection Coherent Gradient Sensing—A Study of Crack Tip K-dominance,”Int. J. Fract.,52,91–117 (1991).

Rosakis, A.J., “Two Optical Techniques Sensitive to Gradients of Optical Path Difference: The Method of Caustics and the Coherent Gradient Sensor (CGS),”Experimental Techniques in Fracture, Vol. 3, ed. tJ. Epstein, SEM, Bethel, CT, 327 (1993).

Sørensen, B.F. andHolmes, J.W., “Effect of Loading Rate on the Monotonic Tensile Behavior of a Continuous-fiber-reinforced Glassceramic Matrix Composite,”J. Am. Ceram. Soc.,79,313–320 (1996).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Walter, M.E., Ravichandran, G. Experimental simulation of matrix cracking and debonding in a model brittle matrix composite. Experimental Mechanics 37, 126–131 (1997). https://doi.org/10.1007/BF02317847

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02317847