Abstract

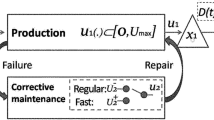

In this paper, we consider a minimax production planning model of a flexible manufacturing system with machines that are subject to random breakdown and repair. The objective is to choose the rate of production that minimizes the related minimax cost of production and inventory/shortage. The value function is shown to be the unique viscosity solution to the associated Hamilton-Jacobi-Isaacs equation. Under certain conditions, it is shown that the value function is continuously differentiable. A verification theorem is given to provide a sufficient condition for optimal control. Finally, two examples are solved explicitly.

Similar content being viewed by others

References

Akella, R., andKumar, P. R.,Optimal Control of Production Rate in a Failure-Prone Manufacturing System, IEEE Transactions on Automatic Control, Vol. 31, No. 2, pp. 116–126, 1986.

Boukas, E. K.,Techniques for Flow Control and Preventive Maintenance in Manufacturing Systems, Control and Dynamic Systems, Vol. 48, pp. 327–366, 1991.

Boukas, E. K.,Control of Systems with Controlled Jump Markov Disturbances, International Journal of Control Theory and Advanced Technology, Vol. 9, No. 2, pp. 577–595, 1993.

Boukas, E. K., andHaurie, A.,Manufacturing Flow Control and Preventive Maintenance: A Stochastic Control Approach, IEEE Transactions on Automatic Control, Vol. 35, No. 9, pp. 1024–1031, 1990.

Hu, J. Q., Vakili, P., andYu, G. X.,Optimality of Hedging Point Policies in the Production Control of Failure-Prone Manufacturing Systems, Preprint, Boston University, 1993.

Sethi, S. P., andZhang, Q.,Hierarchical Decision Making in Stochastic Manufacturing Systems, Birkhäuser, Boston, Massachussetts, 1994.

Basar, T.,Minimax Control of Switching Systems under Sampling, Working Paper, University of Illinois, 1994.

Basar, T., andBernhard, P.,H ∞-Optimal Control and Related Minimax Design Problems, Birkhäuser, Boston, Massachussetts, 1991.

Boukas, E. K., Zhu, Q., andZhang, Q.,Piecewise-Deterministic Markov Process Model for Flexible Manufacturing Systems with Preventive Maintenance, Journal of Optimization Theory and Applications, Vol. 81, No. 2, pp. 259–275, 1994.

Boukas, E. K., Zhang, Q., andZhu, Q.,Optimal Production and Maintenance Planning of Flexible Manufacturing Systems, Proceedings of the 32nd IEEE Conference on Decision and Control, San Antonio, Texas, Vol. 4, pp. 3270–3271, 1993.

Soner, H. M.,Singular Perturbations in Manufacturing Systems, SIAM Journal on Control and Optimization, Vol. 31, No. 1, pp. 132–146, 1993.

Fleming, W. H., andSoner, H. M.,Controlled Markov Processes and Viscosity Solutions, Springer Verlag, New York, New York, 1992.

Zhang, Q.,Risk-Sensitive Production Planning of Stochastic Manufacturing Systems: A Singular Perturbation Approach, SIAM Journal on Control and Optimization, Vol. 33, No. 1, pp. 488–527, 1995.

Fleming, W. H., Sethi, S. P., andSoner, H. M.,An Optimal Stochastic Production Planning Problem with Randomly Fluctuating Demand, SIAM Journal on Control and Optimization, Vol. 25, No. 6, pp. 1494–1502, 1987.

Author information

Authors and Affiliations

Additional information

Communicated by C. T. Leondes

This research was supported by the Natural Sciences and Engineering Research Council of Canada under Grants OGP0036444 and A4169.

Rights and permissions

About this article

Cite this article

Boukas, E.K., Yang, H. & Zhang, Q. Minimax production planning in failure-prone manufacturing systems. J Optim Theory Appl 87, 269–286 (1995). https://doi.org/10.1007/BF02192564

Issue Date:

DOI: https://doi.org/10.1007/BF02192564