Conclusions

-

1.

ML is the result of crack formation in the hybrid composite material.

-

2.

The loss of continuity in uniaxial loading can be recorded both by the ML method and (in individual cases) by strain gauging.

-

3.

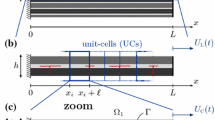

For the hybrid composite in combined loading in the plane stress state, ML indicates (in contrast to strain gauging) the instant of the start of cracking.

Similar content being viewed by others

Literature cited

S. V. Tsai and V. D. Adzi, “Strength of layered composite materials,” Raket. Tekh. Kosmon., No. 2, 142–147 (1966).

V. V. Vasil'ev and A. N. Elpat'evskii, “Special features of deformation of cylindrical shells produced by winding unidirectional glass tape, under the effect of internal pressure,” Mekh. Polim., No. 5, 915–920 (1967).

V. V. Vasil'ev, A. A. Dudchenko, and A. N. Elpat'evskii, “Special features of deformation of an orthotropic fiberglass plastic in tensile loading,” Mekh. Polim., No. 1, 144–147 (1970).

V. A. Kolgadin, “Stresses and strains in a PPN fiberglass plastic in tensile loading,” Probl. Prochn., No. 12, 9–13 (1971).

S. Tsai and Kh. Khan, “Analysis of composite failure,” in: Inelastic Properties of Composite Materials [in Russian], Moscow (1978), pp. 104–109.

V. V. Partsevskii, “Cracking of a layered composite reinforced in two directions,” Probl. Prochn., No. 10, 76–77 (1978).

V. V. Bolotin, “Strength, stability, and oscillations of multiply sheets,” in: Strength Calculations [in Russian], No. 1, Moscow (1965), pp. 31–63.

S. F. Kuznetsov and V. V. Partsevskii, “Mechanism of deformations and failure of multidirectional composite materials,” Mekh. Kompozitn. Mater., No. 6, 1006–1011 (1981).

A. M. Skudra and F. Ya. Bulavs, Structural Theory of Reinforced Plastics [in Russian], Riga (1978).

A. M. Skudra, “Structural theory of the strength of reinforced plastics in tensile and compressive loading,” Mekh. Polim., No. 6, 988–995 (1975).

A. M. Skudra and F. Ya. Bulavs, “Generalized structural criteria of the strength of reinforced plastics for the plane stress state,” Mekh. Kompozitn. Mater., No. 4, 626–633 (1982).

R. B. Rikards and A. K. Chate, “Initial failure surfaces of orthogonally reinforced composites,” in: Mechanics of Deformed Media [in Russian], No. 4, Kuibyshev (1979), pp. 97–107.

G. A. Teters, U. É. Krauya, R. B. Rikards, and Z. T. Upitis, “Examination of failure of composites in the plane stress state by the mechanoluminescence method,” Mekh. Kompozitn. Mater., No. 3, 537–545 (1982).

P. H. Francis, D. E. Wlarath, and D. N. Weld, “First ply failure of graphite/epoxy laminates under biaxial loadings,” Fiber Sci. Technol., No. 2, 97–110 (1979).

R. Y. Kim and H. T. Hahn, “Effect of curing stresses on the first ply failure in composite laminates,” J. Compos. Mater.,13, January, 2–16 (1979).

U. K. Vilks, “A device for strain measurements,” Inventor's Certificate No. 355486, Soviet Union, Otkrytiya. Izobret. Prom. Obraztsy. Tov. Zn., No. 31 (1972).

U. É. Krauya, Z. T. Upitis, and Ya. L. Yansons, “Nature of mechanoluminescence in loading certain composite materials,” Mekh. Kompozitn. Mater., No. 5, 914–919 (1983).

Author information

Authors and Affiliations

Additional information

Translated from Mekhanika Kompozitnykh Materialov, No. 1, pp. 60–66, January–February, 1984.

Rights and permissions

About this article

Cite this article

Upitis, Z.T., Builis, I.V., Krauya, U.É. et al. Initial stages of failure of an orthogonally reinforced composite material. Mech Compos Mater 20, 52–58 (1984). https://doi.org/10.1007/BF00611575

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00611575