Abstract

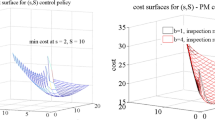

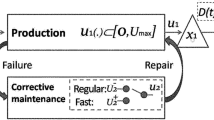

The work presented in this paper examines the joint analysis of the optimal production and maintenance planning policies for a manufacturing system subject to random failures and repairs. When a machine fails, an imperfect corrective maintenance is undertaken. The objective of this study is to minimize a discounted overall cost consisting of preventive and corrective maintenance costs, inventory holding cost, and backlog cost. A two-level hierarchical decision-making approach is proposed, based on the determination of the mean time to failure (first level) and the statement of a joint optimization of production, preventive, and corrective maintenance policies (second level). Hence, the production, preventive, and corrective maintenance rates are determined in the second level, given the failure rates obtained from the first level. In the proposed model, the machine’s failure rate depends on the number of imperfect repairs, and as a result, the control policies of the considered planning problems therefore depend on the number of failures. The structure of the optimal control policies and the usefulness of the proposed approach are illustrated through a numerical example and a sensitivity analysis.

Similar content being viewed by others

References

Rishel R (1975) Control of systems with jump Markov disturbances. IEEE Trans Autom Control 20:241–244

Boukas EK, Haurie A (1990) Manufacturing flow control and preventive maintenance: a stochastic control approach. IEEE Trans Autom Control 35:1024–1031

Kimemia J, Gershwin SB (1983) An algorithm for the computer control of a flexible manufacturing system. IIE Trans 15:353–362

Boukas EK (1998) Hedging point policy improvement. J Optim Theory Appl 97:47–70

Gharbi A, Kenne JP (2000) Production and preventive maintenance rates control for a manufacturing system: an experimental design approach. Int J Prod Econ 65:275–287

Kenne JP, Boukas EK (2003) Hierarchical control of production and maintenance rates in manufacturing systems. J Qual Maint Eng 9:66–82

Gharbi A, Kenne JP (2005) Maintenance scheduling and production control of multiple-machine manufacturing systems. Comput Ind Eng 48:693–707

Zied H, Sofiene D, Nidhal R (2011) An optimal maintenance/production planning for a manufacturing system under random failure rate and a subcontracting constraint. Proceedings of the 2011 International Conference on Industrial Engineering and Operations Management Kuala Lumpur, Malaysia, January 22–24, 2011

Budai G, Dekker R, Nicolai RP (2008) Maintenance and production: a review of planning models. COMPLEX SYSTEM MAINTENANCE HANDBOOK Springer Series in Reliability Engineering

Yan JH, Muammer K, Lee J (2004) A prognostic algorithm for machine performance assessment and its application. Prod Plan Control 15:796–801

Kenne JP, Gharbi A, Beit M (2007) Age-dependent production planning and maintenance strategies in unreliable manufacturing systems with lost sale European. J Oper Res 178:408–420

Nakagawa T, Kowada M (1983) Analysis of a system with minimal repair and its application to replacement policy European. J Oper Res 12(2):176–182

Dehayem FID, Kenne JP, Gharbi A (2009) Hierarchical decision making in production and repair/replacement planning with imperfect repairs under uncertainties. Eur J Oper Res 198:173–189

Love CE, Zhang ZG, Zitron MA, Guo R (2000) Discrete semi-Markov decision model to determine the optimal repair/replacement policy under general repairs. Eur J Oper Res 125(2):398–409

Kijima M (1989) Some results for the quasi-stationary distribution in birth-death processes. Res Rep Inform Sci B (Oper Res) 219:1–15

Shin I, Lim TJ, Lie CH (1996) Estimating parameters of intensity function and maintenance effect for repairable unit. Reliab Eng Syst Saf 54(1):1–10

Mohafid A, Castanier B (2006) Optimisation de la maintenance imparfaite à efficacité aléatoire. In: 6e Conference Francophone de Modélisation et Simulation. MOSIM’06 - Rabat- Morocco

Jiwen S, Lifeng X (2011) Optimal maintenance policy for degrading manufacturing systems using long-term average cost criterion. Prod Plan Control 22(2):124–136

Yin KK, Liu H, Yin GG (2003) Stochastic models and numerical solutions for production planning with applications to the paper industry. Comput Chem Eng 27:1693–1706

Kenne JP, Nkeungoue LJ (2008) Simultaneous control of production, preventive and corrective maintenance rates of a failure-prone manufacturing system. Appl Numer Math 58(2):180–194

Kenne JP, Boukas EK, Gharbi A (2003) Control of production and corrective maintenance rates in a multiple-machine, multiple-product manufacturing system. Math Comput Model 38:351–365

Hajji A, Gharbi A, Kenne JP (2009) Joint replenishment and manufacturing activities control in a two stage unreliable supply chain. Int J Prod Res 47:3231–3251

Akella R, Kumar PR (1986) Optimal control of production rate in a failure prone manufacturing system. IEEE Trans Autom Control 31:116–126

Boulet JF, Gharbi A, Kenne JP (2009) Multiobjective optimization in an unreliable failure-prone manufacturing system. J Qual Maint Eng 15:397–411

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kouedeu, A.F., Kenné, JP., Dejax, P. et al. Production and maintenance planning for a failure-prone deteriorating manufacturing system: a hierarchical control approach. Int J Adv Manuf Technol 76, 1607–1619 (2015). https://doi.org/10.1007/s00170-014-6175-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6175-y