Abstract

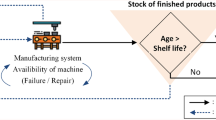

Failure-prone manufacturing systems facing dynamical market conditions that result in demand variations are considered. The combined production and corrective maintenance optimization problem for a one-machine-one-product system is addressed. Repairing the machine after the failure, the manager has to solve the dilemma: to choose an inexpensive (but lower) repair rate, or to use the higher, (but more expensive) repair rate. The former decision seems to be appropriate when there is no risk of inventory shortage, while the latter one has to be used in critical (stock shortage) situations. Precise solution to this problem presented in the paper is theoretically instructive and valuable for practitioners. Optimality conditions in the form of time-dependent Hamilton–Jacoby–Bellman equations are obtained and a novel numerical approach is proposed for solving these equations for the case of periodically time-varying demand. The optimal policy is shown to be the hedging-curve-policy, that extends the hedging-point-policy to the case of varying level of safety stock. The simulation results show that the optimal policies have an important property of anticipating the future demand evolutions and making the optimal decisions relevant to such dynamic conditions. In particular, it has been shown that in the large domain of the system parameters it is advantageous to use the lower (and inexpensive) repair rate when the stock is approaching the hedging level and especially when the demand level is near its bottom edge.

Similar content being viewed by others

References

Akella R, Kumar PR (1986) Optimal control in production rate in a failure prone manufacturing system. IEEE Trans Autom Control 31(2):116–126

Boukas EK (1998) Hedging point policy improvement. J Optim Theory Appl 97(1):47–70

Boukas EK, Haurie A (1990) Manufacturing flow control and preventive maintenance. IEEE Trans Autom Control 35(9):1024–1031

Boukas EK, Yang J, Zhang Q, Yin G (1996) Periodic maintenance and repair rate control in stochastic manufacturing systems. J Optim Theory Appl 91(2):347–361

Chelbi A, Ait-Kadi D (2004) Analysis of a production/inventory system with randomly failing production unit submitted to regular preventive maintenance. Eur J Oper Res 156:712–718

Dehayem Nodem F, Kenne J-P (2011) Simultaneous control of production, repair/replacement and preventive maintenance of deteriorating manufacturing systems. Int J Prod Econ 134(1):271–282

Gershwin SB (2011) Manufacturing systems engineering. Massachusetts Institute of Technology, Cambridge

Gharbi A, Kenne J-P, Hajji A (2006) Operational level- based policies in prouction rate control of unreliable manufacturing systems with set-ups. Int J Prod Res 44(3):545–567

Hlioui R, Gharbi A, Hajji A (2017) Joint supplier selection, production and replenishment of an unreliable manufacturing supply chain. Int J Prod Econ 187:53–67

Kenne J-P, Boukas EK (1997) Production and corrective maintenance planning problem of a failure prone manufacturing system. In: Proceedings of the American Control Conference, Albuquerque, New Mexico, pp 1013–1014

Kenne J-P, Gharbi A (2000) Production planning problem in manufacturing systems with general failure and repair time distributions. Prod Plan Control 11(6):581–588

Kenne J-P, Gharbi A (2004) Stochastic optimal production control problem with corrective maintenance. Comput Ind Eng 46:865–875

Kenne J-P, Boukas EK, Gharbi A (2003) Control of production and corrective maintenance rates in a multiple-machine, multiple-product manufacturing system. Math Comput Model 38:351–365

Kieckhafer RM, Azadmanesh MH, Y Hui (2000) On the sensitivity of NMR unreliability to non-exponential repair distributions. In: Proceedings of the fifth IEEE international symposium on high assurance systems engineering, pp 293–299

Kleber R, Minner S, Kiesmuller G (2002) A continuous time inventory model for a product recovery system with multiple options. Int J Prod Econ 79:121–141

Kushner HJ, Dupuis P (1992) Numerical methods for stochastic control problems in continuous time. Springer, New York

Leo W, Syntetos A, Bolyan J, E J (2011) On the interaction between forecasting and stock control: the case of nonstationary demand. Int J Prod Econ 133:470–480

Minner S, Kleber R (2001) Optimal control of production and remanufacturing in a simple recovery model with linear cost functions. OR Spectr 23(3):3–24

Mishra VK, Singh LS (2011) Deteriorating inventory model for time dependent demand and holding cost with partial backlogging. Int J Manag Sci 6(4):267–271

Mok P, Porter B (2005) Evolutionary optimization of hedging points for unreliable manufacturing systems. Int J Adv Manuf Technol 28:205–214

Ouaret S, Polotski V, Kenne J-P, Gharbi A (2013) Optimal production control of hybrid manufacturing/remanufacturing failure-prone systems under diffusion-type demand. Appl Math 2013(4):550–559

Polotski V, Kenne J-P, Gharbi A (2018) Production control of hybrid manufacturing-remanufacturing systems under demand and return variations. Int J Prod Res. https://doi.org/10.1080/00207543.2018.1461272

Prak D, Teunter R, Syntetos A (2016) On the calculation of safety stocks when demand is forecasted. Eur J Oper Res 256:454–461

Rivera-Gomez H, Gharbi A, Kenne J-P (2013) Joint control of production, overhaul an preventive maintenance for a production system subject to quality and reliability deteriorations. Int J Adv Manuf Technol 69(9–12):2111–2130

Rivera-Gomez H, Kenne J-P, Gharbi A, Hernnndez Gress ES (2016) Production control problem integrating overhaul and subcontracting strategies for a quality deteriorating manufacturing system. Int J Prod Econ 171:134–150

Sajadi S, Seyyed-Esfahani MM, Srensen K (2011) Production control in a failure-prone manufacturing network using discrete event simulation and automated response surface methodology. Int J Adv Manuf Technol 53:35–46

Saltoglu R, Himaira N, Inalhan G (2016) Aircraft scheduled airframe maintenance and downtime integrated cost model. Adv Oper Res, ID: 2576825

Saranga H (2004) Opportunistic maintenance using genetic algorithms. J Qual Maint Eng 10(1):66–74

Sethi S, Zhang Q (1994) Hierarchical decision making in stochastic manufacturing systems. Birkhauser, Boston

Tripathi PR (2011) EOQ model with time dependent demand rate and time dependent holding cost function. Int J Oper Res Inf Syst 2(3):79–92

Vasil’eva AB, Butuzov VF (1973) Assymptotic expansions of the solutions of singularly perturbed equations. Nauka, Moscow

Wang C, Huang R (2014) Pricing for seasonal deteriorating products with price- and ramp-type time-dependent demand. Comput Ind Eng 77:29–34

Wang K, Jiang Z, Li N, Geng N (2014) Optimal production control of a service-oriented manufacturing system with customer balking behavior. Flex Serv Manuf J 26(3):387–407

Wu K, McGinnis L (2012) Performance evaluation for general queueing networks in manufacturing systems: characterizing the trade-off between queue time and utilization. Eur J Oper Res 221:328–339

Wu K, Zhou Y, Zhao N (2016) Variability and the fundamental properties of production lines. Comput Ind Eng 99:364–371

Acknowledgements

The authors are grateful to the anonymous reviewers for their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Polotski, V., Kenne, JP. & Gharbi, A. Optimal production and corrective maintenance in a failure-prone manufacturing system under variable demand. Flex Serv Manuf J 31, 894–925 (2019). https://doi.org/10.1007/s10696-019-09337-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-019-09337-8