Abstract

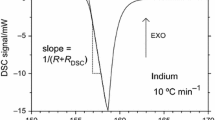

This paper presents a new method for the calculation of the purity of organic, non-polymeric samples using the recorder trace from a Differential Scanning Calorimeter (DSC), Perkin-Elmer Corp. The entire DSC recorder trace is employed rather than only the initial portion of the curve. The previous trial and error choice of energy lost by the DSC trace has been replaced by a definite numerical value. Meaningful purity values have been obtained from a single DSC trace on samples of from 95 to 99.9% purity. This new method has been demonstrated to provide more accurate and less ambiguous results than the manufacturer's procedure.

Résumé

On décrit une nouvelle méthode à calculer la pureté des substances organiques non polymères à l'aide de la courbe enregistrée sur un “Differential-Scanning Calorimètre”Perkin-Elmer. Au lieu d'utiliser seulement la partie initiale du pic, on se sert du tracé complet. On attribue une valeur numérique définie à la perte d'énergie, précédemment déterminé e par approximations successives. Un seul enregistrement sur le DSC permet d'obtenir des valeurs significatives de la pureté, avec des échantillons à 95–99.9 %. On montre que cette nouvelle méthode fournit des résultats plus exacts et moins ambigus que celle des fabricants

Zusammenfassung

Es wird über eine neue Methode zur Ermittlung der Reinheit von organischen, nicht-polymeren Stoffen mit Hilfe einer durch ein Differential-Scanning Calorimeter Perkin-Elmer gezeichneten Kurve berichtet. Die Methode beruht auf der Verwendung der vollen Kurve und gibt für den Energieverlust definitive numerische Werte. Verläßliche Reinheitswerte von Proben von 95 bis zu 99.9 % Reinheit können durch eine einzige Kurve erhalten werden. Die neue Methode gibt sicherere und eindeutigere Ergebnisse als die von den Geräterzeugern vorgeschlagene.

Резюме

В работе описан новый метод расчëта чистот ы органических неполи мерных образцов с использов анием сигнала прибор а ДТЦ (Фирма Перкин-Элмер). При расч ëте авторы использовали полную кривую ДТЦ, а не только еë начальную часть. Полу чены значительные величи ны чистоты по одной кр ивой в случае образцов чист ой от 95 до 99,9 %. Новый метод расчëта о беспечивает более то чные и достоверные результ аты, чем получаемые в заводских условиях.

Similar content being viewed by others

References

Cited in Analytical Calorimetry,R. S. Porter andJ. F. Johnson, Eds., Plenum Press New York, 1968, en toto.

W. L. G. Gent, J. Phys. E., 2 (1969) 69.

D. E. Martire, P. A. Blasco, P. F. Carone, L. C. Chow andH. Vince, J. Phys. Chem., 72 (1968) 3489.

Perkin-Elmer Corporation, Thermal Analysis Newsletter, 5, Norwalk, Connecticut.

Perkin-Elmer Corporation, Thermal Analysis Newsletter, 6, Norwalk, Connecticut.

M. J. O'Neill, Anal. Chem, 36 (1964) 1238.

S. V. R. Mastrangelo andR. W. Dornte, Anal. Chem., 29 (1957) 794.

J. K. Shillington, W. J. Watt andR. D. Whitaker, J. Chem. Ed., 41 (1964) 96.

E. S. Watson, M. J. O'Neill, J. Justin andN. Brenner, Anal. Chem., 36 (1964) 1233.

A.Gray, personal communication.

Author information

Authors and Affiliations

Additional information

The authors express sincere appreciation to the National Institutes of Health, HE 11343, for financial support of this study.

Rights and permissions

About this article

Cite this article

Davis, G.J., Porter, R.S. Application of the differential scanning calorimeter to purity measurements. Journal of Thermal Analysis 1, 449–458 (1969). https://doi.org/10.1007/BF01983087

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01983087